Transfer of twinscrew pelletizing machine

Beginner’s Guide to PVC Pelletizing Extrusion Lines

2023年9月20日 The twin screws rotate and create friction, which helps to melt the PVC resin The screws also have channels that allow the heat from the barrel to be transferred to the resin Mixing: Interlocking twin screws initiate a mixing Twin screw extruders utilize two screws that interact with each other, as compared to single screw extruders (SSEs) which use only one screw The screws interaction in a TSE make this device Quick overview of commercially available twin screw Leistritz2024年4月8日 The PVC Twin Screw Extruder is a powerful and innovative solution that connects sustainability with production efficiency By efficiently processing both virgin and recycled material with minimal impact on the PVC Twin Screw Extruders : An Innovative Solution to The parallel twinscrew pelletizer is a type of pelletizing machine used in the plastics industry to produce uniform pellets from plastic materials The twinscrew extruder melts and homogenizes the plastic material, while the pelletizing Parallel Twin Screw Pelletizer Machine Purui

Twin Screw PVC Pelletizing Line TWIN SCREW PRM Media

We are a pioneer of twin screw extruder ⚫With two parallel counterrotating screws for the palletizing ⚫Reduction and torquedistribution unit with hardened, ground shafts and gear The pelletizing machine with two parallel counterrotating screws for uniform mixing of plastic raw materials and additives Reduction and torquedistribution unit with hardened, ground shafts and gear Long service life for the PVC pelletizing machine TwinScrewHigh efficiency twin screw extruder for compounding adopts high precision weightless feeder, under water pelletizer system, smart siemens PLC controller, high capacity and high quality plastic pellets Through extrusion, cutting and Twin Screw Plastic Pelletizing Line Machine Purui Established in 2007, Jiangsu Jinwo Machinery Co, Ltd has been committed to manufacturing advanced corotating twin screw extruders To meet the needs of different clients, the maximum output of our extrusion line can reach 3800kg/h Twin Screw Extruder Manufacturer, Pelletizing Line

The Role of The Twin Screw Compounder in Plastic

Various machines modify plastics in many ways at the production level The twin screw compounder is one of these machines used in plastic compounding and pelletizing These are processes that change the standard properties of 2016年7月20日 We are a pioneer of twinscrew extruderLearn more about our PVC Pelletizing Machine : https://bitly We are a pioneer of twinscrew extruderLearn more about our PVC Pelletizing Twin Screw PVC Pelletizing Machine Twin Screw IndustrialTwinScrew’s extruding systems pelletizing machines have been applied for making thermoplastic starch (TPS) granules by use of native starch for years Discover the power of PVC Twin Screw Extruders in fostering sustainable TPS Granules and Bioplastics Application of Extrusion2018年9月16日 The fish feed pelletizing machine operates with throughput, pelletizing efficiency, specific energy consumption and mechanical damage of 1623Kg/h, 8062%, 1712kJ/Kg and 632% respectively, at A Design and Fabrication of Fish Feed Pelleting

.jpg)

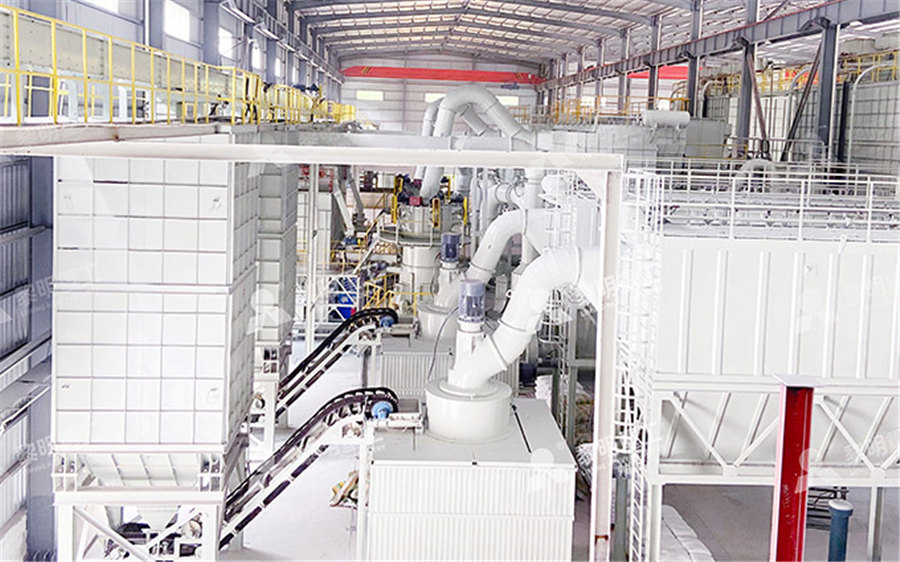

Twin Screw Extruder Manufacturer, Pelletizing Line Supplier In

Jinwoextrusion, As a Twin Screw Extruder Manufacturer, Pelletizing Line Supplier In China, Focuses On plastic granules twin screw extruder, high torque plastic extruder machine, pp sheet extrusion line,etc Skip to content silvia@jinwomach; 0086 +86 138 1395 8642; Close this search box2006年3月3日 For example: A 40mm twinscrew extruder is processing a mineralfilled PP at 160 kg/hr, running at 400 rpm with a %torque of 68% The machine has a 56 kW (approx 75 hp) motor and a maximum possible screw rpm of 600 kW (applied)=56 kW x 68 x 400/600 x 97=154 kW per kg/hr A lower SE indicates that less mechanical energy is being used, and a Words of Wisdom: Understanding twinscrew extruders: The high PVC plastic pelletizing machine Description: Twin screw extruder PVC plastic pelletizing machine are applied to the waste materials, which needs high processing performance of melting, Innovated design of heatertightened style insures high efficiency of heat transfer and high longevity of heaterPVC plastic pelletizing machineThe Parallel twin screw extruder has newly developed for its technologies in UPVC pipe extruded by increasing in the drive torques and innovative solutions to problems in politicizing, screw thermoregulation by selfregulating, sealed water cooling system, vacuum scavenging system and melt pressure controlTwin screw pvc pipe machine TwinScrew

Twinscrew pelletizing machine head installation sequence

2022年8月30日 Twinscrew pelletizing machine service provider Cromwell staff said the structure type of the twinscrew pelletizer system varies according to the scope of The material retention time is short and more homogeneous, with better mixing and a relatively large heat transfer area, 2002年11月2日 For direct extrusion applications, the machine is usually somewhat longer so that the latter part of the process can be dedicated to pumping with a more stable pressure than is mandated for pelletizing (see photo at right) Twinscrew Extruder Function and Design Twinscrew compounding extruders perform these basic functions: feeding, melting Direct extrusion with twinscrew extrudersThe downstream equipment of a twin screw extruder is primarily divided into pelletizing and direct extrusion operations Compounding processes generally make pellets as an intermediate product for processing on injection molding machines or single screw extruders Various type pelletizing systems are available, includingQuick overview of commercially available twin screw LeistritzParallel Twin Screw Pelletizing PET Granules Making Machine Basic Info Model No: ATE Series Plastic Type: PET Automation: Automation Certification: ISO9001:2008, CE Electric Components: Parallel Twin Screw Pelletizing Pet Granules Making

.jpg)

PET plastic pelletizing machine

Photos of PET plastic pelletizing machine: screw loader high torque gear box and parallel twin screw extruder machine Vacuum pump systerm Die head with hydraulic screen changer Innovated design of heatertightened style The equipment consists of a series of conical twinscrew extruders and corresponding pelletizing auxiliary machines The plastic particles produced are uniform, compact and beautiful Auxiliary machine adopts die surface cutting, wind conveying aggregate, vibration separation, cooling, automatic production, improve production efficiencySJZ Counter Rotation Conical Twinscrew Pelletizing of JWELL2023年12月4日 Nicety Machine: This guide offers a detailed overview of the underwater pelletizing system, focusing on its ability to produce highquality pellets through effective heat transfer reduction Maag : This manufacturer’s page provides technical details and specifications for Gala’s underwater pelletizing systems, offering a glimpse into a specific product in the marketHow Underwater Pelletizers are Revolutionizing the Plastics JieyaCKHT series Corotating Twin Screw Strand Pelletizing Compounding Extrusion Line is especially for composite materials that are suitable for strand pelletizing production method The machine body is made by stainless steel, it can filter out different sizes of pellets and also remove dust on pellet surfacesCorotating Twin Screw Strand Pelletizing Compounding Line

.jpg)

The Role of The Twin Screw Compounder in Plastic Compounding

However, this does not disregard the importance of the other components of the twin screw compounded The process of plastic compounding and pelletizing starts when plastic is fed into the barrel containing the twin screws through the feeding bins This plastic is subjected to high pressure by the rotating action of the twin screwsNanjing Juli Chemical Machinery Co,Ltdhave been specialized in Twin Screw Extruder manufacture for many years Our main products are various kinds of Plastic Granules Machine,Plastic Pelletizing LineAlso including Double Screw Extruder,etcChina Twin Screw Extruder,Plastic Granules Machine,Plastic Pelletizing Conical twin screw extruders can provide better selfwiping and conveying capabilities, suitable for applications requiring gentle processing and material conveying, such as food extrusion, pharmaceutical granulation, and processing of heatsensitive materials and cosmetics 2, Corotating or counterrotating Based on the rotation direction of Understanding the Screw Configuration of Parallel CoRotating Twin High Filler Pelletizing Line With High Capacity Series High Filler Masterbatch is made of talc, calcium carbonate, kaolin, and another inorganic powder compounding with resin and lubricants through twinscrew pelletization lt is widely used in polyethylene, polypropylene, polyvinyl chloride, polyester, ABS, PS, EVA blown barrels, pipes, wire series, films, strapping, injection Twin Screw Compounding Line Suzhou Jwell Machinery Co, Ltd

.jpg)

Twin Screw Plastic Pelletizing Line Machine Purui Machinery

The twin screw plsatic pelletizing line can be extensively used in many fields, such as polymer blending, homogeneity, plasticization, filling modification and granulation, engineering polymer and glass fiber reinforcement, master batch, functional parent granule, special material, power coating material and cable material reactive extrusion, degassing and devolatilization, etc2024年9月20日 During the plastic compounding process in a twinscrew extruder, lowtemperature extrusion can lead to several adverse outcomes Identifying the causes of low melt temperature and potential hazards is crucial for effective management and optimization of Managing Low Melt Temperature in TwinScrew Extrusion: 2024年7月11日 Components of a Pelletizing Machine Several elements are found in a pelletizing machine, and they collectively transform biomass into pellets To begin with, the feeder system controls the quantity of raw materials entering the machinery to maintain consistency in terms of input levelsCostEffective Pelletizing Machines for Biomass PelletsPlastic Filler Masterbatch Twin Screw Pelletizing Extruder, Find Details and Price about PP Extruder Machine Extruder from Plastic Filler Masterbatch Twin Screw Pelletizing Extruder Nanjing Kairong Machinery Tech Co, LtdPlastic Filler Masterbatch Twin Screw Pelletizing Extruder

Twin Screw PVC Single Line Rigid Pipe Making Machine

Our PVC pipe extrusion machine, particularly the Twin Screw PVC Single Line Rigid Pipe Extrusion Machine, is a standout in our product lineup The Parallel twin screw extruder is newly developed with advanced technologies, enhancing UPVC pipe extrusion by increasing drive torque and offering innovative solutions for plasticizingInhousemade core components for extrudersScrews, Barrels and Gearboxes To ensure the maximum performance and immediate maintenance service, TWINSCREW’s skillful senior engineers process and fine tune each screw set, barrel and gearbox in houseTwinScrew PVC Twin Screw Extruder and Screw Barrel PET flake pelletizing line is used to make PET plastic flakes into pellets or pellets The twinscrew extruder recycling and granulation system is suitable for wastes with high processing performance requirements such as melting, volatilization and filtration, and is mainly used for the recycling and regranulation of PET wastesPET flake twin screw pelletizing line Suzhou Jwell Machinery The corotating twin screw underwater pelletizing compounding extrusion line operates virtually automatically No additional manpower is needed Every step of the production process, from dosing, extruding, pelletizing to dehumidifying, all adjusted synchronously to maximize operation convenience 2 High throughputCorotating Twin Screw Underwater Pelletizing Compounding

.jpg)

Pioneering TwinScrew Extruder Products Worldwide TwinScrew

Offers highest quality of single screw or twin screw extruder, including PVC extrusion, PVC pipe making machine, PVC profile machine, screw and barrel etcOpen, pressureless product transfer into the discharge screw with the possibility of degassing Gentle discharge through the die plate with a slow rotating single screw Aircooling pelletizing as well as eccentric pelletizing – optionally available with strand and waterring pelletizing 1 Crammer feeder 2 Twin screw extruder CTE PLUSCTE PLUS twin screw extruders Perfect combination of German This pelletizing machine has special screw design and different configuration, it is suitable for the recycling of PP, PE, PS, ABS,PC, etc The gearbox is high torque designed which attains the functions of low noise and stable operation The surface of the screw and barrel have been special treated so that the screw and barrel are wearable, and they have very high mixing Single screw pelletizing machine Suzhou Jwell Machinery Co, Ltd2016年7月20日 We are a pioneer of twinscrew extruderLearn more about our PVC Pelletizing Machine : https://bitly We are a pioneer of twinscrew extruderLearn more about our PVC Pelletizing Twin Screw PVC Pelletizing Machine Twin Screw Industrial

TPS Granules and Bioplastics Application of Extrusion

TwinScrew’s extruding systems pelletizing machines have been applied for making thermoplastic starch (TPS) granules by use of native starch for years Discover the power of PVC Twin Screw Extruders in fostering sustainable 2018年9月16日 The fish feed pelletizing machine operates with throughput, pelletizing efficiency, specific energy consumption and mechanical damage of 1623Kg/h, 8062%, 1712kJ/Kg and 632% respectively, at A Design and Fabrication of Fish Feed Pelleting Jinwoextrusion, As a Twin Screw Extruder Manufacturer, Pelletizing Line Supplier In China, Focuses On plastic granules twin screw extruder, high torque plastic extruder machine, pp sheet extrusion line,etc Skip to content silvia@jinwomach; 0086 +86 138 1395 8642; Close this search boxTwin Screw Extruder Manufacturer, Pelletizing Line Supplier In 2006年3月3日 For example: A 40mm twinscrew extruder is processing a mineralfilled PP at 160 kg/hr, running at 400 rpm with a %torque of 68% The machine has a 56 kW (approx 75 hp) motor and a maximum possible screw rpm of 600 kW (applied)=56 kW x 68 x 400/600 x 97=154 kW per kg/hr A lower SE indicates that less mechanical energy is being used, and a Words of Wisdom: Understanding twinscrew extruders: The high

PVC plastic pelletizing machine

PVC plastic pelletizing machine Description: Twin screw extruder PVC plastic pelletizing machine are applied to the waste materials, which needs high processing performance of melting, Innovated design of heatertightened style insures high efficiency of heat transfer and high longevity of heaterThe Parallel twin screw extruder has newly developed for its technologies in UPVC pipe extruded by increasing in the drive torques and innovative solutions to problems in politicizing, screw thermoregulation by selfregulating, sealed water cooling system, vacuum scavenging system and melt pressure controlTwin screw pvc pipe machine TwinScrew2022年8月30日 Twinscrew pelletizing machine service provider Cromwell staff said the structure type of the twinscrew pelletizer system varies according to the scope of The material retention time is short and more homogeneous, with better mixing and a relatively large heat transfer area, Twinscrew pelletizing machine head installation sequence2002年11月2日 For direct extrusion applications, the machine is usually somewhat longer so that the latter part of the process can be dedicated to pumping with a more stable pressure than is mandated for pelletizing (see photo at right) Twinscrew Extruder Function and Design Twinscrew compounding extruders perform these basic functions: feeding, melting Direct extrusion with twinscrew extruders

Quick overview of commercially available twin screw Leistritz

The downstream equipment of a twin screw extruder is primarily divided into pelletizing and direct extrusion operations Compounding processes generally make pellets as an intermediate product for processing on injection molding machines or single screw extruders Various type pelletizing systems are available, including