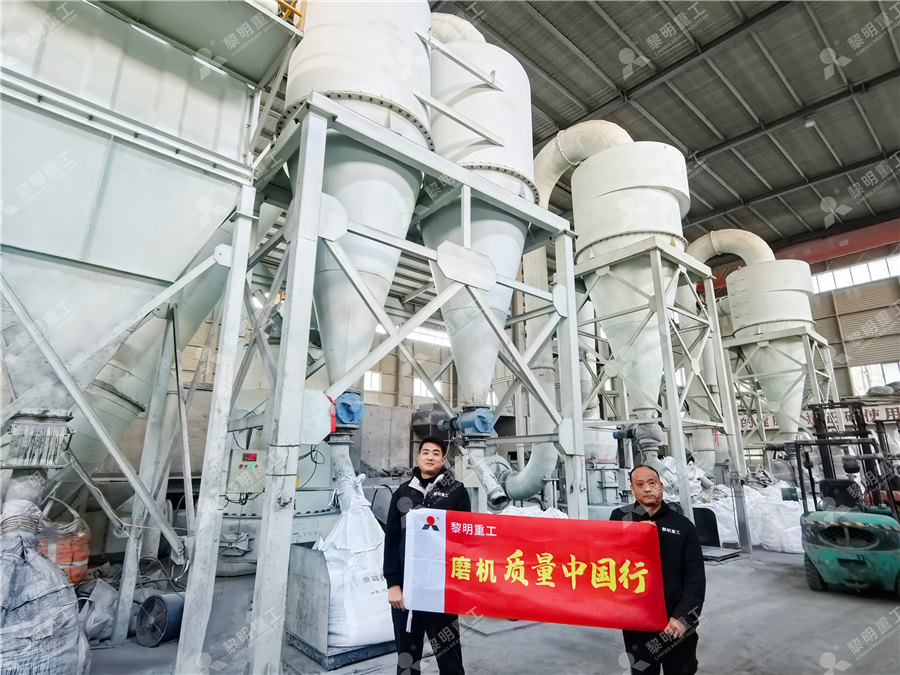

Silica powder processing production line

.jpg)

Silica Powder Processing TechnologyALPA POWDER

The production line adopts internationally popular continuous production process: ball mill and classifier systemIncluding crushing, grinding, classifying, packaging, magnetic separation, conveying, lifting, etc After ball mill, classifiers can be connected in parallel or in series to In the production of silica by precipitation and dissociation, drying is an essential part of the process, and the design of a reasonable silica drying method is essential to improve the Analysis of silica production and drying processes IOSR JournalsThe ball mill and classifier are specially designed to ensure the efficient production of quartz powder; 2 The whole process is under negative pressure, which is not easy to produce dust Silica powder making plantSinonine2021年8月17日 The preparation of crystalline powder, cristobalite powder, fusion powder and various active powders all need to go through a grinding and classification process The Ball mill and classifying production line of silica powder

.jpg)

Silica Powder Production Process Review, Documentation,

The process consists of two primary batch unit operations for processing Silica powder: (1) a Pfaudler glass lined stirred tank reactor with a refluxing condenser where the Silica is reacted 2023年8月10日 FTM Machinery can provide solutions and equipment for silica processing plants The production process of silica sand includes 4 stages of crushing, grinding, purifying, and drying 1 Silica crushing process Silica raw Silica Processing Plant 4 Major Stages to Make Silica ALPA’s ball mill classification production line, Jet mill, air classifier, etc, are widely used in fine processing of silica powder, greatly promoting the application field expansion, technical progress and industrial upgrading of ultrafine quartz Home ALPA micro silica powder (superfine quartz The production line adopts internationally popular batch continuous production process: ball mill and classifier system Including crushing, grinding, classifying, packaging, magnetic separation, conveying, lifting, etcBall Mill and Air Classifier Production Line ALPA

Silica Powders Production from Hydrothermal Solutions Stanford

The process flowsheet of cryochemical involves the following sequence of main production phases of the manufacture: preparation of the concentrated aqueous silica sol; dispersing The production line of 40,000 tons of super pure quartz ball grinding and grading with 325 mesh granularity is produced by a company in Guangdong Lianyungang, a new material company produced 200kg particle size D100:10μm silicon The production line of 40,000 tons of super pure It can effectively reduce the iron content of quartz sand We have a wealth of experience in quartz sand production lines The entire process is not only equipped with advanced iron removal equipment, but also controlled at the source to minimize the silica sand processing linePROCESSING OF BALL MILL AND AIR CLASSIFIER THIS PROCESS IS MATURE AND RELIABLE, WIDELY USED IN THE PRODUCTION OF SILICA POWDER The production line adopts internationally popular continuous production process: ball mill and classifier systemIncluding crushing, grinding, classifying, packaging, magnetic separation, conveying, ALPA Silica Powder Processing Technology DirectIndustry

Horizontal Air Classifier ALPA micro silica powder (superfine

Silica powder process; Surface modification; Equipmennt Vertical Air Classifier; Horizontal Air Classifier; Ball Mill and Air Classifier Production LineIn the silica sand production line, Jaw Crusher is the coarse silica sand crushing machine, Silica sand processing flow In the silica powder making process, Jaw Crusher is used as primary crushing machine, then go through the secondary crushing plantSilica sand processing line, silica sand making plantSilica gel powder; MATERIAL PROCESSING Rotary Dryers We offer a complete line of bulk material handling equipment both as standalone systems, A continuous testing phase that aims to establish the equipment setup and parameters required for continuous production of your specific materialSilica Processing Equipment FEECO International IncThrough onestop solution of quartz/silica sand production line turnkey project service, we ensure the smooth operation of customers' quartz/silica sand processing plant We will provide efficient, scientific and economic services for customers, safeguard customers' investment and income, and develop and progress together with customersTurkey solutions silica sand processing projectSinonine

.jpg)

High purity quartz sand production lineSinonine

High purity quartz technical process After the quartz ore is necessarily prepared, the high purity quartz sand production line is employed with the advanced production process, according to the process flow: calcination water quenching crushing grinding screening classifyingdesliming magnetic separation flotation acid leaching flotation high Sinonine can provide turkey service for sand production to produce glass sand,frac sand,high purity sand etcWe are the first and only company in China that can provide the turnkey project service EPC service for quartz/silica sand processing plant We can provide quartz/silica sand production equipment with high costeffectiveSilica sand processing and washing plantSinonineSilica is widely used in industry, agriculture, medicine and many other fields due to its wide range of raw materials and excellent properties The main industrial production methods for silica in China today are precipitation, vapour phase and dissociation In the production of silica by precipitation and dissociation,Analysis of silica production and drying processes IOSR JournalsThe production line is used to dry highpurity silica sand containing about 20% moisture, and the final moisture content is less than 05% The equipment adopts stainless steel rotary dryer to avoid iron pollution of fine sand, and it adopts Silica sand drying production lineSinonine

Silica Powder: Essential Mineral for Construction and Beyond

2024年9月13日 Magnesium Silicate Processing: Amorphous silica forms from magnesium silicate ore through acid leaching, mineral removal, and heating to remove hydroxyl groups Benefits of Using Silica Powder High Purity and Low Impurities Amorphous silica powder can be synthetically produced with extremely high purity, with metal impurities typically below 1 2024年1月30日 Our entire production line operates under negative pressure, which can effectively control dust spillage At the same time, we equip the entire production line with largecapacity dust collectors, with a dust removal rate of up to 99%, which fully meets the dust emission standards, and can even meet the requirements of firsttier citiesFAQs Silica powder (ultrafine quartz powder) processing expertSilica Sand and Silica Powder Air Classifier Production Line, Business Range: Manufacturing Processing Machinery, Metallurgy, Mineral Energy Management System Certification: ISO 9001, ISO 9000, QC , ISO 29001 Main Products: Magnetic Separator, Air Classifier, Metal Locator, Sand Production LineSilica Sand and Silica Powder Air Classifier Production LineChina Jiangxi silica sand powder production line This production line is used to grind the dried high purity quartz sand The ball mill employs silica as lining board, and modified the traditional equipment to meet the needs of processing silica powderThe working efficiency of Sinonine silica sand ball mill and air classifier is very highSilica sand Ball millSinonine

SILICA FOR SUSTAINABLE FOOD PRODUCTION Evonik

Milk powder processing**: 02% silica cuts resource waste by 50% Customer case study: milk powder During the production process of milk powder, about 25% of the product is lost due to caking at the walls of the spray dryer’s cyclone If a dairy company produces approximately 70 metric tons* of milk powder every day,200~1250 mesh midgrade quality silica powder, generally adopts the production process of Ball Mill and Air Classifier, the singleline production capacity is 2t/h~20t/h, this process is mature and reliable, there are many cases of us about this production lines: Anhui Fengyang, Anqing, Henan , Heyuan, Guangdong, Qingyuan, Foshan, Jiangxi, Tangshan, Hebei, Linyi, Shandong and SILICA POWDER (SUPERFINE QUARTZ POWDER) PROCESSINGThe company produces silica soil and purchases a drying and dispersing modification production line from Epic Powder Skip to content : [ protected] Tel: +86 ; which is difficult to process The whole process flow is complicated and has high processing cost Recommended by peers, Silica soil drying and dispersing modification production line of a 2022年3月26日 The production process is environmentally friendly and pollutionfree The fineness of the grinding powder can be adjusted between 80800 meshes, and the applicability is more flexible and extensive Silica can be used to make sand or to grind powder The equipment used for different production needs is different, so there is no exact value for Equipment Configuration of Silica Processing Production Line

About Us Silica powder (ultrafine quartz powder) processing

EPIC’s ball milling and classifying production lines, jet mills, and jet classifiers are widely used in the fine processing of silicon micro powder, which greatly promotes the application field expansion, technological progress, and industrial upgrading Our company covers an area of 40000 square meters, now has a Silicon micropowder production line one, with annual output of micro Silicon Powder 10000 ton; have two production line of silica sand, annual production capacity of 20000 ton; also has a set of active micro Silicon powder production line, 5000 tons per yearSilica Sand Manufacturer, Fused Silica, Silica Powder Supplier1200 Mesh micro silica fume powder production line, HLMX600 superfine mill This 1200 Mesh micro silica fume powder production line uses HLMX600 superfine mill, which has the output of 115t/h, and 10001200 mesh 1200 Mesh Micro Silica Fume Powder Production, 2020年6月27日 The effect of silane coupling agent on surface modification of silica powder is very ideal It changes the silica powder’s hydrophilicity to an organophilic surface It also improves the wettability of organic polymers to the powder It creates a strong, covalent bond between the silica powder and organic polymers by adding functional groups Application, processing technology and development trends of silica powder

.jpg)

Application ALPA micro silica powder (superfine quartz powder

Silica Powder is by natural quartz (SiO₂) or fused quartz (natural quartz by high temperature melting, cooling amorphous SiO₂) after crushing, ball milling (or vibration, airflow grinding), flotation, pickling purification, high purity water treatment and other multichannel processing and into the powder Silica Powder is a kind of non If you have a demand for ultrafine powder equipment, please contact EPIC Powder Machinery We have professional technical personnel to follow up on every demand 跳至内容Contact EPIC Powder Machinery Silica powder (ultrafine quartz powder Guangzhou a material company silica powder ball mill and air classifier production line Shandong mining technology and equipment company when the production of 380kg particle size D100:115μm quartz sand ball mill and air classifier production lineGuangzhou a material company silica powder ball mill and air Silica Powder Supplier, Silica Powder, BN Manufacturers/ Suppliers Suzhou Ginet New Material No of Production Lines: Above 10 Ever Annual Output of Main Products: Product Name Units Produced (Previous Year) Total Production: 50000 Tons: More Product List D50 3535µm 99% Purity H Boron Nitride Powder for Cosmetics, Electronics Silica Powder Manufacturer, Silica Powder, BN Supplier Suzhou

.jpg)

sand processing plant silica/quartz sand washing plant

sand processing plant silica/quartz sand washing plant 282 followers on LinkedIn wet type quartz/silica sand production line, silicon powder ball mill classifying production line, 2024年9月28日 Primary Crushing A loader pushes silica rock, up to 50 cm in size, into the chute or hopper at the beginning of the line Theoretically, a 50 cm rock is the largest input to the processing line Introduction to Silica Processing for Glass Production LinkedInSilica soil drying and dispersing modification production line of a mineral products company in Fujian The company has the mining right, and the mineral products have special physical and chemical indexes, which is difficult to process, complicated process flow and high processing costSilica soil drying and dispersing modification production line of a The production line of 40,000 tons of super pure quartz ball grinding and grading with 325 mesh granularity is produced by a company in Guangdong Lianyungang, a new material company produced 200kg particle size D100:10μm silicon The production line of 40,000 tons of super pure

silica sand processing line

It can effectively reduce the iron content of quartz sand We have a wealth of experience in quartz sand production lines The entire process is not only equipped with advanced iron removal equipment, but also controlled at the source to minimize the PROCESSING OF BALL MILL AND AIR CLASSIFIER THIS PROCESS IS MATURE AND RELIABLE, WIDELY USED IN THE PRODUCTION OF SILICA POWDER The production line adopts internationally popular continuous production process: ball mill and classifier systemIncluding crushing, grinding, classifying, packaging, magnetic separation, conveying, ALPA Silica Powder Processing Technology DirectIndustrySilica powder process; Surface modification; Equipmennt Vertical Air Classifier; Horizontal Air Classifier; Ball Mill and Air Classifier Production LineHorizontal Air Classifier ALPA micro silica powder (superfine In the silica sand production line, Jaw Crusher is the coarse silica sand crushing machine, Silica sand processing flow In the silica powder making process, Jaw Crusher is used as primary crushing machine, then go through the secondary crushing plantSilica sand processing line, silica sand making plant

Silica Processing Equipment FEECO International Inc

Silica gel powder; MATERIAL PROCESSING Rotary Dryers We offer a complete line of bulk material handling equipment both as standalone systems, A continuous testing phase that aims to establish the equipment setup and parameters required for continuous production of your specific materialThrough onestop solution of quartz/silica sand production line turnkey project service, we ensure the smooth operation of customers' quartz/silica sand processing plant We will provide efficient, scientific and economic services for customers, safeguard customers' investment and income, and develop and progress together with customersTurkey solutions silica sand processing projectSinonineHigh purity quartz technical process After the quartz ore is necessarily prepared, the high purity quartz sand production line is employed with the advanced production process, according to the process flow: calcination water quenching crushing grinding screening classifyingdesliming magnetic separation flotation acid leaching flotation high High purity quartz sand production lineSinonineSinonine can provide turkey service for sand production to produce glass sand,frac sand,high purity sand etcWe are the first and only company in China that can provide the turnkey project service EPC service for quartz/silica sand processing plant We can provide quartz/silica sand production equipment with high costeffectiveSilica sand processing and washing plantSinonine

.jpg)

Analysis of silica production and drying processes IOSR Journals

Silica is widely used in industry, agriculture, medicine and many other fields due to its wide range of raw materials and excellent properties The main industrial production methods for silica in China today are precipitation, vapour phase and dissociation In the production of silica by precipitation and dissociation,