Working principle of coal mill

.jpg)

Coal Mill an overview ScienceDirect Topics

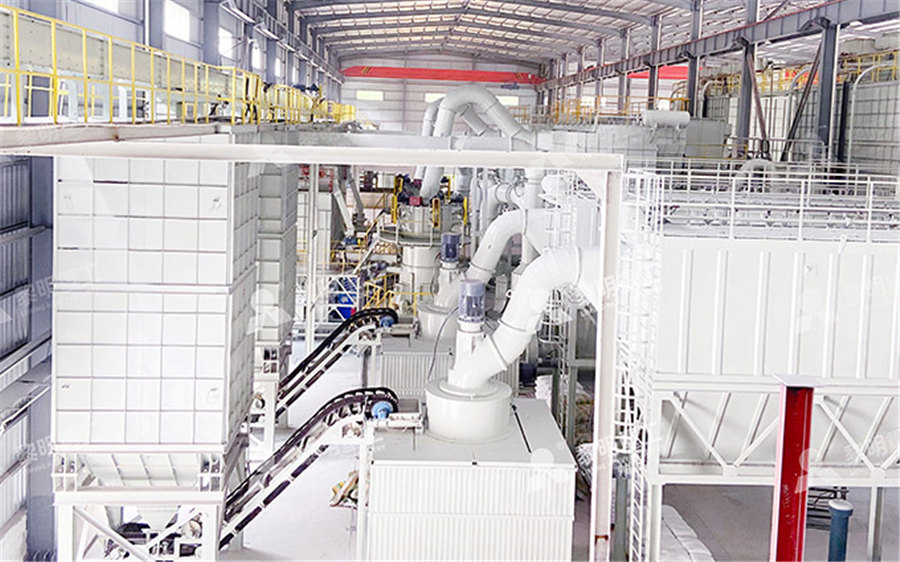

Coal mills or pulverizers play a very essential part in the coalfired power production system Coal mills grind the coal into fine powder, and the primary air entering the mill dries and drives the coal into the power plant furnace for combustion Mills can be a bottleneck for the power generation The first is that the CO 2 concentration in the flue gas is noticeably higher in a cement plant (Cement PlantCoal mill is an important component of the thermal power plant It is used to grind and dry the moisturized raw coal and transport the pulverized coal – air mixture to the boiler Poor dynamic Modeling and Control of Coal Mill2013年3月1日 The present work focuses on vertical spindle roller pressure coal mills, which are one of the most common arrangements for coal grinding The working principles of these mills Nonlinear coal mill modeling and its application to model

.jpg)

A unified thermomechanical model for coal mill operation

2015年11月1日 Coal mills are bottleneck in coal–fired power generation process due to difficulty in developing efficient controls and faults occurring inside the mills In this paper, a dynamic 2020年4月7日 The main task of a coal mill system is to provide qualified fuel for the pulverized coal boiler In the coal mill system, raw coal is firstly grinded into fine powder, and then dried and transmitted into the boiler by the primary airModeling of Coal Mill System Used for Fault Simulation A highquality coal mill can effectively solve the fineness problem of coal powder and ensure uniform grinding of raw coal The fineness of pulverized coal has a great influence on the ignition temperature and burning time of the equipmentCoal Ball Mill Grinding for Different Kinds of Learn about the Vertical Grinding Mill (Coal Pulverizer)! How it works, its components, design, advantages, disadvantages and applicationsVertical Grinding Mill (Coal Pulverizer) Explained saVRee

Schematic diagram of the working principle of MPS

Firstly, an improved coal mill dynamic model considering the joint influence of drying force, ventilation force, and grinding force is established, and a synchronous optimization approach ofDownload scientific diagram Working process of a Tubeball mill from publication: A new modelbased approach for power plant Tubeball mill condition monitoring and fault detection With the Working process of a Tubeball mill ResearchGateAbstract: The paper presents development and validation of coal mill model (including the action of classifier) to be used for improved coal mill control The model is developed by using the mass and heat balance equations of the coal mill Genetic Algorithm is used to estimate the unknown parameters that are used in the model validationModeling and Control of Coal MillThe working principle of the vertical coal grinding mill is similar to that of vertical raw mill Grinding mill motor start: The start working of vertical coal mill is driven by an electric motor The raw coal enters the vertical mill bin: The reducer Vertical Coal Mill for Coal Grinding in Cement Plant

Pulverizer Wikipedia

A control circuit monitors the coal level in the mill, and controls the speed of the raw coal feeder to maintain it Maintaining the coal level in the mill offers a builtin capacity cushion of pulverized fuel to take care of short interruptions in the raw coal circuit The mill is pressurized and the airtightness is ensured by plenum chambers Working principle of air swept coal mill The airswept coal mill has two functions of drying and grinding When it is working, the raw material is loaded into the mill through the feeding equipment, and the hot air enters the mill through the air inlet pipe , Air Swept Coal Mill Cement Plant Machinery2020年6月29日 6 TYPES OF COAL PULVERIZER • Tube or ball mills: Lowspeed machines that grind the coal with steel balls in a rotating horizontal cylinder If the diameter of the cylinder is greater than the length of the cylinder, the mill is called a ball mill If the length of the cylinder is greater than the diameter of the cylinder, it is called a tube millclassifications and working of mills in a power plant PPTAirswept coal mill is the main equipment of cement plant, also called coal mill in cement plant, used for grinding and drying various hardness of coal, crushing the coal briquette into pulverized coalIt is the important auxiliary equipment of pulverized coal furnace The airswept coal mill runs reliably, can work continuously, also has a large production capacity and less energy Coal Mill In Cement Plant, Airswept Coal Mill Coal Mill

.jpg)

Live Working of Ball and Tube Coal Mill in Thermal Power Plant/ Coal

2021年8月29日 In this video you will get a live overview of ball and tube type coal mill used in thermal power plant2024年1月28日 2 Liners: An abrasionresistant material such as manganese steel or rubber typically lines the inner surface of the cylindrical shell to protect it from wear due to the grinding action 3 Balls: They place steel or ceramic balls, typically used as grinding media in a ball mill, inside the shell and rotate them with it 4 Feed and Discharge: Entering the hollow shell at the Ball mill: Principles, construction, working, uses, merits, and Request PDF On Sep 1, 2016, Deniz Altun and others published Operational parameters affecting the vertical roller mill performance Find, read and cite all the research you need on ResearchGateOperational parameters affecting the vertical roller mill Download scientific diagram Working principle of section mill from publication: Field test and numerical simulation of the section mill in Ushaped wells of coalbed methane In order to Working principle of section mill Download

.jpg)

Coal mill pulverizer in thermal power plants PPT

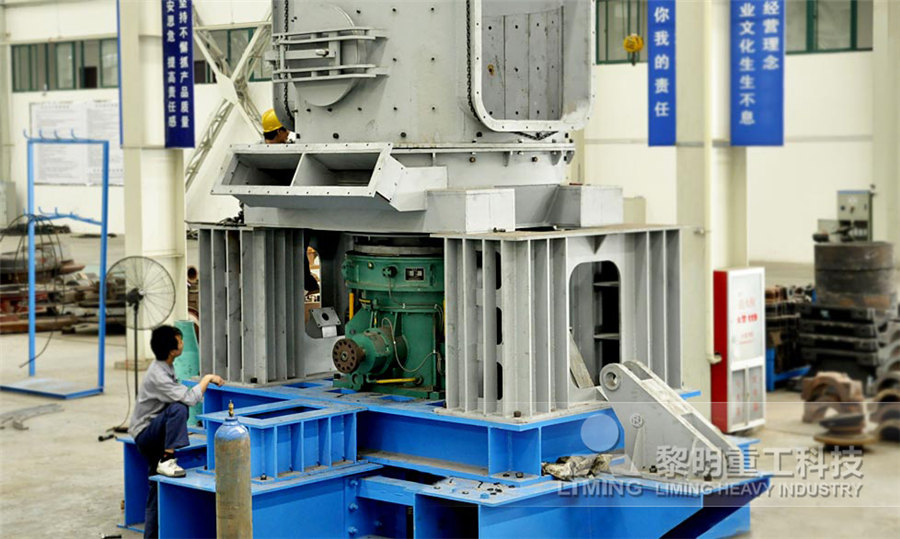

2012年11月17日 20 131Fineness Fineness is an indicator of the quality of the pulverizer action Specifically, fineness is a measurement of the percentage of a coal sample that passes through a set of test sieves usually designated at 50, Introduction This article concerns itself with vertical grinding mills used for coal pulverization only (coal pulverizers), although vertical grinding mills can and are used for other purposes The 3D model in the saVRee database represents a vertical grinding bowl millOther grinding mill types include the ball tube mill, hammer mill, ball and race mill, and , roll and ring millVertical Grinding Mill (Coal Pulverizer) Explained saVRee2014年3月26日 In this video you will learn about the main components of a Loesche Mill for Cement and Granulated Blast Furnace SlagMain Components and Functional Principle of a Loesche CS MillWorking principle Three stationary grinding rollers roll on a rotating grinding table MPS 200 BK coal mill, Krimzement Bakhchisarayski, Ukraine MPS 3070 BK coal mill, Jaypee Cement Balaji, India MPS 180 GC vertical roller mill for the grinding, drying and calcining of Coal mill, gypsum mill, clay mill, etc Pfeiffer MPS mills

.jpg)

Bowl Mill Coal Pulverizer COAL HANDLING PLANTS

2023年12月14日 Fine coal is discharged through the coal piping to the coal nozzles at the furnace Working of Coal Pulverizer The maximum capacity of a pulverizer is dependent on the following: 1 Pulverizer size 2 Raw coal properties – Hardgrove index and moisture level 3 Pulverized coal fineness The raw coal is fed into a rotating bowl via a center 2023年7月4日 Working principle: the motor drives the grinding table to rotate through the reducer, (5R) Their working conditions are basically the same, while four rollers are the most commonlyused The Raymond mill is mainly used to grind coal, nonmetallic ore, glass, ceramics, cement, gypsum, pesticide, chemical fertilizer, Roller Mill SpringerLinkThe Raymond Mill is a grinding machine, suitable for the preparation of various kinds of mineral powder and coal powder preparation SBM has launched three upgrade series of Raymond Mills, MB5X Pendulum Roller Mill, MTW European Grinding Mill Raymond Mill History, Working Principle ApplicationsSBM The coal mill casing is the main working area for pulverized coal grinding is to ensure the uniform distribution of pulverized coal particles and to control the particle size of pulverized coal Separators usually use the principle of rotary separation to separate the Air Swept Coal Mill Cement Plant Equipment Coal Grinding Mill

Nonlinear coal mill modeling and its application to model

2013年3月1日 Nonlinear coal mill modeling and its application to model predictive control Author links open overlay panel Andrea Cortinovis a, Mehmet Mercangöz a, which are one of the most common arrangements for coal grinding The working principles of these mills are extensively explained in Niemczk and Andersen (2009), Shin and Li 2024年3月27日 Bowl Mill internals Working Principle Coal mill internals Working Principle Coal pulveriserhttps://youtu/lvC5ukKj3dw?si=AA6Umx7OcvtRkLQ1https://yoBowl Mill internals Working Principle Coal mill internals Working 2024年3月24日 Bowl mill internal working principle। operation of coal mill। pulverizer plantHello friends, This channel is more informative regarBowl mill internal working principle।। Vertical roller coal mill Working Principle of Coal Mill Structural Advantages of Coal Mill Combined Design and High Production Efficiency Coal mill has a combination design of grinding liner and drying bin, which adopts different lining board structure according to different stages of the coal mill, which makes the coal mill reach a productivity of 3~40TPHCoal Mill with Industrial Solutions Fote Machinery(FTM)

The Ultimate Guide to Understanding Ball Mill Diagrams

On the other hand, the dry ball mill is suitable for grinding dry materials, such as cement, limestone, and coal The ball mill diagram is essential for understanding the operation of the ball mill Ball Mill Critical Speed Working Principle Recent Posts Comparing Stocks and Mutual Funds with a Venn Diagram Worksheet;The coal mill in a cement plant should be reliable and should be operated with great care, or it is easy to cause safety accidents In the process of grinding, storage, transportation, and burning of pulverized coal, The working principle of vertical mill is as follows: Coal Mill in Cement Plant Vertical Roller Mill AirSwept Ball Mill2022年6月1日 Coal pulverizer Power Plant #boiler #mechanical coal mill Operation maintenance Question Answer for interviews #thermalpowerplantcoal pulverizer plant Coal Mill working and operationRaymond Mill Raymond Mill is beneficial for energy saving and environmental protection It has high processing capacity, 1,000,000TPY Coal Grinding Plant 100,000TPY Calcite Grinding Plant India 30TPH Limestone Grinding Plant 620TPH Raymond Mill: Working Principle Parts Powder Raymond Mill

Beater wheel mill Geckointech

Application Beater wheel mill is high speed (7501500rpm) coal mill, which is widely used for direct firing lignite pulverizing system in thermal power plant with capacity 200MW or higher Working principle Beater wheel mill has a fast rotating beater wheel, which is armed with beater plates at radial directionWhat Is Raymond Mill Raymond mill is also called Raymond roller mill It is a new type of highfineness grinding mill with high efficiency and closed circulation, which can completely replace the cement ball millThis kind of machine is commonly used in cement plants for raw materials fine grinding, such as limestone, coal, gypsum, etc Under normal conditions, these materials’ Raymond Mills Raymond Roller Mill Grinding Mill AGICO Download scientific diagram Working process of a Tubeball mill from publication: A new modelbased approach for power plant Tubeball mill condition monitoring and fault detection With the Working process of a Tubeball mill ResearchGateAbstract: The paper presents development and validation of coal mill model (including the action of classifier) to be used for improved coal mill control The model is developed by using the mass and heat balance equations of the coal mill Genetic Algorithm is used to estimate the unknown parameters that are used in the model validationModeling and Control of Coal Mill

Vertical Coal Mill for Coal Grinding in Cement Plant

The working principle of the vertical coal grinding mill is similar to that of vertical raw mill Grinding mill motor start: The start working of vertical coal mill is driven by an electric motor The raw coal enters the vertical mill bin: The reducer A control circuit monitors the coal level in the mill, and controls the speed of the raw coal feeder to maintain it Maintaining the coal level in the mill offers a builtin capacity cushion of pulverized fuel to take care of short interruptions in the raw coal circuit The mill is pressurized and the airtightness is ensured by plenum chambers Pulverizer WikipediaWorking principle of air swept coal mill The airswept coal mill has two functions of drying and grinding When it is working, the raw material is loaded into the mill through the feeding equipment, and the hot air enters the mill through the air inlet pipe , Air Swept Coal Mill Cement Plant Machinery2020年6月29日 6 TYPES OF COAL PULVERIZER • Tube or ball mills: Lowspeed machines that grind the coal with steel balls in a rotating horizontal cylinder If the diameter of the cylinder is greater than the length of the cylinder, the mill is called a ball mill If the length of the cylinder is greater than the diameter of the cylinder, it is called a tube millclassifications and working of mills in a power plant PPT

.jpg)

Coal Mill In Cement Plant, Airswept Coal Mill Coal Mill

Airswept coal mill is the main equipment of cement plant, also called coal mill in cement plant, used for grinding and drying various hardness of coal, crushing the coal briquette into pulverized coalIt is the important auxiliary equipment of pulverized coal furnace The airswept coal mill runs reliably, can work continuously, also has a large production capacity and less energy 2021年8月29日 In this video you will get a live overview of ball and tube type coal mill used in thermal power plantLive Working of Ball and Tube Coal Mill in Thermal Power Plant/ Coal 2024年1月28日 2 Liners: An abrasionresistant material such as manganese steel or rubber typically lines the inner surface of the cylindrical shell to protect it from wear due to the grinding action 3 Balls: They place steel or ceramic balls, typically used as grinding media in a ball mill, inside the shell and rotate them with it 4 Feed and Discharge: Entering the hollow shell at the Ball mill: Principles, construction, working, uses, merits, and