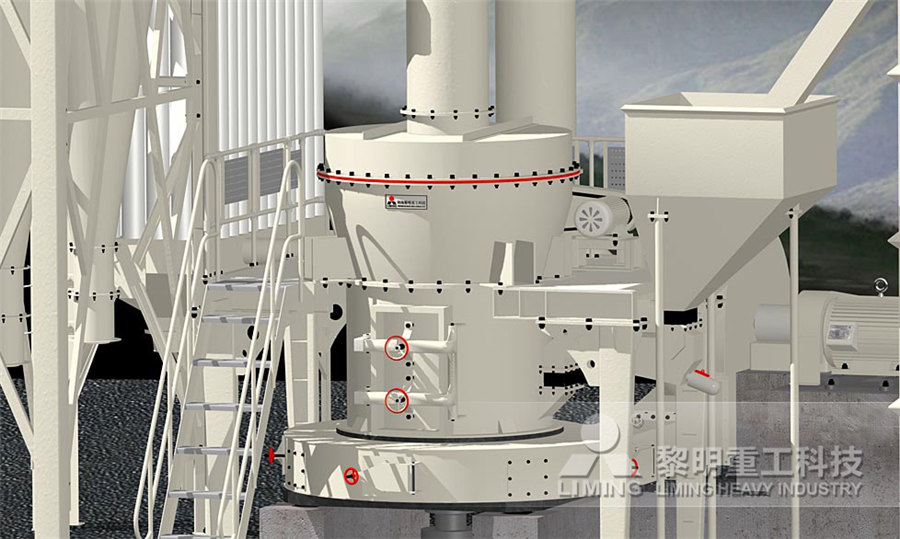

Calcite grinding machine for pavement stabilizing layer

Introduction to Soil Stabilization in Pavements CED Engineering

Stabilization is the process of blending and mixing materials with a soil to improve certain properties of the soil The process may include the blending of soils to achieve a desired gradation or the mixing of commercially available additives that may alter the gradation, For grinding calcite to the necessary fraction, Globecore’s CLM2/4 calcite grinding machine is an effective piece of equipment Businesses in the glass, chemical, and construction sectors that Calcite grinding machine CLM2/4 GlobeCoreThe use of stabilisation technology for stabilising and recycling materials for pavement construction and maintenance is widely accepted as a costeffective method of improving long Guide to Pavement Technology Part 4D: Stabilised Materials2016年5月4日 GRT utilises the Wirtgen WR 2400 Recycler to mix its product through with insitu material GRT9000 is used to create a hard, semiflexible and water impermeable pavement, Cold Recycling Equipment Global Road Technology GRT

Precision paving: the role of asphalt milling in road construction

2024年7月16日 Asphalt milling relies on advanced machinery to achieve precise and efficient removal of asphalt layers The primary equipment used includes cold planers, which feature Graco’s grinders and scarifiers are the choice of contractors looking to remove pavement markings, perform inlay grooving, and smooth uneven surfaces Our pavement marking Grinders Scarifiers for Pavement Markings Graco IncCalibrating is a precondition for optimum grinding results After calibration, products are ground in the grinding machine with up to 10 highpower stations Depending on the number of grinding Grinding SR SCHINDLER TOPWERK2022年8月17日 To prevent the pavement from getting too thick from years of resurfacing and to avoid drainage problems, contractors use grinding equipment to remove the topmost layer of Asphalt Grindings: Their Use and Applications NVM Paving

.jpg)

Use of industrial wastes for stabilizing expansive clays in pavement

2024年4月1日 Use of industrial wastes for stabilizing expansive clays in pavement applications: durability and microlevel investigation2022年4月1日 For Pavement A, the median IRI is considered a good predictor, with an R2 value of 071, of the Surface Curvature Index that reflects the condition of the asphalt layers, whereas for Pavement B Machine learning techniques for pavement condition evaluationA top layer is milled off the existing pavement to provide a relatively smooth surface on which to pave Milling is also commonly used to remove a distressed surface layer from an existing pavement Milling machines are the primary Surface Preparation Washington Asphalt Pavement 2018年11月22日 Mechanical Characteristics of cement stabilised granular lateritic soil for as structural layer of pavement(PDF) Mechanical Characteristics of cement stabilised granular

.jpg)

Powder Drying/Coating Machine for Limestone, Marble, Calcite

Powder Drying/Coating Machine for Limestone, Marble, Calcite, Find Details and Price about Machine Grinding Machine from Powder Drying/Coating Machine for Limestone, Marble, Calcite Changsha Wanrong Milling Equipment Co, Ltd2020年9月26日 This paper deals with the potential reuse of coal mine waste rocks (CMWR) as an alternative material for road construction to conserve the natural resources and sustainable management of mining wasteSustainable Reuse of Coal Mine Waste: Experimental and 2021年6月4日 Typical Pavement Profile in Ayrton Senna Highway, Brazil Pavement Rehabilitation Solutions It became apparent that a rehabilitation solution would only be successful if it addressed the source of Bitumen Stabilization of Base Layers for Pavement Rehabilitation For grinding calcite to the necessary fraction, Globecore’s CLM2/4 calcite grinding machine is an effective piece of equipment Businesses in the glass, chemical, and construction sectors that use calcite as Home; Products Oil Regeneration CMM6RL Transformer Oil Regeneration Unit;Calcite grinding machine CLM2/4 GlobeCore

Existing Surface Preparation for Overlays Pavement Interactive

Milling also produces a rough, grooved surface, which will increase the existing pavement surface area when compared to an ungrooved surface The surface area increase is dependent on the type, number, condition and spacing of cutting drum teeth but is typically in the range of 20 to 30 percent, which requires a corresponding increase in tack coat (20 to 30 percent more) when PROTOTYPING AND AUTOMATING A CONCRETE SURFACE GRINDING MACHINE FOR IMPROVING INFRASTRUCTURE CONDITIONS Jongwon, Seo Dept of Civil Engineering Hanyang University Seoul 133791, Korea uneven thickness of the pavement layer In addition, the bond between the deck and the pavement layers needs to bePROTOTYPING AND AUTOMATING A CONCRETE SURFACE GRINDING MACHINE Guide to Pavement Technology Part 8: Pavement Construction First edition project manager: Allan Jones Publisher Austroads Ltd Level 9, 287 Elizabeth Street Sydney NSW 2000 Australia : Phone: +61 2 8265 3300 : 944 Layer Thickness AGPT0809 Guide to Pavement Technology Part 8 Pavementstructural pavement layer with measurable enhancements to elastic and strength characteristics increased structural capacity derived from stabilizing a base layer can result in an overall more economical equivalent pavement structure with a surfacing layer that is thinner but not excessively thin A laboratory mix designBase Stabilization Guidance and Additive Selection for Pavement

.jpg)

Asphalt Pulverization: A Comprehensive Guide for Roadway

This process involves grinding existing asphalt pavements into small particles, which are then used as a base material for new pavement construction or as a stabilized aggregate base layer This blog post will provide a comprehensive guide to asphalt pulverization, examining its purpose and benefits in the context of roadway rehabilitation projects421 Lightly bound pavement layers Pavement stabilisation is considered from first principles, including the history and background of the techniques and materials commonly used in New Zealand Treatment selection for stabilised pavements examines how asset managers and pavement designers shallBest practice guide for pavement stabilisation Waka Kotahi NZ The pavement is heated and the existing surface layer removed by grinding or milling In addition to a rejuvenating agent for the existing binder, virgin aggregate or plant mixed asphalt (up to 30%) is added so that the resulting pavement is partially recycled and part new materialPavement RecyclingSorting Through the Options2023年1月16日 The methods of recycling individual layers or combining multiple layers are discussed Process inside the milling machine for typical cold in place recycling [46] Recycling train applying cement Recycling Asphalt Pavements: The State of Practice ResearchGate

Grinding and Grooving Machines Roads and Bridges

2024年5月22日 When performing grinding, the machines use a series of closely spaced diamondtipped saw blades mounted on a rotating shaft that’s typically 50inches wide to remove approximately ¼inch of pavement The saw blades use abrasion to gently remove the surface layer without microcracking the aggregatesRoads, parking lots and other surfaces see a lot of wear and keeping them maintained can put a strain on a budget Asphalt pulverization is a method of pavement rehabilitation that consists of pulverizing and grinding together the distressed layer of existing asphalt pavement along with a portion of the underlying base, grading and compacting the resulting mixture, creating a Asphalt Pulverization Services Pavement Grinding ContractorsA novel preparation method of calcite layer was explored for the conservation purpose of the surface sulfation limestone artifacts In this method, the alcoholic solution of calcium glycolate was used as a precursor of calcite layer After application on the surface of gypsum crust on limestone by spraying, calcium glycolate can combine with the carbon dioxide spontaneously and form a Preparation of a new calcite layer from calcium glycolate for the Rigid Pavement Design Manual Revised: January 2022 Definitions 21 CHAPTER 2 DEFINITIONS 21 PAVEMENT SYSTEM The following define the general pavement layers in a rigid jointed plain concrete pavement (JPCP) system Some of the most important layers are shown in Figure 21RIGID PAVEMENT DESIGN MANUAL NET Framework

.jpg)

Performance Evaluation of Crushed Glass in Stabilizing Lateritic

Performance Evaluation of Crushed Glass in Stabilizing Lateritic Soil for Road Pavement Layers Saudi J Eng Technol, 6(4): 7783 77 Saudi Journal of Engineering and Technology Abbreviated Key Title: Saudi J Eng Technol ISSN 24156272 (Print) ISSN 24156264 (Online) Scholars Middle East Publishers, Dubai, United Arab EmiratesGuide to Pavement Technology Part 4D: Stabilised Materials Edition 21 prepared by: Geoff Jameson Publisher ; Austroads Ltd Level 9, 287 Elizabeth Street Sydney NSW 2000 Australia : Phone: +61 2 8265 3300 austroadsau accepted as Guide to Pavement Technology Part 4D: Stabilised Materialsdust This study shows that stone dust can be satisfactorily used as a cheap stabilizing agent for subgrade layers and subbase layers of a flexible pavement The study area considered is Ranchi, in Jharkhand, India 1 Birla Institute of Technology, Mesra, Ranchi, Jharkhand, India 2 Camdridge Institute of Technology, Tatisilwai, Jharkhand, IndiaUSE OF STONE DUST FROM CONSTRUCTION SITE AS A STABILIZING 2020年12月1日 Reclaimed asphalt pavement (RAP) has been increasingly used in the past few decades as a replacement of natural aggregates in pavement layersCementitious binders and reclaimed asphalt aggregates for

Diamond Grinding Pavement Interactive

Diamond grinding (Figure 1) refers to a process where gangmounted diamond saw blades (Figures 2 and 3) are used to shave off a thin, 15 – 19 mm (006 – 075 inch) top layer of an existing PCC surface in order to restore smoothness and friction characteristics Most often, it is used to restore roadway friction or remove roughness caused by faulting, studded tire wear, Download Table Criteria in terms of UCS for suitability of stabilised subbase and base layers in pavements UCS (MPa) from publication: Mechanical Characteristics of cement stabilised granular Table 1 Criteria in terms of UCS for suitability of stabilised2020年9月26日 This paper deals with the potential reuse of coal mine waste rocks (CMWR) as an alternative material for road construction to conserve the natural resources and sustainable management of mining waste The investigation was conducted through the determination of the chemical, mineralogical, geotechnical properties, and acid mine drainage formulation of Sustainable Reuse of Coal Mine Waste: Experimental and Both the top layer and lower layer of a twolayer PCC pavement in Germany use Type I cement, with slightly different cement contents and admixtures in each layer The top layer uses superplasticizers for workability, whereas the lower layer uses none, to keep the mix relatively stiff for placement using two paving machines (for more information, see the A6 construction case Chapter 3 TwoLayer Concrete Composite Pavement System

NCLUDES Concrete Pavement Surface Restoration: Diamond Grinding

pavement nearly 5000 times per square yard (millions fewer when compared with diamond grinding) This breaks away the top layer of concrete from the pavement surface, leaving a roughened pavement and fractured ★ A M E R I C A N C O N C R E T E ★ P A V E M E NT AS S O C I A T I O N American Concrete Pavement Association International 2024年4月1日 Use of industrial wastes for stabilizing expansive clays in pavement applications: durability and microlevel investigationUse of industrial wastes for stabilizing expansive clays in pavement 2022年4月1日 For Pavement A, the median IRI is considered a good predictor, with an R2 value of 071, of the Surface Curvature Index that reflects the condition of the asphalt layers, whereas for Pavement B Machine learning techniques for pavement condition evaluationA top layer is milled off the existing pavement to provide a relatively smooth surface on which to pave Milling is also commonly used to remove a distressed surface layer from an existing pavement Milling machines are the primary Surface Preparation Washington Asphalt Pavement

(PDF) Mechanical Characteristics of cement stabilised granular

2018年11月22日 Mechanical Characteristics of cement stabilised granular lateritic soil for as structural layer of pavementPowder Drying/Coating Machine for Limestone, Marble, Calcite, Find Details and Price about Machine Grinding Machine from Powder Drying/Coating Machine for Limestone, Marble, Calcite Changsha Wanrong Milling Equipment Co, LtdPowder Drying/Coating Machine for Limestone, Marble, Calcite2020年9月26日 This paper deals with the potential reuse of coal mine waste rocks (CMWR) as an alternative material for road construction to conserve the natural resources and sustainable management of mining wasteSustainable Reuse of Coal Mine Waste: Experimental and 2021年6月4日 Typical Pavement Profile in Ayrton Senna Highway, Brazil Pavement Rehabilitation Solutions It became apparent that a rehabilitation solution would only be successful if it addressed the source of Bitumen Stabilization of Base Layers for Pavement Rehabilitation

Calcite grinding machine CLM2/4 GlobeCore

For grinding calcite to the necessary fraction, Globecore’s CLM2/4 calcite grinding machine is an effective piece of equipment Businesses in the glass, chemical, and construction sectors that use calcite as Home; Products Oil Regeneration CMM6RL Transformer Oil Regeneration Unit;Milling also produces a rough, grooved surface, which will increase the existing pavement surface area when compared to an ungrooved surface The surface area increase is dependent on the type, number, condition and spacing of cutting drum teeth but is typically in the range of 20 to 30 percent, which requires a corresponding increase in tack coat (20 to 30 percent more) when Existing Surface Preparation for Overlays Pavement Interactive