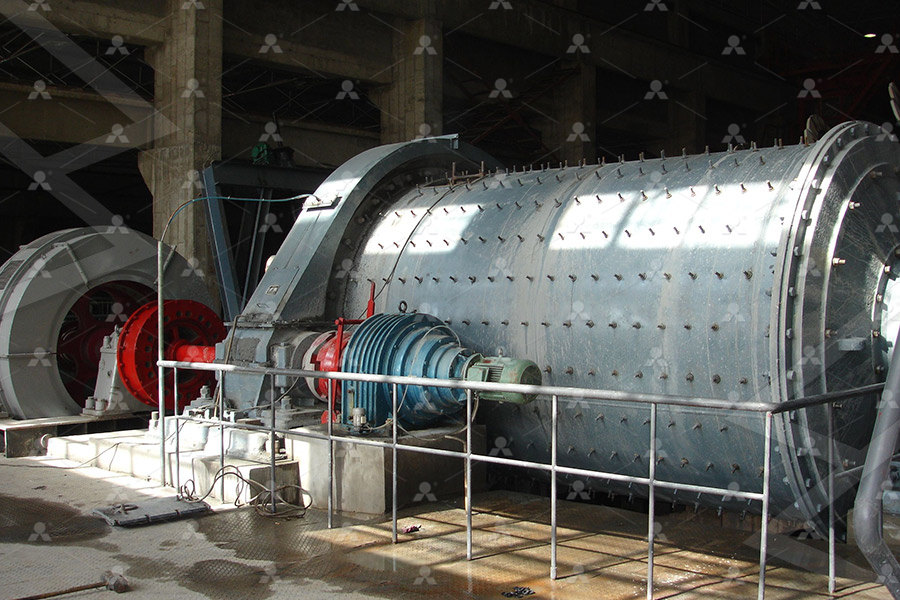

Battery grinding equipment

Grinding Equipment Used In Lithium Battery Material Longly

We offer automated feeding, premixing, dispersion, and intelligent batching for new energy batteries Our comprehensive solutions include precision measurement, automatic canning, Unlock the secret to superior battery performance! Discover the essential grinding equipmenGrinding Equipment for Battery MaterialsFrom grinding to recycling: ON offers a wide range of machines and systems for your battery production What all our machines and systems for processing active and raw materials for battery production have in common: They are tailor Cathode active material production processDiscover the cuttingedge grinding equipment revolutionizing battery anode materials! Learn how Longly's advanced tech optimizes graphite lithium batteries for peak performance and longevity Click now!Grinding Equipment Used In Battery Anode Material

5 Key Considerations for Selecting the Right Grinding Equipment

Discover the key factors in selecting grinding equipment for battery materials, including particle size, material compatibility, throughput capacity, energy efficiency, and maintenance supportBühler’s precursor and active material grinding solutions and extensive expertise in nanoparticle processing enhances the conversion of electrode active materials for highperformance lithiumion batteries (LIB)Efficient precursor and active material grinding Bühler Only PRG grinds to the tolerances required for advanced battery manufacturing PRG provides the tightest grinding tolerances in the world — as precise as 40 millionths of an inch TIR The rolls you receive from PRG are serviced and LithiumIon Batteries Precision Roll Grinders Inc2024年11月20日 Unlock the secret to superior battery performance! Discover the essential grinding equipment used in battery materials with Longly's top solutions Boost efficiency and Grinding Equipment for Battery Materials Dongguan Longly

.jpg)

Battery Grinder Machine MadeinChina

China Battery Grinder Machine wholesale Select 2024 high quality Battery Grinder Machine products in best price from certified Chinese Machine Supplies manufacturers, Z Machine China Battery Grinder wholesale Select 2024 high quality Battery Grinder products in best price from certified Chinese Grinder Equipment manufacturers, China Grinder suppliers, Battery Grinder MadeinChinaRevolutionize your battery production with toptier grinding equipment for cathode active material, LNMO Main Process of Chemical Processing Equipment in Battery Cathode Material Automatic Production Line →1Powder ingredients Grinding Equipment Used In Battery Cathode Discover the key factors in selecting grinding equipment for battery materials, including particle size, material compatibility, throughput capacity, energy efficiency, and maintenance support Ir para o conteúdo5 Key Considerations for Selecting the Right Grinding Equipment

5 Key Considerations for Selecting the Right Grinding Equipment

Discover the key factors in selecting grinding equipment for battery materials, including particle size, material compatibility, throughput capacity, energy efficiency, and maintenance supportWhen selecting grinding equipment for battery materials, it’s essential to understand the grinding process to make an informed decision Here are 5 key considerations to keep in mind: Particle Size Distribution: The grinding process should achieve the desired particle size distribution for the battery materials, ensuring uniformity and consistency5 Key Considerations for Selecting the Right Grinding Equipment Discover the key factors in selecting grinding equipment for battery materials, including particle size, material compatibility, throughput capacity, energy efficiency, and maintenance support5 Key Considerations for Selecting the Right Grinding Equipment Discover the key factors in selecting grinding equipment for battery materials, including particle size, material compatibility, throughput capacity, energy efficiency, and maintenance support5 Key Considerations for Selecting the Right Grinding Equipment

LithiumIon Batteries Precision Roll Grinders Inc

Only PRG grinds to the tolerances required for advanced battery manufacturing PRG provides the tightest grinding tolerances in the world — as precise as 40 millionths of an inch TIR The rolls you receive from PRG are serviced and ground to the proper roundness, TIR and surface finish — all critical to building a better batteryOur experienced battery technologists can help you test new battery products on stateoftheart Bühler process solutions so you can see how products behave in a manufacturing scenario and define potential production requirements We will test your product on our wet grinding and dispersing equipment to help you define the best possible ROIBattery application lab, Japan Grinding and Dispersing Bühler Bühler’s lithiumion battery (LIB) manufacturing solutions cover crucial process steps They include wet grinding active materials and precursors plus a continuous twinscrew electrode slurry mixer, designed to reduce costs in largescale productionLithiumion Battery Production Bühler Group2024年11月20日 Enhance your grinding equipment's performance, efficiency, and results Explore proven methods now! Lithium ion batteries are basically comprised of a negative electrode (anode), a positive electrode (cathode) and a separator membrane Battery MaterialsGrinding Equipment Application Technology Longly

Cell Manufacturing Equipment Battery Design

2024年11月22日 Cell manufacturing covers a lot of specialist areas and hence there is a range of equipment suppliers The cell manufacturing process is laid out in 14 steps covering everything from mixing chemicals, dryers, printing and electrical testing This then breaks down again, requiring equipment and supporting equipment, building infrastructure and software2024年11月22日 Allwin’s precise wet grinding solutions are designed specifically for battery cell manufacturing Ceramic Revolutionize Your Ceramic Processing with Allwin, est 1993 in China, specializes in wet grinding mill equipment Wet Grinding and Dispersing Equipment Allwin Material: Natural flake graphite, particle size ≤100 mesh, carbon content: 90%95% Process:GrindingSpheroidizationPurificationShaping ClassifyingCoatingCarbonizationDeagglomerationSievingProduct The raw material is Grinding Shaping Equipment Lithium battery 2023年2月20日 environmentfriendly lithium battery positive and negative sheet material crushing and recycling production line, Grinding Equipment; Lithium battery recovery machine Types and main components of lithium batteryList of main components of lithium batteryElementAluminum foilFeGr Battery recycling Equipment Waste Paper Recycling Equipment

Cordless angle grinders Cutting, grinding, metalworking

Also 18 V battery packs of our CAS partners can be used Discover the new cordless freedom cordlessalliancesystem In addition to the battery packs and chargers, especially for cordless angle ginders, the grinding wheels also play an important role We offer you an extensive range of cutting and grinding discs for any application areaGrinding Machine 2L/5L slurry mixing machine Transfer coating Machine Vacuum Oven (120) Calendar Machine (300) Equipment for battery pack production line Assembly line Tab cutting machine Tab flattening machine Battery Production Line EquipmentGelon Lib Group Co, LtdAfter continuous research and development, ALPA has a set of perfect lithium battery anode and cathode material processing scheme and equipment, which can meet the complex process requirements, including dustfree feeding, magnetic separation, ultrafine grinding, classification, powder transport, metering packaging, automatic batching Positive Negative Lithium Battery Materials ALPA Powder EquipmentDiscover the key factors in selecting grinding equipment for battery materials, including particle size, material compatibility, throughput capacity, energy efficiency, and maintenance support5 Key Considerations for Selecting the Right Grinding Equipment

.jpg)

Grinding Equipment Used In Battery Anode Material Longly

Discover the cuttingedge grinding equipment revolutionizing battery anode materials! Learn how Longly's advanced tech optimizes graphite lithium batteries for peak performance and longevity Main Process of Chemical Processing Equipment in Battery Anode Material Automatic Production LineOur experienced battery technologists can help you test new battery products on stateoftheart Bühler process solutions so you can see how products behave in a manufacturing scenario and define potential production requirements We will test your product on our wet grinding and dispersing equipment to help you define the best possible ROIBattery Application Test Facilities Grinding and DispersingProduct Description 72V Intelligent Lithium Battery Profiling Grinding Machine *The depth of the feed, the realtime battery power digital display, the operator is clear at a glanceLiBattery Electric Railway Grinding Machine/ Rail GrinderProduct Details STCXQM02A planetary ball grinding equipment is widely used in many fields like geology, mine, metallurgy, electric industry, construction, ceramics, chemicals, light industry, medicine, etc Different material of milling Planetary Ball Grinding Equipment for Lab Lithium

Grinding Equipment Manufacturer,Grinding Equipment Supplier,Grinding

Tmax Battery Equipments has engaged in the production Grinding Equipment for over 20 years Contact us directly to receive a quote en fr de ru es pt ko tr pl th Give us a call +54 us David@batterymaking Language : English en fr de ru es pt ko tr pl th Home; Company; ProductsHighPrecision Grinding Equipment for Battery Material Processing Highprecision grinding equipment is key for shaping battery materials into the fine powders necessary for highperformance batteries These machines achieve particle sizes with such precision that they ensure uniformity and quality, which are crucial for battery efficacy and The Role of HighPrecision Grinding in Advancing Battery MaterialsBattery 30 years of experience in the industry A range of models with varying sizes and capacities Streamline production processes and increase throughput ☎ Call +86 023Battery allwingrinding2023年2月20日 environmentfriendly lithium battery positive and negative sheet material crushing and recycling production line, Grinding Equipment; Lithium battery recovery machine Types and main components of lithium batteryList of main components of lithium batteryElementAluminum foilFeGr Battery recycling Equipment Waste Paper Recycling Equipment

.jpg)

Cathode active material production process Hosokawa Micron

Equipment for battery production From grinding to recycling: ON offers a wide range of machines and systems for your battery production What all our machines and systems for processing active and raw materials for battery production have in common: They are tailormade to 2024年11月11日 Unlock the secrets behind the powerful grinding equipment used in electronic ceramics and discover why MLCC capacitors rely on topnotch machinery for peak performance Lithium Battery Conductive Agent Carbon Nanotubes and Production Equipment Bead MillGrinding Equipment Used In Electronic Ceramics LonglyGrinding Corded Corded Power Tools Grinding 100mm (4”) Angle Grinders GA4030100mm (4') Angle Grinder View Details GA4031100mm (4') Outdoor Power Equipment Batteries Chargers; Blowers; Brushcutters; Chainsaws; Earth Augers; Hedge Trimmers; High Pressure Washers; Lawn Mowers; Lawn Scarifiers; MultiFunction Powerheads; Blowers;Grinding Makita AustraliaLithiumion batteries materials solution Air Classifier Jet Mill Roller Mill Impact Mill Classifying Ball Mill Production Line Powder Surface Modification Powder Disggregate Mill Powder Shaping Machine Wet Grinding Mill Powder Fusion Machine Powder Mixer Laboratory Equipment Others Powder ProcessingZhengyuan Powder Equipment

Grinding Equipment Used In Battery Cathode

Revolutionize your battery production with toptier grinding equipment for cathode active material, LNMO Main Process of Chemical Processing Equipment in Battery Cathode Material Automatic Production Line →1Powder ingredients Discover the key factors in selecting grinding equipment for battery materials, including particle size, material compatibility, throughput capacity, energy efficiency, and maintenance support Ir para o conteúdo5 Key Considerations for Selecting the Right Grinding Equipment Discover the key factors in selecting grinding equipment for battery materials, including particle size, material compatibility, throughput capacity, energy efficiency, and maintenance support5 Key Considerations for Selecting the Right Grinding Equipment When selecting grinding equipment for battery materials, it’s essential to understand the grinding process to make an informed decision Here are 5 key considerations to keep in mind: Particle Size Distribution: The grinding process should achieve the desired particle size distribution for the battery materials, ensuring uniformity and consistency5 Key Considerations for Selecting the Right Grinding Equipment

5 Key Considerations for Selecting the Right Grinding Equipment

Discover the key factors in selecting grinding equipment for battery materials, including particle size, material compatibility, throughput capacity, energy efficiency, and maintenance supportDiscover the key factors in selecting grinding equipment for battery materials, including particle size, material compatibility, throughput capacity, energy efficiency, and maintenance support5 Key Considerations for Selecting the Right Grinding Equipment Only PRG grinds to the tolerances required for advanced battery manufacturing PRG provides the tightest grinding tolerances in the world — as precise as 40 millionths of an inch TIR The rolls you receive from PRG are serviced and ground to the proper roundness, TIR and surface finish — all critical to building a better batteryLithiumIon Batteries Precision Roll Grinders IncOur experienced battery technologists can help you test new battery products on stateoftheart Bühler process solutions so you can see how products behave in a manufacturing scenario and define potential production requirements We will test your product on our wet grinding and dispersing equipment to help you define the best possible ROIBattery application lab, Japan Grinding and Dispersing Bühler

Lithiumion Battery Production Bühler Group

Bühler’s lithiumion battery (LIB) manufacturing solutions cover crucial process steps They include wet grinding active materials and precursors plus a continuous twinscrew electrode slurry mixer, designed to reduce costs in largescale production2024年11月20日 Enhance your grinding equipment's performance, efficiency, and results Explore proven methods now! Lithium ion batteries are basically comprised of a negative electrode (anode), a positive electrode (cathode) and a separator membrane Battery MaterialsGrinding Equipment Application Technology Longly