How to grind electrolytic manganese powder correctly

.jpg)

How to grind electrolytic manganese

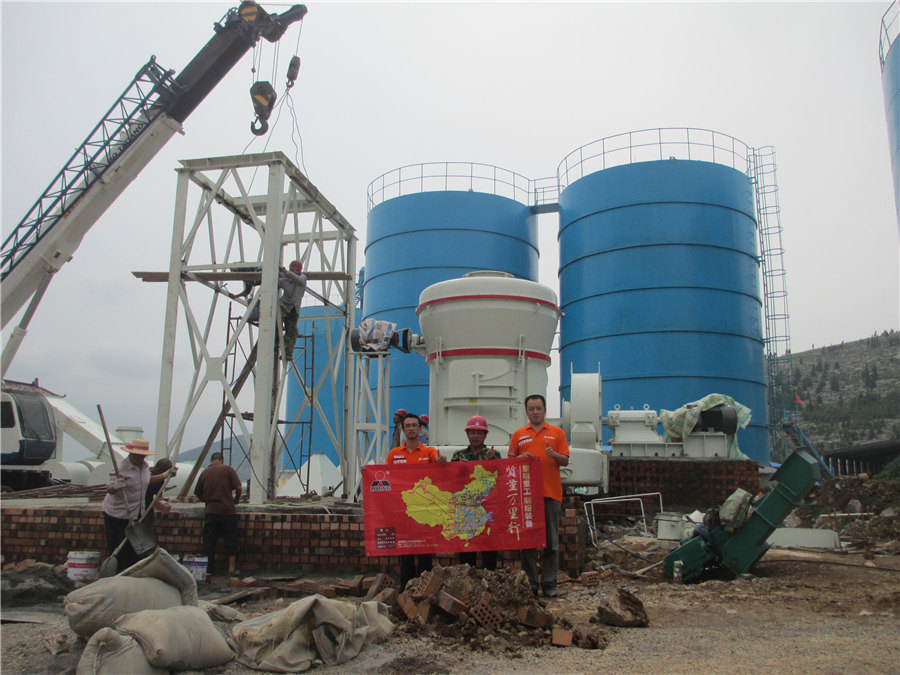

The quality of electrolytic manganese dioxide powder has a decisive impact on the performance of battery discharge and storage At present, the grinding device of electrolytic manganese dioxide finished product generally adopts Raymond mill, but ordinary Raymond mill has many The crushing, grinding and washing of deposited electrolytic manganese dioxide is one of the most important process steps in the production of EMD suitable for dry cells If the crushing Crushing and grinding of electrodeposited manganese dioxideStage I: Crushing of raw materials The large Manganese material is crushed by the crusher to the feed fineness (15mm50mm) that can enter the pulverizer Stage II: GrindingGrinding Manganese PowderTo sum up, there are mainly two kinds of equipment for grinding in electrolytic manganese powder workshop: new Raymond mill and vertical mill, and users can choose according to production News How to choose the electrolytic manganese powder

How To Select Equipment For Producing Manganese Powder From

The basic principle of mechanical crushing method is to use the brittleness of manganese flakes to crush manganese flakes into manganese powder through shearing, impact, bending, En resumen, existen principalmente dos tipos de equipos para la molienda en el taller de polvo de manganeso electrolítico: el nuevo molino Raymond y el molino vertical, y los usuarios pueden How to choose the electrolytic manganese powder grinding mill 2023年5月24日 Commonly used desulfurizer mills include Raymond mills and vertical grinding mills, both of which can meet the requirements for the preparation of 200mesh manganese How to choose manganese ore powder desulfurizer grinding millIn the process of electrolytic manganese, manganese sulfate is first produced The existing production method of the manganese sulfate solution is: crushing the manganese ore intoMethod for producing electrolytic manganese metal by using two

HPMSM Processing 101 Canadian Manganese

Purified manganese sulfate solution serves as the electrolyte to produce standardgrade electrolytic manganese (EMM) or electrochemical manganese dioxide (EMD) It is also the In electrolytic grinding, the total amount of material removed can be divided into the amount removed by mechanical grinding and electrolytic elution The amount removed by the Surface Finishing Tutorial Technical Tutorial MISUMI2023年4月8日 Huge amounts of manganeserich solid residues are yearly produced worldwide by industrial electrolysis, calling for advanced methods of recycling in the context of the circular economy Here, we review manganese recycling with focus on ore reserves, electrolytic production, residue stockpiling and environmental impact, reducing the amount of residue and Recyling manganeserich electrolytic residues: a reviewThe global electrolytic manganese metal (EMM) market is expected to grow at a CAGR of 55% during the forecast period from 2018 to 2028Global Electrolytic Manganese Metal (EMM) Market Industry

.jpg)

Electrolytic Manganese Market Report Global Forecast To 2028

The global electrolytic manganese market is expected to grow at a CAGR of 45% during the forecast period, to reach USD 12 billion by 2030 The growth of this market is driven by the increasing demand for alkaline batteries and zincarbon batteries in various applications such as electric vehicles, power tools, and medical devices751%, electrolytic manganese dioxide yield was 236%, acid recovery was 623%, and the energy consumption was 5701kWht−1 The surface of metal manganese produced at the cathode was smooth and dense, with a silverwhite metallic luster and uniform growth of each phase The electrolytic manganese dioxide (EMD) of the anode product was αMnOElectrodeposition of Manganese Metal and Coproduction of Electrolytic 2021年7月15日 Electrolytic manganese metal (EMM) industry in China: (a) distribution of the EMM industry in China; (b) openair storage of electrolytic manganese residue (EMR); (c) pollution of the surrounding environment by EMR; (d) general appearance and Xray diffraction (XRD) pattern; (e) scanning electron microscopy (SEM); and (f) energy dispersive Xray Hazardfree treatment and resource utilisation of electrolytic 2019年10月11日 Electrolytic manganese powder – Electrowinning – Leaching – Lowgrade manganese ore – Hydrometallurgy Ziel dieser Arbeit ist es, geringhaltiges Manganerz, das von (PDF) Production of Electrolytic Manganese Powder from Egyptian

.jpg)

ELECTROLYTIC MANGANESE METAL POWDER MSDS

Register now and get a free online MSDS binder Your new online MSDS binder is a place for you to store the material safety data sheets you need to deploy Other companies are charging thousands of dollars to set up accounts and give you access to their msds online databaseOverview of Electrolytic Manganese Metal Powder Electrolytic Manganese Metal Powder comprises a broad category of finely divided, solid particles derived from various metals or metal alloys These powders exhibit unique characteristics that make them indispensable in modern manufacturing and advanced technologiesElectrolytic Manganese Metal Powder Onestop Metal Electrolytic Manganese Metal Supplier, Fluorspar Powder, Fluorspar Lumps Manufacturers/ Suppliers Hunan Xuan Resources Co, Ltd Sign In Join Free For COMPANY was established in 2008, which mother company HUNAN TAIHE METALLURGY LIMITED COMPANY, was a producer of FERRO MANGANESE LUMPS AND POWDER plant since the year 1995Electrolytic Manganese Metal Manufacturer, Fluorspar Powder, Micromesh Minerals Metals/Aquachem India Offering Electrolytic Manganese Dioxide Powder, Manganese Dioxide Powder at Rs 250/kg in Nagpur, Maharashtra Check best price of Manganese Dioxide in Nagpur offered by verified suppliers with contact number Electrolytic Manganese Dioxide Powder IndiaMART

.jpg)

(PDF) Manganese in ferrous powder metallurgy ResearchGate

2001年1月1日 powder Manganese as elemental (electrolytic) or in the form of ferromanganese, also after crushing by a producer and storage f or a longtime at an ambient temperature a nd humidity,2024年1月17日 Introduction to electrolytic manganese flakes price, content, size, production, usage, effectiveness, and purchasing method of electrolytic manganese Agree Join LinkedInAll about Electrolytic Manganese Flakes LinkedInThis grade of powder can be injected directly to molten aluminium at 720750ºC for rapid dissolution This eliminates the need to use MnAl powder compacts, resulting in a significant cost saving Click link to download: Electrolytic Manganese Metal Unstabilised Powder (UP40) Specification SDS – Powder GHS format SDS – Powder REACH formatManganese Metal Company Electrolytic Manganese Metal 2023年8月26日 Benefits of Manufacturing using Electrolytic Manganese Dioxide When utilized in making procedures, electrolytic manganese dioxide (EMD) has numerous beneficial residential properties EMD is first as well as primary recognized for its superb pureness as well as consistent top quality, which assures trustworthy as well as highperformance manufacturing Own Electrolytic Manganese Dioxide (EMD) Manufacturing

.jpg)

How Can Manganese Powder Be Refined Into Electrolytic Manganese

Manganese ore excavated from the mine is ground into powder by using manganese powder Raymond mill, which is called manganese powder The metallic manganese obtained by electrolysis after the manganese powder is treated with sulfuric acid and other chemical materials is called “electrolytic manganese”2Electrolytic metal manganese is widely used in manganese copper alloys, manganese aluminum alloys and 200 series stainless steels Electrolytic Manganese flakes can improve the hardness, strength, toughness, wear resistance and corrosion resistance of metal materialsElectrolytic Manganese Flake ZHEN AN INTERNATIONAL CO, LTDChemicals and Materials Global Electrolytic Manganese Metal Market Report and Forecast 20242032 Global Electrolytic Manganese Metal Market Size, Forecast: By Form: Flake , Powder; By Application: Steel, Aluminium Alloy, Magnetic Material, Chemical, Others; Regional Analysis; Market Dynamics: SWOT Analysis: Porter’s Five Forces Analysis; Competitive Landscape: Electrolytic Manganese Metal Market Size, Share 2032Sample: Availiabe Purity: 998%Min Einecs No: 2318696 Product Name: Electrolytic Manganese Powder Grade: Industral Grade CAS No: 98% Purity Used in Alloy Steel Electrolytic Manganese Powder

.jpg)

Electrolytic Manganese Powder Global Market Insights and

Due to its high purity and less impurities, electrolytic manganese powder is an important alloying element in the production of stainless steel, highstrength lowalloy steel, aluminummanganese alloy, coppermanganese alloy, vibrationdamping alloy and permanent magnet alloy In the iron and steel industry, electrolytic manganese is used as a deoxidizer and desulfurizer, and can Use detailed tutorial to learn the stepbystep procedure for starting the manufacturing of electrolytic manganese dioxide (EMD) Learn about the key methods, tools, and factors needed to start EMD manufacturing successfully This report helps you market and place the product correctly by identifying the target customer group of the productHow to Start Electrolytic Manganese Dioxide (EMD) ProductionManganese metal is divided into metal manganese produced by fire reduction and electrolytic metal manganese produced by wet electrowinning The pyrometallurgical manganese is massive and difficult to crush; The wet electrolytic manganese metal is flake, easy to crush and high purity At the same time, the production scale of manganese metal powder is generally large, but the How To Select Equipment For Producing Manganese Powder From Manganese Purified manganese sulfate solution serves as the electrolyte to produce standardgrade electrolytic manganese (EMM) or electrochemical manganese dioxide (EMD) It is also the starting solution for crystallizing regulargrade HPMSM Processing 101 Canadian Manganese

Electrolytic Manganese Powder Market Overview Verified

Electrolytic Manganese Powder Market size is rising upward in the past few years it is estimated that the market will grow significantly in the forecasted period Electrolytic Manganese Powder Market Size, Share and Growth Analysis [2030]Electrolytic Manganese Dioxide White Paper Free download as Word Doc (doc / docx), PDF File (pdf), Text File (txt) or read online for free 1) Global demand for lithiumion batteries and electric vehicles is expected to grow significantly by 20302040, driving increased demand for electrolytic manganese dioxide (EMD) 2) EMD is a key cathode material for lithiumion Electrolytic Manganese Dioxide White Paper PDF Scribd2020年6月6日 A novel circulation process of electrolytic manganese metal (EMM) production with lowgrade manganese oxide ores (LGMO) and highsulfur manganese ores (HSMO) was studied and developed The unit operations mainly include dissolution of LGMO, purification of leach liquor and electrolysis for EMM preparation Based on the theoretical thermodynamic A Novel Circulation Process to Effectively Produce Electrolytic 2024年11月9日 Article historyThis paper aims to recycle the electrolytic manganese powder from spent ZnMnO2 primary batteries by electrowinning technique After the purification process of the solution, the manganese ions became 3475 gm/L The electrolysis process is the most effective way to produce pure manganeseProduction of Electrolytic Manganese Powder from Paste of

How is electrolytic manganese made? #silicon YouTube

2024年4月8日 How is electrolytic manganese made?Electrolysis: Electrolysis is carried out by passing an electric current through the manganese sulfate solution This procElectrolytic manganese metal is obtained by acid leaching of manganese ore to obtain manganese salt, and then sent to the electrolytic cell to resolve the elemental metal Appears like iron, irregularly shaped, firm and brittle, one side bright, the other side is rough, silvery white to brown, silvery gray after processing into powder; easily oxidized in air, dissolved and displaced Method for producing electrolytic manganese metal by using Electrolytic Manganese Metal PowderChina Manufacturer:Specifications:Mn 997%min Se 0001%max C 002%max S 004%max P 0003%max Fe 005%max Si 00025%max High purity About Us License and CertificateElectrolytic Manganese Metal Powder Electrolytic Manganese The Electrolytic Manganese Committee is one of the 6 IMnI Committees This Committee is open to companies manufacturing manganesebased electrolytic products Contact Us International Manganese Institute, 11 rue Dulong 75017 Paris, FRANCE imni@manganese Tel: +33 (0) 1 Manganese in Batteries International Manganese Institute

.jpg)

Recyling manganeserich electrolytic residues: a review

2023年4月8日 Huge amounts of manganeserich solid residues are yearly produced worldwide by industrial electrolysis, calling for advanced methods of recycling in the context of the circular economy Here, we review manganese recycling with focus on ore reserves, electrolytic production, residue stockpiling and environmental impact, reducing the amount of residue and The global electrolytic manganese metal (EMM) market is expected to grow at a CAGR of 55% during the forecast period from 2018 to 2028Global Electrolytic Manganese Metal (EMM) Market Industry The global electrolytic manganese market is expected to grow at a CAGR of 45% during the forecast period, to reach USD 12 billion by 2030 The growth of this market is driven by the increasing demand for alkaline batteries and zincarbon batteries in various applications such as electric vehicles, power tools, and medical devicesElectrolytic Manganese Market Report Global Forecast To 1%, electrolytic manganese dioxide yield was 236%, acid recovery was 623%, and the energy consumption was 5701kWht−1 The surface of metal manganese produced at the cathode was smooth and dense, with a silverwhite metallic luster and uniform growth of each phase The electrolytic manganese dioxide (EMD) of the anode product was αMnOElectrodeposition of Manganese Metal and Coproduction of Electrolytic

Hazardfree treatment and resource utilisation of electrolytic

2021年7月15日 Electrolytic manganese metal (EMM) industry in China: (a) distribution of the EMM industry in China; (b) openair storage of electrolytic manganese residue (EMR); (c) pollution of the surrounding environment by EMR; (d) general appearance and Xray diffraction (XRD) pattern; (e) scanning electron microscopy (SEM); and (f) energy dispersive Xray 2019年10月11日 Electrolytic manganese powder – Electrowinning – Leaching – Lowgrade manganese ore – Hydrometallurgy Ziel dieser Arbeit ist es, geringhaltiges Manganerz, das von (PDF) Production of Electrolytic Manganese Powder from Egyptian Register now and get a free online MSDS binder Your new online MSDS binder is a place for you to store the material safety data sheets you need to deploy Other companies are charging thousands of dollars to set up accounts and give you access to their msds online databaseELECTROLYTIC MANGANESE METAL POWDER MSDSOverview of Electrolytic Manganese Metal Powder Electrolytic Manganese Metal Powder comprises a broad category of finely divided, solid particles derived from various metals or metal alloys These powders exhibit unique characteristics that make them indispensable in modern manufacturing and advanced technologiesElectrolytic Manganese Metal Powder Onestop Metal

Electrolytic Manganese Metal Manufacturer, Fluorspar Powder,

Electrolytic Manganese Metal Supplier, Fluorspar Powder, Fluorspar Lumps Manufacturers/ Suppliers Hunan Xuan Resources Co, Ltd Sign In Join Free For COMPANY was established in 2008, which mother company HUNAN TAIHE METALLURGY LIMITED COMPANY, was a producer of FERRO MANGANESE LUMPS AND POWDER plant since the year 1995Micromesh Minerals Metals/Aquachem India Offering Electrolytic Manganese Dioxide Powder, Manganese Dioxide Powder at Rs 250/kg in Nagpur, Maharashtra Check best price of Manganese Dioxide in Nagpur offered by verified suppliers with contact number Electrolytic Manganese Dioxide Powder IndiaMART