Knowledge about ore powder production line

.jpg)

Study on the Basic Characteristics of Iron Ore Powder with MDPI

2022年7月30日 In order to study in depth the differences in basic characteristics between iron ore fines commonly used by a steel company, and guide the sintering performance plant to choose the best ore allocation method, experimental studies on the basic characteristics of Feature papers represent the most advanced research with significant Versions Notes2021年9月6日 We describe a micronsized ore powder production by propulsion and rapid unloading of highpressure gas The research consists of three parts Firstly, we obtain the Micronsized ore powder production by propulsion and rapid Powder metallurgy – science of producing metal powders and making finished /semifinished objects from mixed or alloyed powders with or without the addition of nonmetallic constituentsPowder metallurgy – basics applications IIT Guwahati

.jpg)

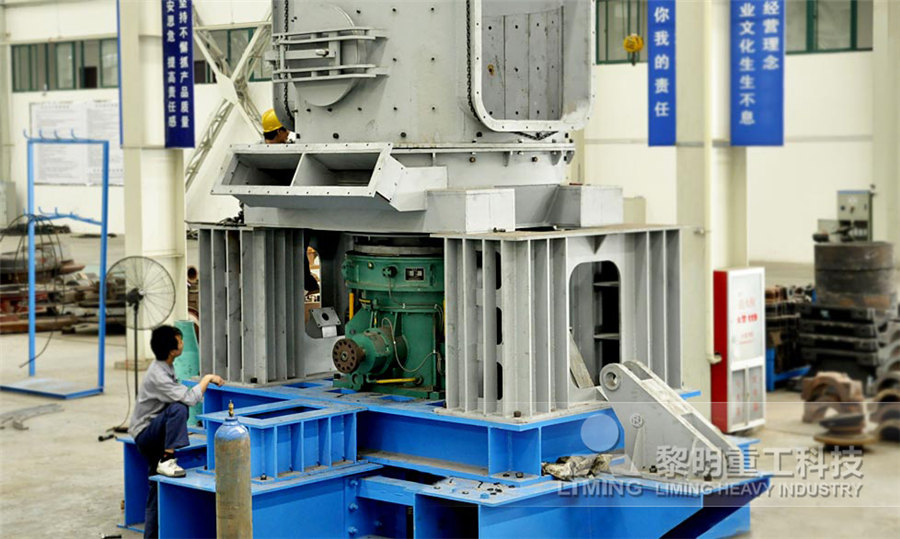

Advancements in ore powder production process equipment:

Ore powder production involves the conversion of mined ore into fine particles through a series of crushing, grinding, and classifying processes The equipment used in this process must be 2014年6月1日 An efficient metallurgical operation with excellent ore characterization and frequent process mineralogy support, superlatively equipped and run, will overcome the Ore characterization, process mineralogy and lab automation a 2023年11月1日 In response to the problems of low production efficiency, high defect rate, and slow mold change in a certain company’s powder production site, this study combines the Research on Lean Improvement of a Powder Production Line The gold ore processing production line is a complex process involving multiple stages and equipment, which requires strict control of quality and environmental protection requirements Gold Ore Processing Production Line TAYMACHINERY

Micronsized ore powder production by propulsion and rapid

2021年9月6日 We describe a micronsized ore powder production by propulsion and rapid unloading of highpressure gas The research consists of three parts Firstly, we obtain the 2018年7月11日 Iron ore and iron ore pellets are important sources of iron for manufacturing steel The iron ore production has significantly expanded in recent years, owing to increasing Iron Ore Pelletizing Process: An Overview ResearchGate2018年3月1日 Iron ore powder production after CO 2 substitution is an effective method, which not only optimizes the grain size distribution but also saves 95% of the liquid CO 2 The initial Experiment on micronsized particle production of iron ore by Company News Product Knowledge Industry News GYPSUM POWDER PRODUCTION LINE Processing capacity: 50,000300,000 tons/year Processing materials gypsum is graded according to the content of calcium sulfate GYPSUM POWDER PRODUCTION LINE

.jpg)

Biological Products Powder Mixing Production Line

Jiangyin Mill Powder Technology Company specializes in RD and production of biological products powder mixing production line high quality +86 Request A Quote2024年9月27日 Insitec is a fully automated and online laser diffraction system, enabling realtime monitoring of particle sizes during the powder coating production process Operators can see the consequences of milling, for instance, ensuring that every batch complies with tight particle size parameters, and helping avoid overmillingParticle size analysis for powder coatings Malvern Panalytical2023年11月1日 This content was downloaded from IP address 20620457132 on 02/12/2023 at 13:11Research on Lean Improvement of a Powder Production Line Milk Powder Production Line Carbonated Drinks Production Line However, what's most unique about us is our knowledge of handling powder products We use computational fluid dynamics (CFD) techniques to simulate trials before carrying out pilot tests in a physical plantMilk Powder Production line Shanghai Zhelv Engineering

Gypsum Powder Production Line Hebei Xiangyi Mechanical

XIANGYI is one of the most professional gypsum powder production line manufacturers and suppliers in China for over 15 years We warmly welcome you to buy cheap gypsum powder production line for sale here from our factory For price consultation, contact us2024年11月12日 Key Components of a Milk Powder Production Line A milk powder production line is a complex of interconnected equipment that enables to turn fresh liquid milk into a solid and highly resistant to spoilage product with a very long shelf life These integrations mean that every phase of production is enhanced for productivity, quality, and safetyOptimize Your Milk Powder Production Line Process TodayHere, we delve into the key components and technologies that make up the modern ore powder production process Key Components of Ore Powder Production Equipment: 1 Crushers The initial step in ore powder production is the reduction of ore size, which is accomplished by crushers Jaw crushers, cone crushers, and impact crushers are commonly Advancements in ore powder production process equipment: 2023年3月15日 In this study, iron ore powder fines, collected from the iron ore pelletization process, with a size range between 10 and 45 μm (with the mean size D 50 = 28 μm), and atomized Al powder (995% Al) with a size range between 50 and 160 μm (D 50 = 1026 μm) were employed to investigate the possibility of iron ore reduction via a laserirradiated Laserassisted reduction of iron ore using aluminum powder

Which Kind of Grinding Equipment is Suitable for Iron Ore Knowledge

2020年11月19日 Gravity Beneficiation Line For Gold Ore; 1000T/D CIL Production Line; Home > Knowledge > Content Which Kind of Grinding Equipment is Suitable for Iron Ore Nov 19, 2020 while Raymond mill is inclined to nonmetallic ore powder, 2022年6月21日 Jiangyin Powder Mill Technology Co, Ltd Is mainly application in a full range of powder field, from the unit to the system, from the crushing, conveying, mixing, sieving to granulation, relates to production areas including food additives, baking ingredients, pharmaceutical intermediate, health food, chemical raw materials and other industriesPowder Production Line Mill Powder Technology in ChinaDegree of automation: The production line adopts advanced automatic control system, which is easy to operate and manage Advantages of Hongji gold ore beneficition production line 1 The mineral processing effect is good and the grade of gold ore powder is improved 2 The production line is reasonable and the gold recovery rate is high 3Gold Ore Beneficiation Production LineHongji Mining MachineryGypsum powder is a product made by processing natural gypsum ore or industrial byproduct gypsum into fine powder through a series of physical and chemical treatment processes, such as crushing, grinding, calcination, etc Gypsum powder has a wide range of uses and can be used in many fields such as building materials, chemicals, medicine, agriculture, etc Usually, the Gypsum Powder Production Line Hongji Mining Machinery

Automatic rubber powder production line Plastic recycling

2024年7月29日 The automatic rubber powder production line is used to recycle waste tires and process tires into rubber powder In addition, the Shuliy waste tire recycling machine can separate the rubber, steel wire, and fiber contained in the tires in a single processFull lines for Powder Coating Production IPCO is an OEM of full powder paint or powder coating production line equipment Upon receiving the blended dry raw premix (resin, filler, extender, pigment, curing agent, recycled additive and more) our equipment can uniformly convert the blended premix into a homogenous material according to the manufacturer’s requirementsFull Powder Paint Lines IPCO01000t/h cheap price, fully automation gypsum powder production for Building Gypsum and Plaster Board Some Common Knowledge about Gypsum Powder Plant: Capacity: 30,000 300,000 ton/year Automation: fully automatic Calcination system: using boiling furnace to calcine, adopting heat conductive oil furnace as heat sourceGypsum Powder Production Line Zoomjo Groupprocess stages, the ore is exposed to a number of heat cycles, which lead to material oxidation35 Therefore, the pellets and the iron ore fines mainly consist of hematite (Fe 2O 3) by the end of their manufacturing process In this study, iron ore powder fines, collected from the iron ore pelletization process, with a size range between 10 Laserassisted reduction of iron ore using aluminum powder DiVA

.jpg)

SBM Ultrafine Powder Technology Industrial Grinding Mill,

SBM is recognized by many customers at home and abroad for its professional industry knowledge and skills, highquality ore grinding equipment, and perfect service system The main products include: ore stone HGM Ultrafine Grinding Mill Is Applied To The CCM Powder Production Line CCM Powder Production Line: Raw material: custic calcined 2021年9月6日 Before smelting, the ore must be broken utilizing mechanical methods such as crushing and milling because of lowergrade content The industrial production of iron powder started in 1937 in the USA [3, 4]Ore powder production is generally executed by the ball milling method that requires reduplicative ball milling []Multistage crushing together with the ball Micronsized ore powder production by propulsion and rapid Our granulating process can granulate the pulverized ore produced in the process of phosphate mining and yellow phosphorus production as well as the phosphate concentrate After granulate, the pellets can meet the requirement of strength and size for the production of yellow phosphorus electrical furnace This process will reduce the comprehensive cost of yellow phosphorus' PHOSPHATE ORE PELLETIZATION PRODUCTION PROCESSP/M part depends on size, shape, and surface area of powder particles • Single powder production method is not sufficient for all applications Powder production methods: 1 Mechanical methods, 2 Physical methods, 3 Chemical methods 1 Mechanical methods => cheapest of the powder production methods; These methodsPowder metallurgy – basics applications IIT Guwahati

Slag Grinding Production Line TAYMACHINERY

The slag grinding production line is a production system specially used to process slag and make slag powder Slag, as a byproduct in the industrial production process, can be converted into valuable resources through grinding processing and used in cement mixtures, highperformance concrete admixtures, etc2005年2月1日 Food powder handling and processing: Industry problems, knowledge barriers and research opportunities February 2005 Chemical Engineering and Processing Process Intensification 44(2):209214Food powder handling and processing: Industry 2013年11月19日 Gypsum Powder Production Line, Find Details and Price about Gypsum Powder Making Equipment from Gypsum Powder Production Line Henan Dafu Mechanical Import and Export Co, Ltd Home Product Directory Manufacturing Processing Machinery Building Material Making Machinery Gypsum Powder MachineGypsum Powder Production Line Gypsum Powder Making Here are the primary uses of lithium ore production lines: 1 Battery Manufacturing Lithiumion Batteries: The most significant use of lithium is in the production of lithiumion batteries, which power electric vehicles (EVs), portable electronics (smartphones, laptops, tablets), and renewable energy storage systemsLithium Ore Production Line TAYMACHINERY

Research on Fault Detection Method of Mineral Powder Production Line

2020年3月17日 Fo r the rare earth ore powder production line, the realtime data detected on the extraction and stirring device, through this method, the equipment operation status of theDownload Citation On Jan 1, 2023, Davide Porcellato and others published Composition and Fate of HeatResistant SporeFormers in the Milk Powder Production Line Find, read and cite all the Composition and Fate of HeatResistant SporeFormers in the Milk Powder 2023年9月5日 Additionally, it serves as an indispensable complementary process for some powder production methods, such as grinding electrolytically produced brittle cathode precipitates, or grinding spongelike metal chunks produced through reduction Therefore, the mechanical pulverization method occupies a significant position in powder productionMetal Powder Preparation Methods and Principles: A This means that we protect the quality of your powder every step of the way Tailormade powder packaging lines There is no such thing as the ideal powder packaging line But your ideal powder filling line does exist Our powder filling lines for filling openmouth bags are composed of three machines that work together like clockwork Contact Powder packaging line for powdery products

.jpg)

Manganese ore powder drying production line in Kazakhstan

2023年6月4日 The manganese ore powder drying production line purchased by Kazakhstan customers from our company has been installed and debugged and officially put into production Since the signing of theCompany News Product Knowledge Industry News GYPSUM POWDER PRODUCTION LINE Processing capacity: 50,000300,000 tons/year Processing materials gypsum is graded according to the content of calcium sulfate GYPSUM POWDER PRODUCTION LINEJiangyin Mill Powder Technology Company specializes in RD and production of biological products powder mixing production line high quality +86 Request A QuoteBiological Products Powder Mixing Production Line 2024年9月27日 Insitec is a fully automated and online laser diffraction system, enabling realtime monitoring of particle sizes during the powder coating production process Operators can see the consequences of milling, for instance, ensuring that every batch complies with tight particle size parameters, and helping avoid overmillingParticle size analysis for powder coatings Malvern Panalytical

.jpg)

Research on Lean Improvement of a Powder Production Line

2023年11月1日 This content was downloaded from IP address 20620457132 on 02/12/2023 at 13:11Milk Powder Production Line Carbonated Drinks Production Line However, what's most unique about us is our knowledge of handling powder products We use computational fluid dynamics (CFD) techniques to simulate trials before carrying out pilot tests in a physical plantMilk Powder Production line Shanghai Zhelv Engineering XIANGYI is one of the most professional gypsum powder production line manufacturers and suppliers in China for over 15 years We warmly welcome you to buy cheap gypsum powder production line for sale here from our factory For price consultation, contact usGypsum Powder Production Line Hebei Xiangyi Mechanical 2024年11月12日 Key Components of a Milk Powder Production Line A milk powder production line is a complex of interconnected equipment that enables to turn fresh liquid milk into a solid and highly resistant to spoilage product with a very long shelf life These integrations mean that every phase of production is enhanced for productivity, quality, and safetyOptimize Your Milk Powder Production Line Process Today

CFB石灰石脱硫剂制备64.jpg)

Advancements in ore powder production process equipment:

Here, we delve into the key components and technologies that make up the modern ore powder production process Key Components of Ore Powder Production Equipment: 1 Crushers The initial step in ore powder production is the reduction of ore size, which is accomplished by crushers Jaw crushers, cone crushers, and impact crushers are commonly 2023年3月15日 In this study, iron ore powder fines, collected from the iron ore pelletization process, with a size range between 10 and 45 μm (with the mean size D 50 = 28 μm), and atomized Al powder (995% Al) with a size range between 50 and 160 μm (D 50 = 1026 μm) were employed to investigate the possibility of iron ore reduction via a laserirradiated Laserassisted reduction of iron ore using aluminum powder2020年11月19日 Gravity Beneficiation Line For Gold Ore; 1000T/D CIL Production Line; Home > Knowledge > Content Which Kind of Grinding Equipment is Suitable for Iron Ore Nov 19, 2020 while Raymond mill is inclined to nonmetallic ore powder, Which Kind of Grinding Equipment is Suitable for Iron Ore Knowledge