How much does a water slag iron oxide alumina iron grinding machine cost

(PDF) Iron and Steel Slags ResearchGate

2017年3月5日 The physicochemical properties of four different types of iron and steel slags, including blast furnace slag, basic oxygen furnace slag, electric arc furnace slag, and ladle furnaceThe exact composition of iron/steel slag varies with the type of furnace used, type of steel grades used and the pre treatment method Steel and iron slags primary components include Iron and Steel Slag Utilization: A Comprehensive AnalysisThe iron ore is a mixture of iron oxides, silica, and alumina From this and the added fluxing agents molten slag and iron are formed The physical characteristics such as density, porosity, Iron and Steel Slag Statistics and Information2017年8月7日 The aim of this study was to evaluate the properties of highalumina iron silicate slags under copper smelting conditions and to determine experimentally the solubility of Slag Chemistry of HighAlumina Iron Silicate Slags at 1300

Chemical composition of iron and steel slag

The primary components of iron and steel slag are limestone (CaO) and silica (SiO 2) Other components of blast furnace slag include alumina (Alsub>2 O 3) and magnesium oxide (MgO), 2019年7月1日 The BOS slag is first homogenized into a powder and then mixed with the appropriate amount of water The amount used in the method being referenced was 10 wt%, The recycling and reuse of steelmaking slags — A review2019年10月29日 In this article, the potential application of iron and steelmaking slag has been reviewed, which included the slag utilization in construction as cement and sand, in water, soil, The potential utilization of slag generated from iron and 4 天之前 Many researchers have proposed that nozzle clogging caused by highmeltingpoint calcium aluminates and CaS should be avoided [13], [14], [15]Previous studies have focused Influence of refining slag composition on nonmetallic inclusions in

Carbon mineralization of steel and ironmaking slag: Paving the

2024年4月1日 In particular, the annual amounts of iron slag and steel slag globally generated were estimated to be 390 Mt and 290 Mt, respectively, in 2022 Steel and ironmaking slag 2011年10月27日 This gives rise to two significant differences in the slag, which is otherwise fairly similar in chemical composition First, because much of the phosphorus has already been removed the slag does not need to be so basic Thus any free lime present is normally at a lower level, and less likely to cause any significant expansion of the aggregateBasics of slag production Article on the slag industry from Global Slag2019年10月29日 Slag is the byproduct of iron and steelmaking processes Normally, around half to one tonne of slag would be generated for yielding one tonne of rolled iron or steel (Lobato et al 2015)It was reported that the world The potential utilization of slag generated from iron2019年4月9日 The alumina slag consisted mainly of alumina (αAl2O3), calcium hexaluminate (CaAl12O19), gehlenite (Ca2Al2SiO7), and small amounts of hercynite (FeAl4O7), and metallic iron (MFe) This work presents a semi SemiSmelting Reduction and Magnetic Separation

.jpg)

Ironalumina composites: From discrete iron particles to

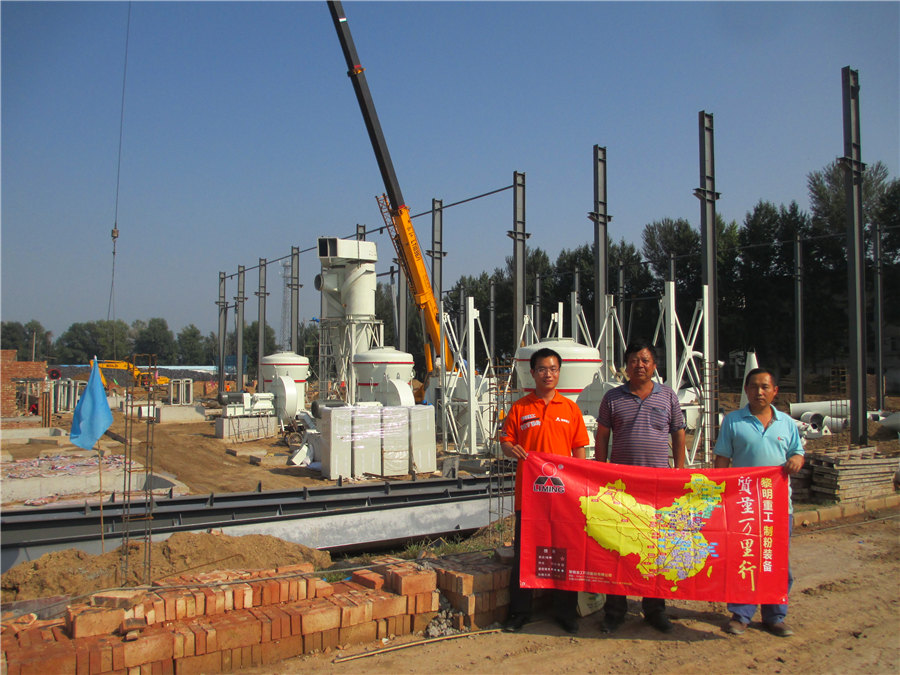

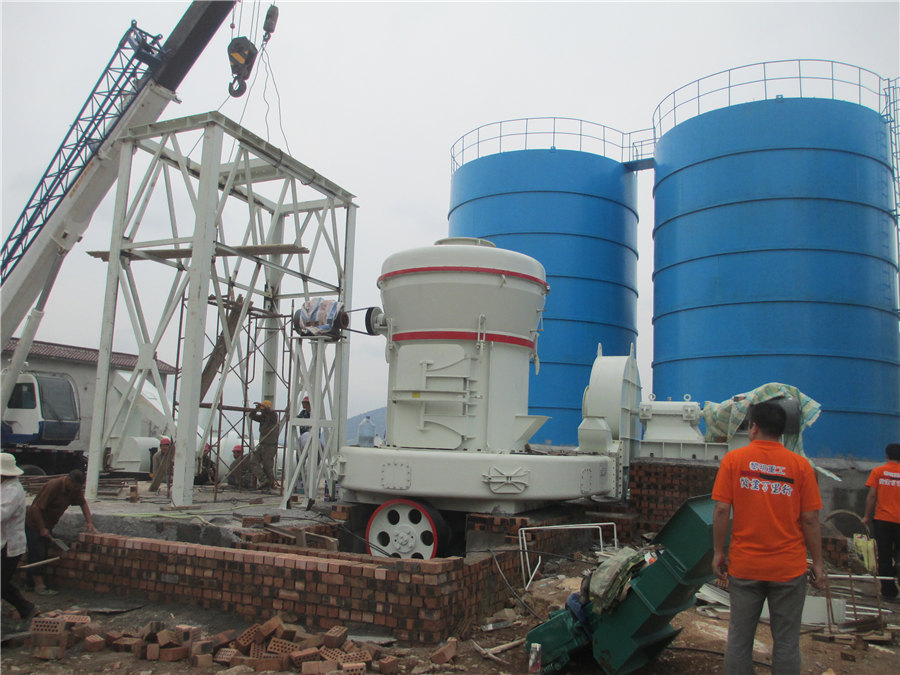

2023年12月1日 Indeed, on the one hand, any free iron oxide (or an ironrich oxide) would have crystallized as hematite (αFe 2 O 3 or a hematiterich solid solution) at about 250 °C and on the other hand, it is known [[32], [33], [34], 37], that the (Al 1x Fe x) 2 O 3 oxide solid solutions prepared form the decomposition in air of the mixedoxalates crystallize into the eta (η) form, a 2017年10月17日 Figure 1: Steelmaking byproducts for blast furnace (BF), basic oxygen furnace (BOF) and electric arc furnace (EAF) processes Source: World Steel Association (worldsteel) The first step in the production of steel or cast iron alloys is the reduction of iron ore—which contains iron oxide and gangue or mineral impurities—to unrefined, reduced iron formFrom Ore to Iron with Smelting and Direct Iron Reduction2024年4月1日 Fig 2 illustrates the iron ore beneficiation process, particularly magnetic separation, resulting in the generation of inevitable tailings Due to the characteristics of iron ores and the conditions during beneficiation, it is inevitable that approximately 25–3 tons of IOTs are generated for every 1 ton of iron ore concentrate produced [7]A critical review on metallurgical recovery of iron from iron ore How much does a blast furnace slag grinding mill cost Release date: Blast furnace slag grinding machine, we generally choose vertical grinding machine, which is more productive and efficient Next: Iron Ore Slag Grinding MachineHow much does a blast furnace slag grinding mill cost

Clinker Production Clinker Manufacturing Cement Manufacturing Machines

Cement Kiln In Cement Plant AGICO offers different types of cement kilns from 105000t/d with steady running, high efficiency and large output We adopt the most advanced calcination technology so that the production investment of clinker is small and the income is high2021年2月25日 The properties of iron oxides in the slag, activity of iron in the alloy and the prevailing oxygen partial pressure in the system are interrelated in oxidic dissolution of metals as (1) [Fe] Pd/Pd + n/2O 2 (g) = (FeO n) slag which covers simultaneously the both iron oxide species dissolving in the molten slags as (1a) [Fe] Pd/Pd + ½O 2 (g) = (FeO) and (1b) [Fe] Iron activity measurements and spinelslag equilibria in alumina 2018年1月1日 Therefore, a wide range of researchers has focused on the comparative study of pollutants removal using NAOs with other minerals [69,96,153,178,179]Application of Iron Oxide and Iron Oxide/Alumina 2019年7月1日 Raw iron ore is characterized by the most abundant ironcontaining mineral found in the ore: magnetite (Fe 3 O 4), hematite (Fe 2 O 3), siderites (FeCO 3), and limonites (2Fe 2 O 3 3H 2 O) (Walker, 1986)All the impurities in iron ore (silica, alumina, titania, sulfur, and phosphorus) are collectively known as gangueAll iron ore that is mined has to be crushed, The recycling and reuse of steelmaking slags — A review

.jpg)

Iron Oxide Pellet an overview ScienceDirect Topics

where F is the extent of the reaction, t is the reaction time, and n is an exponent associated with the nucleus shape n is calculated to be 16 During granulation, 8 % water is uniformly added for a few minutes to obtain preagglomerated products This process lasts for 30 min Typically, particles of iron ore with sizes exceeding 07 mm are used as nuclei, whereas particles smaller The primary components of iron and steel slag are limestone (CaO) and silica (SiO 2)Other components of blast furnace slag include alumina (Alsub>2 O 3) and magnesium oxide (MgO), as well as a small amount of sulfur (S), while steelmaking slag contains iron oxide (FeO) and magnesium oxide (MgO)In the case of steelmaking slag, the slag contains metal elements Chemical composition of iron and steel slagBlast furnace slag includes alumina (Al2O3), magnesium oxide (MgO), and small quantity of sulfur (S) whereas steelmaking slag contains iron oxide (FeO) and magnesium oxide (MgO) Figure 1 Typical Compositions of iron/steel slag (in %) III SLAG TREATMENT PROCESS The iron/steel slag processing flow is schematically shown in Figure 2 There are Iron and Steel Slag Utilization: A Comprehensive Analysis2017年8月7日 All iron oxide in the spinel was recalculated to "FeO" for the ease of presentation Klemettinen et al [14] and Avarmaa et al [15] observed the spinel composition of the ironalumina spinel Slag Chemistry of HighAlumina Iron Silicate Slags at

Arsenic (III) adsorption on iron acetate coated activated alumina

2013年12月20日 Introduction Arsenic contamination in natural water is the worldwide problem There have been widespread reports of arsenic poisoning, in the major parts of Ganga delta in West Bengal [], Brahmaputra basin [], in northern eastern part of India, particularly Golaghat district of Assam [] and other lowlying areas in Bangladesh []The provisional standard 2005年2月1日 Steelmaking slag, an important metallurgical byproduct, is composed of a large amount of valuable components, including CaO, Fe t O, MnO, and MgO, all of which are required in the steelmaking (PDF) Industrial uses of slag The use and reuse of iron and Slag) and GGBFS (Ground Granulated Blast Furnace Slag) as stabilising binders in recent years has significantly increased the area of usage The types of slag covered in this guide are: 1 Blast Furnace Slag — known as BF Slag or BFS or Rock Slag (iron process) 2 Basic Oxygen Steel Slag — known as BOS Slag or BOS (steel process) 1 guide to the use of iron and steel slag in roads2017年3月5日 12 Electric Arc Furnace (EAF) An electric arc furnace (EAF) is a furnace that heats a charged material by means of an electric arc Figure 112 shows a typical EAF process for stainless steel manufacturing using scrap material The EAF normally comprises of three graphite electrodes, molten bath, tapping spout, refractory movable brick roof, and brick shellIron and Steel Slags SpringerLink

Processing of aluminarich Indian iron ore slimes Request PDF

2006年10月1日 The current washing practice results in three products, the coarser lump ores (20010 mm), classifier fines (10 mm) and slimes (01 mm) Due to high iron values, the coarser lump ores were 2020年2月20日 Therefore, a large portion of hydrogen could reduce iron oxide and form water During the operation, iron oxide was reduced and its amount decreased, which caused a decrease in η H 2 There was no considerable difference between the η Slag Formation during Reduction of Iron Oxide Using Hydrogen will turn the aluminium oxide in the BR into water soluble NaAlO 2 and reduce the iron oxides The temperature is lower in the Naroute than in the Caroute, which means that the iron oxide is not reduced to metallic iron, but rather to magnetite, Fe 3O 4 Step (ii) is water leaching Sodium and aluminium will dissolve as Na+ and Al3+Recovery of Copper, Iron, and Alumina from Metallurgical Waste SLAG IRON AND STEEL 16 Slag Iron and Steel S lag is a byproduct generated during manufacturing of pig iron and steel It is produced by action of various fluxes upon gangue materials within the iron ore during the process of pig iron making in blast furnace and steel manufacturing in steel melting shopSLAG IRON AND STEEL Indian Minerals Yearbook 2018 IBM

Impact of organic matter, iron oxides, alumina, silica and drying

2014年6月1日 Intensive mixing in water does not lead to total destruction of the aggregates ranging mostly between 8 and 9 for alumina and between 7 and 9 for iron oxide (Kosmulski, 2002) positive charges developed on their surfaces at the studied pH (around 6) may form strong bonds with negatively charged organic matter and negatively 2023年4月4日 Introduction Iron and steelmaking are essential parts of the US economy, generating 87 million metric tonnes (MMT) of steel and $88 billion in total revenue as of 2023 1 These industries rely on fossil resources as heat sources and as reducing agents for the reduction of iron oxide in ore Global iron and steelmaking are responsible for 8% of the global final Green steel: design and cost analysis of hydrogenbased direct iron 2017年9月8日 Fig 1 Categories of alumina refractories Refractories containing 50 % and 60 % Al2O3 show improved refractoriness over fireclay products There are two fundamental mineral mixtures used in the production of these refractories, and the physical properties of the refractories depend, in part, on which mineral mixture has been used in the manufactureAlumina and its Role in Iron and Steelmaking – IspatGuru2022年7月1日 In ferruginous laterite soils, iron (hydr)oxide predominates, while alumina predominates in aluminous laterite soils Iron in laterite – or clayey soils in general – is usually present as (hydr)oxide minerals, although a wide variety of minor minerals containing Fe 2+ can also be present depending on the atmosphere and presence of anions, such as vivianite, Sustainable ironrich cements: Raw material sources and binder

.jpg)

Chapter 11 Iron and Steel Slags Springer

Iron and steel slags can be generally categorized as iron slag, carbon steel slag, and stainless steel slag [3] The chemical composition of iron and steel slags, primarily in the form of Ca and Mg silicates, is similar to natural sand, gravel, and crushed stones The composition of slags varies widely depending on the source and particle sizes of iron and steel slag The primary components of iron and steel slag are limestone (CaO) and silica (SiO 2) Other components of blast furnace slag include alumina (Al 2 O 3) and magnesium oxide Recent trends in slag management utilization in the steel industry2019年4月9日 The alumina slag consisted mainly of alumina (αAl2O3), calcium hexaluminate (CaAl12O19), gehlenite (Ca2Al2SiO7), and small amounts of hercynite (FeAl4O7), and metallic iron (MFe)SemiSmelting Reduction and Magnetic Separation for the 2011年10月27日 This gives rise to two significant differences in the slag, which is otherwise fairly similar in chemical composition First, because much of the phosphorus has already been removed the slag does not need to be so basic Thus any free lime present is normally at a lower level, and less likely to cause any significant expansion of the aggregateBasics of slag production Article on the slag industry from Global Slag

.jpg)

The potential utilization of slag generated from iron

2019年10月29日 Slag is the byproduct of iron and steelmaking processes Normally, around half to one tonne of slag would be generated for yielding one tonne of rolled iron or steel (Lobato et al 2015)It was reported that the world 2019年4月9日 The alumina slag consisted mainly of alumina (αAl2O3), calcium hexaluminate (CaAl12O19), gehlenite (Ca2Al2SiO7), and small amounts of hercynite (FeAl4O7), and metallic iron (MFe) This work presents a semi SemiSmelting Reduction and Magnetic Separation 2023年12月1日 Indeed, on the one hand, any free iron oxide (or an ironrich oxide) would have crystallized as hematite (αFe 2 O 3 or a hematiterich solid solution) at about 250 °C and on the other hand, it is known [[32], [33], [34], 37], that the (Al 1x Fe x) 2 O 3 oxide solid solutions prepared form the decomposition in air of the mixedoxalates crystallize into the eta (η) form, a Ironalumina composites: From discrete iron particles to 2017年10月17日 Figure 1: Steelmaking byproducts for blast furnace (BF), basic oxygen furnace (BOF) and electric arc furnace (EAF) processes Source: World Steel Association (worldsteel) The first step in the production of steel or cast iron alloys is the reduction of iron ore—which contains iron oxide and gangue or mineral impurities—to unrefined, reduced iron formFrom Ore to Iron with Smelting and Direct Iron Reduction

.jpg)

A critical review on metallurgical recovery of iron from iron ore

2024年4月1日 Fig 2 illustrates the iron ore beneficiation process, particularly magnetic separation, resulting in the generation of inevitable tailings Due to the characteristics of iron ores and the conditions during beneficiation, it is inevitable that approximately 25–3 tons of IOTs are generated for every 1 ton of iron ore concentrate produced [7]How much does a blast furnace slag grinding mill cost Release date: Blast furnace slag grinding machine, we generally choose vertical grinding machine, which is more productive and efficient Next: Iron Ore Slag Grinding MachineHow much does a blast furnace slag grinding mill costCement Kiln In Cement Plant AGICO offers different types of cement kilns from 105000t/d with steady running, high efficiency and large output We adopt the most advanced calcination technology so that the production investment of clinker is small and the income is highClinker Production Clinker Manufacturing Cement Manufacturing Machines2021年2月25日 The properties of iron oxides in the slag, activity of iron in the alloy and the prevailing oxygen partial pressure in the system are interrelated in oxidic dissolution of metals as (1) [Fe] Pd/Pd + n/2O 2 (g) = (FeO n) slag which covers simultaneously the both iron oxide species dissolving in the molten slags as (1a) [Fe] Pd/Pd + ½O 2 (g) = (FeO) and (1b) [Fe] Iron activity measurements and spinelslag equilibria in alumina

Application of Iron Oxide and Iron Oxide/Alumina

2018年1月1日 Therefore, a wide range of researchers has focused on the comparative study of pollutants removal using NAOs with other minerals [69,96,153,178,179]