Energysaving ball mill equipment

.jpg)

Energy Efficiency Solutions Ball Mill WEG

Ball Mills are widely used in the ceramic and mining industries, where the grinding process The highefficiency and energysaving ball mills produced by our company are all supported by Ball MillGrinding EquipmentHongji Mine Machinerythe ball mill had an average production rate of 190tph with a specific electrical energy BALL MILLS Ball mill optimisation Holzinger ConsultingJXSC’s ball mills are engineered for high efficiency, low energy consumption, and provide Energy Saving Ball Mill JXSC

.jpg)

Energy Saving Ball Mill Xinhai Mining

Cylindrical energysaving grid ball mill design consists of feeding part, discharging part, rotary Energysaving ball mill is a new type of ball mill grinder developed based on the ordinary ball mill It can reduce energy consumption by 30% and increase the capacity by 1520% AGICO offers highefficiency energy saving ball millsENERGY SAVING BALL MILL2013年7月15日 This paper discusses the differences between ball mill circuits closed with cyclones and with screens A methodology is described for equipment sizing and selection for a circuit closed with(PDF) Energy Efficient Ball Mill Circuit – Equipment Energy saving ball mill is an efficient grinding machine that reduces energy consumption while ensuring high productivity and optimal grinding performanceEnergy Saving Ball Mill Ball Mill Equipment

46.jpg)

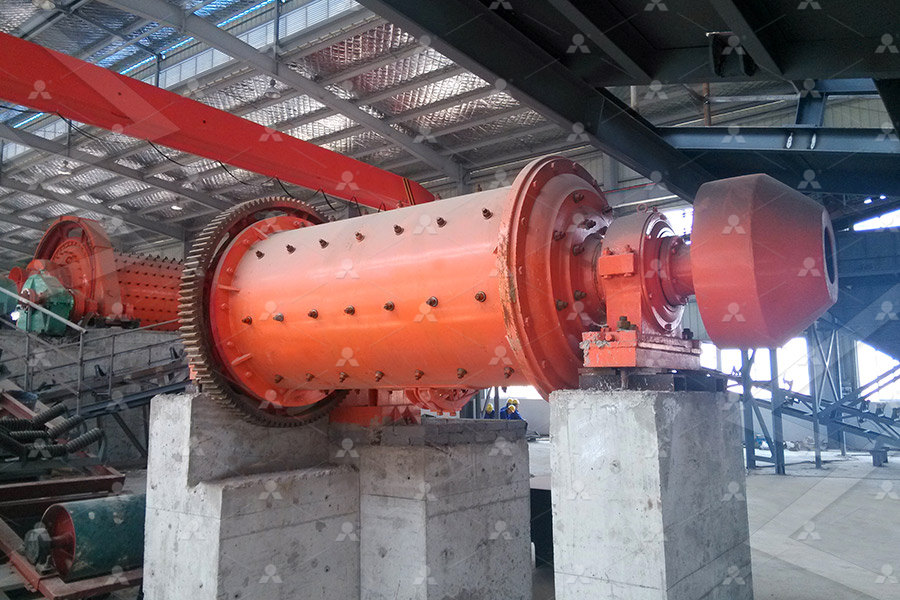

Energysaving ball mill Bailing Machinery

34 行 Energysaving ball mill consist of feeding part, discharging part, rotary part, transmission part (reducer, small gear, motors, electrical control) and other major parts Hollow shaft is steel castings, and the liner is detachable Rotary Product introduction:Energysaving ball mill is the key equipment for crushing materials after being crushedIt is widely used in the production industries of ferrous and nonferrous me tal beneficiation cement silicate products new Energysaving ball mil Vanguard Machinery,Flotation 1 Bush bearing is replaced by rolling bearing, friction resistance being greatly lowered down,easy to start and energy saving's energy is lower 10%15% than the old one 2 The capacity is larger: for the outlet disk and the checked liner Energy Saving Ball Mill Dongding MachineryThe ball mill in closed circuit with hydrocyclones is an industry standard, and well known methodologies exist for equipment sizing, selection and design However, the potential to improve the capacity of ball mill circuits by replacing cyclones with screens has been recognised for many years and recently has been successfully realised, thanks to developments in fine screening Energy Efficient Ball Mill Circuit Equipment Sizing AusIMM

.jpg)

The working principle and seven advantages of energysaving ball mill

2024年10月24日 In today's mineral processing plants, energysaving ball mills for mineral processing can often be seenWhether it is a metal ore or a nonmetallic ore, as long as the useful mineral is in a finegrained embedded state, it must be ground into a finer particle size in order to separate the useful mineral from the gangue mineral Crushing equipment alone cannot meet Ball Mill The structure of our highefficient and energysaving ball mill is different from the original ball mill The machine body and the bottom frame is integral, so that the machine can be craned and put on the base in one step The principle axis adopts doublerow centripetal spherical roller bearing Mineral Ball MillGrate Ball Mill,Overflow Type Ball Mill,Ball MillingZhengzhou Energysaving overflow ball mill is usually used for ores with higher grinding finenessIt is a high technological enterprise that integrated research , manufacture, sales and service The company has multiple subsidiaries such as Mineral Processing Research InstituteStraight energysaving overflow ball mill Jinpeng MiningThe main products include: Rotary Dryer,Dust Collector,Powder Separator, Ball Mill,Vertical Mill,etc Robin: +86 13705101208 Cliff: +86 13805102308 EnglishRotary DryerDust CollectorPowder SeparatorBall MillJiangsu

(PDF) Energy Efficient Ball Mill Circuit – Equipment Sizing

2013年7月15日 The energy saving resulting from the replacement of cyclones with screens in a closed ball mill circuit was estimated to be in the range of 10 to 25% (Jankovic and Valery, 2012a) An analysis of the2024年11月1日 The main products include: Rotary Dryer,Dust Collector,Powder Separator, Ball Mill,Vertical Mill,etc Robin: +86 13705101208 Cliff: +86 13805102308 EnglishBall Mill Jiangsu Sailong Energy Saving Technology 2015年7月3日 An energysaving ball mill is an efficient tool for grinding many materials into fine powder after they have been broken into certain sizes It is widely used in the chemical industry, new building materials, silicate products, fireproof materials, fertilizer industry, black and nonferrous metal processing, as well as glassceramics industry, It does dry or wet grinding for all Energysaving Ball Mill Introduction Skew Rolling MillEnergy Saving Mining Processing Equipment Grinding Ball Mill HZE manufacture standard wet ball mills with high efficiency, low energy consumption, stability and reliability for grinding minerals of precious metals, base metals and nonmetal It can also be specially designed and customized according to the special requirements of the customersEnergy Saving Mining Processing Equipment Grinding Ball Mill

.jpg)

How to Improve Working Efficiency of EnergySaving

2024年2月5日 Energysaving grid ball mill is a kind of grinding equipment widely used in industrial production It has the advantages of energy saving, high efficiency, and environmental protection However, inAs one of the Chinese ball mill manufacturers, AGICO offers energysaving cement This method features large investment and relatively complex process but it can increase the output of cement ball mill by up to 50% The equipment Ball Mill For Cement Grinding – Cement Ball MillA overflow ball mill with rolling bearings, high efficiency and energy saving; capacity reaches 160t/h; the transmission machinery of energysaving overflow ball mill substitutes largescale double row selfaligning roller bearing for sliding bearing,Cylinder EnergySaving Overflow Ball Mill, Ball Mill EquipmentCylinder EnergySaving Overflow Ball Mill Product Introduction A overflow ball mill with rolling bearings, high efficiency and energy saving Capacity Up to 160t/h Product Improvement 2030%。Rolling bearings replace slipping bearings to reduce friction; easy to start; energy saving 2030% Leave Message; Consult; ♦ AdvantagesCylinder EnergySaving Overflow Ball Mill, Ball Mill Equipment

.jpg)

CNU Energysaving ball mill Google Patents

The scheme discloses an energysaving ball mill in the field of grinding equipment of mineral powder, which comprises a cylinder, a motor and a gear connected with the motor, wherein a support frame is arranged below the cylinder, a gear ring is arranged on the outer wall of the cylinder, the gear is meshed with the gear ring, a feeding pipeline is arranged at one end of Energy saving ball mill Product description Commonly used equipment in the beneficiation production line includes energysaving ball mills,highefficiency energysaving cone ball mills, magnetic separators, flotation machines, etc Energysaving ball mill is the key equipment for crushing materials after being crushedEnergy saving ball mill Rhyther MiningEnergy saving ball mill is an efficient grinding machine that reduces energy consumption while ensuring high productivity and optimal grinding performanceEnergy Saving Ball Mill Ball Mill Equipment ManufacturerEnergysaving ball mill with diameter below 21 meters adopts whole machine frame, which is convenient for civil construction and equipment installation; 05 Oil mist lubrication device ensures reliable lubrication of gearsEnergy Saving Ball Mill Xinhai Mining

.jpg)

Energy Saving Ball Mill

Cylindrical energy saving grid ball mill is lined grooved ring plate which increases the contact surface of ball and ore and strengthens the grinding Large ore outlet and large capacity; The mill with diameter below 21 meters adopts whole machine frame, which is convenient for civil construction and equipment installationThe advantage of energy saving ball mill is energy saving This equipment is a new type of mineral selection equipment designed according to the new concept The matching motor power can be reduced by 1815%, saving 70%of lubricant, saving 90%of cooling water, comprehensive energy saving of more than 20%or more Essence In the process of use, in addition to energy Energy saving ball mill with dust removal machineThe energysaving ball mill reduces power consumption while maintaining high efficiency, ideal for costeffective grinding in mining and industrial applications Grate Ball Mill The grate ball mill allows efficient discharge of materials, Ball Mills Manufacturer JXSC2021年3月23日 New ball mill drive system with the prototype energysaving SMH motor [37] Startup of the LSPMSM SMH1732T motor with a filled ball mill after two hours of downtime: (a) active power, (b Energy Efficiency Analysis of Copper Ore Ball Mill Drive Systems

.jpg)

Spray Dryer Manufacturer, Ball Mill, Kiln Supplier Foshan

Spray Dryer Supplier, Ball Mill, Kiln Manufacturers/ Suppliers Foshan Qinghua EnergySaving Kiln Co, Ltd Sign In Join Free For Buyer Products As the energysaving ceramic equipment pioneer, it is Qinghua that first opened the energysaving epoch since its If you need energysaving small ball mills, please don’t hesitate to contact us >> SPECIFICATION Specification(mm) Capacity(t/h) Discharge Size(mm) Rotation Speed(r/min) The equipment motor complies with international standards It ensures the longterm and stable operation of the ball mill Price The strict production process, Mini Ball Mill – Mineral Grinding Small Ball Mill For Sale AGICOMill is essential and widely used equipment for raw material crushing Energysaving grate ball mill adopts groovetype circular lining plate that is instrumental in increasing contact areas of iron balls and ores, which enhances grinding action and ore lifting capacity and decreases energy consumption 3Wet energysaving grate ball mill Yantai Jinpeng Mining equipment 2024年11月12日 The CLUM Series Ultrafine Vertical Mill sets a new standard in ultrafine powder production by combining advanced ecofriendly and energysaving technology with precision engineering CLUM Series Ultrafine Vertical Grinding Mill Key Advantages: CLUM Series Ultrafine Vertical Mill 1 UltraLow Operating Cost WearResistant Alloy Material: The CLUM Series Mill: EcoFriendly and EnergySaving, Leading Ultra

.jpg)

Ball Mill (QMJ) Ball Mill and Energy Saving Ball Mill Madein

Ball Mill (QMJ), Find Details and Price about Ball Mill Energy Saving Ball Mill from Ball Mill (QMJ) Zinc, tungsten, molybdenum, manganese and nonmetal ores such as fluorite and quartz Sandstone making equipment is applicable to make construct airport, railway, freeway, average highway, national large bridge, subbottom tunnel, Cylindrical energy saving grid ball mill is one of energy saving mills developed by Xinhai, which is easy to start and saves 2030% energy The mill with diameter below 21 meters adopts whole machine frame, which is convenient for civil construction and equipment installationEnergy Saving Ball Mill, Energy Saving Ball Mill, Cylindrical Energy Ball mill is a key equipment for grinding materials thus grinding ball mills are widely used in the mining beneficiation process, and it has a wide range of suitable grinding mineral and can works on wet and dry grinding processing our JXSC's ball mills are perfectly used for ores such as gold, iron, zinc ore, copper, etc JXSC Mining produce reliable effective ball mill for long life and Ball Mill for Sale Grinding Machine JXSC MiningProduct introduction:Energysaving ball mill is the key equipment for crushing materials after being crushedIt is widely used in the production industries of ferrous and nonferrous me tal beneficiation cement silicate products new Energysaving ball mil Vanguard Machinery,Flotation

[GYQ0R)ZQ]ESS4NJ.jpg)

Energy Saving Ball Mill Dongding Machinery

1 Bush bearing is replaced by rolling bearing, friction resistance being greatly lowered down,easy to start and energy saving's energy is lower 10%15% than the old one 2 The capacity is larger: for the outlet disk and the checked liner The ball mill in closed circuit with hydrocyclones is an industry standard, and well known methodologies exist for equipment sizing, selection and design However, the potential to improve the capacity of ball mill circuits by replacing cyclones with screens has been recognised for many years and recently has been successfully realised, thanks to developments in fine screening Energy Efficient Ball Mill Circuit Equipment Sizing AusIMM2024年10月24日 In today's mineral processing plants, energysaving ball mills for mineral processing can often be seenWhether it is a metal ore or a nonmetallic ore, as long as the useful mineral is in a finegrained embedded state, it must be ground into a finer particle size in order to separate the useful mineral from the gangue mineral Crushing equipment alone cannot meet The working principle and seven advantages of energysaving ball mill Ball Mill The structure of our highefficient and energysaving ball mill is different from the original ball mill The machine body and the bottom frame is integral, so that the machine can be craned and put on the base in one step The principle axis adopts doublerow centripetal spherical roller bearing Mineral Ball MillGrate Ball Mill,Overflow Type Ball Mill,Ball MillingZhengzhou

.jpg)

Straight energysaving overflow ball mill Jinpeng Mining

Energysaving overflow ball mill is usually used for ores with higher grinding finenessIt is a high technological enterprise that integrated research , manufacture, sales and service The company has multiple subsidiaries such as Mineral Processing Research InstituteThe main products include: Rotary Dryer,Dust Collector,Powder Separator, Ball Mill,Vertical Mill,etc Robin: +86 13705101208 Cliff: +86 13805102308 EnglishRotary DryerDust CollectorPowder SeparatorBall MillJiangsu 2013年7月15日 The energy saving resulting from the replacement of cyclones with screens in a closed ball mill circuit was estimated to be in the range of 10 to 25% (Jankovic and Valery, 2012a) An analysis of the(PDF) Energy Efficient Ball Mill Circuit – Equipment Sizing 2024年11月1日 The main products include: Rotary Dryer,Dust Collector,Powder Separator, Ball Mill,Vertical Mill,etc Robin: +86 13705101208 Cliff: +86 13805102308 EnglishBall Mill Jiangsu Sailong Energy Saving Technology

.jpg)

Energysaving Ball Mill Introduction Skew Rolling Mill

2015年7月3日 An energysaving ball mill is an efficient tool for grinding many materials into fine powder after they have been broken into certain sizes It is widely used in the chemical industry, new building materials, silicate products, fireproof materials, fertilizer industry, black and nonferrous metal processing, as well as glassceramics industry, It does dry or wet grinding for all