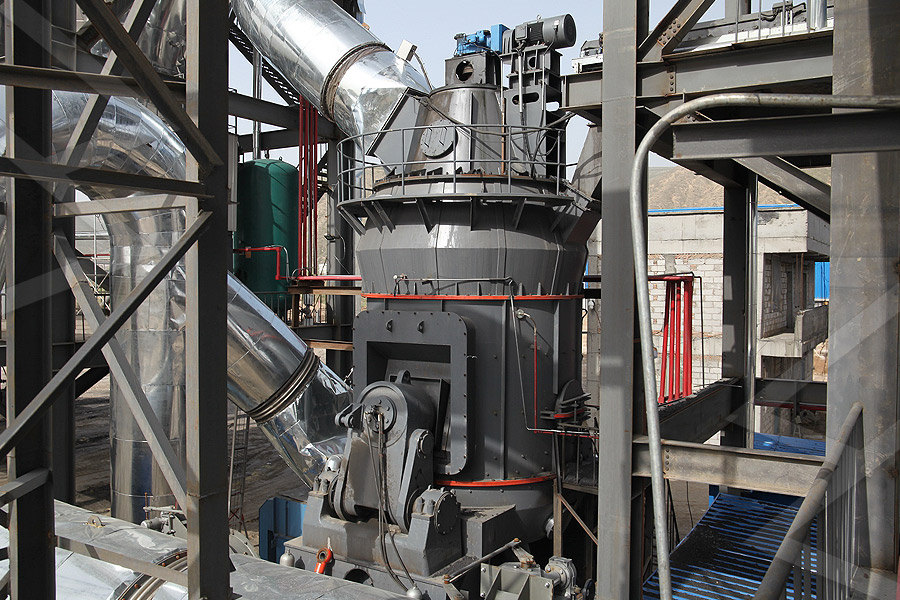

Chromium calcite ore selection equipment

Chromium selecting device for lateritic ore Google Patents

Chromium selecting device for lateritic ore according to the embodiment of the invention, adopt hydrocyclone, spiral chute, shaking table and magnetic separator, can selectIn terms of equipment selection, shakers and jigs are mostly used in the gravity separation stage, while the equipment selection in the magnetic separation stage is determined based on the Chromite purification methods and equipment LZZG2024年11月28日 The extraction of chrome ore is a critical process for meeting the growing demand for chromium in various industries Understanding the top methods for extracting Top 5 Methods to Extract Chrome Ore Mining Pedia2023年12月20日 Ore crushing and pretreatment: Chromium ore undergoes crushing, grinding and screening steps to reach appropriate particle size for subsequent processing Typically, Chrome Mineral Gravity Separation Technology, Process and

Laboratory Experimental Equipment for Chromite Separation

2023年9月13日 The laboratory shaking table is one of the equipment for conducting ore beneficiation testing, and smallscale beneficiation in laboratories It is suitable for separating Chromite ore is predominantly used in the production of ferrochrome – an alloy of chrome and iron We offer a range of equipment for the processing of chromite ore Our scalping and Mining Equipment Coal, Chromite and Copper Mining CDEThe Chromium Ore Washing Plant in Difens, Oregon, US uses chrome ore washing equipment including shakers, ore washers, dry weak magnetic separators, dry strong magnetic Chrome ore washing plant working principle LZZGThe rod mill is used for grinding to achieve monomer dissociation and then enters the gravity separation process The equipment suitable for chromite gravity separation is mainly skipped Chrome ore beneficiation process and washing equipment

.jpg)

Developing an optimum beneficiation route for a lowgrade

2018年12月28日 In this study, an optimum beneficiation route was developed for an existing concentrator that processes lowgrade chromite deposits This objective is challenging as the 2018年12月28日 In this study, an optimum beneficiation route was developed for an existing concentrator that processes lowgrade chromite deposits This objective is challenging as the grade of the ore under Developing an optimum beneficiation route for a 2023年12月14日 ( Spiral Chute Gravity Separation Equipment in Chrome Ore Beneficiation ) Jigging Machines Jigging machines are another common gravity separation equipment utilized in chrome ore beneficiation The jigging process Ultimate Guide to Gravity Separation Equipment in Chromium ore is mainly a byproduct of the production of zinc metal from sulfide ore concentrates So typical cadmium ore crushing is also the crushing of zinc ores The mined zinc ores are crushed and ground by cadmium ore crushers and cadmium mills to liberate the zinc sulfide particles from the waste host rockChromium Ore Ore Crushing Solutions DSMAC

.jpg)

Chrome Ore Beneficiation Process JXSC Mining

2019年5月15日 Chrome process equipment is wet type strong magnetic separator, and spiral chute (chrome spiral plant) of gravity separator 3 Experimental results and discussion 31 Chrome magnetic separation process The chrome raw ore is a flotation tail ore, which is mainly formed in the chromite, and the chromite is the target recovering mineral2019年6月13日 The commonly used chrome ore gravity separation equipment includes shaking table and jig The selection of chrome ore beneficiation equipment shall be determined according to the different ore The main gangue minerals are quartz, calcite, chlorite and so on Mining processing solution: "Gravity and magnetic combination Questions about Chrome Ore Beneficiation Miningpedia2024年11月28日 1 What is Chrome Ore? Chrome ore refers to the mineral chromite, which is the only commercial source of chromium Chromite is typically found in ultramafic rocks and is extracted through various mining techniques The extracted ore is then processed to produce ferrochrome, an essential alloy used in stainless steel production 2Top 5 Methods to Extract Chrome Ore Mining Pedia2023年10月1日 1 Introduction The international market for chromite ore (synthetic formula – FeOCr 2 O 3), the only commercially viable source of new chromium (Cr) units, is predominantly driven by the global demand for ferrochrome (FeCr)Secondary FeCr markets comprise of the Cr chemicals, abrasives, refractories, and foundry sand industries and account for a relatively Chemical beneficiation of chromite ore to improve the chromium

Quartz Ore Ore Crushing Solutions DSMAC

Quartz sand is the mainly production of quartz application It is crushed by crushing plant from quartz, tridymite, cristobalite The complete quartz crushing and screening plant ensure high process efficiency, combining fieldwork with our engineering expertise results in a specific system that delivers the desired end products in a profitable way2007年5月17日 Calcium polysulfide (CaS 5) has been used for the reduction of Cr(VI) in groundwaterThe highly soluble Cr(VI) was reduced by CaS 5 to the insoluble, and nontoxic Cr(III), which was then precipitated as chromium hydroxide The highest reduction rate (70%) occurred during the first 6 months and the reductant continued to react with Cr(VI) for a total of Assessment of calcium polysulfide for the remediation of 2016年2月10日 To this end, the test and selection of the specific chemical reagent for efficient chromium extraction from phosphate ore were studied The effects of some parameters were taken into consideration Distribution and extraction of chromium from phosphate oreThe ore samples were supplied from a new lowgrade chromium ore deposit located in Eastern Anatolia in Turkey, and they were characterized in detail in terms of their physical, chemical, and mineralogical properties The grindability of the ore was determined using the standard Bond Work Index method with a test sieve having a size of 106 µmDeveloping an optimum beneficiation route for a lowgrade chromite ore

.jpg)

Specific Gravity of Expansive Chromium Ore Processing Residue

Specific Gravity of Expansive Chromium Ore Processing Residue with Complex Microstructure ABSTRACT: Specific gravity tests were performed on chromium ore processing residue (COPR), an expansive Featured selections Trade Assurance Buyer Central Help Center Get the app Become a supplier Alibaba; Construction Building Machinery; Energy Mineral Equipment; 50TPH Factory Cheap Price Chromium Gravity Mining Process Complete Chrome Ore Processing Equipment $10,50000$98,80000 Min Order: Find A Wholesale chromium ore equipment Online22092019 calcite ore mining process stainless steel calcite ore mining process stainless steel; Leave a Reply 12May Iron ore Wikipedia Iron ore is the raw material used to make pig iron, which is one of the main raw materials to make steel—98% of the mined iron ore is used to make steel Read Morecalcite stainless steel powder equipment2023年9月20日 In this study, Cr(VI)contaminated soil mixed with COPR by using ferrous sulfate (FeSO 4), enzyme residue (ER), and their combination under aerobic or anaerobic condition were investigatedThe concentration of Cr(VI) decreased from 149805 to 10463 mg kg −1 after the simultaneous addition of FeSO 4 (30 %, w/w as FeSO 4 7H 2 O) and ER (30 %, w/w) at 45 d Remediation of Cr(VI)contaminated soil mixed with chromite ore

Extraction of Chromium from Chromite Ore 911Metallurgist

2017年7月20日 The average grade of the metallurgical chromite ore was 434 pct Cr2O3, with 52 pct of the ore having a chromiumtoiron ratio of 3:1 or over, 176 pct having a ratio between 2:1 and 3:1, and 304 pct having a ratio less than 2:1 Chemicalgrade chromite ore generally ranged from 40 to 46 pct Cr2O3 with a chromiumtoiron ratio of 15:1 to 2:1As the important resource of nowadays industry production, ore minerals are required nearly in every business in the industry Together with the professional crushing, grinding and screening technology of world class, DSMAC supply professional rock crusher including Metal Ore Minerals、Non Metallic Minerals crushing plants, grinding equipments, screening machines Ore Crushing, Stone Crushing Equipment, Rock Crusher, Rock Shale is a finegrained, clastic sedimentary rock composed of mud that is a mix of flakes of clay minerals and tiny fragments of other minerals, especially quartz and calcite Shale crusher is the important equipment in shale quarryShale Ore Crushing Solutions DSMAC2020年4月1日 Chromite production is required for numerous industrial applications worldwide, with Turkey emerging as a major supplier of chromite ore The decreasing grade of chromiumore bodies and Process optimization of a chrome ore gravity concentration plant

.jpg)

Pebble Ore Crushing Solutions DSMAC

A pebble is a clast of rock with a particle size of 4 to 64 millimetres based on the Krumbein phi scale of sedimentology Pebbles are generally considered to be larger than granules (2 to 4 millimetres diameter) and smaller than cobbles (64 to 256 millimetres diameter)2016年12月21日 Android从44起提供基于Chromium实现的WebView。此前WebView基于WebKit实现。WebKit提供解析、布局和绘制以及JS运行等基础功能。Chromium在WebKit基础上为WebView提供进程、线程和渲染等基础构架。因此基于Chromium实现的WebView更好地提供了浏览功能。从本文开始我们启动对Android Chromium WebView的学习。Chromium ore roll mill in Grenada CSDN博客2024年9月4日 Chrome wash and beneficiation plants are essential to the production of highquality chrome ore, with various technologies available to suit different types of ore and operational requirements In South Africa, these Comprehensive Guide to Chrome Wash and 2017年6月5日 The Stillwater Complex in Montana (mainly the Benbow and Mouat deposits) contains an estimated 157 million short tons of ore containing 13 million short tons of recoverable chromiumThis represents approximately 75 percent of available domestic chromite and could supply US needs for about 4 to 5 years, but it is low in grade and has a low Flotation of Chromite Ore 911Metallurgist

.jpg)

Alluvial Chrome Ore Washing Plant Customized Quote Solution

2 Secondly, the small chromium ore from the crushing equipment is sent to the ball mill or rod mill at a uniform speed through the auxiliary equipment for effective grinding, and then the chromium ore is screened and graded by the classifier This step is to effectively filter out the impurities, to reduce the impurity content of chromium ore 3Get latest factory price for Chrome Ore Request quotations and connect with India manufacturers and B2B suppliers of Chrome Ore Page Clear All Selection petrochemical products, marine parts accessories , energy mineral equipment, timber , plant animal oil and chemicals Supplier Of Arabica Coffee India Chrome Ore Suppliers and Manufacturers go4WorldBusinessJul 05, 2021 The export of chrome ore should be implemented now and recreate the thousands of jobs already lost, such a tax would have to be implemented at differentiated rates as the cost of producing UG2 is significantly lower than the cost of traditional chrome ore mining Economic recovery in South Africa a state of emergency ug2 tailings recovery of chrome ore recovery rate Welcome to This process is secondary process in chromium ore mining process Ball mill grinds chromium ore into powder whose size is about 200300Mesh After grinding, chromium ore powder enter classifier and flotation separator Then we can get chromium ore concentrate Calcite Chromium Cone Crushers' ManufacturerCalcite Chromium Cone Crushers' Introduction PRLog

.jpg)

Development and use of screening methods to determine chromium

3 contents foreword 5 1 introduction 7 11 executive order on rohs 7 12 homogeneous materials and passivation layers 7 13 probability considerations in relation to the selection of samples 8 14 screening using xray fluorescence spectrometry (xrf) 9 2022年3月4日 Tantalum and niobium ore beneficiation coarse separation is usually used the gravity separation method, also, the flotation, electromagnetic selection and electrometallurgical separation are used in a combined process, when dealing with powder or primary mud content of ore, washing and scrubber operations are essential, while the use of highefficiency grinding NiobiumTantalum Ore Beneficiation JXSC MiningChromite ore is usually a combination of spinels with associated minerals such as calcite, magnetite, talc, serpentines and The mining of chromium ore started in India and Southern Africa around 1906 Today, roughly one third to one half of the chromite ore in the world is produced from South Africa; Kazakhstan, India, and Turkey are Chromite Ore an overview ScienceDirect Topics2018年12月28日 In this study, an optimum beneficiation route was developed for an existing concentrator that processes lowgrade chromite deposits This objective is challenging as the grade of the ore under Developing an optimum beneficiation route for a

Ultimate Guide to Gravity Separation Equipment in

2023年12月14日 ( Spiral Chute Gravity Separation Equipment in Chrome Ore Beneficiation ) Jigging Machines Jigging machines are another common gravity separation equipment utilized in chrome ore beneficiation The jigging process Chromium ore is mainly a byproduct of the production of zinc metal from sulfide ore concentrates So typical cadmium ore crushing is also the crushing of zinc ores The mined zinc ores are crushed and ground by cadmium ore crushers and cadmium mills to liberate the zinc sulfide particles from the waste host rockChromium Ore Ore Crushing Solutions DSMAC2019年5月15日 Chrome process equipment is wet type strong magnetic separator, and spiral chute (chrome spiral plant) of gravity separator 3 Experimental results and discussion 31 Chrome magnetic separation process The chrome raw ore is a flotation tail ore, which is mainly formed in the chromite, and the chromite is the target recovering mineralChrome Ore Beneficiation Process JXSC Mining2019年6月13日 The commonly used chrome ore gravity separation equipment includes shaking table and jig The selection of chrome ore beneficiation equipment shall be determined according to the different ore The main gangue minerals are quartz, calcite, chlorite and so on Mining processing solution: "Gravity and magnetic combination Questions about Chrome Ore Beneficiation Miningpedia

.jpg)

Top 5 Methods to Extract Chrome Ore Mining Pedia

2024年11月28日 1 What is Chrome Ore? Chrome ore refers to the mineral chromite, which is the only commercial source of chromium Chromite is typically found in ultramafic rocks and is extracted through various mining techniques The extracted ore is then processed to produce ferrochrome, an essential alloy used in stainless steel production 22023年10月1日 1 Introduction The international market for chromite ore (synthetic formula – FeOCr 2 O 3), the only commercially viable source of new chromium (Cr) units, is predominantly driven by the global demand for ferrochrome (FeCr)Secondary FeCr markets comprise of the Cr chemicals, abrasives, refractories, and foundry sand industries and account for a relatively Chemical beneficiation of chromite ore to improve the chromium Quartz sand is the mainly production of quartz application It is crushed by crushing plant from quartz, tridymite, cristobalite The complete quartz crushing and screening plant ensure high process efficiency, combining fieldwork with our engineering expertise results in a specific system that delivers the desired end products in a profitable wayQuartz Ore Ore Crushing Solutions DSMAC2007年5月17日 Calcium polysulfide (CaS 5) has been used for the reduction of Cr(VI) in groundwaterThe highly soluble Cr(VI) was reduced by CaS 5 to the insoluble, and nontoxic Cr(III), which was then precipitated as chromium hydroxide The highest reduction rate (70%) occurred during the first 6 months and the reductant continued to react with Cr(VI) for a total of Assessment of calcium polysulfide for the remediation of

.jpg)

Distribution and extraction of chromium from phosphate ore

2016年2月10日 To this end, the test and selection of the specific chemical reagent for efficient chromium extraction from phosphate ore were studied The effects of some parameters were taken into consideration