HOME→Calcium carbide mud steelmaking plant steel slag treatment plant calcium carbide mud steelmaking plant steel slag treatment plant calcium carbide mud steelmaking plant steel slag treatment plant

Calcium carbide mud steelmaking plant steel slag treatment plant calcium carbide mud steelmaking plant steel slag treatment plant calcium carbide mud steelmaking plant steel slag treatment plant

.jpg)

Use of Calcium Carbide and Alumina based Slag Conditioner

2018年2月11日 The present study pertains to the use of calcium carbide as deoxidizer in combination with a slag conditioner in the form of Calcined Alumina Briquettes during EAF2022年5月1日 For the chloralkali industry, CCS can regenerate massive CaO through purification, molding, calcination Thus, CCS can be used as raw material for CaC2 Recycling and utilization of calcium carbide slag ScienceDirect2021年2月1日 Industrial calciumbased byproducts such as steelmaking slag and carbide slag are often used as inexpensive mineralizers for CO 2 In this investigation, the pH was tested Synergistic mechanisms of steelmaking slag coupled with carbide 2024年2月26日 Carbide slag is highly alkaline and contains a large amount of calcium elements, making it an excellent material for CO 2 mineralization Our idea was to acquire qualified Research on Utilizable Calcium from Calcium Carbide Slag with

.jpg)

Study on CO2 Adsorption Performance of HighCalciumBased

4 天之前 Steel slag is a prospective CO2 capture material due to its substantial yield and calciumrich mineral content Numerous scholars have researched methods to enhance CO2 2018年8月1日 Different countries use a variety of steel slag treatment methods In Japan, the most commonly used method to prevent the expansion of steel slag is the aging treatment Steel slag in China: Treatment, recycling, and management2020年10月15日 Enhancing the development and deployment of treating waste from the steelmaking process will be environment friendly and resourcesaving Capturing CO 2 by Cotreatment of Waste From Steelmaking Processes: Steel Slag 2024年5月26日 Slag from the steel industry is studied as a common source of CaCO 3 via mineral carbonation owing to its high Ca content Despite numerous preliminary studies, the Experimental study on indirect mineral carbonation using five

.jpg)

Resource utilization of solid waste carbide slag: a brief review of

The calcium carbide industry is an indispensable industry to support the basic life of people The huge production capacity of calcium carbide is accompanied by a large number of solid waste 2018年11月14日 It is well known that calcium (Ca) is more effective deoxidant compared to aluminium and calcium carbide is a cheaper source to provide this calcium Density of calcium Use of calcium carbide for slag killing at ladle furnace in silicon 2012年5月1日 It was observed that calcium extraction from steelmaking slag significantly increased with an increase in the amount of hydrochloric acid, and the CO(2) flow rate had a positive effect on the carbonation reaction rate but did not affect the morphology of the calcium carbonate produced The conversion of steelmaking slag (a waste product of the steelmaking Recovery of calcium carbonate from steelmaking slag and 2020年1月1日 In this study, steel slag a byproduct from steel industry was used to remove phosphorus content from the municipal wastewater The Langmuir isotherm model revealed a maximum adsorption capacity of 38 mg phosphate/g of steelmaking slag The results showed that the phosphate removal efficiency of granular slag was about 90%Recycling steel slag from municipal wastewater treatment plants

Calcium leaching from waste steelmaking slag: Significance of leachate

2014年10月15日 As part of iron and steel production processes, a number of calcium rich slag byproducts are produced The slag produced in the highest volumes is blast furnace slag, which is generally fully utilised as both an aggregate for road construction and as an additive in Portland cement (Hiltunen and Hiltunen, 2004)The second most produced slag is basic oxygen 2022年5月1日 Abstract Considering the BSSF steelmaking slag generated in a Brazilian steelwork, it would be worth to separate iron and calcium from it, with the objective of increasing its iron content, or Separation of Iron and Calcium from a BSSF Steelmaking Slag 2024年11月1日 In this investigation, the pH was tested online during the mineralization process of CO2 and steelmaking slag, carbide slag and the compounded system of steelmaking slag and carbide slagCarbon fixation performance and mechanism of composite 2014年12月16日 Calcium in Steels satyendra; December 16, 2014; 6 Comments ; calcium, clean steel, clogging, fluidity, inclusions, Nozzle, steel, Calcium in Steels Calcium (Ca) (atomic number 20 and atomic weight 4008) has density of 154 gm/cc Melting point of Ca is 842 deg C and boiling point is 1484 deg CCalcium in Steels IspatGuru

.jpg)

EXPERIENCES WITH CALCIUM TREATMENT OF STEEL

2017年12月11日 Calcium (Ca) treatment is commonly used to control the shape and composition of oxide and sulphide inclusions in aluminium (Al) and AlSi killed steels2017年4月1日 Calcium extraction from unmilled BOF slag for energyefficient CO 2 sequestration using graphical analysis and application for AMD treatment Calcium extraction from unmilled BOF slag for energy Calcium extraction from steelmaking slag and production of the steelmaking slag 2 Effective Utilization and Treatment method of Steelmaking Slag The steelmaking slag resembles crushed stone in its appearance The major composition of crushed natural stone is SiO 2 while that of steelmaking slag is CaO Additionally, since steelmaking slag has a component close to that of Portland cement, steelmaking Stabilization of Calcium Compounds in Steelmaking SlagCalcium carbide has the nominal formula of CaC 2 and the molecular weight of 640992 g/mol The pure material is colorless, but most samples have a color ranging from black to grayishwhite, depending on the grade Its density is 222 g/cc and it melts at 2160 °C with a boiling point (under an inert atmosphere) of 2300 °C, where it decomposesIts main use industrially is in the Calcium Carbide an overview ScienceDirect Topics

.jpg)

Recovery of calcium carbonate from steelmaking slag and utilization

2012年5月1日 The conversion of steelmaking slag (a waste product of the steelmaking process) to calcium carbonate (CaCO(3)) was tested using hydrochloric acid, ammonium hydroxide and carbon dioxide via a pH 2024年4月1日 Steelmaking sludge, also known as steel mill sludge or steel plant sludge, is produced during BOF or EAF operations or through secondary refining processes (ladle furnace (LF) or vacuum degassing) It originates from the descaling of steel surfaces, the removal of impurities from molten metal, and the treatment of wastewaterCarbon mineralization of steel and ironmaking slag: Paving the 2020年9月1日 Calcium treatment was widely used to modify Al 2 O 3 and MgOAl 2 O 3 inclusions in Alkilled steels A large number of experimental studies have been carried out to reveal the modification mechanism and transient behavior of inclusions after calcium treatment [19], [20]It was reported that the Al 2 O 3 inclusion was directly reduced by dissolved calcium Effect of calcium treatment on inclusions in SiMn2024年9月20日 As marinedredged mud and waste steel slag in coastal port cities continue to soar, the traditional treatment method of land stockpiling has caused ecological problems Thus, it is necessary to find a largescale resourcecomprehensive utilization method for dredged mud and waste steel slag This study uses waste steel slag and composite solidifying agents Experimental Study on Mechanical Properties and Stability of

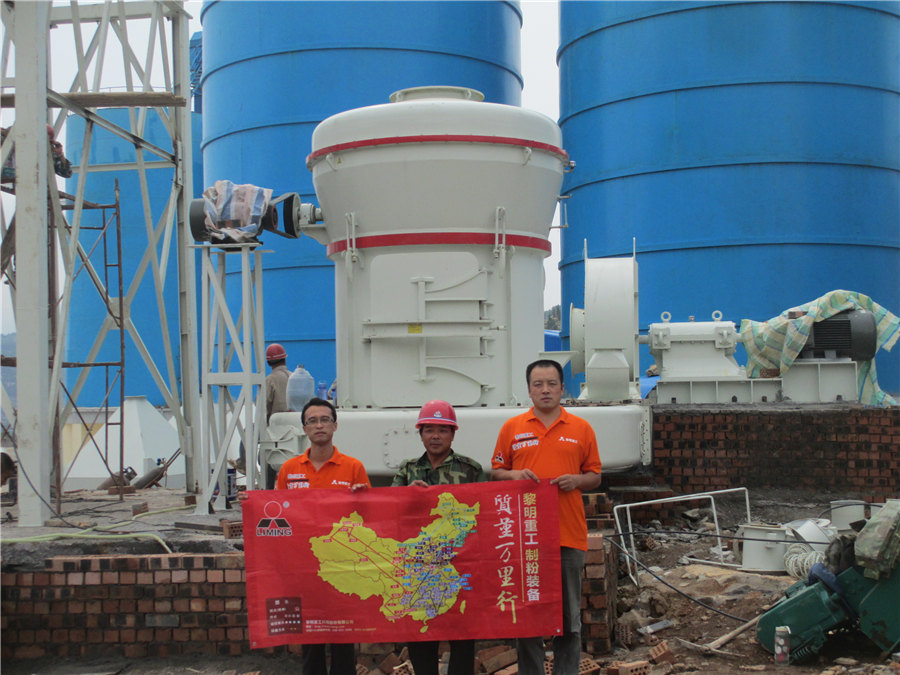

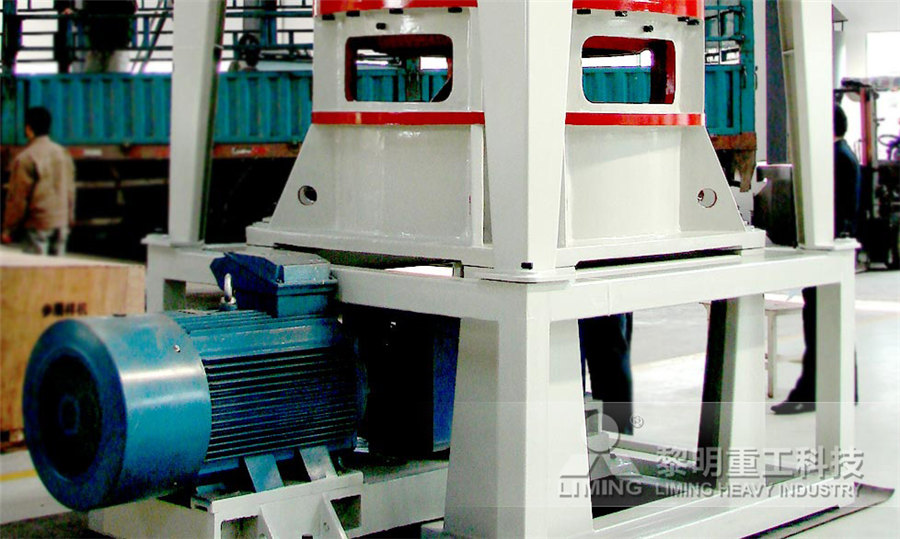

CALCIUM CARBIDE STEEL MAKING / SLAG CONDITIONING

CALCIUM CARBIDE STEEL MAKING / SLAG CONDITIONING GRADES HEALTH SAFETY INFORMATION Date Issued: 5/1/09 Revision No: 90 2 Carbide Industries 24 Hour Emergency Response Line (502) 7754123 Chemtrec 8004249300 EMERGENCY PHONE NUMBERS 3 HEALTH SAFETY INFORMATIONCarbide slag is a calciumrich residue that is a byproduct of ethyne gas production, containing residual minerals like magnesium, iron, and silicon It is utilized as a primary raw material in industries such as polyvinyl chloride and cement processing, and can also be used to derive calcium oxidebased catalysts for various applications like biodiesel productionCarbide Slag an overview ScienceDirect TopicsSteel slag is the main waste product in the steelmaking process Because of its chemical composition and technical properties, it can be reused as raw material in steel plants and can serve as a substitute for aggregates in civil engineering In this paper, we reviewed steel slag treatment, recyclin Steel slag in China: Treatment, recycling, and management2023年1月1日 So far, carbon dioxide sequestration by steel slag carbonization has been widely studied by many scholars Ding et al [8] proposed a new linear programming model to evaluate the economic cost of carbon dioxide capture and storage in Chinese steel plants, and believed that the adoption of carbon capture and storage technology in steel plants could obtain Carbon capture and storage technology by steelmaking slags:

.jpg)

USE OF CALCIUM CARBIDE AND ALUMINA BASED SLAG

USE OF CALCIUM CARBIDE AND ALUMINA BASED SLAG CONDITIONER BRIQUETTES IN STEELMAKING AT JSPL ANGUL KEY WORDS : Slag conditioner briquettes, calcium carbide in steel makingas a deoxidizer and aand composition adjustment The yield of iron/steel slag is about 300 kg/tp per ton of pig iron for blast furnace slag and about 100150 kg/ts per ton of molten steel for steelmaking slag In Japan, some 40 million tons of iron/steel slag are presently produced annually (Table 1) Technology UDC 669 054 82 : 669 184 244 66Processing and Reusing Technologies for Steelmaking SlagDOI: 102166/wst2012143 Corpus ID: ; Recovery of calcium carbonate from steelmaking slag and utilization for acid mine drainage pretreatment @article{Mulopo2012RecoveryOC, title={Recovery of calcium carbonate from Table 1 from Recovery of calcium carbonate from 2024年8月1日 1 Introduction Steel slag (SS) is a byproduct of the steelmaking process Approximately 200 million tons of SS are generated annually around the world, yet the utilization rate of SS is less than 20% (Zhuang and Wang, 2021)In the past, SS was discharged into nature and occupied much land (Gencel et al, 2021)However, SS contains many utilizable Engineering properties optimization of dispersive soil by calcium

.jpg)

Macro–micro investigation on stabilization sludge as subgrade

2024年4月1日 Macro–micro investigation on stabilization sludge as subgrade filler by the ternary blending of steel slag and fly ash and calcium carbide residue Author links open overlay panel Jian–feng Zhu and efficacy in silt treatment and recycling (Chen and Lin, 2009 power plant and steelmaking industry (Bieda B Calcium‑Treated Steel Cleanliness Prediction Using High‑Dimensional Steelmaking Process Data Stephano Piva 1 Andre Nogueira Assis 1 Petrus Christiaan Pistorius 1 Michael Kan 2CalciumTreated Steel Cleanliness Prediction Using High 2017年12月14日 The use of calcium carbide in steel, R Javier Santiago, Luis A Mombello, 15th IAS Steelmaking Conference, 2005, San Nicolas, Argentina ($))6ODJJRQGLWLRQLQJJ8VLQJJDOFLXPPDUELGH Recommendations (PDF) Use of calcium carbide and alumina based slag conditioner 2024年2月1日 The abundant resources of steel slag make it an intriguing prospect for longterm CO 2 storage by mineral carbonation Herein, the dissolution of steel slag in an acetic acid (HAc) solution and the fixation of CO 2 in the leachate of steel slag to synthesize highvalue CaCO 3 were investigated Results show that the microwave water bath condition is beneficial for Microwaveenhanced selective leaching calcium from steelmaking slag

.jpg)

Research on the Properties of Steel Slag with Different MDPI

2024年3月28日 To promote the resource utilization of steel slag and improve the production process of steel slag in steelmaking plants, this research studied the characteristics of three different processed steel slags from four steelmaking plants The physical and mechanical characteristics and volume stability of steel slags were analyzed through density, water 2021年6月8日 Steel slag is a byproduct discharged from the steelmaking process, which is characterized by abundant free calcium/magnesium oxide, low cementitious properties, and high contents of heavy metalsUse of steel slag as sustainable construction materials: A review of 2023年6月13日 Control of calcium treatment in steel is challenging due to the reactivity of Ca and difficulty of measuring total oxygen of steel inprocess to make actionable decisions In this work, a method combining statistics and process engineering are developed using partial least squares regression (PLS) to predict nonmetallic inclusion content (oxides and CaS) and CalciumTreated Steel Cleanliness Prediction Using High 关键词: CO 2 mineralization, Calcium carbide slag, Light calcium carbonate, Process simulation, Lifecycle assessment Abstract: The production of polyvinyl chloride by calcium carbide method is a typical chemical process with high coal consumption, leading to massive flue gas and carbide slag emissionsCurrently, the carbide slag with high CaO content is usually stacked in residue CO 2 mineralization of carbide slag for the production of light calcium

Recovery of calcium carbonate from steelmaking slag and

2012年5月1日 It was observed that calcium extraction from steelmaking slag significantly increased with an increase in the amount of hydrochloric acid, and the CO(2) flow rate had a positive effect on the carbonation reaction rate but did not affect the morphology of the calcium carbonate produced The conversion of steelmaking slag (a waste product of the steelmaking 2020年1月1日 In this study, steel slag a byproduct from steel industry was used to remove phosphorus content from the municipal wastewater The Langmuir isotherm model revealed a maximum adsorption capacity of 38 mg phosphate/g of steelmaking slag The results showed that the phosphate removal efficiency of granular slag was about 90%Recycling steel slag from municipal wastewater treatment plants 2014年10月15日 As part of iron and steel production processes, a number of calcium rich slag byproducts are produced The slag produced in the highest volumes is blast furnace slag, which is generally fully utilised as both an aggregate for road construction and as an additive in Portland cement (Hiltunen and Hiltunen, 2004)The second most produced slag is basic oxygen Calcium leaching from waste steelmaking slag: Significance of leachate 2022年5月1日 Abstract Considering the BSSF steelmaking slag generated in a Brazilian steelwork, it would be worth to separate iron and calcium from it, with the objective of increasing its iron content, or Separation of Iron and Calcium from a BSSF Steelmaking Slag

.jpg)

Carbon fixation performance and mechanism of composite

2024年11月1日 In this investigation, the pH was tested online during the mineralization process of CO2 and steelmaking slag, carbide slag and the compounded system of steelmaking slag and carbide slag2014年12月16日 Calcium in Steels satyendra; December 16, 2014; 6 Comments ; calcium, clean steel, clogging, fluidity, inclusions, Nozzle, steel, Calcium in Steels Calcium (Ca) (atomic number 20 and atomic weight 4008) has density of 154 gm/cc Melting point of Ca is 842 deg C and boiling point is 1484 deg CCalcium in Steels IspatGuru2017年12月11日 Calcium (Ca) treatment is commonly used to control the shape and composition of oxide and sulphide inclusions in aluminium (Al) and AlSi killed steelsEXPERIENCES WITH CALCIUM TREATMENT OF STEEL2017年4月1日 Calcium extraction from unmilled BOF slag for energyefficient CO 2 sequestration using graphical analysis and application for AMD treatment Calcium extraction from unmilled BOF slag for energy Calcium extraction from steelmaking slag and production of

.jpg)

Stabilization of Calcium Compounds in Steelmaking Slag

the steelmaking slag 2 Effective Utilization and Treatment method of Steelmaking Slag The steelmaking slag resembles crushed stone in its appearance The major composition of crushed natural stone is SiO 2 while that of steelmaking slag is CaO Additionally, since steelmaking slag has a component close to that of Portland cement, steelmaking Calcium carbide has the nominal formula of CaC 2 and the molecular weight of 640992 g/mol The pure material is colorless, but most samples have a color ranging from black to grayishwhite, depending on the grade Its density is 222 g/cc and it melts at 2160 °C with a boiling point (under an inert atmosphere) of 2300 °C, where it decomposesIts main use industrially is in the Calcium Carbide an overview ScienceDirect Topics