Y limestone g ore mill

.jpg)

Limestone Grinding Mill Plant TAYMACHINERY

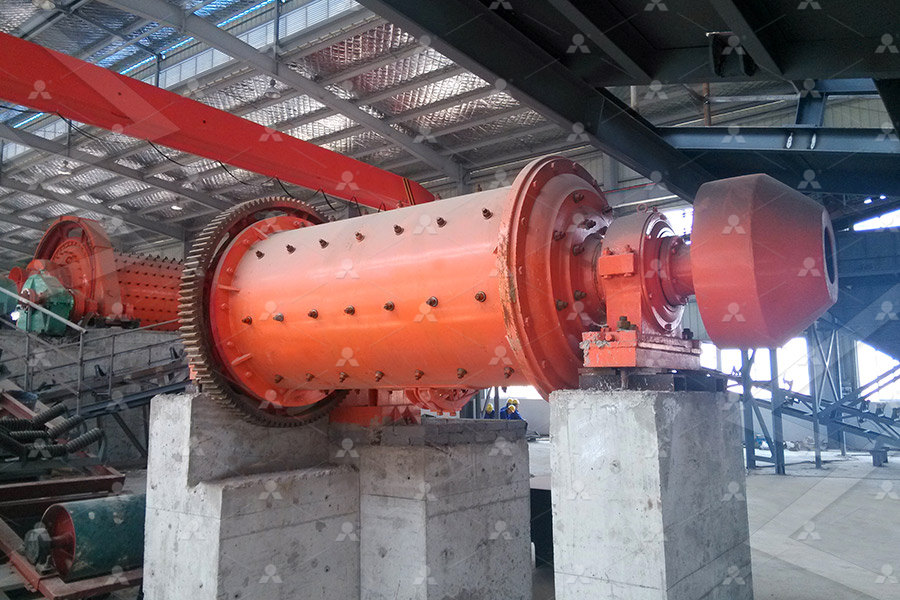

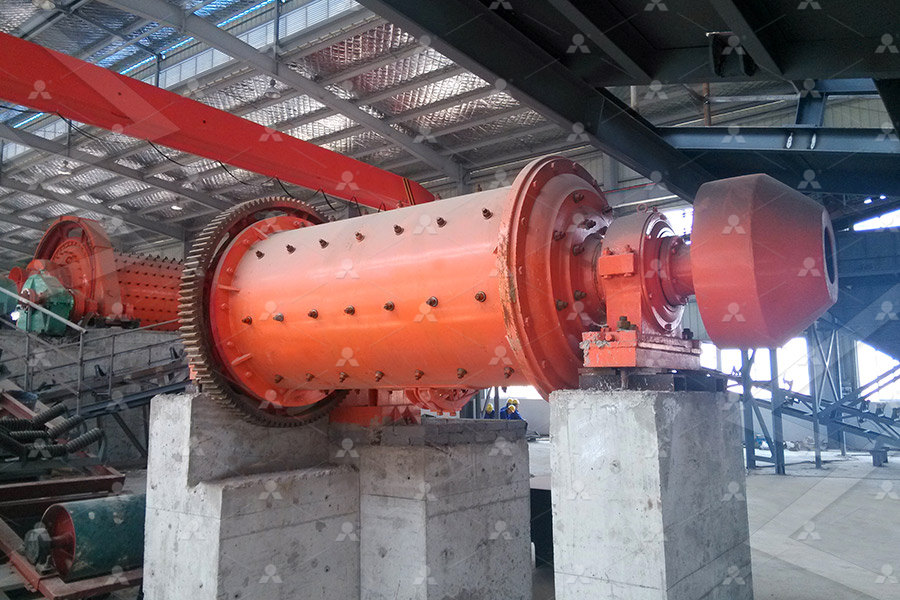

A Limestone Grinding Mill Plant is a facility designed to process limestone into fine powder for various applications Limestone is a sedimentary rock primarily composed of calcium The limestone grinding production line grinds limestone into powders of different fineness through crushing, grinding, classification, and other processes to meet the needs of different fields Limestone Grinding Mill Plant TAYMACHINERYLimestone powder grinding mills offer several advantages, including: Efficient grinding: Limestone powder grinding mills are designed to provide efficient and precise grinding of limestone into Limestone Mills CM Mining MachineryLimestone grinding mill is mainly suitable for ultrafine powder processing of noninflammable and explosive brittle materials with medium and low hardness and Mohs hardness ≤6, such as Limestone grinding mill Hengtu Machinery

Limestone crushing plant, limestone grinding mill production line

The proposed limestone crusher is Impact Crusher, it can crush the material from 1m to –25 mm size The crushed limestone will be sent by a belt conveyor to vibrating screen becoming final 2023年9月19日 A limestone grinding mill is a machine used for grinding limestone into powder It is a mechanical device that grinds materials into powders by friction, crushing, and grinding to Limestone Grinding Mill That You Need To Know Mortar PlantLimestone grinding mill is a kind of equipment specially used for processing nonmetallic minerals such as limestone Its main function is to grind limestone raw materials into the required fine Limestone Processing MachineLimestone Grinding Mill Machine2024年1月18日 Highquality limestone, after ultrafine grinding, is widely used in the production of paper, rubber, paint, coatings, pharmaceuticals, cosmetics, feed, sealing, bonding, polishing, How to choose a limestone grinding mill SANDMINE

.jpg)

Limestone mill, Limestone grinding mill All DirectIndustry

Find your limestone mill easily amongst the 34 products from the leading brands (SIEBTECHNIK, Liming, NEUE HERBOLD, ) on DirectIndustry, the industry specialist for your professional 2024年1月29日 As limestone powder has numerous applications across various industries, selecting the appropriate limestone grinding machine is essential The choice depends on How to choose limestone grinding mill? SANDMINE2023年4月13日 The effect of ball size and interstitial filling on the performance of dry ball mill grinding was investigated for a limestonetype brecciated uranium ore The optimum grinding was obtained with the combination of different balls (127–375 mm) and interstitial filling of 50% (20% ball filling ratio at fixed material filling ratio = 4%) The net power consumption in a ball mill is Optimization of Ball Mill Grinding of a LimestoneType Brecciated The limestone grinding production line is a production process for the fine processing of limestone raw materials The limestone grinding production line grinds limestone into powders of different fineness through crushing, grinding, classification, and other processes to meet the needs of different fields This production line covers the complete process from raw material processing Limestone Grinding Mill Plant TAYMACHINERY

Ore mill, Ore grinding mill All industrial manufacturers

Find your ore mill easily amongst the 42 products from the leading brands (Fritsch GmbH, Retsch, Eriez, ) on DirectIndustry, the industry specialist for your professional purchases horizontal for limestone stone ball grinding mill Ф2200×7500 Final grain size: 74 µm 400 µmOre Powder Making Machine Raymond Roller Grinding Mill for Bartite Limestone Gypsum Powder Production Plant US$7,00000158,00000 / Set 1 Set (MOQ)Ore Powder Making Machine Raymond Roller Grinding Mill for P a g e 6 Journal of Petroleum and Mining Engineering Effect of Partial Replacement of Iron Ore by Mill Scale on the Sinter Process Saleh, A B,*a, Kahlifa bM G b and Abd Elmomen S S a Egyptian Iron and Steel Company b Tabbin Institute for Metallurgical Studies Tabbin, Egypt, PO Box: 109 Helwan11421 CairoEffect of Partial Replacement of Iron Ore by Mill Scale on the 2017年12月21日 (a) Acidic iron ore pellet without mill scale (b) Acidic iron ore pellet with 15% mill scale Figure 6 Effect of mill scale on apparent porosity in acidic pellet(PDF) Mill scale as a potential additive to improve the quality

Conceptual kinetic study for the catalytic effect of limestone on mill

2021年1月22日 When the limestone mixed with coal in the crucible, it was referred to as coal mixture (coal + limestone) in this research work So the total weight of coal mixture required for reduction 15 g mill scale will be 195 g coal +15 g limestone, which equals to 21 g coal mixtureand interstitial lling on the performance of dry ball mill grinding was also investigated for a limestonetype brecciated uranium ore The ball mill grinding was modeled by the combined use of the matrix and the PBM The breakage function was determined by the BII method Monosize fraction for the determination of was avoided, and SOptimization of Ball Mill Grinding of a Limestone‐Type Brecciated Clirik Stone Ultra Mill included limestone ultra grinding mill,gypsum ultra mill,calcite ultra fine mill and so onthe stone ultra mill is widely uesed for kinds of Hot Sales: HGM Ultra Fine Grinding Mill, Ultra Fine Grinder for Ore, YGM Raymond Mill, CLUM Ultrafine Vertical Mill ABOUT US China famous professional manufacturer of Stone Ultra MillLimestone Ultra Grinding Mill,Gypsum Ultra Mill fractions of iron ore fines, slime, and mill scale used in the study are shown in Table 1 Raw materials were ground to around 2200 cm 2/g Blaine fineness as per the optimized value for the same ore in our previous study [16 ] Their particle size distribution is given in Table 2 Fluxes including limestone, olivine, and bentonite were ground Development of hematite ore pellet utilizing mill scale and iron ore

Effect of Partial Replacement of Iron Ore by Mill Scale on the

P a g e 6 Journal of Petroleum and Mining Engineering Effect of Partial Replacement of Iron Ore by Mill Scale on the Sinter Process Saleh, A B,*a, Kahlifa bM G b and Abd Elmomen S S a Egyptian Iron and Steel Company b Tabbin Institute for Metallurgical Studies Tabbin, Egypt, PO Box: 109 Helwan11421 CairoType Group Sub Group Iron ore % Mill scale % Olivine % Limestone % Bentonite % Desired MgO % Desired Basicity (CaO/SiO 2) Basic A A1 9658 0 2 092 05 1 015 A2 9565 0 2 185 05 1 03Mill scale as a potential additive to improve the quality of 1830×3000 Limestone Quartz Ball Mill Machine new Manufacturer: Liming 1830×3000 Ball mill is common used grinding plant in the industry, and it is key equipment used for milling after materials are crushed This machine can be can grind all kinds of ores and other materials, which Used Limestone Grinding Mills for sale Raymond equipmentWet / Dry Grinding Machine 900X1800 1200X2400 Limestone Small Ball Mill Price, Find Details and Price about Gold Mill Gold Ore Processing Plant from Wet / Dry Grinding Machine 900X1800 1200X2400 Limestone Small Ball Mill Price Baichy Heavy Industrial Machinery Co, LtdWet / Dry Grinding Machine 900X1800 1200X2400 Limestone Small Ball Mill

Mill Circuit Pump Manual 911 Metallurgist

crushed ore is fed into a SAG/Ball mill circuit with a median size of approximately 12,000 microns Most SAG Mills are operated in closed circuit with a screen The screen fi lters undersized ore, normally minus ½ inch, to a ball mill discharge sump The combined mill dischargRock Limestone Glass Clay Ore Hummer Crusher Gold Hammer Mill Supplier Coal Crusher Price US$1,400009,90000 1 Set (MOQ)Rock Limestone Glass Clay Ore Hummer Crusher Gold Hammer Mill The raw materials used for the preparation of the green pellets are iron ore, mill scale, limestone, bentonite and Corex sludge and their chemical composition is given in Table 1 Iron ore fines of –10 mm size and mill scale of –6 mm were ground together in laboratory ball mill to get the required finenessRecycling of steel plant mill scale via iron ore sintering plantChina Limestone Grinding Mill wholesale Lab Mineral Wet / Dry 06 1 Ton/Hr 2 Ton 5tphore Grinding Pulverizer Grinding Used Ball Mill Price for Gold Mining Copper Ore Test Limestone Powder US$ 15003250 / Set 1 Set (MOQ) Zhengzhou Zhongjia Heavy Industry Co, LtdLimestone Grinding Mill MadeinChina

.jpg)

Limestone grinding mill Hengtu Machinery

Limestone grinding mill is mainly suitable for ultrafine powder processing of noninflammable and explosive brittle materials with medium and low hardness and Mohs hardness ≤6, such as calcite, chalk, limestone, calcite, carbon black, kaolin, bentonite, talc, mica, magnesite, illite, pyrophyllite, vermiculite, sepiolite, attapulgite, rectorite, diatomaceous earth, calcite, gypsum, alum Gulin Least News suger mini mill plant photo » The More » chromate, chrome ore and soda ash, dolomite or limestone » environmental effects of limestone ore » m sand manufacture in coimbatore » austin g t shreve’s chemical process industries pdf » limestone minig process and material saving Contact Us Tel: 8621; Office Add: Pudong New Area, Shanghai, environmental effects of limestone ore – Grinding Mill ChinaPowder Grinding Mills engineered by FTM mainly include Raymond mill, ultrafine mill, bucket elevator Materials with humidity below 8%, such as nonmetallic minerals (eg, limestone, gypsum, calcium carbonate, barite Applicable Powder Grinding Mills Engineered by FTM Fote A Limestone Grinding Mill Plant is a facility designed to process limestone into fine powder for various applications Limestone is a sedimentary rock primarily composed of calcium carbonate (CaCO₃) and is widely used in industries such as construction, agriculture, and manufacturingLimestone Grinding Mill Plant TAYMACHINERY

.jpg)

Development of hematite ore pellet utilizing mill scale and iron ore

fractions of iron ore fines, slime, and mill scale used in the study are shown in Table 1 Raw materials were ground to around 2200 cm 2/g Blaine fineness as per the optimized value for the same ore in our previous study [16 ] Their particle size distribution is given in Table 2 Fluxes including limestone, olivine, and bentonite were ground 2023年12月15日 White mud (WM) is a solid waste that is generated when an Na 2 CO 3 solution reacts with CaO to regenerate NaOH during the caustic reaction in the alkali recovery process of paper (ie, pulp) mills Approximately 2 tons of dry WM is obtained for each ton of NaOH regenerated by the pulp mill (Cheng et al, 2009a)The main component of waste WM is A new disposal method for white mud: Replacing limestone in iron ore 2022年9月1日 A conceptual diagram with considerations for selecting minetomill ore it identifies attributes that contribute to the realised value of a resource and enables eg ore Measurement and analysis by Reichholf, 2013, Iravani et al, 2020 showed that for iron ore, magnesite and limestone, around 50 % Towards waterless operations from mine to mill ScienceDirectIntroduction Limestone is a sedimentary rock composed mainly of calcium carbonate (CaCO3) that is widely used in various industries, such as cement, agriculture, construction, and chemicals The process of extracting limestone and grinding it into powder requires the use of specialized machinery One such machine is the limestone powder grindingLimestone Mills CM Mining Machinery

OPTIMIZATION OF LATERITE ORE GRINDING PROCESS USING BALL MILL

2022年12月31日 He, and Y Li, "Grinding kinetics of quartz and chlorite Optimization of Laterite Ore Grinding Process/ Gyan Prameswara 123 in wet ball milling," Powder Technology, vol 305, pp 418425, 2017The official 2013 Men's Lacrosse Roster for the Limestone University Saints Skip To Main Content Md / Old Mill HS: 20: Corey Rich: A: Sr 511: 189: Sacramento, Calif / Amherst HS: 21: Christian Vadala: D: Jr 60: 204: Ore Hood River Valley HS Men's Lacrosse Roster Limestone University Athletics2018年1月1日 Development of hematite ore pellet utilizing mill scale and iron ore slime combination as additive January 2018; limestone, olivine, and bentonite were ground to lessDevelopment of hematite ore pellet utilizing mill scale and iron ore 2022年5月22日 limestone sample in the Bond mill was 11245 kg and the proportion by weight of 50–50 g limestone samples from the 063–125 The literature showed that during ore processing, EnergyModel and Life CycleModel for Grinding Processes of Limestone

.jpg)

Optimization of Ball Mill Grinding of a LimestoneType Brecciated

2023年4月13日 The effect of ball size and interstitial filling on the performance of dry ball mill grinding was investigated for a limestonetype brecciated uranium ore The optimum grinding was obtained with the combination of different balls (127–375 mm) and interstitial filling of 50% (20% ball filling ratio at fixed material filling ratio = 4%) The net power consumption in a ball mill is The limestone grinding production line is a production process for the fine processing of limestone raw materials The limestone grinding production line grinds limestone into powders of different fineness through crushing, grinding, classification, and other processes to meet the needs of different fields This production line covers the complete process from raw material processing Limestone Grinding Mill Plant TAYMACHINERYFind your ore mill easily amongst the 42 products from the leading brands (Fritsch GmbH, Retsch, Eriez, ) on DirectIndustry, the industry specialist for your professional purchases horizontal for limestone stone ball grinding mill Ф2200×7500 Final grain size: 74 µm 400 µmOre mill, Ore grinding mill All industrial manufacturersOre Powder Making Machine Raymond Roller Grinding Mill for Bartite Limestone Gypsum Powder Production Plant US$7,00000158,00000 / Set 1 Set (MOQ)Ore Powder Making Machine Raymond Roller Grinding Mill for

.jpg)

Effect of Partial Replacement of Iron Ore by Mill Scale on the

P a g e 6 Journal of Petroleum and Mining Engineering Effect of Partial Replacement of Iron Ore by Mill Scale on the Sinter Process Saleh, A B,*a, Kahlifa bM G b and Abd Elmomen S S a Egyptian Iron and Steel Company b Tabbin Institute for Metallurgical Studies Tabbin, Egypt, PO Box: 109 Helwan11421 Cairo2017年12月21日 (a) Acidic iron ore pellet without mill scale (b) Acidic iron ore pellet with 15% mill scale Figure 6 Effect of mill scale on apparent porosity in acidic pellet(PDF) Mill scale as a potential additive to improve the quality 2021年1月22日 When the limestone mixed with coal in the crucible, it was referred to as coal mixture (coal + limestone) in this research work So the total weight of coal mixture required for reduction 15 g mill scale will be 195 g coal +15 g limestone, which equals to 21 g coal mixtureConceptual kinetic study for the catalytic effect of limestone on mill and interstitial lling on the performance of dry ball mill grinding was also investigated for a limestonetype brecciated uranium ore The ball mill grinding was modeled by the combined use of the matrix and the PBM The breakage function was determined by the BII method Monosize fraction for the determination of was avoided, and SOptimization of Ball Mill Grinding of a Limestone‐Type Brecciated

Stone Ultra MillLimestone Ultra Grinding Mill,Gypsum Ultra Mill

Clirik Stone Ultra Mill included limestone ultra grinding mill,gypsum ultra mill,calcite ultra fine mill and so onthe stone ultra mill is widely uesed for kinds of Hot Sales: HGM Ultra Fine Grinding Mill, Ultra Fine Grinder for Ore, YGM Raymond Mill, CLUM Ultrafine Vertical Mill ABOUT US China famous professional manufacturer of fractions of iron ore fines, slime, and mill scale used in the study are shown in Table 1 Raw materials were ground to around 2200 cm 2/g Blaine fineness as per the optimized value for the same ore in our previous study [16 ] Their particle size distribution is given in Table 2 Fluxes including limestone, olivine, and bentonite were ground Development of hematite ore pellet utilizing mill scale and iron ore