Screen width and length of high fine vertical mill 3YA2160

YA Series Vibrating ScreenVanguard Machinery

YA Vibrating Screen follows classical structural design of screening equipment and its performance is fully guaranteed The vibration source is more stable and the exciting force is Ya Type Circular Vibrating Screen (3YA2160), Find Details and Price about Vibrating Sieve Screen Machine from Ya Type Circular Vibrating Screen (3YA2160) Weifang Better Heavy [Hot Item] Ya Type Circular Vibrating Screen (3YA2160)This series of crushers with novel design can effectively save energy, so that our company has become one of the few Chinese enterprises that can design and process highperformance YA Series Vibrating Screen 3YA 2160Derrick® Corporation has once again redefined high capacity, high efficiency, fine particle wet screening with the introduction of the SuperStack® With 8 decks operating in parallel and FINE SCREENING Derrick Corporation

ISO Linear Vibrating Screen Machine for Mining From China

2024年1月2日 Min Order FOB Price; 1 set: US$2,0000020,00000: Port: Shanghai, China: Production Capacity: 10700 T/H: Contact Now Inquiry BasketThe Raymond Vertical Mill is designed to pulverize materials into the extreme fineness range, with particle sizes as small as 510 microns It uses a principle of integral air classification to Raymond Vertical Mill Technical DatasheetType: Gravity Separator Voltage: 380V Weight: 924t Material: Carbon Steel Material Feature: Fire Resistant Certification: ISO9001:2008, ISO9001:2000, CE3ya2160 Mining Circular Vibrating Screening Machine Screen Type: Gravity Separator Voltage: 380V Weight: 924t Material: Carbon Steel Material Feature: Fire Resistant Certification: ISO9001:2008, ISO9001:2000, CE3ya2160 Mining Circular Vibrating Shaker/Sieve/Sorting

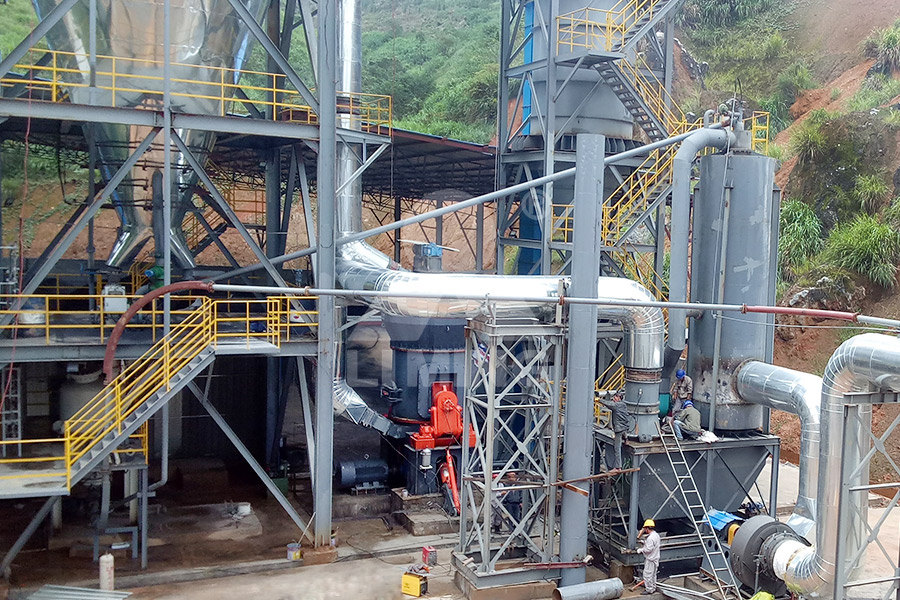

Two sets of 3YA2160 vibrating screen exported to Africa

Two sets of 3YA2160 vibrating screen exported to Africa LZZG is a professional sand sieving machine manufacture, which is an international company with specialized customized Final grain size: 100 µm 100 µm Output: 60,000 kg/h 480,000 kg/h Motor power: 2,200, 4,000, 3,000 W The Waste water Grinder from United Tech Machinery is a high torque, low rotating speed and double shaft grinder under waterVertical mill, Vertical grinding mill All industrial manufacturersfeed slurry to a fine screen should be around 20% solids by volume to achieve reasonable separation short screen length Therefore screen width, rather than screen area, is an important design consideration Brocal grinding circuit with screen classification Rod Mill Rod Mill Rod Mill Overflow 138 t/h 483 t/h Ball Mill Ball Mill 621 t/h Fine Sizing with the Derrick Stack Sizer ScreenAlso, equipment like ball mill is used at the final stages of grinding Among the comminution and grinding equipment, HPGR is increasingly utilized as tertiary crusher or primary mill because of Three Stage Flow Sheet with Two Stage HPGR and

CLUM Ultrafine Vertical Mill

CLUM ultrafine vertical mill is a new type of ultrafine grinding equipment integrating powder grinding, grading, conveying, secondary powder selection, and finished product packaging Capacity: 0245 t/h Max feeding size: 30mm Processing ability: 0245 t/h Application of CLUM ultrafine vertical mill:Vertical roller mill is used to pulverize materials like limestone, coal, feldspar, calcite, fluorite, LM130M highefficiency pulverized coal production line has high efficiency and environmental protection, GX Series Fine Vertical Grinding Mill Model: LM110XGX: LM130XGX: LM150XGX: LM190XGX: LM220XGX: Grinding Roller(pcs) 3: 3: 3 LM Vertical Roller Mill, Vertical Mill ManufacturerFig3 Effects of bar width Fig3 Effects of bar width L c = contour length L p = projected length (eff length) bar width profile height Fig4 Limitation of bar width Fig4 Limitation of bar width B) Effect of Profile Height– One of the main challenges in screening process is thickeningTHE PROFILE : KEY TO REENGINEERED SCREENING IPPTAUltrafine vertical mill is a highefficient industrial grinding mill, be used to grind hard stones into ultrafine powder, like talc, mica, etc +17 [ protected]Ultrafine Vertical Mill

.jpg)

Research and Application for Finishing Hot Mill Strip Width Model

Download Citation On Nov 6, 2020, Xiang Rong SONG and others published Research and Application for Finishing Hot Mill Strip Width Model Find, read and cite all the research you need on The Raymond Vertical Mill is designed to pulverize materials into the extreme fineness range, with particle sizes as small as 510 microns It uses a principle of integral air classification to efficiently produce finely ground materials The mill is available in 18inch and 35inch sizes and can process a variety of materials including minerals, chemicals, and manufactured products It Raymond Vertical Mill Technical DatasheetFine screens are made of brass or bronze plates or wire mesh so as to provide resistance to rust and corrosion They have perforations or openings of size 15 to 3 mm Fine screens have generally a net submerged open area of not less than 005 m 2 for every 1000 m 3 of average daily flow of sewage from a separate system, the corresponding figure being 0075 m 2 for Design of Screen and Screen Channels Waste ManagementPORTABLE VERTICAL IMPACT (VSI) CRUSHERS WITH SCREEN Guaranteed highly cubical end products Home Page; Crushing Screening Plants; their effectiveness in a host of missions such as production of high quality PORTABLE VERTICAL IMPACT (VSI) CRUSHERS

A full Line of Mechanical Variable Speed and Electronic Variable

Knee Width 1142" (290mm) 1142" (290mm) 1339" (340mm) Column Bearing Length 1654" (420mm) 1791" (455mm) 1693" (430mm) Saddle/Table Bearing Length 1988" (505mm) 2028" (515mm) 2028" (515mm) Ram/Turret Bearing Length 1614" (410mm) 1732" (440mm) 1713" (435mm) Ram Length 2894" (735mm) 4173" (1060mm) 3346" (850mm) Table Load 665 Ibs of 80mm The raw materials are mixed in a certain proportion and fed into a vertical roller mill (LOESCHE mill) The vertical roller mill grinds the marital to D 85 of 90µm The ground product is calcined in a preheater to 850900℃ After calcination, the materials enter to a rotary kiln and heated to 1450℃ to become clinkerModeling and simulation of vertical roller mill using population Finemesh Screen System Efficiency There are two aspects to assessing the efficiency of a finemesh screen at reducing IME: 1) reduction in entrainment through the use of a smaller screen mesh, and 2) determining the survival of organisms impinged on the screens then returned Potential survival needs to beEvaluation of Finemesh Intake Screen System for the Diablo Complex applications require adaptable equipment – and that’s what our range of vertical mill technologies offers With multiple options for mill heads, spindle configurations, mill footprint, and movement options, our high rail and gantry vertical mills and profilers can be precisely tailored to your process requirementsHigh rail vertical mills, gantries and profilers for precision

Width control systems with roll force automatic width control and

2008年9月12日 This paper proposes a new width control system composed of an RF (roll force) AWC (automatic width control) in the roughing mill and a FVM (finishing vertical mill) AWC in the finishing mill which aims at obtaining the desirable width margin in the hot strip millThe RF AWC is designed by the control model on the basis of a gauge meter equation using the roll force of The document provides installation and operation instructions for the HRM1700M Vertical Roller Coal Mill It describes the mill's technical parameters, components, structure, working principles, and installation process Key aspects include grinding rollers that can be removed for maintenance, a hydraulic system that controls grinding pressure, and a separator that Operation Manual: HRM1700M Vertical Roller Coal MillHere are some features of our 5deck highfrequency screens: The stack vibrating screen adopts the structural design of superposed multilayer screen boxes, with an effective screening area of 96m and five screen box layersThe effective screening width of the singlelayer screen box is 1200mm, the effective screening length of the screen machine is 1600mm, and there are two Stack High Frequency Fine Screen JXSC MineralThe vertical semicircle planetary mill is a device for mixing, fine grinding, Application of Vertical semicircular laboratory planetary ball mill: Vertical semicircular planetary mill is widely used in geological, mineral, metallurgy, Length X width X height(mm) Noise≤db: PBM02A: ordinary: grease: frequency control: 18: 430X250X270 Vertical Semicircular Laboratory Planetary Ball Mill with Four

Simulation of overflow ball mill discharge and trommel flow using

2015年9月1日 Discharge of pebbles, finer rock, ball scats and slurry from mills and its flow through trommels, and into other processing operations has strong impacts on overflow ball mill performanceWe manufacturer all types of Wiremesh, Perforated Screens used in sugar industry since past 35 years Currently, we are one of the largest suppliers and have supplies to around 250 sugar industries in and outside India To cater their needs, we have a specialized department that deals with all their specifications, patterns spareSugar Mill Screens – Dinco Industries2017年1月10日 The stirred mill was fit to use for fine grinding the middling with a high content of complex intergrowth, especially appropriated for milling P80 1030 μm minerals to liberate more valuable Effect of operating parameters on fine particle Download scientific diagram A wedge wire screen basket W = wire width, S = slot width and P = contour (profile) height (Kleinhappel et al 1995) from publication: Fractionation of A wedge wire screen basket W = wire width, S

(PDF) Performance Comparison of the Vertical and ResearchGate

2023年2月23日 Francis, B Scaleup and Operations of a Vertical Stirred Mill, Master’s Thesis, The University of British Columbia, Vancouver, BC, Canada, 2014 Minerals 2023 , 13 , 315 16 of 16The Ultrafine Grinding Mill, also known as a Micro Powder Grinding Mill or Ultra Fine Powder Grinding Machine, is a highefficiency and lowconsumption grinding mill that is widely used in the powder processing of various materials Bellian Mining Machinery offers a range of Ultrafine Grinding Mills, including the Ultrafine Vertical Mill and Fine Powder Mill Grinder, designed to Ultrafine Grinding Mill, Micro Powder Grinding Mill Bellian Date of publication xxxx 00, 0000, date of current version xxxx 00, 0000 Digital Object Identifier 101109/ACCESS2023 A Digital Twin Model for Automatic WidthA Digital Twin Model for Automatic Width Control of Hot Rolling Mill2020年8月12日 PDF This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, Find, read and cite all the research you An investigation of performance characteristics and energetic

.jpg)

[Conference News] HCM’s Vertical Mill Injects Green And Low

HLMX ultrafine vertical mill is a highend ultrafine grinding mill equipment developed by the HCM research and development team on the basis of coarse powder vertical mills and a series of optimization and upgrades for ultrafine powder grinding and screening Advantages and characteristics of HLMX series ultrafine vertical mill 1High Range rpm Main Spindle Taper Spindle Travel Quill Feed in/rev (mm/rev) Quill Diameter CONSTRUCTION AND WEIGHT Column Turret Diameter Knee Width Column Bearing Length Saddle/Table Bearing Length Ram/Turret Bearing Length Ram Length Table Load Machine Net Weight Machine Shipping Weight 9” x 49” (230 x 1245mm) 3638” (16mm) 208 VERTICAL KNEE MILLS Clausing IndustrialHigh Speed Screen; PTech Screen; Classifiers Dry Classifier; Bucket Wheel Type Classifier; Screen Height: Screen Centers: Screen Width: PHSS 2160 2D 2 X 187 2108 3627 2100 Suitable for very fine separation View our expansive machinery With Puzzolana, PHSS 2160 PuzzolanaFinal grain size: 100 µm 100 µm Output: 60,000 kg/h 480,000 kg/h Motor power: 2,200, 4,000, 3,000 W The Waste water Grinder from United Tech Machinery is a high torque, low rotating speed and double shaft grinder under waterVertical mill, Vertical grinding mill All industrial manufacturers

Fine Sizing with the Derrick Stack Sizer Screen

feed slurry to a fine screen should be around 20% solids by volume to achieve reasonable separation short screen length Therefore screen width, rather than screen area, is an important design consideration Brocal grinding circuit with screen classification Rod Mill Rod Mill Rod Mill Overflow 138 t/h 483 t/h Ball Mill Ball Mill 621 t/h Also, equipment like ball mill is used at the final stages of grinding Among the comminution and grinding equipment, HPGR is increasingly utilized as tertiary crusher or primary mill because of Three Stage Flow Sheet with Two Stage HPGR and CLUM ultrafine vertical mill is a new type of ultrafine grinding equipment integrating powder grinding, grading, conveying, secondary powder selection, and finished product packaging Capacity: 0245 t/h Max feeding size: 30mm Processing ability: 0245 t/h Application of CLUM ultrafine vertical mill:CLUM Ultrafine Vertical MillVertical roller mill is used to pulverize materials like limestone, coal, feldspar, calcite, fluorite, LM130M highefficiency pulverized coal production line has high efficiency and environmental protection, GX Series Fine Vertical Grinding Mill Model: LM110XGX: LM130XGX: LM150XGX: LM190XGX: LM220XGX: Grinding Roller(pcs) 3: 3: 3 LM Vertical Roller Mill, Vertical Mill Manufacturer

.jpg)

THE PROFILE : KEY TO REENGINEERED SCREENING IPPTA

Fig3 Effects of bar width Fig3 Effects of bar width L c = contour length L p = projected length (eff length) bar width profile height Fig4 Limitation of bar width Fig4 Limitation of bar width B) Effect of Profile Height– One of the main challenges in screening process is thickeningUltrafine vertical mill is a highefficient industrial grinding mill, be used to grind hard stones into ultrafine powder, like talc, mica, etc +17 [ protected]Ultrafine Vertical MillDownload Citation On Nov 6, 2020, Xiang Rong SONG and others published Research and Application for Finishing Hot Mill Strip Width Model Find, read and cite all the research you need on Research and Application for Finishing Hot Mill Strip Width ModelThe Raymond Vertical Mill is designed to pulverize materials into the extreme fineness range, with particle sizes as small as 510 microns It uses a principle of integral air classification to efficiently produce finely ground materials The mill is available in 18inch and 35inch sizes and can process a variety of materials including minerals, chemicals, and manufactured products It Raymond Vertical Mill Technical Datasheet

Design of Screen and Screen Channels Waste Management

Fine screens are made of brass or bronze plates or wire mesh so as to provide resistance to rust and corrosion They have perforations or openings of size 15 to 3 mm Fine screens have generally a net submerged open area of not less than 005 m 2 for every 1000 m 3 of average daily flow of sewage from a separate system, the corresponding figure being 0075 m 2 for