Vertical mill ore powder improves early activity

Vertical mill simulation applied to iron ores ResearchGate

2014年11月1日 In this study, a coarse sample of iron ore was tested in a pilot scale grinding circuit with a vertical mill Other three samples of pellet feed had already been tested with the methodology2024年11月27日 An experimental vertical stirred mill was used to grind iron ore, and five different speed parameters from 175 rpm to 350 rpm were set as variables It was found that Experimental Study on the Influence of Rotational Speed on 2015年4月1日 In this study, a coarse sample of iron ore was tested in a pilot scale grinding circuit with a vertical mill Other three samples of pellet feed had already been tested with the Vertical mill simulation applied to iron ores ScienceDirect2013年11月1日 Preliminary tests confirmed that ultra fine grinding substantially improves the extraction of silver from the tailings in cyanide leaching (ie 36% Ag extraction rate from the as Ultra fine grinding of silver plant tailings of refractory ore using

Research of iron ore grinding in a verticalrollermill

2015年3月15日 Two magnetite iron ores were comminuted with a pilot scale verticalrollermill The effect of three mill parameters was quantified using DoE methods The developed 2015年3月15日 We investigated whether the vertical roller mill can be efficiently used in the beneficiation of lowgrade magnesite and whether it can improve upon the separation indices Research of iron ore grinding in a verticalrollermillThe use of vertical stirred mills in the mining industry has increased remarkably over the past few decades as a result of the growing demand for finer ore grinding This equipment is Development and Validation of a Simplified Laboratory Test to 2019年4月16日 Vertical roller mills (VRM) have been used extensively for comminuting both cement raw materials and minerals like limestone, clinker, phosphate, manganese, magnesite, (PDF) LEARNING FROM OTHER INDUSTRIES; WHY THE VRM

.jpg)

Latest Installations And Developments Of Loesche Vertical Roller

2012年9月1日 Mills (VRM) installations and summarises the main benefits of the dry compressive Loesche grinding technologies in Airflow and OverflowMode Some of these Among the alternatives, the vertical stirred mill (Vertimill by Metso) has become a popular option for fine grinding in the minerals industry This is due to a good balance between cost and The Grinding Efficiency of the Currently Largest Vertimill 2021年2月8日 1 Introduction Reducing the consumption of natural resources and enhancing the performance of cement and concrete are the two most important issues in the development of cement and concrete in the world today [1], [2]A powerful approach to address these problems is the widespread use of industrial wastes with potential hydraulic activity, such as blast furnace Study on the particle morphology, powder ScienceDirect2021年11月12日 CLUM ultrafine vertical roller mill This vertical mill can also produce 1503000 mesh ore powder Compared with the ultrafine grinding mill, it has higher fine powder content, high powder whiteness, and good shape, Vermiculite Industrial Milling Equipment SBM

.jpg)

Vertical mill simulation applied to iron ores ScienceDirect

2015年4月1日 Eq (5) is used to describe the selection function of a vertical mill of any scale, pilot or industrial [10]Three samples of iron ore (pellet feed), here named samples A, B and C, were tested in a pilot vertical mill The samples were also characterized in order to generate parameters for Eqsrefractory ore using vertical stirred media mill O CELEP, E Y YAZICI UFG Group, Division of Mineral Coal Processing, Department of Mining Engineering, Karadeniz Technical University, Trabzon 61080, Turkiye Received 21 March 2013; accepted 25 April 2013Ultra fine grinding of silver plant tailings of refractory ore using Perlite crushing and grinding process Perlite raw ore → vibrating feeder → jaw crusher (preliminary crushing) → bucket elevator → raw material warehouse → impact crusher → bucket elevator → impact crusher (secondary crushing) → Perlite ultrafine powder vertical mill equipment → bucket elevator→ conveyor → clinker bin cooling and storage → finished productsPerlite Ultrafine Powder Vertical Mill2020年8月12日 PDF This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, Find, read and cite all the research you An investigation of performance characteristics and energetic

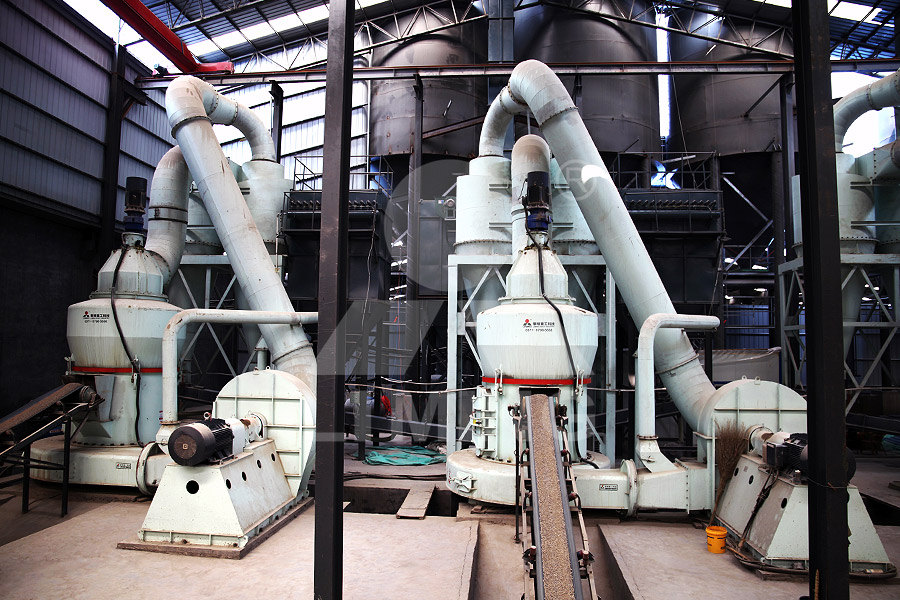

Vertical Roller Grinding Mill Machine CLIRIK Machinery

CLIRIK Machinery produces all kinds of vertical roller mills for ore powder making, such as Raymond roller mill, ultrafine grinding mill, ultrafine vertical roller mill, and so on Home; About; Should We Choose Raymond Mill or Vertical Roller Mill YGM Industrial Raymond Mill Discharge fineness: 80600 mesh Feed size: 35 mm Output: 0435 t/h Materials: Calcite, limestone, wollastonite, gypsum, potassium feldspar, kaolin, bentonite, barite, phosphate rock, manganese ore, quartz stone, marble and other materials with Mohs hardness below 7YGM Industrial Raymond Mill SBM Ultrafine Powder TechnologyProduct advantage of talc powder ultrafine vertical roller mill 1 High quality powder size The fineness of the finished product is D97 545 microns Narrow particle size distribution, can produce 2 micron content of 20%70% products, greatly improving the added value of finished products and application areas 2Talc Powder Ultrafine Vertical Roller MillFebruary 22, 2024 – With the rapid development of the economy, the demand for powder processing in various industries continues to grow As a leading domestic micropowder technology company, SBM is always committed to providing customers with efficient, energysaving and environmentally friendly grinding solutionsSBM micro powder technology leads the market, HGM ultrafine mill

.jpg)

Ultrafine Grinding of Silver Plant Tailings of a Refractory Ore

2013年11月1日 Ultrafine grinding of the plant tailings of a refractory silver ore was studied using a laboratory type vertical stirred media mill Preliminary tests have confirmed that ultrafine grinding 2022年5月5日 CLUM calcium carbonate vertical roller mill CLUM series ultrafine vertical roller mills can grind nonmetallic ores with Mohs hardness less than 7, up to 3000 mesh Among the finished powders it grinds, the content of Calcium Carbonate Grinding Mill Powder ModifyKey Components of Ore Powder Production Equipment: 1 Crushers The initial step in ore powder production is the reduction of ore size, which is accomplished by crushers Jaw crushers, cone crushers, and impact crushers are commonly used to break down the ore into manageable pieces 2 Grinding Mills Grinding mills are central to the powder Advancements in ore powder production process equipment: 2022年5月12日 One of the main equipment of the slag powder production line is the grinding mill >> Vertical micro powder mill The complete set of equipment is mainly composed of jaw crusher, bucket elevator, silo, vibrating feeder, main machine of grinding mill, fan, powder collector, bag filter and so onSlag grinding mill micro powder production line SBM Ultrafine Powder

.jpg)

Research of iron ore grinding in a verticalrollermill

Request PDF On Mar 15, 2015, Mathis Reichert and others published Research of iron ore grinding in a verticalrollermill Find, read and cite all the research you need on ResearchGateVerticalrollermill Free download as PDF File (pdf), Text File (txt) or read online for free The document discusses vertical roller mills, which integrate crushing and grading into a single machine They provide efficient powder grinding with no overgrinding Models range in capacity from 762 tons per hour and can grind materials like coal, limestone, and mineralsVertical Roller Mill PDF Mill (Grinding) Industrial Processes2019年4月16日 Conference: Applying a Successful Technology from the Cement Industry: Advantages of Grinding Ore in a VerticalRollerMill; At: Antalya, Türkey(PDF) LEARNING FROM OTHER INDUSTRIES; WHY THE VRM2019年8月1日 investigation on flotation behavior of a copper sulfide ore after dry grinding by loesche vertical roller mill August 2019 Conference: 58th Annual Conference of Metallurgists (COM 2019)INVESTIGATION ON FLOTATION BEHAVIOR OF A COPPER SULFIDE ORE

.jpg)

Vertical Mill,Vertical roller mill,Vertical powder mill,Vertical

HRM LM ZGM vertical roller mill wear parts Widely used in metallurgy, electric power, cement, chemical, ceramics, nonmetallic minerals, power plant desulfurization, water slag, slag, slag, coal, cement clinker, glass, quartz, limestone and other industries for The invention discloses a method for improving the qualification rate of mineral powder of a slag vertical mill The method comprises the following steps: adjusting an operation process from the operation of firstly drawing negative pressure and then igniting to the operation of firstly igniting and then drawing the negative pressure at the beginning of milling; adjusting the impurity CNA Method for improving qualification rate of 2023年7月19日 Cu powder; the ore powder was made from the copper ore exploited in the Pulang study area and ground into 200 mesh) Then, the soil samples collected from different study areas were dried and(PDF) Mechanical Simulation on the Vertical Migration of Ore 2021年11月27日 Composition of The Powder Grinding Mill The powder grinding mill is composed of a host, a classifier, a blower, a finished cyclone separator, a pipeline device, and a motor The main host machine is composed of a frame, What is Powder Grinding Mill? JXSC Machine

.jpg)

Production method for grinding steeliron slag powder, mineral

The innovation points comprise that the same vertical mill is employed for independently grinding steeliron slag powder, mineral slag powder and steel slag powder, steel slag tailings obtained in the steelslag processing and metal recovery processing step and mineral slag obtained in the mineralslag metalremoval pretreatment step are sent into the vertical mill according to the 2020年1月10日 A test campaign with a pilot scale vertical mill was carried out with five different ore samples to elaborate a simple and robust methodology to scaleup vertical mills and perform simulationsDevelopment and Validation of a Simplified Laboratory Test to Design The mineral powder vertical mill with high specific surface area facilitates the largescale processing and production of ultra S75, S95 and S105 The corresponding 28day activities are 75, 95 and 105 respectively Among them, The maximum specific surface area of In addition to metallurgical solid waste grinding ore powder, News High specific surface mineral powder vertical mill Article Vertical Grinding Mill, An Advanced Mill for Ore Processing Vertical grinding millintegrates drying, grinding, grading and conveying With the advantages of high grinding efficiency, low power consumption, simple equipment process, small floVertical Grinding Mill, An Advanced Mill for Ore Processing

Calcium Carbonate Ultrafine Powder Vertical Mill

SBM high quality calcium carbonate ultrafine powder vertical mill is widely used in many fields +17 [ protected] language >Shibang Industry Technology Group, Shanghai Ultrafine Powder Tech Co, Ltd Home; copper and other minerals These powders are then used in various applications such as ore processing and metallurgyThe mill also has vertical arrangement VXP Mill is a product of FLSmidth company and is vertically oriented stirred media mill The mill is often used in flotation concentrate regrind and precious metals tailings retreatment where the feed size is typically 200 µm [11,12] HIG Mill is a recently developed technology by MetsoOutotech company(PDF) Comparison of Vertical and Horizontal Stirred Mills 2023年2月23日 Francis, B Scaleup and Operations of a Vertical Stirred Mill, Master’s Thesis, The University of British Columbia, Vancouver, BC, Canada, 2014 Minerals 2023 , 13 , 315 16 of 16(PDF) Performance Comparison of the Vertical and ResearchGate2023年10月17日 4 Ultrafine Vertical Grinding Mill Ultrafine vertical grinding mill feed particle size ≤ 20mm, production capacity 120 t/h, production fineness 1503000 mesh CLUMUltrafine vertical grinding mill is a new type of milling equipment that includes grinding, grading, conveying, secondary powder selection, and finished product packagingHow to choose a suitable ore powder grinding mill?

.jpg)

Study on the particle morphology, powder ScienceDirect

2021年2月8日 1 Introduction Reducing the consumption of natural resources and enhancing the performance of cement and concrete are the two most important issues in the development of cement and concrete in the world today [1], [2]A powerful approach to address these problems is the widespread use of industrial wastes with potential hydraulic activity, such as blast furnace 2021年11月12日 CLUM ultrafine vertical roller mill This vertical mill can also produce 1503000 mesh ore powder Compared with the ultrafine grinding mill, it has higher fine powder content, high powder whiteness, and good shape, Vermiculite Industrial Milling Equipment SBM 2015年4月1日 Eq (5) is used to describe the selection function of a vertical mill of any scale, pilot or industrial [10]Three samples of iron ore (pellet feed), here named samples A, B and C, were tested in a pilot vertical mill The samples were also characterized in order to generate parameters for EqsVertical mill simulation applied to iron ores ScienceDirectrefractory ore using vertical stirred media mill O CELEP, E Y YAZICI UFG Group, Division of Mineral Coal Processing, Department of Mining Engineering, Karadeniz Technical University, Trabzon 61080, Turkiye Received 21 March 2013; accepted 25 April 2013Ultra fine grinding of silver plant tailings of refractory ore using

.jpg)

Perlite Ultrafine Powder Vertical Mill

Perlite crushing and grinding process Perlite raw ore → vibrating feeder → jaw crusher (preliminary crushing) → bucket elevator → raw material warehouse → impact crusher → bucket elevator → impact crusher (secondary crushing) → Perlite ultrafine powder vertical mill equipment → bucket elevator→ conveyor → clinker bin cooling and storage → finished products2020年8月12日 PDF This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, Find, read and cite all the research you An investigation of performance characteristics and energetic CLIRIK Machinery produces all kinds of vertical roller mills for ore powder making, such as Raymond roller mill, ultrafine grinding mill, ultrafine vertical roller mill, and so on Home; About; Should We Choose Raymond Mill or Vertical Roller Mill Vertical Roller Grinding Mill Machine CLIRIK Machinery YGM Industrial Raymond Mill Discharge fineness: 80600 mesh Feed size: 35 mm Output: 0435 t/h Materials: Calcite, limestone, wollastonite, gypsum, potassium feldspar, kaolin, bentonite, barite, phosphate rock, manganese ore, quartz stone, marble and other materials with Mohs hardness below 7YGM Industrial Raymond Mill SBM Ultrafine Powder Technology

Talc Powder Ultrafine Vertical Roller Mill

Product advantage of talc powder ultrafine vertical roller mill 1 High quality powder size The fineness of the finished product is D97 545 microns Narrow particle size distribution, can produce 2 micron content of 20%70% products, greatly improving the added value of finished products and application areas 2February 22, 2024 – With the rapid development of the economy, the demand for powder processing in various industries continues to grow As a leading domestic micropowder technology company, SBM is always committed to providing customers with efficient, energysaving and environmentally friendly grinding solutionsSBM micro powder technology leads the market, HGM ultrafine mill