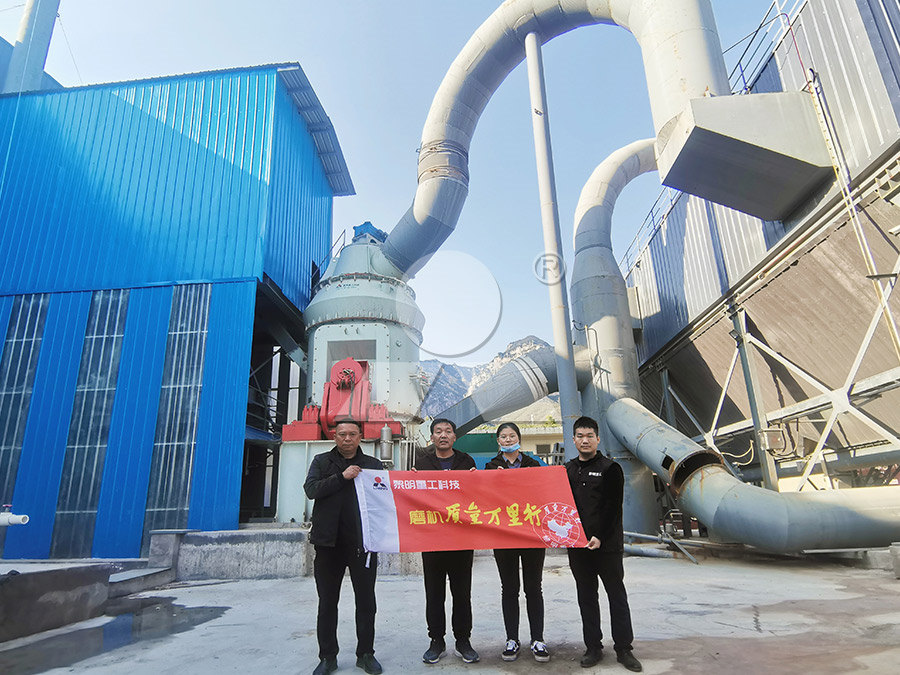

Dongcheng powder selection machine maintenance and disassembly method

.jpg)

DONGCHENG DCJF22 OPERATION INSTRUCTIONS MANUAL Pdf

View and Download Dongcheng DCJF22 operation instructions manual online DCJF22 cutoff machines pdf manual download Also for: Adjf22, Kdjf22View download of more than 40 Dongcheng PDF user manuals, service manuals, operating guides Drill, Grinder user manuals, operating guides specificationsDongcheng User Manuals Download ManualsLibView and Download Dongcheng DCZC22 operation instructions manual online DCZC22 drill pdf manual download Also for: Adzc22, Kdzc22DONGCHENG DCZC22 OPERATION INSTRUCTIONS MANUAL Pdf 2022年6月23日 Be the first to know about the latest products and innovations from DongChengInstruction manual DongCheng Tools

.jpg)

dongchengpowertools

dongchengpowertoolsThe purpose of this invention is to provide and a kind ofly have that rotor stepped zone, fineness of pulverized coal can be controlled, reliable, energyefficient dynamic coal millingDynamic coal milling powderselecting machine Google Patents202410 DongCheng Product Catalogue DOWNLOAD DATA DOWNLOAD DONGCHENGJiangsu Dongcheng Power Tools Co, Ltd, founded in 1995, is one of the key backbone enterprises of the professional power tools manufacturing industry in China, the vice chairman HOME DONGCHENG

.jpg)

Operating instructions and Spare parts list Powder management

This operating manual contains all the important information which you require for the working with the OptiCenter OC09 It will safely guide you through the startup process and give you 2 Fundamentals, Selection, Installation and Maintenance of Gearboxes Part 2 practicalmaintenance Content Chapter Title Page No 1 Storage, Installation and Commissioning of Gearboxes (Gear Drives) 3 2 Tooth Contact Checking 13 3 Lubrication of Gear Drives 26 4 Lubricant Properties 41 5 Lubrication System Maintenance 51Fundamentals, Selection, Installation and Maintenance of 2019年6月20日 7 Replace the motor bearings, methods are: heating method, cooling method, using the cylinder direct pressure method 8 If the bearing is going out of the outer ring, check the cooperation of the end cap bearing seat and the bearing If the bearing is not good, the end cap bearing seat needs to be processedVertical multistage centrifugal pump maintenance and disassembly method2019年10月1日 Hamzeh and Xu (2019) have performed a literature review on general technology selection methods and concluded that AHP, Data Envelopment Analysis (DEA), fuzzy logic, Financial Analysis Techniques Technology Selection Methods and Applications in Manufacturing

(PDF) Disassembly method based on connection interface and

2013年6月1日 In the proposed method, valid disassembly trajectories of a component relative to its surrounding ones are modeled based on the mobility operator, the swept volume approach is used to evaluate Naturally, after setting the goal, we move on to establishing / adopting the maintenance method that will be used The team in the maintenance department, taking into account the experience gained, proposed the rational method of maintenance, for the implementation of which the following rules must be observed: to be availablePLANNING AND SCHEDULE OF MAINTENANCE WORKS FOR INJECTION MACHINES 2014年1月1日 Therefore, in the context of design for disassembly (DfD) for remanufacturing, the fundamental requirements are: ξ Simplify joining method for quick disassembly ξ Prioritize retrieval of cores over non remanufacturable parts ξ Protection of core to maintain part’s integrity ξ Incorporate DfD as early as possible in the product design stage in order to Design for Disassembly for Remanufacturing: Methodology and 2011年3月4日 disassembly, disassembly modeling, disassembly process, information modeling, and remanufacturing 1 Introduction Manufacturing is one of the fundamental aspects of an industrialized society Today many manufacturers are facing challenges of natural resource shortages [1, 2], industrial waste accumulations [3], and economic stagnationDisassembly Process Information Model for Remanufacturing

Research on Disassembly Sequence Planning Method for Maintenance

disassembly sequence and the disassembly direction of each part or component was generated as: component 4(X)part 7(X)part 5(X)part 4(X) The disassembly difficulty factor of the optimal sequence is 13 VI C ONCLUSIONS Paper presented a disassembly sequence planning method The hierarchical disassembly module was built for2024年8月11日 2 Material selection basis (1) Load conditions Engineering materials are exposed to various forces during operation, such as tensile stress, compressive stress, shear stress, cutting stress, torque, and impact force, among othersMetal Material Selection Principles Methods MachineMFG2024年5月3日 When deciding on the type of powder blending machine, it’s crucial to consider factors such as batch size, powder characteristics, mixing intensity, and process requirements Each machine has unique advantages and limitations, so choosing the right one ensures efficient blending and homogeneous mixtures for your specific applicationSelecting the Ideal Powder Blending Machine: Key Factors to 2020年9月24日 packing machine for powder are widely used in the field of pharmaceutical production, as well as in the fields of food and daily chemicals After we purchase the packing machine for powder, we need to maintain it so that we can extend its replacementNext, the editor will explain to you the maintenance methods of the powder packaging machineMaintenance method of packing machine for powder

What Are the Methods of Disassembly and Repair of Screws?

In November 2021, LESUN Sets Sail Again December 28, 2021 In the past 20 years, LESUN has developed as fast as a torrential riverA team of less than 50 people has gone through all the difficulties and obstacles at the beginning of its establishment, and rid view; Measures to Strengthen the Wear and Corrosion Resistance of Screw Barrel March 28, 2022 According to 2020年5月23日 59 Wear: • Wear is a kind of tooth damage where in layers of metal are removed more or less uniformly from the surface It is nothing but progressive removal of metal from the surface Consequently tooth thins down REPAIR METHODS FOR BASIC MACHINE ELEMENTS We remark that in Case 1a (highest machine throughput selection rule), TBQ is the smallest (80) while its highest value (210) is reached for Case 1b (lowest machine cost selection rule) This result is coherent since in Case 1a the selected machines are more expensive, and the budget remaining to allocate buffers is then lower than Case 1bSelecting machines and buffers in unreliable assembly/disassembly 2021年1月1日 According to the World Bank statistical report, Vietnam has an average of 1,6002,700 hours of sunshine and normal direct radiation averaging 45 kWh per square meter a dayModularity design of instant coffee powder packaging machine

Modular Design of Machine Tools to Facilitate Design for Disassembly

2014年1月1日 Combined with the characteristics of the various stages of product life cycle, disassembly criteria for modular design of machine tools for remanufacturing have been established from the aspects of materials selection, remanufacturing process performance, use and maintenance performance, economic efficiency, and functional and physical feasibility2018年7月18日 Disassembly is one of the most timeconsuming and laborintensive activities during the value recovery of endoflife (EOL) products The completion time (makespan) of disassembling EOL products Target Disassembly Sequencing and Scheme Evaluation for CNC Machine (when able to) what is required to make the system maintainable by means of diagnostic methods Plant manufacturers will often build test points into the system To do so later becomes very expensive Built in test facilities are generally for first line maintenance staff, such as lamps, pressure gauges, multi meters etcFAULT FINDING, MAINTENANCE AND DIAGNOSTIC SKILLS2021年9月17日 A Coupled Method for Disassembly Plans Evaluation Based on Operating Time and Quality Indexes Computing September 2021 International Journal of Precision Engineering and ManufacturingGreen Technology(PDF) A Coupled Method for Disassembly Plans Evaluation Based on

.jpg)

Selection of Conceptual Design for Spin Grind Dryer Seaweed Powder Machine

2021年8月15日 The results of the selection process showed that design concept 1 was selected as the best conceptual design for the spin grid dryer seaweed powder machine due to it has the maximum relative 2018年12月25日 Design for Manufacturing, Assembly, and Disassembly is important in today’s production systems because if this aspect is not considered, it could lead to inefficient operations and excessive Design for manufacturing and of the temporary maintenance area to be avoided whenever maintenance personnel are present These maintenance areas should be defined by barricades, post and chain fences, flashing lights, a cranelockout system, or other methods 4 The employer should establish and follow a schedule of planned inspections as requiredInspection and maintenance of mechanical power presses2022年11月30日 Bearings as elementary parts of every machine have a significant role in the functioning of machines, its maintenance and reliability, because they have the task of applying the load from the power transmission []The reliability of the machine depends on the reliability of each of its individual parts, especially the moving components and elements, including roller Selection, Dimensioning and Maintenance of Roller Bearings

The Selection, Care, and Maintenance of a Polymer Quenchant

2024年11月19日 Because the polymer remixes easily with water it does not plate out on the machines and fixtures and the carryout on the parts is greatly reduced Since there is less plate out on the fixtures and machines along with the polymer remixing with water, there is a reduced need to dump the machine sump due to house cleaning issues1 Machine maintenance and installation is important for manufacturing industries to prevent failures and ensure equipment functions properly 2 Professionals involved include maintenance planners, engineers, and technicians who work in industries like manufacturing, construction, food processing, and hotels 3 The document provides an introduction to machine maintenance Introduction To Machine Maintenance and Installation2018年6月30日 The period from the 1990s has seen a large body of work in the areas of Plant Maintenance and Reliability Management While strategies like RCM and TPM are popular and well known, there is also a Modern Plant Maintenance and Reliability Management Methods 2020年11月25日 Design for disassembly (DFD) is an essential design technique to consider the disassembly and recyclability of a product at the initial design stageScheme selection of design for disassembly (DFD) based on

.jpg)

(PDF) Equipment Disassembly and Maintenance in an

2023年8月16日 Disassembly sequence planning (DSP) is a key approach for optimizing various industrial equipmentmaintenance processes Finding fast and effective DSP solutions plays an important role in ing features to facilitate disassembly, minimizes repair cycle time and helps to prevent damage to components that could radically compromise their design life or performance Basic Types of Component and Assembly Interfaces First we should examine the basic methods of attachments Figures 1–4 illustrate some basic diagrams for theBest Practices for Gearbox Assembly and Disassembly Power 2015年3月20日 In general, using a wellplanned maintenance strategy will decrease the needed spare parts inventory unlike corrective maintenance (CM), may also, reduce production loss due to repetitive failures Maintenance Strategy and Decision Making–AHP Method2 Fundamentals, Selection, Installation and Maintenance of Gearboxes Part 2 practicalmaintenance Content Chapter Title Page No 1 Storage, Installation and Commissioning of Gearboxes (Gear Drives) 3 2 Tooth Contact Checking 13 3 Lubrication of Gear Drives 26 4 Lubricant Properties 41 5 Lubrication System Maintenance 51Fundamentals, Selection, Installation and Maintenance of

.png)

Vertical multistage centrifugal pump maintenance and disassembly method

2019年6月20日 7 Replace the motor bearings, methods are: heating method, cooling method, using the cylinder direct pressure method 8 If the bearing is going out of the outer ring, check the cooperation of the end cap bearing seat and the bearing If the bearing is not good, the end cap bearing seat needs to be processed2019年10月1日 Hamzeh and Xu (2019) have performed a literature review on general technology selection methods and concluded that AHP, Data Envelopment Analysis (DEA), fuzzy logic, Financial Analysis Techniques Technology Selection Methods and Applications in Manufacturing2013年6月1日 In the proposed method, valid disassembly trajectories of a component relative to its surrounding ones are modeled based on the mobility operator, the swept volume approach is used to evaluate (PDF) Disassembly method based on connection interface and Naturally, after setting the goal, we move on to establishing / adopting the maintenance method that will be used The team in the maintenance department, taking into account the experience gained, proposed the rational method of maintenance, for the implementation of which the following rules must be observed: to be availablePLANNING AND SCHEDULE OF MAINTENANCE WORKS FOR INJECTION MACHINES

.jpg)

Design for Disassembly for Remanufacturing: Methodology and

2014年1月1日 Therefore, in the context of design for disassembly (DfD) for remanufacturing, the fundamental requirements are: ξ Simplify joining method for quick disassembly ξ Prioritize retrieval of cores over non remanufacturable parts ξ Protection of core to maintain part’s integrity ξ Incorporate DfD as early as possible in the product design stage in order to 2011年3月4日 disassembly, disassembly modeling, disassembly process, information modeling, and remanufacturing 1 Introduction Manufacturing is one of the fundamental aspects of an industrialized society Today many manufacturers are facing challenges of natural resource shortages [1, 2], industrial waste accumulations [3], and economic stagnationDisassembly Process Information Model for Remanufacturingdisassembly sequence and the disassembly direction of each part or component was generated as: component 4(X)part 7(X)part 5(X)part 4(X) The disassembly difficulty factor of the optimal sequence is 13 VI C ONCLUSIONS Paper presented a disassembly sequence planning method The hierarchical disassembly module was built forResearch on Disassembly Sequence Planning Method for Maintenance2024年8月11日 2 Material selection basis (1) Load conditions Engineering materials are exposed to various forces during operation, such as tensile stress, compressive stress, shear stress, cutting stress, torque, and impact force, among othersMetal Material Selection Principles Methods MachineMFG

.jpg)

Selecting the Ideal Powder Blending Machine: Key Factors to

2024年5月3日 When deciding on the type of powder blending machine, it’s crucial to consider factors such as batch size, powder characteristics, mixing intensity, and process requirements Each machine has unique advantages and limitations, so choosing the right one ensures efficient blending and homogeneous mixtures for your specific application