Steel slag grinding vertical mill for Sany Steel Plant

Steel Slag Grinding Plant CHAENG

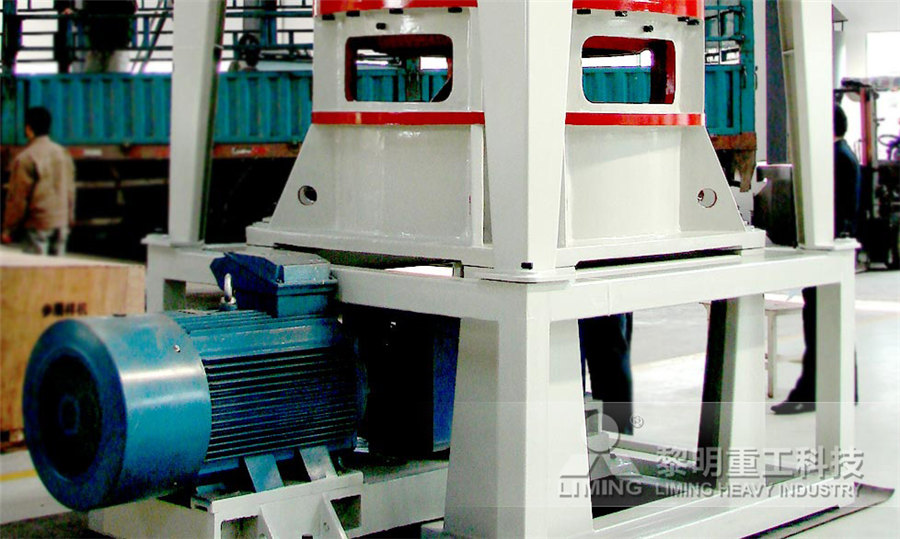

Aiming at the characteristics of steel slag, CHAENG proposes a 200,000 to 15 million tons per year turnkey service plan for the comprehensive utilization of steel slag, which uses vertical CHAENG steel slag vertical mill used in Xuzhou Steel’s steel slag grinding plant with annual Steel Slag Vertical MillCHAENG steel slag vertical mill used in Xuzhou Steel’s steel slag grinding plant with annual output of 300,000 tons In 2010, Xuzhou Steel and CHAENG cooperated to build a steel slag Steel Slag Vertical Mill CHAENGSlag vertical mill set conveying, grinding, drying, powder selecting into an organic whole and work in a closed and negative pressure environment The vibrating screen frame and feeding frame Steel Slag Grinding Plant

Loesche Mills for Metal Recovery and Filler Production from Steel

steel slag combines all the advantages of conventional processes: • Efficient and costeffective metal recovery in the coarse range • Virtually 100% metal recovery down to the finest fractions The vertical mill used for slag is comprehensive equipment that combines crushing, drying, grinding, and classifying It incorporates a specialized grinding mechanism to specifically cater to the grinding and powder selection Slag Grinding Vertical Milling Machine Vertical Mill 2023年12月23日 Steel slag vertical mill technology is the main production link for comprehensive utilization of steel slag The steel slag undergoes multiple processes such as Introduction to steel slag vertical grinding technologyAfter meeting the grinding grain size requirements and reducing the iron content in the steel slag, the advantages of vertical grinding immediately show: high output, low power consumption, and allow up to 20% moisture, and the How is the steel slag vertical mill grinding process?

Steel Slag Vertical Roller Mill

CHAENG steel slag vertical mill has complete models and strengthens the iron dressing process, with the feeding size of ≤ 5mm 【Product capacity】: 200,0001,500,000t/a 【Specific surface HLM steel slag vertical mill plant is a largescale pulverizing equipment for industrial nonmetallic materials processingHLM Vertical Grinding Mill for Steel Slag Processing LineCement Plant, Clinker Grinding Unit, Steel Mill : Annual Output : 200,0001,000,000 tons : Power Consumption : 3545 kWh/t GRMS4641 Slag Powder Vertical Roller Mill Electricity Consumption: 40 kWh/t Standard Production Rate: 105 t/h Effective Diameter of Slag Grinding Plant2008年3月3日 Raising the ground slag The intake and storage of granulated slag as it is received from the steel works is not the full story After the slag is ground, typically in a vertical mill, the finished material generally known as GGBFS must be raised to silo storage before blending or direct dispatchEfficient and reliable handling of GBFS and GGBFS at grinding

.jpg)

Slag Grinding PEC Consulting Group

Steel manufacturing produces steel slag as a byproduct; The slag grinding is done when the slag is milled to very fine particles marketed as Various grinding systems, like a vertical roller mill or a ball mill, can be used to produce GGBFS Nickel Slag Grinding Plant Materials: Nickel Slag Main Equipment: GRMSS Slag Vertical Mill Matching Equipment: belt feeder + vibrating screen + slag vertical mill + hot stove + dust collector + finished product warehouse Steel Slag Grinding Plant Materials: Steel slag Main equipment: GRMSS Steel Slag Vertical Mill Applications: Roads, building materials, soil amendments, slag grinding plant CHAENGGrinding table for vertical millIntroduction Advantage Process Case Inquiry CHAENG is specialized in manufacturing spare parts for vertical roller millThe grinding table is the key part of vertical mill, mainly composed of table body, lining plate, press block, retaining ring, scraper plate, air ring, and wind deflector, etc Weight Material Application Customizable 1132T Carbon steel Grinding Table For Vertical Roller Mill DirectIndustryProduct advantages 1 The specific surface area of slag powder finished product is higher than 450㎡ / kg, which has high activity The specific surface area of CHAENG vertical mill production of steel powder is 450 to 500 ㎡ / kg, which has higher activity with ideal energy consumption indicators at this timeSteel Slag Grinding Plant

.jpg)

Steel Slag Vertical Roller Mill

【Product description】: GRMSS steel slag vertical roller mill made by CHAENG is special equipment for grinding industrial waste steel slag into powder Slag Ball Mill; GGBS Grinding Plant; Steel Slag Grinding Plant; Get a Quote Contact Us Email: Tel:+09 WhatsApp:+092013年6月25日 Grinding Mill; Grinding Plant; Company News; June 25th, 2013 0 Steel Slag crusher and Steel Slag grinding mill are used to processing Steel Slag to small size or slag powder, then the material can be use in impact crusher, cone crusher, mobile crusher There slag mill ball mill, Raymond mill, vertical mill, jet mill and so Steel Slag Crusher and Grinding MillSteel slag is one of the main solid wastes in steel plants, with considerable discharge The recycling of steel slag has become the focus of social attention The micropowder processing scheme using steel slag vertical roller mill can provide an effective way for the recycling of steel slag HCMilling(Guilin Hongcheng) provides customers with professional micropowder News Introduction To The Way Of Steel Slag Recycling The Successful inauguration of the New Steel Pilot Plant with a LOESCHE Ore Grinding Plant (OGPmobile) in Ouro Preto, MG, Brazil Ouro Preto – The company New Steel has developed a revolutionary new process for iron ore concentration for which New Steel has been awarded with the internationally highly esteemed Platts Global Metals Award for Innovation 2015Mills for minerals and ores Loesche

CFB石灰石脱硫剂制备64.jpg)

Steel Slag Grinding Plant/Slag Mining Plant/Slag Grinding Mill Plant

Type: Slag Grinding Plant Motor Type: AC Motor Motor Power: 22KW Rotationl Speed: 2123r/min Application: Cement Plant, Clinker Grinding Unit, Steel Mill Materials: Slag, Waster Slag, Blast Furnace SlagEPC Steel Slag Grinding Plant for Steel Industry, Find Details and Price about Steel Slag Grinding Plant Steel Industry from EPC Steel Slag Grinding Plant for Steel Industry Xinxiang Great Wall Machinery Co, Ltd Print This Page EPC Steel Slag Grinding Plant for Steel Industry2007年2月1日 Figure 4: Slag grinding plants set up by the top 62 steel and iron manufactures in China Figure 5: Effect of GGBS on chloride ion penetration of concrete (C35, The picture in Figure 6 shows typical iron contents found in a slag grinding plant with vertical roller millSlag grinding with the Polysius Roller Mill in China2022年5月17日 When processing steel slag, when the specific surfa ce area of the vertical mill reaches 4500cm2/g, the average grinding capacity of each steel slag vertical mill is maintained at 90t/h If a ball mill is selected, at least 6 sets of ball mill systems are requiredShould steel slag grinding choose vrm or ball mill?

Advantages of HCM Machinery HLM Vertical Mill Steel Slag Grinding

Grinding mill manufacturer HCM Machinery has developed the HLM series vertical grinding mill after more than 20 years of research and development It adopts a reasonable and reliable structural design, combined with advanced technological processes, and integrates drying, grinding, grading and transportation into one highly efficient machineGreat Wall provide the GGBFS(Ground Granulated Blast Furnace Slag) production line, turnkey solution,56 years experience in this field sales@gwmcn +79Steel Slag Grinding PlantThis dry process developed by Loesche for recovering metals from steel slag combines all the advantages of conventional processes: Efficient and costeffective metal recovery in the coarse range; Virtually 100% metal recovery down to the finest fractions range by means of optimised dry grinding, classification and sorting technologySteel Slag LoescheA slag grinding plant is also referred to as a slag grinding unit or a GGBS grinding unit A GGBS production line main includes slag feeding equipment, a bucket elevator, a dust collector, a slag vertical mill, a powder separator, a fan, a funnel, a conveyor belt, Steel Silo Contact us Phone +86 Grinding Plant GGBS Plant One Stop Solution CNBM

Slag Vertical Roller Mill

2023年1月10日 Its grinding efficiency and grinding quality directly affect the cost and quality of slag grinding production As the core equipment in the production process of slag grinding, the LM slag vertical roller mill of SBM integrates fine crushing, grinding, drying, powder selection and transportation, ensuring the continuity and stability of slag AGICO CEMENT helps you turn waste into worth with a slag grinding plant easily Capacity: 20170tph, FREE to contact! Skip to content +86 s about blog contact EN ES RU Menu Menu Home; Cement Equipment Raw Material A vertical cement mill is also called a vertical slag mill It has the advantages of Slag Grinding Plant GGBS Plant Slag Mill, Slag Grinding Mill2020年4月8日 ArcelorMittal’s Dunkirk steel plant supplies the Ecocem plant with slag from two of its three blast furnaces At the heart of the process is a 100t/hr Loesche vertical roller mill, with a 46m table diameter and a 31MW driveEcocem Dunkirk A modern slag grinding plant Global CementVertical mill process The stacked steel slag is measured and then enters the belt conveyor of Steel Slag Grinding Plant Baosteel's EPC steel slag grinding plant with annual output of 300,000tons Main equipment: 32×13m steel slag ball Steel slag grinding plant

.jpg)

Options for Grinding Slag and Pozzolan for Use as

Highpressure grinding rolls (HPGR) technology was first utilized in the grinding of clinker and raw material in the mid1980s and quickly proved be an economical choice in the comminution process 10 The HPGR compresses the material Its technical characteristics are mainly the following aspects: the selection of vertical mill grinding steel slag powder, with advanced technology, reliable production, high labor productivity characteristics, with vertical mill to produce a ton of specific surface area of 400m2/kg ~ 500m2/kg slag, steel slag powder, than the traditional ball mill production of the same weight of powder News Application prospect of ultrafine steel slag grindingCUSTOMER STORIES In November, 2015, chairman of Indonesia Growth Steel Group came to CHAENG and signed the EPC Turkey Project contract of 300,000 t/y nickel slag grinding plant In May 2016, the vertical mill, auxiliary machine, and accessories of 300,000 t/y nickel slag grinding plant ordered by Indonesia Growth Steel Group were sent to Indonesia;Slag grinding plant Xinxiang Great Wall Machinery Co, Ltd2016年5月31日 Grinding materials : blast furnace slag,Steel slag,nickel slag,Manganese slag Equipment matching : Belt feed+Vibrating screen+slag vertical mill+hot blast stove+dust collector+warehouse As the important equivalent substitutes for cement production,GGBFS can not only significantly improve the overall performance of cement and concrete, but also Slag Grinding Plant

2 µm 5 µm Loesche

Grinding of cement clinker and granulated blast furnace slag in roller grinding mills (vertical airswept grinding mills) is a technology introduced by Loesche The first use of a Loesche mill, with a grinding track diameter of only 11 metres, was used as long ago as 1935 However, the breakthrough in grinding this type of material on the vertical1 Preliminary considerations Byproducts from the steel industry contain valuable contents So this article mainly refers to approximately 200 million t/a of steel slags from converters and electricarc furnaces worldwide, and does not discuss blast furnace slags, which have already been processed to a large extent for many years as a latent hydraulic composite material in Processes for the dry processing of steel slags with LOESCHE mills Our vertical roller mills are able to pulverise steel slag into powder 01403 223 101 enquiriesUK@loesche Home; About Us Back Our Contact; Cement The Loesche Group is the authority in the cement industry on grinding technology By combining this hardearned knowledge with a focus on environmental sustainability Loesche is able to Cement Pulverisation Steel Slag Vertical Roller Mill TechnologyConsult Xinxiang Great Wall Machinery Co, Ltd's Steel slag vertical roller millimportant equipment in the steel slag grinding plant brochure on DirectIndustry Page: 1/1 Exhibit with usSteel slag vertical roller millimportant equipment in the steel slag

Slag Grinding Plant

Cement Plant, Clinker Grinding Unit, Steel Mill : Annual Output : 200,0001,000,000 tons : Power Consumption : 3545 kWh/t GRMS4641 Slag Powder Vertical Roller Mill Electricity Consumption: 40 kWh/t Standard Production Rate: 105 t/h Effective Diameter of 2008年3月3日 Raising the ground slag The intake and storage of granulated slag as it is received from the steel works is not the full story After the slag is ground, typically in a vertical mill, the finished material generally known as GGBFS must be raised to silo storage before blending or direct dispatchEfficient and reliable handling of GBFS and GGBFS at grinding Steel manufacturing produces steel slag as a byproduct; The slag grinding is done when the slag is milled to very fine particles marketed as Various grinding systems, like a vertical roller mill or a ball mill, can be used to produce GGBFS Slag Grinding PEC Consulting GroupNickel Slag Grinding Plant Materials: Nickel Slag Main Equipment: GRMSS Slag Vertical Mill Matching Equipment: belt feeder + vibrating screen + slag vertical mill + hot stove + dust collector + finished product warehouse Steel Slag Grinding Plant Materials: Steel slag Main equipment: GRMSS Steel Slag Vertical Mill Applications: Roads, building materials, soil amendments, slag grinding plant CHAENG

.jpg)

Grinding Table For Vertical Roller Mill DirectIndustry

Grinding table for vertical millIntroduction Advantage Process Case Inquiry CHAENG is specialized in manufacturing spare parts for vertical roller millThe grinding table is the key part of vertical mill, mainly composed of table body, lining plate, press block, retaining ring, scraper plate, air ring, and wind deflector, etc Weight Material Application Customizable 1132T Carbon steel Product advantages 1 The specific surface area of slag powder finished product is higher than 450㎡ / kg, which has high activity The specific surface area of CHAENG vertical mill production of steel powder is 450 to 500 ㎡ / kg, which has higher activity with ideal energy consumption indicators at this timeSteel Slag Grinding Plant【Product description】: GRMSS steel slag vertical roller mill made by CHAENG is special equipment for grinding industrial waste steel slag into powder Slag Ball Mill; GGBS Grinding Plant; Steel Slag Grinding Plant; Get a Quote Contact Us Email: Tel:+09 WhatsApp:+09Steel Slag Vertical Roller Mill2013年6月25日 Grinding Mill; Grinding Plant; Company News; June 25th, 2013 0 Steel Slag crusher and Steel Slag grinding mill are used to processing Steel Slag to small size or slag powder, then the material can be use in impact crusher, cone crusher, mobile crusher There slag mill ball mill, Raymond mill, vertical mill, jet mill and so Steel Slag Crusher and Grinding Mill

News Introduction To The Way Of Steel Slag Recycling The

Steel slag is one of the main solid wastes in steel plants, with considerable discharge The recycling of steel slag has become the focus of social attention The micropowder processing scheme using steel slag vertical roller mill can provide an effective way for the recycling of steel slag HCMilling(Guilin Hongcheng) provides customers with professional micropowder Successful inauguration of the New Steel Pilot Plant with a LOESCHE Ore Grinding Plant (OGPmobile) in Ouro Preto, MG, Brazil Ouro Preto – The company New Steel has developed a revolutionary new process for iron ore concentration for which New Steel has been awarded with the internationally highly esteemed Platts Global Metals Award for Innovation 2015Mills for minerals and ores Loesche