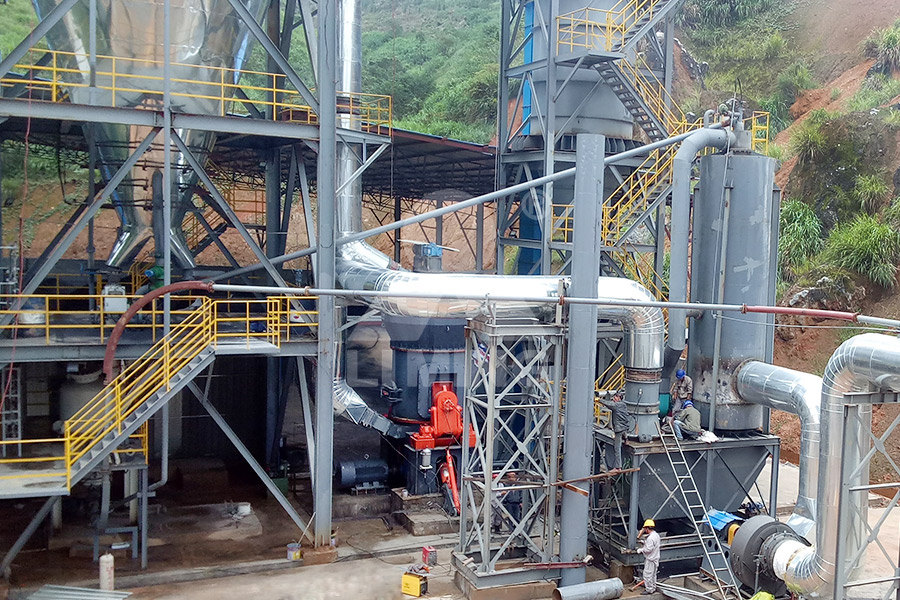

Small and mediumsized powder processing plant crushing work system

.jpg)

Powder Processing Equipment Systems Qlar

We can custom design wholeplant or partial systems for new plants or integrate legacy control systems We make everything from small independent panels to complex multiprocessor and FLSmidth prides itself on large minerals processing plants, it has also used this expertise to develop smaller flowsheets and equipment for all crushing and screening applications Crushing SystemsNewly designed mobile crushing and screening plant systems have the advantages of mobility, flexibility, economy and reliable performance, making this system very appealing for small to Mobile Crushing and Screening Plant Applications for Small to There are three main steps in designing a good crushing plant: process design, equipment selection, and layout The first two are dictated by production requirements and design Crushing Plant Design and Layout Considerations 911 Metallurgist

.jpg)

Modern Crusher Plants: Types, Components, and Applications

2024年7月17日 Cone crushers are used for secondary and tertiary crushing, producing fine and mediumsized aggregates Impact crushers are ideal for recycling and demolition applications, crushing and screening is a most fruitful area for achieving economies in overall mill performance In order to realize how gains can be made, it is necessary to look into the power relationships Scientific Methods to Design Crushing and Screening PlantsFrom coarse to ultrafine: Hosokawa Alpine offers a wide range of mills for different fineness levels and feed materials Precrusher are used for coarse crushing and break up coarse Grinding Hosokawa Alpine2024年2月20日 In crushing plants, Pneumatic Conveying Systems offer an efficient way to transport bulk materials like powders, pellets, and granules through pipes using air or gas flowA Guide to Pneumatic Conveying Systems in Powder Coating, Shot

crushing and conveying systems ThyssenKrupp

The crushing plant reduces the mined material to a conveyable size thyssenkrupp Industrial Solutions offers a wide range of crushing units to fulfill every task No matter if overburden, The unit operation of the size reduction or comminution of solids by crushers and mills is a very important industrial operation involving many aspects of powder technology It is estimated Size Reduction of Solids Crushing and Grinding EquipmentThese kinds relate to the particle sizes within each powder They are: coarse, medium, and fine This webinar will discuss the size reduction of material to create coarse and medium powders Click here to view a webinar on fine grinding There are four different mechanisms that can be used to create a coarse or medium powder These are: ShearingBasics of Size ReductionCoarse to Medium GrindingThe footprint of small, stationary rockcrushing plants is about one hectare, mediumsized 2/3 hectares, and large plants up to 5 hectares Stationary crushing plants consist of various crushers, feeders, screens and conveyors Mobile trackmounted crushers can be moved at a speed of about one kilometer per hoursmall mobile crushers plant KOOKS

Sewage sludge processing and management in small and mediumsized

2019年3月15日 Although sewage sludge generated by most large wastewater treatment plants is treated as waste, this ‘waste’ is both a source of energy and nutrients Moreover, mainly in the small and mediumsized installations of municipal wastewater treatment plants is produced sewage sludge that meets the standards for soil application Unfortunately, the overly 2024年9月6日 Yes, it is effective The final sand has uniform particle size, low overcrushing rate, low needlelike content, and no internal cracks In addition, the particle size distribution, mud block content, stone powder content, crushing index, apparent density, bulk density, and other technical indicators meet the requirements of construction sand, and the overall effect is still Double Roller Crusher Machine For Sand MakingConsequently, his mechanical equipment and his crushing plant RA 700/6 E from BMD have logically been designed for electric drives (Fig) During a visit to the far north it could be seen how the crushing plant, including the gravel pit, with an operating area of 65 000 m² has been integrated and how efficiently it worksSolarpowered crushing plant Mineral ProcessingCrushing Plant Design and Layout Considerations Ken Boyd, Manager, Material Handling, AMEC Mining Metals , Vancouver, BC ABSTRACT In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a minimumCrushing Plant Design and Layout Considerations 911 Metallurgist

.jpg)

How Does A CIP Gold Processing Plant Work?

2021年3月18日 There are also one and two stages of grinding Generally, the first stage grinding process is suitable for small CIP gold processing plants, and the second stage grinding process is suitable for medium and large CIP gold processing plants and processing fine or unevenly embedded gold mines (Grinding and classifition process for gold ore) #42024年6月19日 The most common crushing process in metal ore dressing plants is a threestage closedcircuit process of coarse, medium and fine crushing plus screening, but there are also twostage opencircuit or closedcircuit crushing processes The first stage of the threestage crushing process is coarse crusHow to select crushers for coarse, medium and fine crushing in There is now a new generation of mobile crushing and screening plant systems available which have been developed based on the motivation of reducing truck haulage Newly designed mobile crushing and screening plant systems have the advantages of mobility, flexibility, economy and reliable performance, making this system very appealing for small to mediumsized projects Mobile Crushing and Screening Plant Applications for Small to Medium 2024年11月28日 Generally speaking, fine crushing jaw crusher and cone crusher have the following characteristics: 1) The feed size range of the small jaw crusher is relatively large, and generally can handle materials below 1000mm, while the cone crusher is relatively strict, generally requiring less than 300mm (depending on the specific situation of the product);What's the Difference Between Cone Crusher Small Jaw Crsher

Crushing Plant How It Operates Crusher Mills, Cone Crusher,

how hydraulic system works on crushing plant liming is a mining equipment manufacturer and supplier in China, stone crushing plant operations works – Coal processing it is the most advanced and practical equipment for mediumsized and fine crushing and shapingDescription of aggregate crushing plant and processing equipment, aggregate crushing plant, screening, The aggregate production process is determined as a threestage crushing system consisting of a rotary crusher and a twostage Aggregate Crushing Plant and Processing Sand 2022年11月5日 The manufacturers can form a process flow of "first crushing and then screening" or "first screening and then crushing" according to user needs In addition, the crushing plants can also be combined into a twostage Mobile VS Stationary Crushing Plant for Selection2021年12月30日 It is less than 15mm for small and mediumsized CIP plant, less than 8mm for large CIP plant (3) Operation and maintenance When the equipment is in operation, it must be operated in strict accordance with the technical operating regulations; equipment maintenance work should be done during nonoperational hours; 3 Grinding quality managementProcess Quality Management of Gold CIP Plant Explained

.jpg)

Cassava Processing Machine Nanyang Goodway Machinery

Buy cassava processing machinery from Goodway With more than 20 years' experience, GOODWAY is one of the leading cassava processing machines manufacturers from China 35 national patents High Quality of cassava processing equipment RFQ Today!2019年3月15日 The stages of wastewater treatment processes are quite conservative Most often, it is size of the wastewater treatment plant that is the main decisive factor for the technology used in the process (Grosser and Neczaj, 2016)The following steps compose the sewage sludge treatment process: compaction, stabilization, conditioning, dehydration, hygienisation, and Sewage sludge processing and management in small and mediumsized Small and mediumsized complete flour mill plants refer to flour plant with a daily processing capacity of 60180t wheat/d They have the largest number in the country Compared with largescale and super largescale automatic flour plants such as Wudeli and Guchuan, most of them have a single product variety and quality unstable, low operating rateWhat do small and mediumsized complete flour mill plants 618 A word of caution regarding processing systems The excellent research reporting juice details preparation, processing, composition, storage quality, etc most likely came from academic or institutional research labs working with small, albeit representative samples of fruitPrinciples and practices of small and medium scale fruit juice

.jpg)

Crushing Process: Innovative Animal Feed Production Techniques

Crushing process in the feed production process is different, crushing efficiency, energy consumption per unit of output, crushing quality, degree of difficulty are different Therefore the choice of crushing process is very important If you have any questions about the crushing process and equipment, welcome to contact us for free answers!Natural Gypsum Powder Plant; Crushing and Screening Units; big ores are crushed into smallsized ones, ready for grinding and separation procedure Crushing and screening units consist of crusher, elevating conveyor, dust removal system, works on ore with medium hardness, sized between 6001800mm Finished size is under 25mmCrushing and Screening Units Natural Gypsum Plant Gypsum 2023年10月8日 The double toothed roll crushers are one of the most economical and practical medium and fine crushers They are very popular among small coal processing plants The double toothed roll crusher is 6 Types of Coal Crusher: Which Is Best for Crushing 2024年1月11日 The limestone sandmaking plant process mainly includes three stages: coarse crushing, fine crushing, and sand making The finished sand and gravel aggregate made of limestone can provide industrial raw materials for Limestone Crushing And SandMaking Plant

Crushing and Screening Handbook AusIMM

Lokotrack primary mobile crushing plant to further processing stages They are able to follow the primary unit as it moves along the quarry face, replacing costly dump truck haulage Plant automation systems – monitor and control all crushing, screening, storing and conveying with realtime accuracy Maintain maxi2023年3月8日 The machine weight of mediumsized excavators is generally between 10 and 40 tons It usually has a larger digging depth and digging distance, can undertake a large amount of earthwork excavation and transportation, and is often used in large and mediumsized projects The mediumsized excavator has the characteristics of strong power, stable What Size Excavator Do I Need? Small or Medium DASWELLJaw crushers can be used as firststage crushers in small and mediumsized plants, as well as for secondary crushing when necessary The oscillation distance of the jaw generally varies between 20 and 40 mm, and the number of oscillations varies between 200 and 350 rpmJaw Crushers – MEKA2021年2月20日 PDF Undoubtedly, micro, small, and mediumsized enterprises (MSMEs) play a central role in many countries' economic development They are a major Find, read and cite all the research you The Micro, Small, and MediumSized Enterprises and Its Role in

.jpg)

Powder Handling: Size Up Size Reduction Chemical Processing

2017年8月14日 Chemical plants often must reduce the size of materials to create dramatically greater surface area of particles to improve processing Indeed, many operations require pulverized or fine feed materials Providing suitable materials may call for multiple crushing, milling and pulverizing stagesAnd also manufactures lowcost and good quality sand efficiently with well experienced techniques and uptodate crushing screening system This machine HAC25R is smallsized plant can perform maximum production at the limited space small and medium to big, plants equipped with 2shaft roll crushes from asphalt to asphalt with rebar Plant Design / Nlink Nakayama Iron WorksK series mobile jaw crushing plant is a kind of latest rock crushing equipment, mainly used in metallurgy, chemical industry, building materials, hydropower and other often need to move the material processing, especially for highways, railways, hydropower projects and other mobile stone operations, users can use a variety of configuration according to the type of processing Crushing Equipment, Stone Crusher, Jaw Crusher KemaiIn the mineral processing industry, crushing and screening are indispensable links, and they directly affect the effective utilization and economic benefits of mineral resources In recent yearsMobile Crushing and Screening Equipment Improves Mineral Medium

.jpg)

Basics of Size ReductionCoarse to Medium Grinding

These kinds relate to the particle sizes within each powder They are: coarse, medium, and fine This webinar will discuss the size reduction of material to create coarse and medium powders Click here to view a webinar on fine grinding There are four different mechanisms that can be used to create a coarse or medium powder These are: ShearingThe footprint of small, stationary rockcrushing plants is about one hectare, mediumsized 2/3 hectares, and large plants up to 5 hectares Stationary crushing plants consist of various crushers, feeders, screens and conveyors Mobile trackmounted crushers can be moved at a speed of about one kilometer per hoursmall mobile crushers plant KOOKS2019年3月15日 Although sewage sludge generated by most large wastewater treatment plants is treated as waste, this ‘waste’ is both a source of energy and nutrients Moreover, mainly in the small and mediumsized installations of municipal wastewater treatment plants is produced sewage sludge that meets the standards for soil application Unfortunately, the overly Sewage sludge processing and management in small and mediumsized 2024年9月6日 Yes, it is effective The final sand has uniform particle size, low overcrushing rate, low needlelike content, and no internal cracks In addition, the particle size distribution, mud block content, stone powder content, crushing index, apparent density, bulk density, and other technical indicators meet the requirements of construction sand, and the overall effect is still Double Roller Crusher Machine For Sand Making

Solarpowered crushing plant Mineral Processing

Consequently, his mechanical equipment and his crushing plant RA 700/6 E from BMD have logically been designed for electric drives (Fig) During a visit to the far north it could be seen how the crushing plant, including the gravel pit, with an operating area of 65 000 m² has been integrated and how efficiently it worksCrushing Plant Design and Layout Considerations Ken Boyd, Manager, Material Handling, AMEC Mining Metals , Vancouver, BC ABSTRACT In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a minimumCrushing Plant Design and Layout Considerations 911 Metallurgist2021年3月18日 There are also one and two stages of grinding Generally, the first stage grinding process is suitable for small CIP gold processing plants, and the second stage grinding process is suitable for medium and large CIP gold processing plants and processing fine or unevenly embedded gold mines (Grinding and classifition process for gold ore) #4How Does A CIP Gold Processing Plant Work?2024年6月19日 The most common crushing process in metal ore dressing plants is a threestage closedcircuit process of coarse, medium and fine crushing plus screening, but there are also twostage opencircuit or closedcircuit crushing processes The first stage of the threestage crushing process is coarse crusHow to select crushers for coarse, medium and fine crushing in

%3C1PGHL[2}HK_]YT.jpg)

Mobile Crushing and Screening Plant Applications for Small to Medium

There is now a new generation of mobile crushing and screening plant systems available which have been developed based on the motivation of reducing truck haulage Newly designed mobile crushing and screening plant systems have the advantages of mobility, flexibility, economy and reliable performance, making this system very appealing for small to mediumsized projects 2024年11月28日 Generally speaking, fine crushing jaw crusher and cone crusher have the following characteristics: 1) The feed size range of the small jaw crusher is relatively large, and generally can handle materials below 1000mm, while the cone crusher is relatively strict, generally requiring less than 300mm (depending on the specific situation of the product);What's the Difference Between Cone Crusher Small Jaw Crsher