Titanium grinding machinery

.jpg)

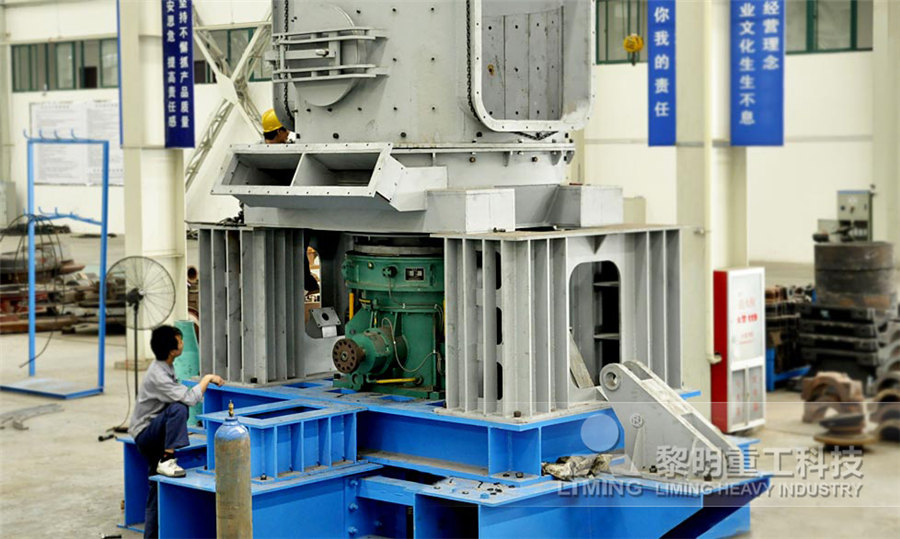

Titanium Industrial Grinding Machinery

Total Grinding Solutions (TGS) specializes in titanium industrial grinding machinery We are a Total Grinding Solutions (TGS) specializes in titanium grinders We are a worldwide manufaTitanium Grinders Total Grinding Solutions (TGS)Titanium has a strong alloying tendency or chemical reactivity with materials in the cutting tools Machining Titanium: Titanium Processing, Titanium Technical When grinding titanium, the user needs to process the material at a low cutting speed on Titanium — Klingspor Abrasive Technology

.jpg)

Titanium Machining And Cutting Kyocera SGS Europe

As a leading provider of titanium milling equipment, we are uniquely placed to help machining We produce quality titanium machined service for aerospace machining, medical machining, Titanium Grinding and PolishingTotal Grinding Solutions (TGS) specializes in titanium grinders We are a worldwide Titanium Grinders Total Grinding Solutions (TGS)When grinding titanium, the user needs to process the material at a low cutting speed on account of the specific material properties of titanium To achieve perfect stock removal results, we recommend a cutting speed of 12 15 m/s and the use of a hard contact wheelTitanium — Klingspor Abrasive Technology

.jpg)

10 Tips for Milling Titanium Kennametal

2023年5月25日 Titanium is a highly valuable and soughtafter material used in a wide range of industries, including aerospace, medical, and automotive While it offers many benefits, such as excellent strengthtoweight ratio and corrosion resistance, it is also notoriously difficult to machine, making it a challenging material for many metalworking professionalsTotal Grinding Solutions specializes in titanium milling machines In addition to providing top quality machinery at competitive prices we also provide assemblies, components, accessories, and spare parts PHoNE: 5865415300; : sales@totalgrindingsolutions;Titanium Milling Machines Total Grinding SolutionsProcessing Custom Fabrication, Cutting, Grinding More Reduce Costs with Titanium Industries View the Services that Make Us A Leading Global Distributer of Titanium Mill Products High Performance Metals [ protected] 188TITANIUM (18884826486) Shop Now My account Cart MENU MENU CREATE QUOTE;Processing Custom Fabrication, Cutting, Grinding More Titanium Total Grinding Solutions specializes in titanium grinders In addition to providing top quality machinery at competitive prices we also provide assemblies, components, accessories, and spare parts PHoNE: 5865415300Titanium Grinders Total Grinding Solutions

.jpg)

Guide To Machining Titanium Is It Really That Hard? Kingsbury

Carbidetipped tools with a PVD coating are the best suited tool for cutting titanium Newer, more advanced tool coatings are also available such as TiAIN (Titanium Aluminum Nitride) Titanium is a relatively springy material, and as such, a sharp tool is absolutely critical Blunt tools will rub the surface and cause chatter2024年6月9日 When grinding titanium, don’t skimp on cooling 5 Consider using Variable Helix End Mills CNC Milling Machine When working with titanium, variable helix tools are helpful because they can cut smoothly without noise or vibrations They help spread the cutting pressure so it doesn’t just go in one wayTop Tips for Milling Titanium Every Machinist Should KnowColloid mills provided by Zhejiang Hao Star Machinery Equipment Manufacturing Co, Ltd, specializing in manufacture of developing and making dairy equipments, food and beverage machinery, pharmaceutical and chemical machinery, and this Colloid mills matches the vertical type motor, organism and the electrical machinery joined bodies coaxial structure, therefore Colloid mill, mixer, rotor pump, emulsion pump, mixing pump, titanium Titanium Machining Guide kennametal Machining Guides • Titanium Machining Guides Alpha (α) Alloys Pure titanium and titanium alloyed with αstabilizers, such as tin and aluminum (eg, Ti5Al25Sn), are classified as αalloys They are nonheat treatable and are generally weldable They have low to mediumAerospace — Titanium Machining Guide Kennametal

Tackling Titanium: A Guide to Machining Titanium and Its Alloys

2017年8月8日 Although titanium and its alloys are often grouped together, there are some key differences between them that must be noted before determining the ideal machining approach Helical Solutions’ HVTI End Mill is a great choice for high efficiency toolpaths in Titanium2022年4月20日 11 A Subsection Sample Grinding is one of the crucial technologies to achieve the desired surface quality of the components Recently, progress in materials science has led to the development of new materials especially in the aerospace industry, where high heat resistance materials are preferred, such as Ti6Al4V and gamma titanium aluminide (γTiAl)Grinding of Titanium Alloys (Ti6Al4V) Using Vibration Assisted When grinding titanium, the user needs to process the material at a low cutting speed on account of the specific material properties of titanium To achieve perfect stock removal results, we recommend a cutting speed of 12 15 m/s and the use of a hard contact wheelTitanium — Klingspor Abrasive Technology1 Mechanical grinding: Titanium has high chemical reactivity, low thermal conductivity, high viscosity, low mechanical grinding and grinding ratio, and is easy to react with abrasives Ordinary abrasives are not suitable for titanium grinding and polishing Hard abrasives, such as diamond, cubic boron nitride, etc, the polishing linear speed is generally 900 ~ 1800m/min, otherwise, Titanium Grinding and Polishing

.jpg)

Grinding Titanium Blade Chasers

2023年8月9日 Choosing the right grinding wheel is essential when it comes to working with titanium The ideal grinding wheel for titanium should have the characteristics of hardness, toughness, and strength It should also be able to resist wear and abrasion This is especially important when grinding titanium, as the metal is extremely hard and difficult Moon Tool Die can machine, weld, and assemble any material, including various titanium grades Each series has unique performance characteristics that are worth scrutinizing when choosing Titanium for a project Titanium Grade 5 A commonly available grade of titanium Typical uses are components that require welding and fabricationTitanium CNC Machining Services Titanium Precision Parts2021年1月1日 Conventional and super abrasives perform differently in grinding titanium alloys Silicon carbide wheels were found to perform better than aluminum oxide wheels [2, 3, 7, 8] Sol gel wheels are more suitable for grinding titanium alloys than both conventional silicon carbide and aluminum oxide wheels [1]High performance grinding of titanium alloys with electroplated diamond Titanium has an endurance limit of 372 MPa (54 ksi) for the gentle grinding and values of 83 and 97 MPa (12 and 14 ksi) for conventional and abusive conditions, respectively As can be seen, in operations like end mill cutting or turning, the same sensitivity to abusive conditions was not observed, possibly due to residual surface compressive stressesMachining Titanium: Titanium Processing, Titanium Technical

Titanium Processing Equipment, Process Flow, Cases JXSC

2019年8月26日 Of the 801 types of igneous rocks analyzed by the United States Geological Survey, 784 contained titanium Its proportion of soils is approximately 05 to 15% Common titaniumcontaining minerals are anatase, brookite, ilmenite, perovskite, rutile, and titanite (sphene) Akaogiite is an extremely rare mineral consisting of titanium dioxideAcme’s Centerless Grinding Finishing Processes Heavy stock removal for rough OD belt grinding can achieve 030” 060” (075mm to 15mm) Tolerance grinding/sizing from 3 to 100 feet per minute (FPM) (10 to 300 meters per minute)Acme Centerless Grinding Machines Acme ManufacturingTotal Grinding Solutions specializes in titanium grinding machinery In addition to providing top quality machinery at competitive prices we also provide assemblies, components, accessories, and spare parts PHoNE: 5865415300; : sales@totalgrindingsolutions;Titanium Grinding Machinery Total Grinding Solutions (TGS)2020年4月28日 Rapid progress of manufacturing industry intends to evolve an appropriate method to shape advanced materials, such as titanium and its alloys, with improved properties Enhanced strength at elevated temperatures in addition to superior corrosion resistance and biocompatibility have made titanium a popular metal employed in manufacturing, petroleum, Grinding titanium alloys applying small quantity lubrication

.jpg)

Colloid mill, mixer, rotor pump, emulsion pump, mixing pump, titanium

Colloid mills provided by Zhejiang Hao Star Machinery Equipment Manufacturing Co, Ltd, specializing in manufacture of low temperature colloid mill, high temperature grinding machine, Titanium powder grinding pump, white carbon beating pump (model: shear colloid homogenizer, high shear mixed homogenization pump), wearresistant 2023年10月10日 Titanium Ore Grinding Machine: After the initial crushing process, the Titanium Ore Grinding Machine takes over to refine the ore into even smaller particles Grinding is vital for liberating the valuable titanium minerals Titanium Ore Crushing and Grinding Machine2010年6月24日 Grinding can be used for titanium alloys Compared with steels, you need to use a more gentle process From the ASM Handbook Volume 16 Machining: Wheel Grinding Selection of wheel, wheel speed, and fluid is important For hard wheel grinding, vitrified bonded wheels are the most effectiveGrinding Titanium Machines Machining engineering EngTipsTitanium HighSpeed Grinding Machine (New Colloid Mills) Hao Sar is committed to the development of large highspeed grinding machine colloidal mill Colloid Mill made great scientific and technological fruits, such as the patented new products: Multipurpose grinding machine using a special dynamic seal (using a number of patented technologies), No material may be Titanium HighSpeed Grinding Machine China Manufacturer

.jpg)

Tube Cutoff and Grinding Machines Glebar

Choosing the right machine is crucial for cutting and grinding tubes and bars Based on your application, Glebar experts can recommend several machine solutions all designed to increase efficiencies and productivity while holding even the tightest of tolerances Glebar’s Tube and Bar cutoff and grinding machines can process materials from Alumina to Zirconium, and everything Specialty Metals Processing is a boutique processor of quality metals including Titanium, Stainless Steel, Aluminum, High Nickel Alloys and more Our grinding, buffing and polishing finishes are perfect for quality critical metals Servicing flat roll and steel coil customers, SMP will help you deliver a fantastic metal finishSMP Specialty Metals Processing Grinding CompanyTitanium dioxidestone grindingmachine is a new type machine to grind Titanium dioxide Stone into super thin Powder The final Powder size can be from 5micron to 47micron as per 97% passing rate Titanium dioxide micro powder grinding mill is mainly applied to noninflammable, nonexplosive and brittle materials with Mohs hardness scale under seven, such as calcite, Titanium dioxide stone grinding machine Shanghai Clirik Machinery 2024年11月22日 Tips for titanium machining, explaining difficulties, Improving throughput in grinding takes more than direct increases to material removal rate Learn more about the variety of technology and machinery Hwacheon Machinery America, Titanium Machining Modern Machine Shop

.jpg)

Machinability of Titanium Machining Doctor

Titanium Machinability Titanium has very low heat conductivity This causes heat generated from the cut to transfer mainly to the cutting tool, instead of flowing to the chips and the workpiece Titanium has high flexibility, thus bending easily by the cutting forces Some of the popular titanium alloys have high hardnessWhen grinding titanium, the user needs to process the material at a low cutting speed on account of the specific material properties of titanium To achieve perfect stock removal results, we recommend a cutting speed of 12 15 m/s and the use of a hard contact wheelTitanium — Klingspor Abrasive Technology2023年5月25日 Titanium is a highly valuable and soughtafter material used in a wide range of industries, including aerospace, medical, and automotive While it offers many benefits, such as excellent strengthtoweight ratio and corrosion resistance, it is also notoriously difficult to machine, making it a challenging material for many metalworking professionals10 Tips for Milling Titanium KennametalTotal Grinding Solutions specializes in titanium milling machines In addition to providing top quality machinery at competitive prices we also provide assemblies, components, accessories, and spare parts PHoNE: 5865415300; : sales@totalgrindingsolutions;Titanium Milling Machines Total Grinding Solutions

.jpg)

Processing Custom Fabrication, Cutting, Grinding More Titanium

Processing Custom Fabrication, Cutting, Grinding More Reduce Costs with Titanium Industries View the Services that Make Us A Leading Global Distributer of Titanium Mill Products High Performance Metals [ protected] 188TITANIUM (18884826486) Shop Now My account Cart MENU MENU CREATE QUOTE;Total Grinding Solutions specializes in titanium grinders In addition to providing top quality machinery at competitive prices we also provide assemblies, components, accessories, and spare parts PHoNE: 5865415300Titanium Grinders Total Grinding SolutionsCarbidetipped tools with a PVD coating are the best suited tool for cutting titanium Newer, more advanced tool coatings are also available such as TiAIN (Titanium Aluminum Nitride) Titanium is a relatively springy material, and as such, a sharp tool is absolutely critical Blunt tools will rub the surface and cause chatterGuide To Machining Titanium Is It Really That Hard? Kingsbury2024年6月9日 When grinding titanium, don’t skimp on cooling 5 Consider using Variable Helix End Mills CNC Milling Machine When working with titanium, variable helix tools are helpful because they can cut smoothly without noise or vibrations They help spread the cutting pressure so it doesn’t just go in one wayTop Tips for Milling Titanium Every Machinist Should Know

.jpg)

Colloid mill, mixer, rotor pump, emulsion pump, mixing pump, titanium

Colloid mills provided by Zhejiang Hao Star Machinery Equipment Manufacturing Co, Ltd, specializing in manufacture of developing and making dairy equipments, food and beverage machinery, pharmaceutical and chemical machinery, and this Colloid mills matches the vertical type motor, organism and the electrical machinery joined bodies coaxial structure, therefore Titanium Machining Guide kennametal Machining Guides • Titanium Machining Guides Alpha (α) Alloys Pure titanium and titanium alloyed with αstabilizers, such as tin and aluminum (eg, Ti5Al25Sn), are classified as αalloys They are nonheat treatable and are generally weldable They have low to mediumAerospace — Titanium Machining Guide Kennametal2017年8月8日 Although titanium and its alloys are often grouped together, there are some key differences between them that must be noted before determining the ideal machining approach Helical Solutions’ HVTI End Mill is a great choice for high efficiency toolpaths in TitaniumTackling Titanium: A Guide to Machining Titanium and Its Alloys