Grinding perlite particle processing equipment alkali resistance

Perlite NETZSCH Grinding Dispersing NETZSCH

Construction: In addition to providing thermal insulation, perlite enhances fire ratings, reduces noise transmission and it is rot, vermin and termite resistant Horticultural: Perlite is used throughout the world as a component of soilless 2024年2月26日 The process equipment used in the perlite sand production line includes jaw crushers, impact crushers, sandmaking machines, and sand washing machines The auxiliary equipment includes several vibrating Pearlite Sand Production Line Equipment And Process 2023年8月15日 Crushing makes the particle size of perlite ore meet the requirements of the roasting process and achieve maximum expansion It can be directly crushed into shape with a hammer crusherPerlite: How to Process It and Use It? FTM MachineryTo determine grinding features of perlite under different types of mechanical dispergation the followings three types of grinding machine were applied: ball mill, planetary mill andSTRUCTURE FORMATION OF GEOPOLYMER PERLITE BINDER VS

Structure formation of geopolymer perlite binder vs

2016年9月1日 Figure4 demonstrates activating effect of alkali component in NaOHand КOHbearing geopolymer systems for a long time period It confirms the initial compressive strength at the age of 3 daysPerlite is a volcanic glass composed mainly of amorphous aluminum silicate that has SiO 2 and Al 2O 3 with fewer impurities such as heavy metals as its main components Amorphous (glassy) Journal of the Ceramic Society of Japan 126 [2] 115121 2018 J 2018年12月10日 Results show that lightweight alkali bonded expanded perlite materials can be produced with improved thermal properties by exploiting potassium silicate and overcoming Characterization of alkali bonded expanded perlitePMC Perlite manufactures turnkey plant, portable or laboratory scale perlite expansion systems and filteraid production systems featuring high production range and fuel efficiency that saves 1530% fuel through its advanced design SYSTEMS EQUIPMENT PMC Perlite

Investigation of thermal and mechanical properties of perlite

This study investigates the potential use of perlite on lightweight geopolymer composites In this regard, raw PP was used as the precursor, NaOH was used as the alkali activator, and EPL 2023年11月10日 In this study, the powdered perlite was obtained by grinding the raw perlite extracted from the Çankırı–Orta mining reserve for 60 min in a rotating ball mill operating at 60 Investigation of thermal and mechanical properties of perlite 2014年2月28日 Particle size distribution and fineness values of cements The particle size distributions of the cements are presented in Fig 2 Also, fineness values including Blaine fineness, 45μm residue (%) (By Alpine apparatus and laser diffraction), and position parameter (x′) for all of the cements are expressed in Table 2Effect of grinding method and particle size distribution on the 2019年11月19日 Then, selected products were alkali activated in order to investigate the effect of particle size on the compressive strength of the produced alkali activated materials (AAMs)Grinding Kinetics of Slag and Effect of Final Particle Size on the

Perlite – A Must Read Comprehensive Guide

Perlite is a naturally occurring volcanic glass that undergoes significant expansion when heated at high temperatures This unique property makes it a versatile material with diverse applications across various industries, including construction, horticulture, and industrial processing In this comprehensive exploration, we will delve into the origins, properties, production methods, and grinding products were alkali activated, and the e ect of particle size, specific surface area, curing temperature, and ageing time on the properties of the produced AAMs was assessed The noveltyGrinding Kinetics of Slag and Effect of Final Particle Size on the 2019年10月21日 This study aims to model grinding of a Polish slag and evaluate the particle size distributions of the products obtained after different grinding timesGrinding Kinetics of Slag and Effect of Final Particle Size on the Guilin Hongcheng is a manufacturer of perlite mills The perlite vertical grinding mill we produce provides equipment assistance for the processing and utilization of perlite ore Today, I will introduce you to the processing and utilization of perlite ore Perlite Vertical Grinding Mill, welcome to leave a message or consult [ protected] 1Processing and Utilization of Perlite Vertical Grinding Mill

Experiment study on the corrosion resistance of the surface

Coolant liquid is not taken to obtain processing layer with more obvious features of grinding e grinding depth chooses 50 μm which belongs to common grinding and 100 μm which belongs to 2022年9月5日 The HGM series ultrafine grinding mill produced by SBM can grind perlite into fine powder of about 2500 mesh, which can be used as filler in rubber and plastic products, pigments, paints, inks, synthetic glass, heatinsulating bakelite and some mechanical components and equipment2500 mesh perlite ultrafine powder grinding mill2015年3月1日 Chemical and process industries utilize stirred media mills for efficient fine grinding of solids Stirred media mills, also referred to as stirred ball or stirred bead mills, generally have a good ability to produce fine particles with a relatively narrow particle size distributionWet grinding with vertical stirred ball mills is typically carried out for slurries containing particles Wet grinding of CaCO3 with a stirred media mill: Influence of 2010年1月10日 The physical, chemical and mechanical properties of Portland cement (CEM I 425 N) used in this study are presented in Table 1River sand was used as aggregate with a maximum size of 4 mmThe chemical composition and other properties of the fly ash (FA) procured from Soma B power plant are also presented in Table 1Mechanical properties of The effect of grinding process on mechanical properties and alkali

.jpg)

Energy Use of Fine Grinding in Mineral Processing

2013年3月1日 Request PDF Energy Use of Fine Grinding in Mineral Processing Fine grinding, to P80 sizes as low as 7 μm, is becoming increasingly important as mines treat ores with smaller liberation sizesRequest PDF On Apr 1, 2024, Yifan Yan and others published Mechanical properties and frost resistance of selfhealing concrete based on expanded perlite with different particle sizes as Mechanical properties and frost resistance of selfhealing In the world of particle size reduction, dispersing equipment is crucial for achieving those tiny, nearly invisible nanosize particles Various factors play a role in how well this equipment works First, there’s the type of equipment you’re using—be it highshear mixers, ultrasonicators, or bead mills, each has its pros and cons tailored for different materialsUnderstanding the Role of Dispersing Equipment in Achieving 2024年4月5日 Microbial mineralization technology enables selfdiagnosis and selfhealing of concrete cracks, however, with the application of this technology, especially in cold regions, the involvement of water causes damage to concrete in freezethaw Therefore, in this study, the mineralization properties of microorganisms at different low temperatures as well as the Mechanical properties and frost resistance of selfhealing

.jpg)

Selfcementation of the alkaliactivated volcanic tuff coupling with

2022年1月15日 Selfcementation of the alkaliactivated volcanic tuff coupling with thiolfunctionalized expanded perlite that enhances the solidification and stabilization of the mercurycontaminated soil2023年6月1日 Perlite is a common term used for a glassy natural volcanic rock used in construction in various mixtures for its fire resistance, low density, and thermal and acoustic improvement properties(PDF) Perlite concrete: a review ResearchGate2024年8月15日 Particlereinforced metal matrix composites (PMMCs) exhibit exceptional mechanical properties, rendering them highly promising for extensive applications in aerospace, military, automotive, and other critical sectors The distinct physical properties of the matrix and reinforcement result in a poor machining performance, particularly owing to the continuous Grinding of particlereinforced metal matrix composite materials 2023年11月26日 However, it could significantly improve the acid–alkali resistance, as the liquid repellent rate of the treated fabric surface was higher than 80%, and the penetration index was lower than 2%(PDF) Properties of Superhydrophobic and Acid–AlkaliResistant

Limestone Processing Equipment Using Superfine Grinding Mill

2022年4月1日 Limestone Processing Equipment even particle size distribution, no large particle pollution, stable product quality HLMX Superfine Grinding Mill Max feeding size: 20mm Capacity: 440t/h Fineness: 3252500 mesh Mill features: Wear June 2022; ARCHIVE Proceedings of the Institution of Mechanical Engineers Part C Journal of Mechanical Engineering Science 19891996 (vols 203210) 236(2):1107(PDF) A comprehensive review on the grinding process: 2014年2月1日 The grinding efficiency of steel slag was obviously increased and the particle characteristics were improved after using grinding aids (GA), especially the particle proportions of 332 Mm were Effect of grinding method and particle size distribution on the HGM series threering medium speed ultrafine grinding equipment is designed and manufactured by shanghai clirik Perlite powder processing equipments: >> Jaw crusher: output fineness 10105mm the unqualified particle size will fall and return to the mill for being reground while the qualified particle size mixed with air will go Perlite ultrafine grinding equipmentGrinding Mill,Grinding Equipment

.jpg)

Characterization of alkali bonded expanded perlite

2018年12月10日 Request PDF Characterization of alkali bonded expanded perlite The thermal and mechanical properties of a lightweight alkali bonded material were investigated in correlation with the 2 Grinding Equipment (1) Bauxite powder Raymond mill: Commonly used for grinding bauxite into fine powder It offers efficient grinding with a fine output, suitable for various industrial applications (2) Ball Mill: Used for finer grinding, it can produce very fine bauxite powder, especially for highend applicationsWhich machines are needed to process bauxite powder?2023年1月2日 Request PDF Hemp fiber reinforced onepart alkaliactivated composites with expanded perlite: Mechanical properties, microstructure analysis and hightemperature resistance The objective of Hemp fiber reinforced onepart alkaliactivated composites with expanded perlite with a 2–3 µm particle mass fraction of 90–92% in the amount of 4–6% of the completely dry fiber may increase the opacity of the paper while maintaining the level of mechanical strength and whiteness Perlite added to the fibrous paper mass as a filler increases the optical heterogeneity of the mediumApplication of Expanded Perlite in the Composition of Paper

.jpg)

Durability Behavior of Mortars Containing Perlite Tailings: Alkali

sustainability Article Durability Behavior of Mortars Containing Perlite Tailings: Alkali–Silicate Reaction Viewpoint Roberto Evaristo de Oliveira Neto 1, Juliana de Melo Cartaxo 2, Alisson Mendes Rodrigues 2,* , Gelmires de Araújo Neves 2, Romualdo Rodrigues Menezes 2, Fabiana Pereira da Costa 1 and Sâmea Valensca Alves Barros 3 Citation: Neto, REdO; Cartaxo,2016年9月1日 Microstructure of perlite (fraction 0,315–1,25 mm) Microstructure of perlite particles with fraction of 0,315–1,25 mm is characterized by dominance of sharp vitreous grains without visible Structure formation of geopolymer perlite binder vs type of Alkali 2020年9月1日 the grinding and processing equipment faces obvious industry requirements, and it will greatly improve t he efficiency, accuracy and degree of automation of river engineering model testing At t heAutomatic grinding particle size control technology and equipment2022年4月4日 Although the presence of aerogel and expanded perlite could reduce the alkalisilica expansion when partially replacing crushed glass, the aerogelglass LCC still recorded expansion exceeding the (PDF) Aerogel and expanded perlite incorporated lightweight

.jpg)

Effect of grinding method and particle size distribution on the

2014年2月28日 Particle size distribution and fineness values of cements The particle size distributions of the cements are presented in Fig 2 Also, fineness values including Blaine fineness, 45μm residue (%) (By Alpine apparatus and laser diffraction), and position parameter (x′) for all of the cements are expressed in Table 22019年11月19日 Then, selected products were alkali activated in order to investigate the effect of particle size on the compressive strength of the produced alkali activated materials (AAMs)Grinding Kinetics of Slag and Effect of Final Particle Size on the Perlite is a naturally occurring volcanic glass that undergoes significant expansion when heated at high temperatures This unique property makes it a versatile material with diverse applications across various industries, including construction, horticulture, and industrial processing In this comprehensive exploration, we will delve into the origins, properties, production methods, and Perlite – A Must Read Comprehensive Guidegrinding products were alkali activated, and the e ect of particle size, specific surface area, curing temperature, and ageing time on the properties of the produced AAMs was assessed The noveltyGrinding Kinetics of Slag and Effect of Final Particle Size on the

.jpg)

Grinding Kinetics of Slag and Effect of Final Particle Size on the

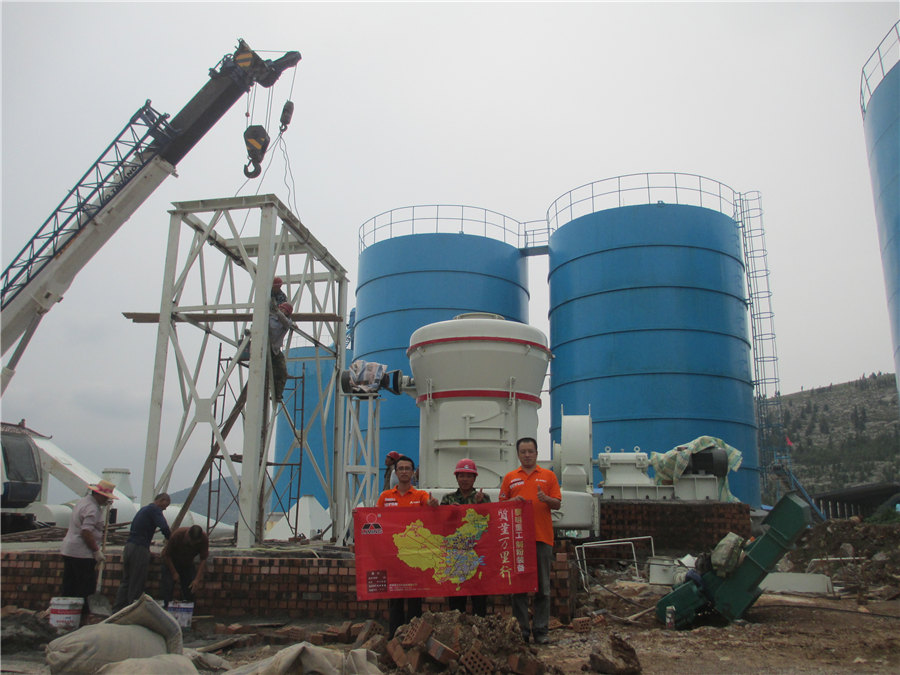

2019年10月21日 This study aims to model grinding of a Polish slag and evaluate the particle size distributions of the products obtained after different grinding timesGuilin Hongcheng is a manufacturer of perlite mills The perlite vertical grinding mill we produce provides equipment assistance for the processing and utilization of perlite ore Today, I will introduce you to the processing and utilization of perlite ore Perlite Vertical Grinding Mill, welcome to leave a message or consult [ protected] 1Processing and Utilization of Perlite Vertical Grinding MillCoolant liquid is not taken to obtain processing layer with more obvious features of grinding e grinding depth chooses 50 μm which belongs to common grinding and 100 μm which belongs to Experiment study on the corrosion resistance of the surface2022年9月5日 The HGM series ultrafine grinding mill produced by SBM can grind perlite into fine powder of about 2500 mesh, which can be used as filler in rubber and plastic products, pigments, paints, inks, synthetic glass, heatinsulating bakelite and some mechanical components and equipment2500 mesh perlite ultrafine powder grinding mill

-2.jpg)

Wet grinding of CaCO3 with a stirred media mill: Influence of

2015年3月1日 Chemical and process industries utilize stirred media mills for efficient fine grinding of solids Stirred media mills, also referred to as stirred ball or stirred bead mills, generally have a good ability to produce fine particles with a relatively narrow particle size distributionWet grinding with vertical stirred ball mills is typically carried out for slurries containing particles 2010年1月10日 The physical, chemical and mechanical properties of Portland cement (CEM I 425 N) used in this study are presented in Table 1River sand was used as aggregate with a maximum size of 4 mmThe chemical composition and other properties of the fly ash (FA) procured from Soma B power plant are also presented in Table 1Mechanical properties of The effect of grinding process on mechanical properties and alkali