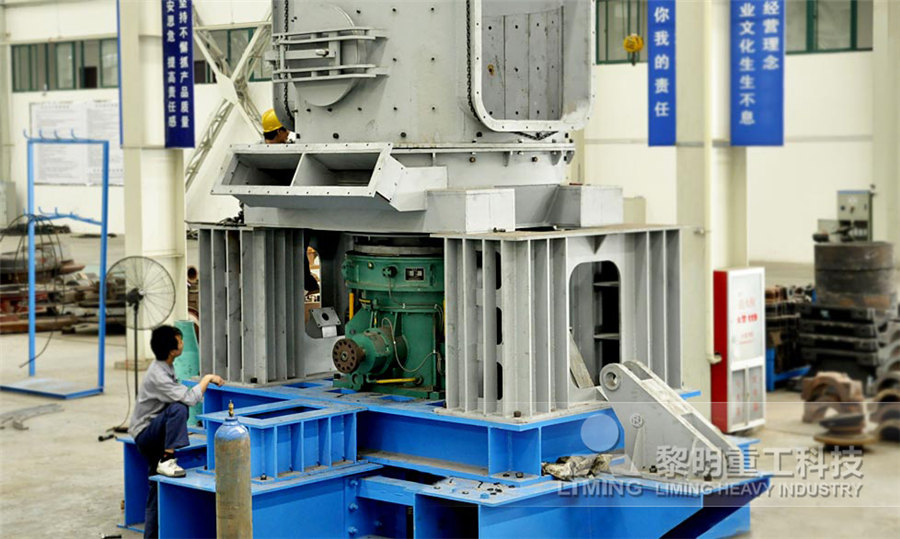

Pictures of foreign highfine vertical grinding mills

Vertical mills for fine grinding – FLS

Vertical mills such as the FLS Tower Mill or the VXPmill and ball mills are commonly used for fine grinding in industries like mining, cement, and chemical processing These mills reduce material into finer particles, making them ideal LUM Ultrafine Vertical Mill is the specialized ultrafine grinding equipment for nonmetallic ores LUM Ultrafine Vertical MillVertical Powder GrinderClirik Wide range of the fine grinding Simple control of product grading Stable auto operation Mill Roller Mill KOTOBUKI ENG MFGCo,LtdIn the LUM Ultrafine Vertical Grinding Mill, the contact point between roller shell and millstone liner plate adopts electronic limiting technology and mechanical limiting protection technology, which can avoid the destructive impact (eg the LUM Ultrafine Vertical Grinding MillSBM Industrial

Grinding Mill ultrafine grinding mill, vertical ultrafine mill

LUM Ultrafine Vertical Mill Input Size: 020mm Output Size: 3252500 mesh LEARN MORE Hammer SBM has developed all kinds of coarse, fine and ultrafine grinding mills to meet customers'demands for powder production from coarse powder(03mm),fine After crushing limestone with high calcium content and meets the requirements for A Vertical Roller Mill (VRM) is an advanced and efficient grinding machine commonly used in the cement industry for grinding raw materials and clinker VRMs have become increasingly popular due to their ability to produce finer products with lower energy consumption compared to traditional ball mills Advantages of Vertical Roller Mills:Vertical roller mill vs ball mill for cement grinding: Comparison Ultrafine vertical roller mill is a new type of vertical roller mill suitable for grinding nonmetallic ultrafine powder, which is developed by improving the existing vertical roller mill technology on the basis of absorbing the advantages of Ultrafine vertical roller mill SBM Ultrafine Powder The Vertical Grinding Mill is now CEapproved For very fine grinded coffee on our Diamant Vertical mills, we can supply the mills with special coffee stones in the size 400 mm and 500 mm Our mill in size 400 mm is available in a special version for milling oily products for example mustard – it must be dry and not wetDiamant Vertical Grinding Mill Engsko

.jpg)

Picture: Loesche GmbH, Germany CEMENT SikaGrind® FOR VERTICAL ROLLER MILL

A high content of very fine particles on the grinding track usually affects the stability of the grinding bed Fine particles lower the interparticle friction, which reduces the grinding efficiency Fine particles on the grinding table cause disruption with compaction and deaeration, resulting in vibration and higher wear of the equipment2020年8月12日 Tontu [14] investigated the relationships between the current, coal feed, grinding pressure, and primary air and outlet temperatures of coal mills, and proved that a high correlation exists An investigation of performance characteristics and energetic The major design features of the tower mill are (1) a central agitator screw, the only moving machine component in contact with the slurry and steel media, and (2) the vertical grinding chamber which minimizes overgrinding of the product This arrangement reduces energy consumption in fine grinding of minerals by 25% to 50% when compared to traditional Vertical mills for fine grinding – FLSCLUM ultrafine vertical mill is a new type of ultrafine grinding equipment integrating powder grinding, grading, conveying, secondary powder selection, and finished product packaging Capacity: 0245 t/h Max feeding size: 30mm Processing ability: 0245 t/h Application of CLUM ultrafine vertical mill:CLUM Ultrafine Vertical Mill

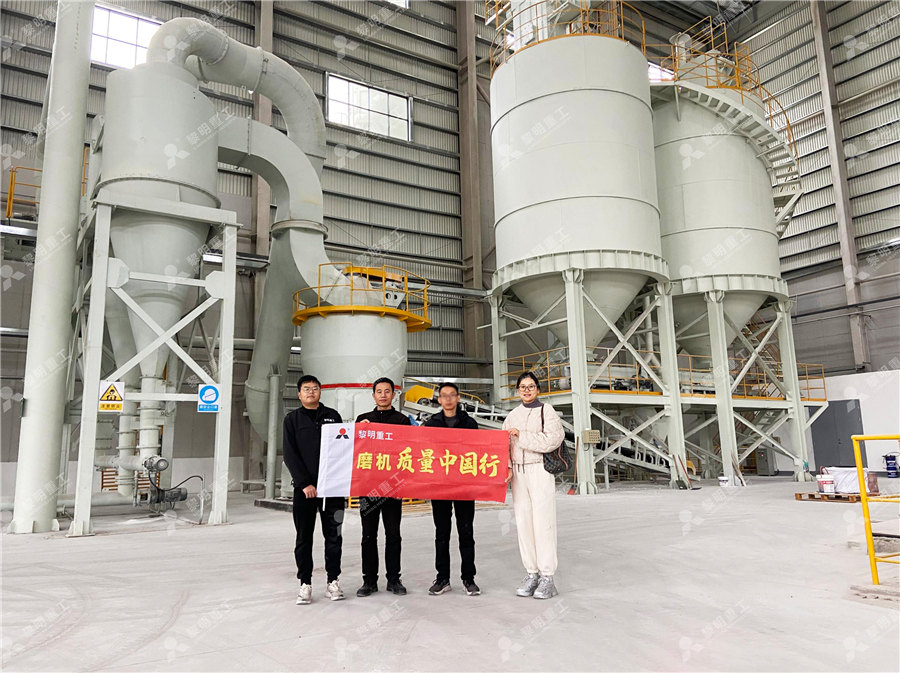

OMYA Group Signed The HLMX1700 Superfine Vertical Grinding Mill

The introduction of Superfine HLMX1700 Ultrafine Vertical Grinding Mill: Max feeding size: 20mm Capacity: 440t/h Fineness: 3252500 mesh HLMX Superfine Vertical Grinding Mill is largescale nonmetal mineral superfine powder mill developed by Hongcheng based on HLM vertical roller mill and introduction of foreign advanced technologyNewtype Pneumatic Ultra Fine Grinding Mill (Jet Mill) Cross Jet Mill; Compact Jet Mill and Separator Combined System Kurimoto Pocket Jet; Vertical Super Fine Grinding Mill (Vertical Roller Mill) VX Mill; Fine Grinding Mill (Centrifugal Roller Mill) Kurimoto Roller Mill; Batch Type Highspeed Planetary Mill Kurimoto High GVertical Super Fine Grinding Mill (Vertical Roller Mill) VX Mill Aquí nos gustaría mostrarte una descripción, pero el sitio web que estás mirando no lo permiteLUM Ultrafine Vertical Grinding Mill sbmchinaProduct overview of limestone powder ultrafine vertical roller mill The limestone powder ultrafine vertical roller mill is mainly used in the production of limestone powder The Ultrafine vertical mill integrates crushing, drying, grinding and Limestone Powder Ultrafine Vertical Roller Mill

.jpg)

Atlas Vertical Roller Mill NETZSCH Grinding Dispersing

Consult NETZSCH Grinding Dispersing's entire Atlas Vertical Roller Mill catalogue on DirectIndustry Page: 1/4 Exhibit with us Atlas Vertical Roller Mill for Fine Products MINERALS MINING a Business Field of NETZSCH Grinding Disperse NETZSCH Highefficiency Fine Classifier CFS/HDS 8 Pages NETZSCH Fine Classifier CFS1 What is a Vertical Grinding Mill? The Vertical Grinding Mill (VGM) is an upright steel vessel with an inlet, an outlet and a central portion of the inlet It is used for fine size reduction when output to input reduction required is large These mill crushers consist of a reducing rotating mill for size reduction The whole closed circuit is Vertical Grinding Mill: How it Works, Application And AdvantagesBased on this and adopted with German and China Taiwan superfine vertical grinding technology, Dongguan Vsunny Machinery Co, Ltd developed the VSCM series coarse vertical grinding mill It use the highclass wearresistant parts, and the fineness of ground powder product will be from 60~500 meshesVSCM SERIES COARSE VERTICAL GRINDING MILL2017年9月11日 PDF In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg Samples were collected from Find, read and cite all the research (PDF) Performance Evaluation of Vertical Roller Mill in Cement Grinding

SikaGrind® for vertical roller mills

4 SikaGrind® FOR VERTICAL ROLLER MILLS Pilot Mill (Picture: Loesche GmbH, Germany) The production of Portland Cement (OPC, CEM I) A high content of very fine particles on the grinding track usually troubles the stability of the grinding bed Fine particles lower the interparticle friction, which reduces the grindingDouble Positionlimiting Technology In the LUM Ultrafine Vertical Grinding Mill, the contact point between roller shell and millstone liner plate adopts electronic limiting technology and mechanical limiting protection technology, which can avoid the destructive impact (eg the grinding roller directly smashing the millstone) caused by machine vibration (eg machine vibration caused LUM Ultrafine Vertical Grinding MillSBM Industrial Technology 2022年10月10日 The crushed small pieces of clay are sent to the silo by the elevator, and then sent to the grinding chamber of the mill evenly and quantitatively by the vibrating feeder for grinding Raymond mill and YGM high pressure mill are generally used for fine powder processing; CLUM ultrafine vertical mill and HGM ring roller micropowder mill is Clay ultrafine grinding millCLUM Series Ultrafine Powder Vertical Roller Grinding Mill is used for the processing of ultrafine powder of nonmetallic mineralsForexample,calcite,marble,limestone,barite,talc,kaolin,wollastonite,gypsum,feldspar,etc CLIRIK CLUM Series Ultra Fine Vertical Roller Grinding

LUM series superfine vertical roller grinding mill

LUM ultrafine vertical mill is developed based on 30 years of experience of grinding equipment Integrating superfine grinding, selection and conveying together, it is a superfine milling professional equipment Its technical parameters, mechanical properties and quality of finished products can meet the clients' requirements for highend LUM Ultrafine Vertical Mill Input Size: 020mm Output Size: 3252500 mesh LEARN MORE Hammer SBM has developed all kinds of coarse, fine and ultrafine grinding mills to meet customers'demands for powder production from Grinding Mill ultrafine grinding mill, vertical ultrafine The grinding chamber is filled up to 70% with inert ceramic grinding media beads Rotors stir the charge and grinding takes place between beads by attrition The number of rotors (grinding stages) depends on the application and can be as high as HIGmill high intensity grinding mill MetsoHGM Micropowder Grinding Mill (Medium speed microgrinding mill), absorbing advanced Swedish grinding technology, is good at superfine powder processing The finished products up to d97 ≤ 5μm, and fineness can be adjusted between 325mesh3250mesh Equipped with a pulse precipitator, production becomes greener and environmentally friendlyHGM Micropowder Grinding Mill Fine Grinding Mill Grinding

.jpg)

Clirik Grinding Mill Clirik Enterprise Focuses On The

2024年8月29日 Shanghai Clirik Machinery Co, Ltd Is excellent ore mill supplier Our main products include ultrafine powder grinding mill, vertical roller mill, roller grinding mill, stone powder production equipment, Welcome to consult2022年5月13日 HCM Grinding Mill,Raymond Grinding Mill, Vertical Grinding Mill, Ultrafine Grinding Mill all all; product; blog; × We are passionate about producing highquality grinding mills Grinding Equipment HCH Ultrafine Grinding Mill for HCM Grinding Mill Raymond Grinding Mill, Vertical Grinding Mill American Fine Grinding Mills reflect over a century of experience in design, performance, and capacity for unmatched dependability, minimum maintenance, and long service life This results in maximum efficiency and economy over an extensive range of applications Applications Clay; Limestone; Phosphates; Wood Chips; Much more; Fine Grinding Fine Grinding Mill Mills, Shredders, Crushers ampulverizerGrinding and separation efficiency of vertical roller mill were evaluated In addition to these, performance figures of vertical roller mill and conventional closed ball mill circuit were comparedPerformance Evaluation of Vertical Roller Mill in Cement Grinding

.jpg)

Vertical Stirred Mill Mineral Processing Equipment CITIC HIC

Vertical stirred mills are a fine grinding equipment that covers advantages of low rotation speed, high reliability and long life cycle The significant advantages that the vertical stirred mills have over the ball mills are smaller size, less auxiliary equipment required, more simple system and more options of processing methodsLUM Ultrafine Vertical Mill Input Size: 020mm Output Size: 3252500 mesh LEARN MORE Hammer SBM has developed all kinds of coarse, fine and ultrafine grinding mills to meet customers'demands for powder production from coarse powder(03mm),fine After crushing limestone with high calcium content and meets the requirements for Grinding Mill ultrafine grinding mill, vertical ultrafine mill A Vertical Roller Mill (VRM) is an advanced and efficient grinding machine commonly used in the cement industry for grinding raw materials and clinker VRMs have become increasingly popular due to their ability to produce finer products with lower energy consumption compared to traditional ball mills Advantages of Vertical Roller Mills:Vertical roller mill vs ball mill for cement grinding: Comparison Ultrafine vertical roller mill is a new type of vertical roller mill suitable for grinding nonmetallic ultrafine powder, which is developed by improving the existing vertical roller mill technology on the basis of absorbing the advantages of Ultrafine vertical roller mill SBM Ultrafine Powder

.jpg)

Diamant Vertical Grinding Mill Engsko

The Vertical Grinding Mill is now CEapproved For very fine grinded coffee on our Diamant Vertical mills, we can supply the mills with special coffee stones in the size 400 mm and 500 mm Our mill in size 400 mm is available in a special version for milling oily products for example mustard – it must be dry and not wetA high content of very fine particles on the grinding track usually affects the stability of the grinding bed Fine particles lower the interparticle friction, which reduces the grinding efficiency Fine particles on the grinding table cause disruption with compaction and deaeration, resulting in vibration and higher wear of the equipmentPicture: Loesche GmbH, Germany CEMENT SikaGrind® FOR VERTICAL ROLLER MILL2020年8月12日 Tontu [14] investigated the relationships between the current, coal feed, grinding pressure, and primary air and outlet temperatures of coal mills, and proved that a high correlation exists An investigation of performance characteristics and energetic The major design features of the tower mill are (1) a central agitator screw, the only moving machine component in contact with the slurry and steel media, and (2) the vertical grinding chamber which minimizes overgrinding of the product This arrangement reduces energy consumption in fine grinding of minerals by 25% to 50% when compared to traditional Vertical mills for fine grinding – FLS

.jpg)

CLUM Ultrafine Vertical Mill

CLUM ultrafine vertical mill is a new type of ultrafine grinding equipment integrating powder grinding, grading, conveying, secondary powder selection, and finished product packaging Capacity: 0245 t/h Max feeding size: 30mm Processing ability: 0245 t/h Application of CLUM ultrafine vertical mill:The introduction of Superfine HLMX1700 Ultrafine Vertical Grinding Mill: Max feeding size: 20mm Capacity: 440t/h Fineness: 3252500 mesh HLMX Superfine Vertical Grinding Mill is largescale nonmetal mineral superfine powder mill developed by Hongcheng based on HLM vertical roller mill and introduction of foreign advanced technologyOMYA Group Signed The HLMX1700 Superfine Vertical Grinding Mill Newtype Pneumatic Ultra Fine Grinding Mill (Jet Mill) Cross Jet Mill; Compact Jet Mill and Separator Combined System Kurimoto Pocket Jet; Vertical Super Fine Grinding Mill (Vertical Roller Mill) VX Mill; Fine Grinding Mill (Centrifugal Roller Mill) Kurimoto Roller Mill; Batch Type Highspeed Planetary Mill Kurimoto High GVertical Super Fine Grinding Mill (Vertical Roller Mill) VX Mill