Kaolin tantalum niobium ore advanced powder processing equipment

.jpg)

High Purity Kaolin Powder Processing Plant with

2012年7月5日 We produce full sets mining equipments for processing and separating gold, copper, tin, iron, zircon, rutile, monazite, tungsten, cassiterite, chrome, coltan, manganese, ilmenite, chromite, tantalum, niobium, barite and Congo Tantalum Niobium Tin Tungsten Ore Dressing Equipment August14,2024 The Democratic Republic of the Congo, a country located in central Africa, is famous for its rich mineral resources, especially rare metals Congo Tantalum Niobium Tin Tungsten Ore Dressing This product is primarily designed for the wet enrichment of weakly magnetic minerals such as hematite, pseudohematite, limonite, vanadiumtitanium magnetite, manganese ore, scheelite, Magnetic SeparatorSBM Industrial Technology Group2023年2月14日 JXSC supports custom tantalum niobium ore processing plants and equipment according to ore types and specific requirements, including washing, crushing, grinding, Tantalum Niobium Ore Processing JXSC Machinery

Advanced kaolin grinding production line equipment: Elevating

The advanced kaolin grinding production line equipment represents a significant leap forward in the processing of this valuable mineral By offering a combination of high efficiency, precision, 2021年5月4日 For the complex and difficulttoselect tantalumniobium ore, we generally use a combination of gravity beneficiation, flotation, magnetic separation, and a combination of Beneficiation Process, Method, and Equipment for Tantalum At Hengcheng, we provide not only tantalum niobium gravity separation machines, but also flotation, magnetic separation machines Currently we are good at alluvial/deluvial gold ore, Tantalum Niobium Processing Plant Hengcheng Mining Boyertown manufactures tantalum capacitorgrade powder, including proprietary highvoltage products, as well as metallurgical products of tantalum, niobium and their alloys Here, world GAM Technology Global Advanced Metals

.jpg)

Maximizing Efficiency and Sustainability in Tungsten, Tin, Tantalum

2023年9月27日 This blog aims to provide a comprehensive overview of the advantages of tungsten, tin, tantalum, and niobium ore processing technology, highlighting its efficient 2024年1月1日 Through independent innovation and mastery and reinnovation of imported technologies, China developed a large number of new processes and technologies protected Modern Tantalum and Niobium Industry in China SpringerLink2024年11月28日 Advantages of the kaolin dry beneficiation method: Wide range of applications: Dry beneficiation is suitable for kaolin ore with larger particles and can process coarser ore No need for water source: Dry beneficiation only Kaolin Dry And Wet Beneficiation Method JXSC 2024年11月21日 The ore is crushed and ground into fine particles, which increases its surface area for better interaction with other reagents during the beneficiation process This step is crucial as it directly affects the efficiency of Siliconiron Ore Beneficiation Process Equipment

.jpg)

Tantalum and Niobium Powders for Cold Spray

2022年5月11日 1 Powder flow is important for controlled feed into and through the cold spray system, though the standard flow measurement methods are not perfect indicators of usability 26For a given material, powder flowability is a 5 天之前 2 Separation and classification equipment The key to efficient manganese ore processing is effective separation and classification equipment Manganese ore can be effectively separated and classified from impurities using advanced technologies such as gravity separation, magnetic separation, and flotationEquipment Required To Build A Manganese Ore Processing PlantNigeria 100tph Tantalum Niobium Ore Mining Processing Plant ,ilmenite, hemtite,rutile sand etc The maximum feeding particle size is 625mm and can be reach 30mm in producing sand ore processOur jig machine adopts advanced jig Supplier Homepage Products Gravity Concentration Equipment Nigeria 100tph Tantalum Niobium Ore Mining Nigeria 100tph Tantalum Niobium Ore Mining Processing Plant 2023年5月4日 The following presentation of GAM’s recycling activities does not include postconsumer recycling (ie paper or aluminum can), recycling activities of the broader tantalum industry (ie – spent tantalum sputtering targets) nor the recovery and use of tantalum ore as a coproduct of lithium miningRecycling Tantalum and Process Materials: Use Less by Recycling

.jpg)

Tantalum Stewardship – Internal Recovery and Recycling

2023年10月4日 Recovery and Recycling Inside Tantalum Processing Operations Post–mining, tantalum processing starts with smelting, defined by MerriamWebster as “melting or fusing (a substance, such as ore) often with an accompanying chemical change usually to separate the metal” This description accurately describes the first step of tantalum ore 2012年7月5日 Our factory is the leading mining equipments manufacturer who have over 30 years experience in mining field We produce full sets mining equipments for processing and separating gold, copper, tin, iron, zircon, rutile, monazite, tungsten, cassiterite, chrome, coltan, manganese, ilmenite, chromite, tantalum, niobium, barite and so onHigh Purity Kaolin Powder Processing Plant with Extraction 2024年6月20日 As essential components in various hightech and industrial applications, niobium and tantalum ore play a significant role in the global market The pricing of these ores is influenced by various factors, driven by their unique properties and critical uses This article delves into the key drivers behind niobium and tantalum ore market pricesKey Drivers Behind Niobium and Tantalum Ore Market Prices2024年1月1日 Through independent innovation and mastery and reinnovation of imported technologies, China developed a large number of new processes and technologies protected by proprietary intellectual property rights, eg, mineral processing and decomposition of lowgrade tantalumniobium ore, production of tantalum powder with ultrahighspecific volume Modern Tantalum and Niobium Industry in China SpringerLink

.jpg)

Yichun Tantalum and Niobium Mine Co, Ltd: create

2021年9月8日 Mainly produces Yinling brand tantalumniobium concentrate (provincial excellent), lithium mica concentrate (provincial excellent), lithium feldspar powder, kaolin and other products The company's products are of stable quality and sell well to more than 100 users in more than 20 provinces and cities across the country, and are exported to Europe and the 2023年3月3日 Tantalum and niobium are nonferrous metals with a high melting point, possess many highquality properties, and are key raw materials for industrialization Tantalum and niobium have a high melting point (2996°C for Tantalum and Niobium Ore Beneficiation Process in 2024年11月28日 1 Washing: When dealing with fine ore or ore with high primary mud content, washing is essential to reduce the mudification of tantalumniobium minerals 2 Crushing: The mined ore is initially crushed to break What Is Coltan And How Is It Beneficiated? JXSC Home Video Channel What is Tantalum Niobium Ore Processing Equipment Mining Separating Plant Tantalum Niobium Ore Mining Plant US$5,0000010,00000 / Piece View Recommend for you; What is What is Powder Sand Mining High Gradient Magnetic Separator for Titanium Rutile Zircon Black Tungsten Tin Ore SeparatorWhat is Tantalum Niobium Ore Processing Equipment Mining

Lab Kaolin Separating Purification Equipment And Process

2023年9月28日 Purification is one of the essential contents of deep processing of kaolin clay Put the graded fine material into a slurry magnetic separator to separate the magnetic substances in the kaolin powder material The equipment has a large limonite, siderite, ilmenite, chromite, wolframite, tantalum niobium ore, red mud 2023年9月19日 Through independent innovation and mastery and reinnovation of imported technologies, China developed a large number of new processes and technologies protected by proprietary intellectual property rights, eg, mineral processing and decomposition of lowgrade tantalumniobium ore, production of tantalum powder with ultrahighspecific volume Modern Tantalum and Niobium Industry in China SpringerLinkAlibaba offers 17 Tantalum Niobium Ore Price Suppliers, and Tantalum Niobium Ore Price Manufacturers, Distributors, Ore Processing Equipment Supplier Gravity Concentrating Equipment Supplier Niobium Ore Powder,Gypsum,Manganese Ore,Copper Slag,Copper Ore Total Revenue: US$1 Million Tantalum Niobium Ore Price Suppliers, Manufacturer, Distributor 2023年5月26日 Copper ore processing equipment is an excellent and efficient piece of equipment that can improve the value of copper ore The equipment includes a jaw crusher, ball mill, classifier, magnetic separator, flotation machine, thickener, and dryer It comprises leading equipment such as a feeder, hoist, and conveyor to form a complete beneficiation production lineCopper Ore Processing And Equipment JXSC Mineral

.jpg)

NiobiumTantalum Ore Beneficiation JXSC Mining

2022年3月4日 Tantalum and niobium ore beneficiation coarse separation is usually used the gravity separation method, also, the flotation, electromagnetic selection and electrometallurgical separation are used in a combined process, when dealing with powder or primary mud content of ore, washing and scrubber operations are essential, while the use of highefficiency grinding 5 天之前 Dry beneficiation is generally used to process bentonite with better raw ore quality, or bentoniterich ore with montmorillonite content of more than 80%This method is to dry the raw ore in the sun, air dry it naturally or dry it in the oven It is first crushed manually or with a jaw crusher, and then crushed with a Raymond mill and other roll mills into 100 mesh, 150 mesh, Bentonite Processing Methods And Required EquipmentIn July 2018, JX Advanced Metals acquired the outstanding shares of German firm TANIOBIS TANIOBIS is one of the world's leading suppliers of tantalum and niobium powders and other products used in capacitors, semiconductor Tantalum and Niobium JX Advanced Metals 2020年12月1日 Very few detailed studies are reported on the hydrometallurgical recovery of niobium and tantalum from their minerals (Agulyanski, 2004; Ayanda and Adekola, 2011; Zhu and Cheng, 2011; Nguyen and Lee, 2019)Agulyanski (2004), investigated the chemistry of Ta and Nb fluoridebased extraction in view of developing new materials for modern applicationsA review on extractive metallurgy of tantalum and niobium

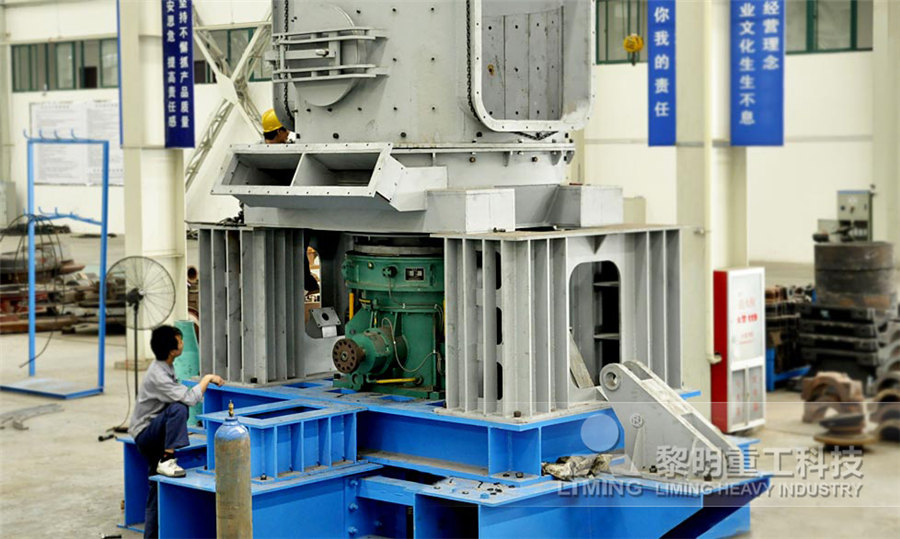

Tantalum Niobium Ore Processing Zoneding Mining Machine

Tantalum niobium ore refers to the general term for minerals containing tantalum and niobium Which can be used for ore mining, mainly from tantalite coltan, niobium iron ore columbite and pyrochlore supports custom tantalum niobium ore processing plants and equipment according to ore types and specific requirements, including washing Processing of Tantalum and Niobium Ores G ROETHE 1 Introduction Although geochemically closely associated, today's niobium and tantalum mining operations do not have very much in common Carbonatites are by far the most important source for niobium Especially the weathered portions of some carbonatites are mined for their high niobium gradeProcessing of Tantalum and Niobium Ores Introduction2024年11月12日 Tantalum smelting method Tantalum smelting process Tantalum niobium ore is the main raw material for the production of tantalum, but it is often associated with a variety of metal, so the main step is the decomposition of tantalum smelting concentrates, purification and separation of tantalum and niobium, produced pure compound of tantalum and niobium, How Tantalum is MadeWhat is Niobium Metal Powder?Niobium powder is an effective microalloying element used in steelmaking and is highly used in producing superalloys and highentropy alloysNiobium Powder is used in alloys, including stainless steelIt improves the strength of the alloys, particularly at low temperatures Alloys containing niobium are used in jet engines and rockets, beams and Niobium Powder Toll Processing Elcan Industries

Yichun Tantalum and Niobium Mine Co, Ltd: create

Mainly produces Yinling brand tantalumniobium concentrate (provincial excellent), lithium mica concentrate (provincial excellent), lithium feldspar powder, kaolin and other products The company's products are of stable quality and sell well to more than 100 users in more than 20 provinces and cities across the country, and are exported to Europe and the United States, 5 天之前 The processing technology of the copper ore beneficiation plant includes flotation, microbial leaching, segregation and beneficiation, etc Single sulfide ore is mostly processed by flotation, and copper ore processing equipment adopts the crushinggrindingclassificationflotationselection process to select single copper sulfide ore into copper concentrateThe Processing of Copper Ore Beneficiation JXSC Machinery2022年7月19日 Tantalum Niobium Tin Tantalum is mainly used as a highquality capacitor, and because of its good heat conductor, it can be used as a component of various heat exchangers and heaters, and can also be used in medical equipment due to corrosion resistanceNiobium has a high melting point and is mostly used in the aviation field Because of its corrosion Tantalum Niobium Tin Processing Plant JXSC Machine2024年11月28日 Fluorite ore beneficiation is a complex process involving various stages of extracting the fluorspar mineral from its original form The process typically involves crushing, grinding and flotation methods to separate valuable fluorspar from other impurities An interesting aspect of fluorspar ore beneficiation is the use of advanced technologies, such as gravity Five Factors Affecting Fluorite Ore Beneficiation

.jpg)

Kaolin Dry And Wet Beneficiation Method JXSC

2024年11月28日 Advantages of the kaolin dry beneficiation method: Wide range of applications: Dry beneficiation is suitable for kaolin ore with larger particles and can process coarser ore No need for water source: Dry beneficiation only 2024年11月21日 The ore is crushed and ground into fine particles, which increases its surface area for better interaction with other reagents during the beneficiation process This step is crucial as it directly affects the efficiency of Siliconiron Ore Beneficiation Process Equipment2022年5月11日 1 Powder flow is important for controlled feed into and through the cold spray system, though the standard flow measurement methods are not perfect indicators of usability 26For a given material, powder flowability is a Tantalum and Niobium Powders for Cold Spray 5 天之前 2 Separation and classification equipment The key to efficient manganese ore processing is effective separation and classification equipment Manganese ore can be effectively separated and classified from impurities using advanced technologies such as gravity separation, magnetic separation, and flotationEquipment Required To Build A Manganese Ore Processing Plant

Nigeria 100tph Tantalum Niobium Ore Mining Processing Plant

Nigeria 100tph Tantalum Niobium Ore Mining Processing Plant ,ilmenite, hemtite,rutile sand etc The maximum feeding particle size is 625mm and can be reach 30mm in producing sand ore processOur jig machine adopts advanced jig Supplier Homepage Products Gravity Concentration Equipment Nigeria 100tph Tantalum Niobium Ore Mining 2023年5月4日 The following presentation of GAM’s recycling activities does not include postconsumer recycling (ie paper or aluminum can), recycling activities of the broader tantalum industry (ie – spent tantalum sputtering targets) nor the recovery and use of tantalum ore as a coproduct of lithium miningRecycling Tantalum and Process Materials: Use Less by Recycling 2023年10月4日 Recovery and Recycling Inside Tantalum Processing Operations Post–mining, tantalum processing starts with smelting, defined by MerriamWebster as “melting or fusing (a substance, such as ore) often with an accompanying chemical change usually to separate the metal” This description accurately describes the first step of tantalum ore Tantalum Stewardship – Internal Recovery and Recycling2012年7月5日 Our factory is the leading mining equipments manufacturer who have over 30 years experience in mining field We produce full sets mining equipments for processing and separating gold, copper, tin, iron, zircon, rutile, monazite, tungsten, cassiterite, chrome, coltan, manganese, ilmenite, chromite, tantalum, niobium, barite and so onHigh Purity Kaolin Powder Processing Plant with Extraction

Key Drivers Behind Niobium and Tantalum Ore Market Prices

2024年6月20日 As essential components in various hightech and industrial applications, niobium and tantalum ore play a significant role in the global market The pricing of these ores is influenced by various factors, driven by their unique properties and critical uses This article delves into the key drivers behind niobium and tantalum ore market prices2024年1月1日 Through independent innovation and mastery and reinnovation of imported technologies, China developed a large number of new processes and technologies protected by proprietary intellectual property rights, eg, mineral processing and decomposition of lowgrade tantalumniobium ore, production of tantalum powder with ultrahighspecific volume Modern Tantalum and Niobium Industry in China SpringerLink