Confiscated kaolin removal project

Industrialscale extraction of high valueadded kaolin from

2023年5月15日 In this contribution, a new strategy was successfully developed for industrial–scale extraction of high valueadded kaolin from the excavation waste of Xiamen This strategy can overcome the challenges of complex and variable chemical compositions, high In this contribution, a new strategy was successfully developed for Demonstration from Xiamenthe anatase present in the kaolin deposits has an intense reddishbrown color This color is likely due to substitution of 2 to 5% iron (expressed as % Fe2O3) for titanium in the crystal lattice of The Removal Of Mineral Impurities From Kaolin Using Flotation2022年7月7日 The current study investigated chemical leaching of iron from kaolin using citric and oxalic acids, and the microbial removal of Fe(III) present in kaolin, using pure cultures of a Iron Removal from Kaolin Waste Dumps by Chemical (Oxalic and

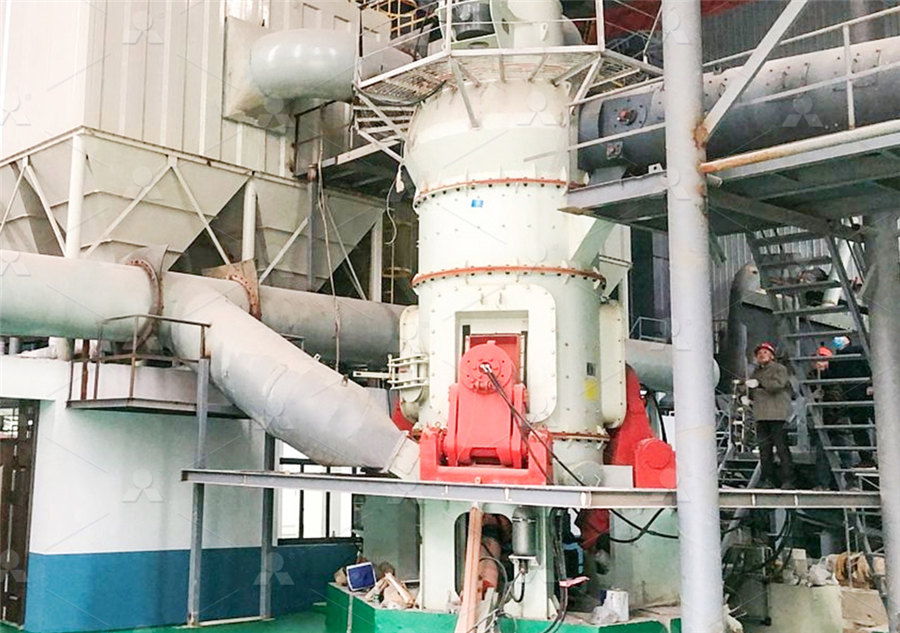

Kaolin Beneficiation And Iron Removal Process

Using the difference in chemical composition and reactivity between impurities and kaolin, magnetization roasting, hightemperature roasting or chlorination roasting, and other treatment 2024年10月28日 Kaolinbiochar composite revealed comparatively higher removal rate of 97 % than pristine kaolin and biochar sorbents Microplastics retained more in vegetated columns Advancing microplastics remediation in bioretention systems using 2013年12月1日 Because of the high cost and environmental impact of techniques currently used to remove these impurities, some effort is now targeted toward the development of alternative (PDF) Refinement of industrial kaolin by microbial removal of iron The excavation waste was subjected to an intensive process of blunging, grinding, sieving, and classifying, as well as successive iron removal by magnetic separation Subsequently, the Industrialscale extraction of high valueadded kaolin from

Enhanced removal performance for Congo red by coalseries

2019年10月9日 Owing to the structural edges of kaolin receiving protons from the hydrochloric acid aqueous solution, the prepared 5AK exhibited excellent adsorption performance for 2023年5月15日 In this contribution, a new strategy was successfully developed for industrial–scale extraction of high valueadded kaolin from the excavation waste of Xiamen Industrialscale extraction of high valueadded kaolin from 2022年4月25日 The kaolin is explored by CADAM, a subsidiary of Vale, in Vitoria do Jari and transported by a pipeline to Barcarena, both in the State of Para According to the report of the Kaolin pipeline on Quilombo land in Moju, Para, Brazil2018年9月1日 PDF Textile Dyes Removal by ZSM5 from Bangka Kaolin Iryani, A1 and Hartanto, D2 1Chemistry Departement, 700k+ research projects; Join for free Public Fulltext 1 Available via license: CC Textile Dyes Removal by ZSM5 from Bangka Kaolin

(PDF) Refinement of industrial kaolin by microbial removal of

2013年12月1日 SEM micrographs of kaolin before and after its bioleaching for 5 days by S putrefaciens CIP8040 at 30 °C using 20 g of clay (a) represents the untreated kaolin, and (b) the bioleached kaolinPDF On Oct 1, 2024, Tauseef Ahmad and others published Advancing microplastics remediation in bioretention systems using biochar/kaolin: Optimizing organics removal, plant health, and microbial Advancing microplastics remediation in bioretention systems using Herein, novel ternary kaolin/CeO 2 /gC 3 N 4 composite was prepared by solgel method followed by hydrothermal treatment The selfassembled 3D “sandwich” structure consisting of kaolin, CeO 2 and gC 3 N 4 nanosheets, was systematically characterized by appropriate techniques to assess its physicochemical properties In the prerequisite of visiblelight Synthesis of Novel KaolinSupported gC3N4/CeO2 Composites kaolin used in our experiments had greater ability to remove red tide organisms, which is completely contrary to the above viewpoint 1 Comparison of the abilities of kaolin and montmorillonite to remove various red tide organisms The abilities of kaolin and montmorillonite to remove Skeletonema costatum,Application of clays to removal of red tide organisms III The

.jpg)

Kaolin Beneficiation And Iron Removal Process

Before selecting a specific process, the chemical composition and iron occurrence state of the kaolin ore should be determined first, and then a single or combined kaolin beneficiation and iron removal process should be adopted according to the difference in the properties of the ore to obtain the ideal iron removal effect and good iron removalIt is a nonswelling clay that is naturally highly adsorbent, so it can help extract and remove undesirable impurities, pathogens or other substances in any given mixture or application Kaolin’s low permeability and adsorptive properties makes it ideal for a geological repository, where it seals hazardous material and counteracts leachingKaolin Tellus2020年12月1日 Statistical optimization and modeling for color removal and COD reduction of reactive blue 19 dye by mesoporous chitosanepichlorohydrin/kaolin clay composite Author links open overlay panel Ali H Authors are grateful to the Researchers Supporting Project No(RSP2020/1), King Saud University, Riyadh, Saudi Arabia Recommended Statistical optimization and modeling for color removal and COD References Fig 6 SEM micrographs of kaolin before and after its bioleaching for 5 days by S putrefaciens CIP8040 at 30 °C using 20 g of clay (a) represents the untreated kaolin, and (b) the bioleached kaolin Arslan, V, Bayat, O, 2009 Removal of Fe from kaolin by chemical leaching and bioleaching Clay Clay Miner 57, 787–794(PDF) Refinement of industrial kaolin by microbial removal of

Crosslinked chitosanglyoxal/kaolin clay composite: Parametric

2021年4月19日 Kaolin clay (KN) was employed as an inorganic filler to modify a crosslinked chitosanglyoxal as Schiff’sbased chitosan composite derivative (CTSGLY)2006年11月1日 Request PDF Removal of Phenol from Contaminated Kaolin Using Electrokinetically Enhanced In Situ Chemical Oxidation The application of electrokinetic treatment to phenol contaminated soil Removal of Phenol from Contaminated Kaolin Using Electrokinetically Statistical Treatment of Bleaching Kaolin by Iron Removal 261 Statistical Treatment of Bleaching Kaolin by Iron Removal Román Ángel Hernández Hernández,*1 Felipe Legorreta García,1 Leticia Esperanza Hernández Cruz,1 and Antonia Martínez Luévanos2 1 Universidad Autónoma del Estado de Hidalgo Área Académica de Ciencias de la Tierra y MaterialesRedalycStatistical Treatment of Bleaching Kaolin by Iron RemovalCombined electrokinetic remediation employing reducing agents represents an extensively utilized approach for the remediation of hexavalent chromium (Cr(VI))contaminated soil In this investigation, electrokinetic remediation of artificially contaminated kaolin was conducted utilizing a separate circulation system for the anolyte, with a 05M solution of acetic acid (HAc) as the Efficient removal of Cr(VI) from contaminated kaolin and anolyte

The Removal Of Mineral Impurities From Kaolin Using Flotation

"full fraction" kaolin, i e, a crude kaolin with oversize particles removed but not yet further fractionated into the size distribution of the ultimate commercial products Details of the process are given by Cundy, 1969, 1976, and Nott, 1978 In 1981 Freeport Kaolin started producing premium brightness kaolin products based on the2021年5月27日 Mine Plan – Production Target White Cloud Kaolin Project From Measured Resources 00 Mt From Indicated Resources 137 Mt From Inferred Resources 00 Mt Total Production Target 1 37 Mt Capital Costs Processing Plant Costs (AUD) $ 68 M Sustaining Capital Costs (AUD) $1 5 M Production Summary Mine life (years) 2 5 Processing rate of kaolinized White Cloud Kaolin Project Scoping Study ListcorpThis research is aimed to utilize kaolin for zeolite synthesis with hydrothermal Removal of water hardness using zeolite synthesized from 6090–6094 Ukwuoma, O 2008 Synthesis of 4AType Zeolite From Calcined Nigerian Kaolinitic Clays Department of Project Management Technology, Federal University of Technology, Owerri (PDF) Removal of water hardness using zeolite synthesized 2023年3月20日 The optimum solid to liquid ratio with the highest percentage removal were 10, 05 and 08 for fly ashbased geopolymer, kaolinbased geopolymer and sludgebased geopolymer adsorbent View full KAOLINBASED GEOPOLYMER AS A HEAVY METAL REMOVAL:

Environmentally Friendly Treatment of Coal‐Bearing Kaolin by

In the present study, a cost‐effective kaolin modification technique based on polyhydroxy‐iron (PHFe(III)) treatment is applied to coal‐bearing kaolin clay (KC) The modified adsorbent (PHFe(III)/KC) shows a two fold increase in specific surface area and renders a 75 mg/g Congo Red (CR) dye uptake amount which significantly outperforms that of the raw KC (∼12 mg/g)2024年9月30日 This work focused on the removal of Pb(II) from aqueous solution using kaolin and bentonite clays modified with hexadecyl trimethyl ammonium bromide (HDTMA) The clays were characterized using a zetasizer, scanning electron microscopy (SEM), powder Xray diffraction (PXRD), BrunauerEmmetTeller (BET), Fouriertransform infrared (FTIR) Removal of Pb(II) ions from aqueous solutions using natural and Here, we fabricated effective and inexpensive kaolinbased ceramic membranes with the addition of dolomite using a simple dry compaction method Moreover, we applied the obtained adsorptive membran EN the optimal membrane showed high removal efficiencies of 9912, 9982, 8562, and 6594% for Pb(II), Cu(II), Zn(II), and Cd(II), respectivelyFabrication and Properties of Adsorptive Ceramic Membrane The results of the present investigation show that natural kaolin is an abundant and low cost material that can be synthesized for the removal of metals such as calcium and magnesium from water Synthetic zeolite contains a high percentage SiO 2 , which makes it a useful material for hardness removalRemoval of water hardness using zeolite synthesized from Ethiopian

The Method of Iron Removal and Purification from

2022年7月13日 The occurrence state of iron in kaolin is the main factor determining the method of iron removal At present, the occurrence state of iron in kaolin at home and abroad is divided into two types: one is existing in kaolinite The HalloysiteKaolin Market Mature Established Market Ceramics (highquality porcelain) –Offtake LOI’s signed for a total of almost 1 million tpa in 3 product forms • Fully refined product value approx AU$700/t (used in Scoping Study) Emerging Market Halloysite Nanotube Technologies –Existing and Emerging • Product value AU$1,000/t AU$5,000/t (depending on Developing a WorldClass HalloysiteKaolin Project2017年6月1日 Request PDF Synthesis of zeolite A using raw kaolin from Ethiopia and its application in removal of Cr(III) from tannery wastewater BACKGROUND The commercial production of zeolite A mainly Synthesis of zeolite A using raw kaolin from Ethiopia and its 2019年9月13日 Ground water samples from residential homes in three Regions of Ghana: Central, Greater Accra and Ashanti, were analyzed for iron and manganese contaminationAdsorptive Removal of Iron and Manganese from Groundwater

Removal of reactive dyes from wastewater assisted with kaolin

2016年4月5日 Reactive dyes effluents release certain chemical hazards and produce amount of environmental problems [1], [2]Most of reactive dyes in wastewater are usually difficult to biodegrade with high pH, high COD and strong color [3]Thus, the various methods are studied in literatures for the removal of dyes from wastewater, including biological processes, combined 2021年1月16日 Synthesis and Characterization of Modified KaolinBentonite Composites for Enhanced Fluoride Removal from Drinking Water January 2021 Advances in Materials Science and Engineering 2021(1):112(PDF) Synthesis and Characterization of Modified KaolinBentonite 2009年12月17日 In a shake flask, bioleaching of kaolin by Aspergillus niger resulted in removal of 7713% of the total Fe, suggesting that this strain is effective at removing Fe impurities from kaolinRemoval of Fe from kaolin by chemical leaching and bioleaching2022年2月28日 Recent studies have shown that chitosan and kaolin can be used to remove numerous water pollutants, including organic anionic dyes [27], biological pollutants [28 Formal analysis, Data curation, Validation, Writing–review editing, Project administration, Serap Çetinkaya: Investigation, Formal analysis Ali Fazıl Yenidünya Epichlorohydrin and tripolyphosphatecrosslinked chitosan–kaolin

Factorial experiments for iron removal from kaolin by using

2013年3月1日 In the present study, to investigate the effects of acidic leaching on the iron removal from kaolin clay supplied by CamSer Madencilik AS, the 2 4 full factorial design of experiments and analysis of variance (ANOVA) were performed The aim of the initial phase of research was to determine the effects of the main and interaction factors which can potentially 2018年9月1日 PDF Textile Dyes Removal by ZSM5 from Bangka Kaolin Iryani, A1 and Hartanto, D2 1Chemistry Departement, 700k+ research projects; Join for free Public Fulltext 1 Available via license: CC Textile Dyes Removal by ZSM5 from Bangka Kaolin2013年12月1日 SEM micrographs of kaolin before and after its bioleaching for 5 days by S putrefaciens CIP8040 at 30 °C using 20 g of clay (a) represents the untreated kaolin, and (b) the bioleached kaolin(PDF) Refinement of industrial kaolin by microbial removal of PDF On Oct 1, 2024, Tauseef Ahmad and others published Advancing microplastics remediation in bioretention systems using biochar/kaolin: Optimizing organics removal, plant health, and microbial Advancing microplastics remediation in bioretention systems using

.jpg)

Synthesis of Novel KaolinSupported gC3N4/CeO2 Composites

Herein, novel ternary kaolin/CeO 2 /gC 3 N 4 composite was prepared by solgel method followed by hydrothermal treatment The selfassembled 3D “sandwich” structure consisting of kaolin, CeO 2 and gC 3 N 4 nanosheets, was systematically characterized by appropriate techniques to assess its physicochemical properties In the prerequisite of visiblelight kaolin used in our experiments had greater ability to remove red tide organisms, which is completely contrary to the above viewpoint 1 Comparison of the abilities of kaolin and montmorillonite to remove various red tide organisms The abilities of kaolin and montmorillonite to remove Skeletonema costatum,Application of clays to removal of red tide organisms III The Before selecting a specific process, the chemical composition and iron occurrence state of the kaolin ore should be determined first, and then a single or combined kaolin beneficiation and iron removal process should be adopted according to the difference in the properties of the ore to obtain the ideal iron removal effect and good iron removalKaolin Beneficiation And Iron Removal ProcessIt is a nonswelling clay that is naturally highly adsorbent, so it can help extract and remove undesirable impurities, pathogens or other substances in any given mixture or application Kaolin’s low permeability and adsorptive properties makes it ideal for a geological repository, where it seals hazardous material and counteracts leachingKaolin Tellus

Statistical optimization and modeling for color removal and COD

2020年12月1日 Statistical optimization and modeling for color removal and COD reduction of reactive blue 19 dye by mesoporous chitosanepichlorohydrin/kaolin clay composite Author links open overlay panel Ali H Authors are grateful to the Researchers Supporting Project No(RSP2020/1), King Saud University, Riyadh, Saudi Arabia Recommended References Fig 6 SEM micrographs of kaolin before and after its bioleaching for 5 days by S putrefaciens CIP8040 at 30 °C using 20 g of clay (a) represents the untreated kaolin, and (b) the bioleached kaolin Arslan, V, Bayat, O, 2009 Removal of Fe from kaolin by chemical leaching and bioleaching Clay Clay Miner 57, 787–794(PDF) Refinement of industrial kaolin by microbial removal of 2021年4月19日 Kaolin clay (KN) was employed as an inorganic filler to modify a crosslinked chitosanglyoxal as Schiff’sbased chitosan composite derivative (CTSGLY)Crosslinked chitosanglyoxal/kaolin clay composite: Parametric