New energysaving grinding equipment

Technological Innovation: Achieving Energy Savings and Medium

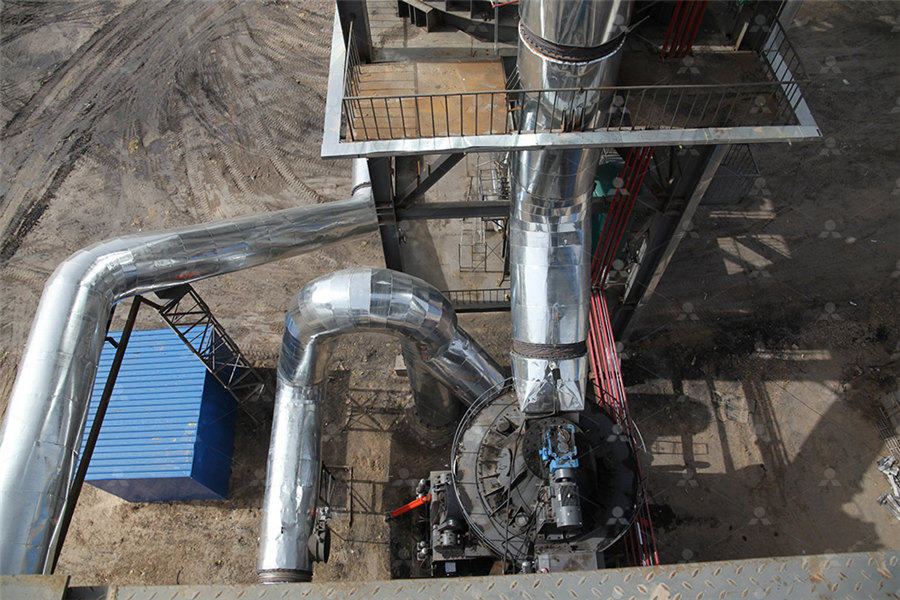

A large mining company successfully achieved significant energy savings by introducing highefficiency crushing equipment and vertical mills, along with comprehensive optimization of 2023年11月1日 The development and application of new fine and ultrafine grinding equipment are particularly important As a new type of grinding equipment, the stirring mill has significant Energy conservation and consumption reduction in grinding For the current problems in the widespread ball mill grinding,a new type of high efficiency energy saving grinding equipment is designedThe grinding equipment set filtering mechanism,a Design of New Energy Efficient Grinding EquipmentKey features of energysaving and environmental protection grinding machines: 1 High efficiency: Energysaving grinding machines are designed to optimize the grinding process, minimizing The arrival of energysaving and environmental protection

Application of sustainable techniques in grinding process for

2024年3月11日 To address challenges in machining advanced materials, hybrid cooling processes that combine various cleaner manufacture techniques can be developed and 2022年7月6日 According to the developer, around 40 percent of energy and material required to produce the worm gears can be saved via the JUMAT Other advantages of the new production process include long tool life and reduced Time and Energy Saved in New Shaft Grinding Concept2008年4月21日 The introduction of a new sensing technology for monitoring acoustic emissions in grinding operations is expected to lead to significant reductions in power consumption From automotive parts to bearings Minimising power consumption in finish grinding2010年10月1日 FCB has just developed a new mill, HOROMILL®, for grinding cement, raw meal and minerals This new grinding process is designed for finish grinding and also for pregrindingApplications of Efficient EnergySaving Cement Grinding

EMAG at the GrindingHub 2024 – Grinding technology

2024年4月25日 Grinding is a key technology for the resourcesaving and lowemission mobility of the future Examples of this include electric drives, which place the highest demands on the precision and surface properties of 2016年5月9日 With Norton Quantum3, SaintGobain Abrasives has reinvented grinding from the ground up, unlocking new layers of efficiency, quality, and savings across the metal fabrication Reinventing the (Grinding) Wheel New Equipment 2018年3月1日 New technology and energysaving equipment for production of composite materials The clinker factor and grinding energy were found to be simultaneously optimized by up to 32% and 5%, (PDF) New technology and energysaving equipment Energy Saving Mining Processing Equipment Grinding Ball Mill HZE manufacture standard wet ball mills with high efficiency, low energy consumption, stability and reliability for grinding minerals of precious metals, base metals and nonmetal It can also be specially designed and customized according to the special requirements of the customersEnergy Saving Mining Processing Equipment Grinding Ball Mill

.jpg)

Microgrinding equipment, energy saving, greening

2018年10月14日 Energysaving emission reduction and green environmental protection have become hot topics in various industries Nowadays, various enterprises have launched new energysaving and environmentallyfriendly products, which means that all industries are developing towards energy conservation, emission reduction and environmental protection2020年11月17日 EnergySaving Small Ball Mill (MQYG, MQGg), Find Details and Price about Grinding Ball Mill Mining Equipment from EnergySaving Small cooperation of professionals in these two kinds majors lead to development and improvement of 80% types of mining equipment and stress on the new technique research and application of the EnergySaving Small Ball Mill (MQYG, MQGg) Grinding Ball Mill Zhaodong DongLong Energy Saving New Technology Co, was established in 1999, With years of industry knowledge and technology accumulation, the company has successfully developed energysaving automatic hydraulic flaking mills, highefficiency crushers, cottonseed peeling machines and other series of productsZhaodong Donglong New Energy Saving Technology Co LtdMetallurgy field Pengfei Group is the global export base of industrial kiln and energysaving grinding equipment,the industry "One Belt and One Road" strategy and the "International Capacity Cooperation" model enterpriseWith equipment general contracting capabilities such as equipment RD,equipment installation,engineering commissioning,and technical services,We ProductsJiangsu Pengfei Group Co,Ltd cement machinery

Optimizing Grinding to Cut Down Cost of Crankshaft Finishing

2014年10月21日 In addition, more rigorous emission limits and safety requirements in various countries drive up production costs, causing planners to seek new cost savings For forged crankshafts, which are essential to engine performance, laborintensive “micrometerrange” grinding is necessary, but requiredBlanket grinding allows for full automation of tools of similar geometries, by consolidating all toolgrinding processes into one single machine A batch of complete finished tools can be produced without interruption directly from lengths of ground bar stock with no operator interventionWhat Is Automated Blanket Grinding and How Can It Benefit You?2022年9月13日 The optimal selection of machine equipment can reduce the energy consumption and processing time of the parts processing process in enterprises The energy consumption and time of using different equipment to process the same product vary greatly Traditional equipment selection is only through qualitative analysis comparing the process EnergySaving and Efficient Equipment Selection for Machining Using highefficiency separators in grinding processes helps reduce overgrinding, optimizing particle size distribution and improving overall grinding efficiency This reduces energy consumption in both raw and finished cement production 10 Most Effective EnergySaving Techniques in the

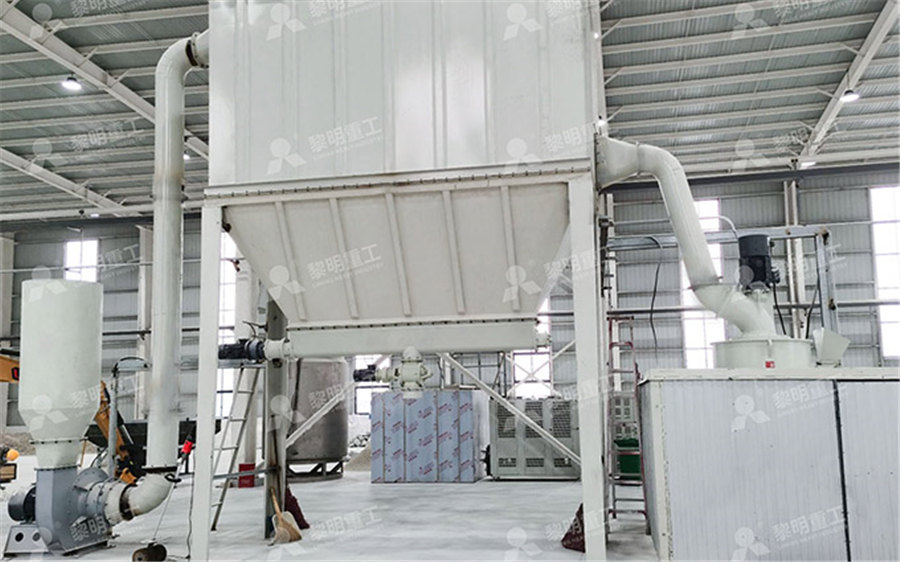

Energy Saving Vertical UltraFine Grinding Equipment

Energy Saving Vertical UltraFine Grinding Equipment, Home Product Directory Manufacturing Processing Machinery Mining Machinery Mining Mill Energy Saving Vertical UltraFine Grinding Equipment Min Order: 1 Set: Port: Shenzhen, China: Payment Terms: L/C, T/T: Contact Now Product Description Company Info2013年8月1日 A technological transformation was carried out for the aging and high energy consumption of the original powder grinding system equipment By comparing different programs, a pregrinding method A Research on EnergySaving Technological Transformation of Cement New EnergySaving Gold Wet Pan Mill Grinding Equipment, Find Details and Price about Milling Machine Grinding Machine from New EnergySaving Gold Wet Pan Mill Grinding Equipment Yantai Fulin Mining Machinery Co, LtdNew EnergySaving Gold Wet Pan Mill Grinding EquipmentAs a new type of grinding equipment, the stirring mill has significant advantages such as high energy efficiency, medium saving, simple installation, and easy operationEnergy conservation and consumption reduction in grinding

.jpg)

Grinding Ball,Qasim Grinding Media,Grinding Ball Production

2017 Further product development,with firstclass university in China roll out the energy saving grinding ball The innovative energysaving grinding ball significantly improved wear performance versus the quality levels of traditional cast grinding balls The Broken rate using on building materials industry is less than 02% for mining ball mill grinding is less than 06% solve the The new energysaving structure of motor builtin wet gold grinding machine, vacuum casting roller, large diameter grinding pot design, make the new rolled gold machine has stable structure, safe use, long service life, high efficiency and energy saving, high yield characteristics, widely used for grinding various ferrous metals, nonferrous metals, nonmetallic minerals, and dilute Grinding gold machine Yantai Jinpeng Mining equipment, ore 1999年10月21日 Aim of the project is the reduction in energy consumption by 27 % for the grinding of cement The reduction will be achieved by usage of special grinding equipment such as a division head diaphragm with controllable material ENERGY SAVING IN CEMENT GRINDING Project CORDISHome Video Channel What is Energy Saving Grinding Ball Mill Equipment Wholesale Ball Mill Machine Ball Mill US$3,0000016,00000 / Piece View Recommend for you; What is New What is New Tungsten Sandblasting Nozzles Sandblasting Boron What is Energy Saving Grinding Ball Mill Equipment Wholesale

Energy Saving Ball MillGrinding MachineMobile Crushing plant

Energy saving ball mill is the key equipment for grinding crushed materials It is mainly used in cement, silicate products, new building materials, refractory materials, fertilizer, ferrous and nonferrous metal ore beneficiation, glass ceramic, etc2021年11月15日 For more information on the technology of Energy saving grinding balls and to give a "new life" to the ball mill, click on the link and contact us Like CelebrateNew Grinding media? New Life?2023年11月1日 As a new type of grinding equipment, the stirring mill has significant advantages such as high energy efficiency, medium saving, simple installation, especially the fine grinding of ore and energy saving and consumption reduction to meet the needs of the future mining and utilization development [17]Energy conservation and consumption reduction in grinding 2021年2月25日 These research and development projects such as "Roller Press Grinding New Process and Equipment" and " Roller Press Grinding Technology and Equipment For Energy Conservation" has provided better solutions for grinding powder in the mining, building materials industry, and they were rewarded silver medals respectively at the state level and at HFCG SERIES ROLLER PRESSHefei Cement Research Design

.jpg)

Vibration Ball Mill New Design Double Tubes Vibratory Ball Mill

Vibration ball mill is a new type of highefficiency and energysaving grinding equipment It has obvious advantages over traditional rotary ball mill in grinding fine and ultrafine powder materials The grinding efficiency of vibrating ball mill can be increased by 25 times, and energy consumption can be reduced by 20% – 30%2017年12月18日 Amazon: ALDKitchen Swing Type Grain Mill Grinder Stainless Steel, Commercial Grade Grind Grain, Roots, Flour, Kernel, Egelation, Olibanum, Milk Vetch ALDKitchen Swing Type Grain Mill Grinder Stainless Steel, This paper explains some deficiencies of grinding equipment in our country at present,introduces the angular screw lining plate and trench lining plate from mill lining plate ,also their application effects; and introduces the static and dynamic pressure bearing and the center drive energysaving mode from the transmission part, on the basis of which take a brief introduction of a The Research Progress of High Efficiency EnergySaving Grinding EquipmentWet Grid Mill Copper Oxide Grinding Ball Mill 22X36m EnergySaving Wet grid mill Copper oxide grinding ball mill 22x36m energysaving ball mill Ball mill introduction The ball mill is a key equipment for grinding materials, widely used in powdermaking production line such as cement, silicate sand, newtype building material, refractory material, fertilizer, ore dressing of ferrous energy saving grinding ball mill manufacturer

.jpg)

7Ways to achieve energy saving in Cement grinding station

2016年6月3日 At the same time, we should vigorously promote and encourage enterprises to use new energysaving grinding equipment For example, to new vertical mill, grinding, and other energysaving ladder 2024年10月15日 Under fine grinding conditions, they reduce overgrinding and equipment wear, lower noise levels, and decrease power consumption (6) Nontoxic and Harmless: Complies with the EU ROHS composition Energy Saving and Consumption Reduction in Ball Mills LinkedInEnergy saving ball mill is new designed equipment for mineral materials secondary grinding after crushing Widely applied in the industries of cement, silicate products, new building materials, refractory materials, fertilizer, etcEnergysaving Overflow Type Ball Mill/Grinding Equipment in2016年5月9日 With Norton Quantum3, SaintGobain Abrasives has reinvented grinding from the ground up, unlocking new layers of efficiency, quality, and savings across the metal fabrication Reinventing the (Grinding) Wheel New Equipment

.jpg)

(PDF) New technology and energysaving equipment

2018年3月1日 New technology and energysaving equipment for production of composite materials The clinker factor and grinding energy were found to be simultaneously optimized by up to 32% and 5%, Energy Saving Mining Processing Equipment Grinding Ball Mill HZE manufacture standard wet ball mills with high efficiency, low energy consumption, stability and reliability for grinding minerals of precious metals, base metals and nonmetal It can also be specially designed and customized according to the special requirements of the customersEnergy Saving Mining Processing Equipment Grinding Ball Mill2018年10月14日 Energysaving emission reduction and green environmental protection have become hot topics in various industries Nowadays, various enterprises have launched new energysaving and environmentallyfriendly products, which means that all industries are developing towards energy conservation, emission reduction and environmental protectionMicrogrinding equipment, energy saving, greening2020年11月17日 EnergySaving Small Ball Mill (MQYG, MQGg), Find Details and Price about Grinding Ball Mill Mining Equipment from EnergySaving Small cooperation of professionals in these two kinds majors lead to development and improvement of 80% types of mining equipment and stress on the new technique research and application of the EnergySaving Small Ball Mill (MQYG, MQGg) Grinding Ball Mill

Zhaodong Donglong New Energy Saving Technology Co Ltd

Zhaodong DongLong Energy Saving New Technology Co, was established in 1999, With years of industry knowledge and technology accumulation, the company has successfully developed energysaving automatic hydraulic flaking mills, highefficiency crushers, cottonseed peeling machines and other series of productsMetallurgy field Pengfei Group is the global export base of industrial kiln and energysaving grinding equipment,the industry "One Belt and One Road" strategy and the "International Capacity Cooperation" model enterpriseWith equipment general contracting capabilities such as equipment RD,equipment installation,engineering commissioning,and technical services,We ProductsJiangsu Pengfei Group Co,Ltd cement machinery2014年10月21日 In addition, more rigorous emission limits and safety requirements in various countries drive up production costs, causing planners to seek new cost savings For forged crankshafts, which are essential to engine performance, laborintensive “micrometerrange” grinding is necessary, but requiredOptimizing Grinding to Cut Down Cost of Crankshaft FinishingBlanket grinding allows for full automation of tools of similar geometries, by consolidating all toolgrinding processes into one single machine A batch of complete finished tools can be produced without interruption directly from lengths of ground bar stock with no operator interventionWhat Is Automated Blanket Grinding and How Can It Benefit You?

.jpg)

EnergySaving and Efficient Equipment Selection for Machining

2022年9月13日 The optimal selection of machine equipment can reduce the energy consumption and processing time of the parts processing process in enterprises The energy consumption and time of using different equipment to process the same product vary greatly Traditional equipment selection is only through qualitative analysis comparing the process