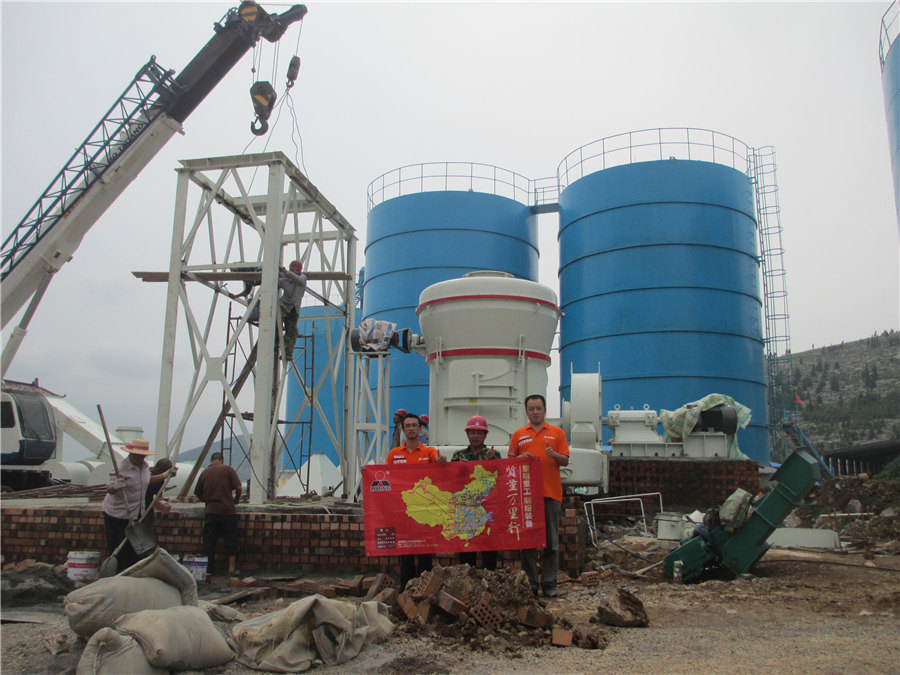

Slag silicate cement Raymond mill

.jpg)

Product Particulars Vipeak Group

Vipeak Group has 20yearexperience of Raymond roller mill manufacturing and development Raymond mill can process barite, calcite, potash feldspar, talc, marble, limestone, ceramics, • The modular system of the cement and granulated blast furnace slag mills is supplemented by the new S roller module • The S roller module consists of the roller, rocker arm, hydraulic 2 µm 5 µm LoescheFind out all of the information about the ShangHai DingBo Heavy Industry Machinery Co,LTD product: Raymond mill YGM series Contact a supplier or the parent company directly to get a Raymond mill YGM series DirectIndustry2019年10月15日 Raymond mill can be used in cement plant and lime calcination plant AGICO CEMENT supplies Raymond mill with customization service and factory price, feel FREE to ask!Raymond Mill, Raymond Mill For Sale For Cement and Lime Plant

.jpg)

Ground granulated iron silicate slag as supplementary

2023年12月1日 Utilizing oxidic byproducts from the metallurgical industry as supplementary cementitious materials (SCMs) can improve resource efficiency and reduce emissions from 2022年1月1日 This paper reviews the potential use of silicomanganese slag (SiMnS) as binder and aggregate in Portland cement and geopolymer concrete SiMnS is a byproduct of alloy A review on characteristics of silicomanganese slag and its 2013年4月6日 SiMn slag was altered by mechanical activation using eccentric vibratory and attrition mill The reaction kinetics during alkali activation of SiMn slag and structural (PDF) Development of alkali activated cement from mechanically 2024年10月29日 Slag silicate cement is produced by mixing granulated blast furnace slag with silicate cement clinker and adding 35% gypsum, followed by fine grinding This type of Slag Powder Grinding Machine Main Machine Selection Scheme

Influence of Carbonation on the Properties of Steel Slagndash

2023年10月18日 Magnesium silicate hydrate (MSH) cement has the advantages of low energy consumption, minimal environmental pollution, carbon negativity, and reduced alkalinity, but Overview Our GGBS ball mill is a key grinding machine mainly used to process materials by crushing process, and it is widely used in various manufacture industries, like cement, silicate, new building material, refractory material, fertilizer, Slag MillWhile reducing the calcium hydroxide content, a portion of hydrated calcium silicate is generated, which improves the density and impermeability of the hardened slurry; it reacts with the cement hydration product calcium hydroxide What is the role of adding glass powder during 2024年10月29日 Slag silicate cement is produced by mixing granulated blast furnace slag with silicate cement clinker and adding 35% gypsum, followed by fine grinding This type of cement is particularly suitable for applications in marine engineering, harbor construction, and Slag Powder Grinding Machine Main Machine Selection Scheme

Steel Slag Loesche

This dry process developed by Loesche for recovering metals from steel slag combines all the advantages of conventional processes: Efficient and costeffective metal recovery in the coarse range Virtually 100% metal recovery down to the finest fractions range by means of optimised dry grinding, classification and sorting technologyAdvantages of cement ball mill Less investment: cement ball mill with advantages of a perfect motor system, low energy consumption and power consumption, and ultralow operating cost, which can save a lot of cost input; Good working environment: reasonable sealing, less dust, low noise, good production environment; Costeffective: the price of the cement ball mill is Cement Ball Mill Ball Mill For Sale Cement Mill 15100t/hAGICO CEMENT supplies Raymond mill with customization service and factory price, feel FREE to ask! Skip to content +86 s about blog contact EN ES RU Menu Menu Slag Cement Manufacturing Process rotary kiln for sale Vertical Lime Kiln Rotary Kiln Lime Rotary Kiln Shaft Kiln Activated Carbon Raymond Mill, Raymond Mill For Sale For Cement and Lime PlantRaymond mill is to grind nonflammable and nonexplosive materials in the fields of building materials, mining, metallurgies and chemical industry with hardness less than 93 in Moh’s scale and humidity less than 6 percentExamples of the materials are: quartz, feldspar, barite, fluorite, dolomite, garnet, bauxite, zircon, marble, calcite, iron ore, rock phosphate, coal, slag and so Raymond MillGrinding Millgrinding mill/ultrafine mill/ball

Cement Mill Cement Ball Mill Vertical Cement Mill Factory

Wide product range: For meeting various requirements from different clients, our cement mill range from cement ball mill, vertical cement mill, Raymond mill, coal mill in cement plant, etc Strong production ability : AGICO CEMENT has a large production capacity and rich experience to produce any cement equipment required in cement plant2 What is raw material substitution? Raw material substitution technology refers to the use of carbide slag, fly ash, steel slag, calcium silicate slag, etc to replace limestone as raw materials for cement production, thereby reducing CO2 emissions during the calcination of raw materialsIndustrial solid waste replaces cement raw materials to promote • ACI 233, “Slag Cement in Concrete and Mortar” Classifications According to ASTM C989, GGBFS is classified into three grades according to its performance in the “slag activity test” The three grades are: Grade 80, Grade 100 and Grade 120 Slag activity is determined by the following formula: Slag activity index, % (SP / P) 100 Where:Ground Granulated BlastFurnace Slag: Its Chemistry and Use 2021年12月29日 A Raymond mill is a grinding mill used to grind materials into excellent powder It is commonly used to produce cement, silicate products, new building materials, refractory materials, fertilizers, black and nonferrous metal dressings, glass ceramics, etc Such as limestone, gypsum, quartz sand, and so onRaymond Mill : The Ultimate FAQ Guide Dry Mortar Plant

.jpg)

Portland cement manufacture

STEP4: Preheating and precalcining of Portland cement When the airflow carries the raw meal into the cyclone, it is forced to make a rotating flow in the annular space between the cyclone cylinder and the inner cylinder (exhaust pipe), and Raymond mill is to grind nonflammable and nonexplosive materials in the fields of building materials, mining, metallurgies and chemical industry with hardness less than 93 in Moh’s scale and humidity less than 6 percentExamples of the Raymond Millgrinding mill/ultrafine mill/ball What is Wet and Dry Material Grind Zirconium Silicate Mill Machine Yellow Stone Raymond Mill for Steel Slag Powder, Raymond manufacturers suppliers on Video Channel of MadeinChinaWhat is Wet and Dry Material Grind Zirconium Silicate Mill Write better code with AI Code review Manage code changessbm slag portland cement raymond millmd

Product Particulars Vipeak Group

Vipeak Group has 20yearexperience of Raymond roller mill manufacturing and development Raymond mill calcium carbonate, gangue, gypsum, grain slag, superfine slag powder, coal dust, bentonite, barite, marble, talc, refractory material Application: Cement, silicate product, new building materials, refractory material, chemical fertilizer The Raymond mill is widely used in cement, chemicals, mining, construction, and metallurgy industries Coal slag grinding plant in Thailand Output 300 kiloton/annually Finished particle size 100 mesh (0149 mm) Raw material Coal slag Material hardness Soft Highefficient Raymond Mill Fote Machinery1 天前 Raymond Mill Ultrafine Mill: This machine is used for grinding extremely fine materials, even down to 3000 mesh It’s often used for materials that are challenging to process with regular milling machines, such as graphite, coal, and othersWhat is Raymond Mill? How Does It Work? alwepoThe clinker cooler, also known as grate cooler or cement cooler, it is a necessary equipment of cement clinker productionThe clinker cooler is mainly used to cool and transport the cement clinker At the same time, cement cooler also provide hotair for rotary kiln and calciner, it is the main equipment of heat recovery for burning system The cooler will make a sufficient heat Clinker Cooler Cement Plant

.jpg)

News How to Process and Reuse Water Slag?

How to deal with water slag? According to the purpose of the water slag, the first step is to grind it into powder Water slag grinding is mainly including four steps: 1 Delivery the water slag to the dryer of the slag grinding mill for drying 2 The water Introduction to cement clinker Cement clinker is the semifinished products based on limestone and clay, iron raw materials as the main raw material, formulated into raw materials according to the appropriate ratio, burning until part or all of the molten, and obtained after cooling In ຝຸ່ນຊີມັງ Clinker ຂັດThe grate cooler is a quenching type cement cooler applied for the cement manufacturing plant According to the movement mode of the grate, the grate cooler can be divided into three types, rotary type, vibrating type, and push Grate cooler Cement Plant2023年10月18日 Slag–Magnesium Silicate Hydrate (MSH) Cement Tian Zeng 1 , Zhiqi Hu 1 , Chengran Huang 2 and Jun Chang 1, * 1 Faculty of Infrastructure Engineering, Dalian University of T echnology , Dalian (PDF) Influence of Carbonation on the Properties of

Raymond Milling Machine MadeinChina

Cement Flour Mill Raymond Milling Machine Price US$ 300013000 / Piece 1 Piece High Quality Raymond Mill Sodium Silicate Milling Machine US$ 5000080000 / Piece 1 Piece (MOQ) Shanghai Vostosun Industrial Co, Materials: Coal, Slag, Flyash, Cement, Calcium Carbonate 1 / 5 Favorites Super Fluorite powder Mandelic Acid Germanite powder Steel slag Pig iron beads/Counterweight iron ore Rubber particles Conductive mica powder Mullite powder Wood Chips Coal fly ash Slag Stone needle powder Lithopone powder Sericite powder Aluminium silicate fibre powder Magnesium sulfate heptahydrate Dolomite Terrazzo Composite rock flakes White Portland cement Shell Calcium Carbonate, Volcanic Mud, Vermiculite, Diatomite, Slag for GGBS Production: The blast furnace slag is used as the raw material for GGBS production, it is mainly composed of the following elements: SiO2, Al2O3, CaO, MgO, MnO, FeO, and S Some slags contain trace amounts of TiO2, V2O5, Na2O, BaO, P2O5, Cr2O3, and others In blast furnace slag, CaO, SiO2, and Al2O3 make up over 90% of the weight After being Slag Grinding PlantPortland cement is also called silicate cement such as Portland pozzolan cement, Portland fly ash cement, Portland slag cement, etc Lime (CaO) 60 to 67%: Silica (SiO2) 17 to 25%: Alumina (Al2O3) 3 to 8%: Iron The frequently used raw mills include cement ball mills, cement vertical mills, Raymond mills, etc The airswept coal mill is Portland Cement Manufacturing – Ordinary Portland Cement

.jpg)

10+ Types Of Special Cement Use Of Cement, Cement Plant, Cement

2019年12月30日 Cement raw material production: raw materials of cement should be crushed by cement crusher such as jaw crusher, cone crusher, impact crusher or mobile crushing plant into certain sizes and preblending, then cement mill will grind them into the raw material of cement, next, stacker and reclaimer will homogenize raw meal for preparation of cement 2024年3月28日 Steel slag contains dicalcium silicate and tricalcium silicate, and, as silicate cement clinker has a similar mineral and WG steel slags into powder with a ball mill The powder of four kinds of steel slag is used to conduct the XRD and TG tests The crystal structure of the sample was characterized by Rigak SmartLab 9KW Xray Research on the Properties of Steel Slag with Different MDPI2001 by slag cement manufacturers and the Slag Cement Association, the American Concrete Institute officially reviewed and changed the terminology from GGBFS to slag cement (ACI Committee 233, 2004) The term slag cement will be used throughout this paper when referring to finelyground granulated blastfurnace slagportland blast furnace slag cement KOOKSOverview Our GGBS ball mill is a key grinding machine mainly used to process materials by crushing process, and it is widely used in various manufacture industries, like cement, silicate, new building material, refractory material, fertilizer, Slag Mill

What is the role of adding glass powder during

While reducing the calcium hydroxide content, a portion of hydrated calcium silicate is generated, which improves the density and impermeability of the hardened slurry; it reacts with the cement hydration product calcium hydroxide 2024年10月29日 Slag silicate cement is produced by mixing granulated blast furnace slag with silicate cement clinker and adding 35% gypsum, followed by fine grinding This type of cement is particularly suitable for applications in marine engineering, harbor construction, and Slag Powder Grinding Machine Main Machine Selection SchemeThis dry process developed by Loesche for recovering metals from steel slag combines all the advantages of conventional processes: Efficient and costeffective metal recovery in the coarse range Virtually 100% metal recovery down to the finest fractions range by means of optimised dry grinding, classification and sorting technologySteel Slag LoescheAdvantages of cement ball mill Less investment: cement ball mill with advantages of a perfect motor system, low energy consumption and power consumption, and ultralow operating cost, which can save a lot of cost input; Good working environment: reasonable sealing, less dust, low noise, good production environment; Costeffective: the price of the cement ball mill is Cement Ball Mill Ball Mill For Sale Cement Mill 15100t/h

Raymond Mill, Raymond Mill For Sale For Cement and Lime Plant

AGICO CEMENT supplies Raymond mill with customization service and factory price, feel FREE to ask! Skip to content +86 s about blog contact EN ES RU Menu Menu Slag Cement Manufacturing Process rotary kiln for sale Vertical Lime Kiln Rotary Kiln Lime Rotary Kiln Shaft Kiln Activated Carbon Raymond mill is to grind nonflammable and nonexplosive materials in the fields of building materials, mining, metallurgies and chemical industry with hardness less than 93 in Moh’s scale and humidity less than 6 percentExamples of the materials are: quartz, feldspar, barite, fluorite, dolomite, garnet, bauxite, zircon, marble, calcite, iron ore, rock phosphate, coal, slag and so Raymond MillGrinding Millgrinding mill/ultrafine mill/ball Wide product range: For meeting various requirements from different clients, our cement mill range from cement ball mill, vertical cement mill, Raymond mill, coal mill in cement plant, etc Strong production ability : AGICO CEMENT has a large production capacity and rich experience to produce any cement equipment required in cement plantCement Mill Cement Ball Mill Vertical Cement Mill Factory 2 What is raw material substitution? Raw material substitution technology refers to the use of carbide slag, fly ash, steel slag, calcium silicate slag, etc to replace limestone as raw materials for cement production, thereby reducing CO2 emissions during the calcination of raw materialsIndustrial solid waste replaces cement raw materials to promote

.jpg)

Ground Granulated BlastFurnace Slag: Its Chemistry and Use

• ACI 233, “Slag Cement in Concrete and Mortar” Classifications According to ASTM C989, GGBFS is classified into three grades according to its performance in the “slag activity test” The three grades are: Grade 80, Grade 100 and Grade 120 Slag activity is determined by the following formula: Slag activity index, % (SP / P) 100 Where: