HOME→Pumice production line process flow pumice production line process flow pumice production line process flow

Pumice production line process flow pumice production line process flow pumice production line process flow

About Pumice: Modern Uses and Applications of Pumice

Pumice makes an aggressive filtration media, especially when compared to sand That’s because pumice media traps impurities on two levels: between particles and on the particle comprehensive production, transport, and deposition processes of drift pumice from terrestrial to marine environments Chapter 1 reviews previous studies on drift pumice and describe the Production, transport, and depositional processes of drift pumice Pumice production is produced to obtain the pumice briquette, which is used for heat and sound insulation in the construction industry Its raw material is pumice stone It is the raw material formed as a result of volcanismPumice Production Globmac2020年9月1日 In present study, the base on the diameters of the pumices are classified into three groups; d max ≤ 5 mm, d max ≤ 10 mm and d max ≤ 20 mm Samples are produced by Influence of pine resin on thermomechanical properties of

New production process for insulation blocks

2012年2月1日 This study introduces a new production method for production of the insulation blocks made of pumice aggregate, lightweight concrete and expanded polystyrene foam (EPS) Products produced via this method were 2020年9月15日 In this context, the current study is aimed to (i) evaluate pumice as holding matrix for impregnation of two different kinds of PCMs, capric acid (CA) and polyethylene Evaluation of pumice for development of lowcost and energy Domestic Production and Use: In 2021, 10 operations in five States produced pumice and pumicite Estimated production 1 was 580,000 tons with an estimated processed value of PUMICE AND PUMICITE USGS Publications WarehousePumice and pumicite were mined in California, Oregon, Idaho, New Mexico, and Kansas, in descending order of production The porous, lightweight properties of pumice are well suited 128 PUMICE AND PUMICITE USGS Publications Warehouse

.jpg)

Pumice and Pumicite USGS Publications Warehouse

In 2020, 10 operations in five States produced pumice and pumicite Estimated production 1 was 480,000 tons with an estimated processed value of about $13 million, free on board (fob) 2016年1月20日 Mass flows are formed when the material runs along a cement production line A production line is composed of three processing stages, and each stage is composed of several units (Fig 5) In each unit's material flow structure, the flow rate and flow direction are varied In the production process, material consumption needs to be investigated Analysis of material flow and consumption in cement production process Bottled water production: how bottled water is made – Discover the intricate process of bottled water production through our comprehensive diagrams, process flow charts, and detailed workflow explanationsOur guide provides Bottled Water Production Process Flow Chart2018年12月17日 There are disadvantages to using the production line manufacturing process The fact that the production line manufactures a single product or similar products limits its ability to manufacture anything else For Manufacturing Production Process Introduction

.jpg)

How to Make a Production Flow Chart for Manufacturing

2022年12月21日 Through this mapping process, manufacturers are able to build a more efficient ordering process for their production line The product flow chart is a visual representation of that process and can be easily shared Because of the nature of its simple design, it’s also easy to read and understand at a glanceIt is also known as mass production, continuous flow production, or assembly line production In flow production, the raw materials or components are continuously fed into the production process and transformed into finished goods without interruptions until the production run is completedFrom Batch to Flow: Different Approaches to Manufacturing Production Production Flow found in: Product development process flow ppt powerpoint presentation ideas cpb, Order Fulfilment Process Flow For Product Based Businesses, Materials and products flow for waste management, Product AndProduction Flow Slide TeamA series of production processes are carried out to prepare order for dispatch (see fig 4 that depicts production process operations) The production flow starts with the mould setup as the Logical flow diagram of the production process operations

What is Process Flow Diagram (PFD)? Purpose, Symbols, Examples

PFDs show the plant design basis indicating feedstock, product, and main stream flow rates and operating conditions A PFD documents a process for training, quality control, As per Fig3, it is clearly showing that there is a flow in the process line, stream number (1) Production usually takes place continuously in a closed process, where the main components are connected by a system of pipes The type of treatment involved and the design of the process depend on the end product The process described in this chapter is general milk pasteurizationDESIGNING A PROCESS LINE Dairy Processing HandbookDownload scientific diagram Flowchart of production process from publication: Materials flow improvement in a lean assembly line: A case study Purpose This paper seeks to analyse the internal Flowchart of production process Download Scientific Diagram2017年4月11日 I talked in detail before about possible layouts of the flow line The most well known ones are the I, U, L, and S lines Their advantages and disadvantages are discussed in my series of posts on Line Layout Strategies Pacing of Flow Lines 1 – Unstructured and Pulse Line

New production process for insulation blocks composed of EPS

22 Production process of insulation block The allin aggregate pumice used in the study was produced via open mining method It was sieved at the quarry site using sieves with 1–16 mm mesh size and then was transported to the factory (where the product was produced) for the production process Pumice2023年9月11日 The production process life cycle has four distinct stages: job shop, batch production connected line flow, assembly line, and continuous process flow This matrix can be applied to produce multiple products in Product Process Matrix: How It Works And How To 2015年8月1日 First, material flow routes for the cement manufacturing process are established, after which three mass balances are built during the three production stages using actual plant data received from Analysis of material flow and consumption in cement production process5 The production line adopts Siemens / Schneider / and other internationally renowned electrical appliance brands, with a high degree of full automation Juice Production Line PROCESS FLOW JUICE Production Line System Production Line Video: 01 Beverage Mixing SystemJuice Production Line Nancheng

Pumice: A FullFeatured Abrasive Printed Circuit Board Preparation

˜e precleaning process of a printed circuit board (PCB)—and in particular its copper components—is key to establishing optimum conditions for the application of ˚lms and solder masks ˜e quality demands pressures remain relentless Pumice scrubs are processmature, cost e˛ective and widely applicable 2021年1月1日 Also, Celik et al [96] and Xu et al [112] found that the employment of NP increases the flow ability of concrete, but increasing the fineness of NP, especially volcanic pumice lessens the flow Role of particle size of natural pozzolanic materials of volcanic 2008年2月14日 Commissioning considers every factor that determines how and when line equipment will begin functioning To manage the process, the owner should craft and follow a comprehensive commissioning plan A well developed, organized plan will enable a new manufacturing operation to come online sooner, reduce downtime and provide quicker returnsHow to launch a new manufacturing line Food Processing2 Dynamic Flow Lines Dynamic flow lines are designed to accommodate varying production speeds and conditions, allowing for a more flexible and responsive production process These lines use sensors, smart controls, and Machine to Machine (M2M) communication to adjust speeds dynamically based on realtime conditions Key Features:Types of Production Lines in Manufacturing Foodmach

.jpg)

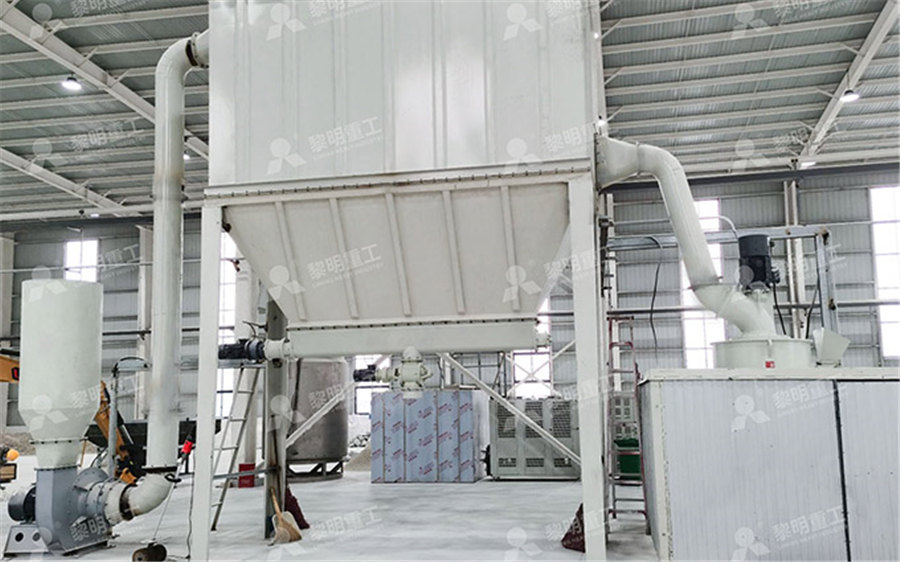

Pumice Production Globmac

Pumice production is produced to obtain the pumice briquette, which is used for heat and sound insulation in the construction industry Its raw material is pumice stone It is the raw material formed as a result of volcanism It has a crystalline, spongy and porous structure2022年8月11日 The technological process of the #feed production line mainly includes: impurity removal process, batching process, crushing process, mixing process, granulation process, and finished product Process flow chart of feed production line2023年7月1日 This work presents a study of synthesis and characterization of catalystsbased cerium and nickel supported on the pumice stone (Ce/Pumice and Ni/Pumice) to be used in the gasification process of an invasive species present in the Canary Islands, such as Pennisetum setaceum to obtain syngas Specifically, the effect of the metal impregnated on the pumice, Ce/Pumice and Ni/Pumice as heterogeneous catalysts for syngas This study introduces a new production method for production of the insulation blocks made of pumice aggregate, lightweight concrete and expanded polystyrene foam (EPS)Production process in insulation block production

What is a Process Flow Diagram? A Complete Guide Miro

Creating a process flow diagram is a structured approach to visualizing and understanding the steps and flow of a process Whether you're mapping a complex manufacturing operation or a simple business procedure, a clear and accurate PFD is invaluable Let's dive into the steps necessary to create an effective process flow diagram 1Example 4 Product Manufacturing Process Roadmap This type of flowchart encompasses the direction and progress envisioned by a company for a specific product or product line Unlike in the previous example, a process roadmap outlines the initiatives that the management established to sustain and improve the manufacturing process of a productManufacturing Process Flowchart Complete Guide Edraw SoftwareA flow shop process uses specialized resources and the work follows a fixed path Consequently, a flow shop is less flexible than a job shop Finer distinctions can be made in the process structure as follows: Project Example: building construction; Job shop Example: print shop; Batch process Example: bakery; Assembly line Example Process Flow Structure NetMBAORIGINAL ARTICLE New production process for insulation blocks composed of EPS and lightweight concrete containing pumice aggregate Ali Sariisik • Gencay Sariisik Received: 25 January 2011 New production process for insulation blocks composed of EPS

Flow chart of insulation block production method

Download scientific diagram Flow chart of insulation block production method from publication: New production process for insulation blocks composed of EPS and lightweight concrete containing 2012年9月1日 A singleline lightweight masonry block with 200 mm × 400 mm × 200 mm dimension for the production process Pumice Flow chart of the production of classic bimsblockNew production process for insulation blocks composed of EPS Lack of Faith: Some people just don’t believe flow is possible, so don’t even try; Resistance to Change: Some people think flow might work, but like things to stay the same Once companies identify and prioritize all of the barriers to flow, they are ready to implement the changes designed to improve the overall process of flow Improving FlowUnderstanding the Principle of Flow in Lean Manufacturing2016年1月20日 Mass flows are formed when the material runs along a cement production line A production line is composed of three processing stages, and each stage is composed of several units (Fig 5) In each unit's material flow structure, the flow rate and flow direction are varied In the production process, material consumption needs to be investigated Analysis of material flow and consumption in cement production process

Bottled Water Production Process Flow Chart

Bottled water production: how bottled water is made – Discover the intricate process of bottled water production through our comprehensive diagrams, process flow charts, and detailed workflow explanationsOur guide provides 2018年12月17日 There are disadvantages to using the production line manufacturing process The fact that the production line manufactures a single product or similar products limits its ability to manufacture anything else For Manufacturing Production Process Introduction2022年12月21日 Through this mapping process, manufacturers are able to build a more efficient ordering process for their production line The product flow chart is a visual representation of that process and can be easily shared Because of the nature of its simple design, it’s also easy to read and understand at a glanceHow to Make a Production Flow Chart for Manufacturing It is also known as mass production, continuous flow production, or assembly line production In flow production, the raw materials or components are continuously fed into the production process and transformed into finished goods without interruptions until the production run is completedFrom Batch to Flow: Different Approaches to Manufacturing Production

Production Flow Slide Team

Production Flow found in: Product development process flow ppt powerpoint presentation ideas cpb, Order Fulfilment Process Flow For Product Based Businesses, Materials and products flow for waste management, Product AndA series of production processes are carried out to prepare order for dispatch (see fig 4 that depicts production process operations) The production flow starts with the mould setup as the Logical flow diagram of the production process operationsPFDs show the plant design basis indicating feedstock, product, and main stream flow rates and operating conditions A PFD documents a process for training, quality control, As per Fig3, it is clearly showing that there is a flow in the process line, stream number (1) What is Process Flow Diagram (PFD)? Purpose, Symbols, Examples Production usually takes place continuously in a closed process, where the main components are connected by a system of pipes The type of treatment involved and the design of the process depend on the end product The process described in this chapter is general milk pasteurizationDESIGNING A PROCESS LINE Dairy Processing Handbook

.jpg)

Flowchart of production process Download Scientific Diagram

Download scientific diagram Flowchart of production process from publication: Materials flow improvement in a lean assembly line: A case study Purpose This paper seeks to analyse the internal