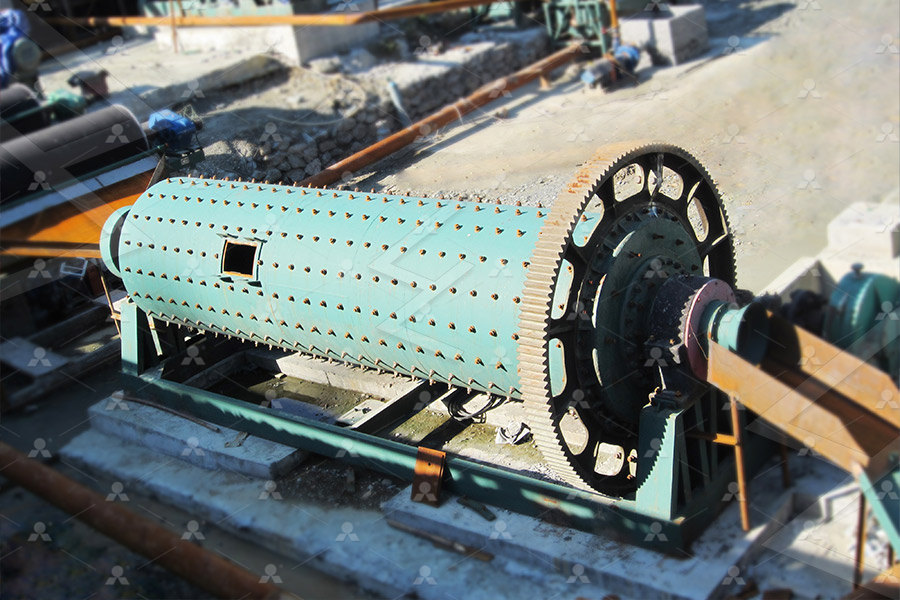

Fine crushing of rare earth ores

Mineral Processing of Rare Earth Ores SpringerLink

Gravity separation is one of the oldest concentration methods used in mineral beneficiation practices It utilizes differences in the specific gravity of valuable and gangue minerals to achieve the separation Taggart has proposed a “concentration criterion,” which is widely used to evaluate the feasibility of gravity 展开2017年9月10日 The purpose of this paper is to comprehensively review and summarize the rare earth processing routes, the mostly employed rare earth separation methods, supply and demand of rare earth(PDF) A Review of Rare Earth Mineral Processing 2019年4月1日 Microstructural characterisation of the rare earth minerals in crushed ore showed that the rare earth minerals were of very fine grain size and occurred as polycrystalline Characterisation of a ferruginous rare earth bearing lateritic ore 2024年4月1日 Rare earth resources are quite abundant worldwide and China has the largest reserves and production Bastnaesite, monazite, and mixed RE ores are generally Journal of Rare Earths ScienceDirect

.jpg)

Wet gravity separation and froth floatation techniques for rare

2023年9月1日 Results showed significant concentration increases of these elements in the WGS concentrate, with high grade and good recoveries achieved for Ce, La, and Nd Overall, the There are different methods involved in production of metals and non metals from rare earths for example; separation, primary crushing, secondary crushing, wet grinding, dry grinding etc The Handbook on Rare Earth Metals and Alloys (Properties, Extraction 2017年8月1日 After mining, comminution and ore beneficiation, hydrometallurgical and pyrometallurgical processes are carried out to recover REE compounds The concentrate A review on the cracking, baking and leaching processes of rare 2022年3月21日 Rareearth elements (REEs) are required for use in modern hightech applications and demand has increased significantly over the last decade 1 However, Processing the ores of rareearth elements MRS Bulletin

The Characterization and Mineralogical Studies of a New Type of

2022年10月28日 The mineralogical characteristics of a new rare earth ore (SREO) in southwest China were investigated by an advanced mineral identification and characterization system Most of the Bayan Obo minerals, particularly in the banded ore, are very fine to extremely fine grained Most Fe−REE−Nb minerals are closely associated with fine grain sizesCHINA’S RARE EARTH ORE DEPOSITS AND BENEFICIATIONERES2014: 1st European Rare Earth Resources ConferenceMilos04‐07/09/2014 PAGE 26 CHINA’S RARE EARTH ORE DEPOSITS AND BENEFICIATION TECHNIQUES Ling ZHI LI1, Xiaosheng YANG2 1China Western Mining Co, Ltd, Xining, Qinghai, PRChina : lzli8288@sinaCHINA’S RARE EARTH ORE DEPOSITS AND BENEFICIATION2016年1月1日 Currently, the rare earth supply in China mainly comes from the Bayan Obo REE–niobium–iron deposit situated in Inner Mongolia, the ion adsorption rare earth deposits in Jiangxi, Guangdong, Fujian, and Guangxi, the Mianning bastnaesite deposit in Sichuan and the Weishan bastnaesite deposit in Shandong, and the placer monazite and xenotime deposits in China’s Rare Earth Resources, Mineralogy, and Beneficiation

.jpg)

Development Review on Leaching Technology and

2023年9月17日 Weathered crust elutiondeposited rare earth ores are key strategic resources and the main source of medium and heavy rare earths This paper summarizes the development of leaching technology of rare earth ores, 2015年8月1日 According to EPA, United States Environmental Protection Agency, 2012, the abundance of REEs in earth’s crust shows that lanthanides with lower atomic numbers are more abundant than one with higher atomic numbers as presented in Table 1They do not occur as metallic elements but exists in wide range of minerals of carbonates, oxides, phosphates and Process development to recover rare earth metals from monazite 2024年11月13日 The selection of appropriate types of equipment for mineral processing is vital in order to increase the yield, reduce the unit cost and, above all, successfully recover the valuable minerals []Comparing Mineral Processing Equipment for Different Ore Types2017年8月1日 JOURNAL OF RARE EARTHS, Vol 35, No 8, Aug 2017, P 739 Foundation item: Project supported by the Research Initiation Grant of Queen’s University, Canada (#) and Ontario Centers of Excellence VIP fund (#25394) * Corresponding author: Ahmad Ghahreman (Email: [ protected]; Tel: +16135333294) DOI: 101016/S1002 A review on the cracking, baking and leaching processes of rare earth

.jpg)

Flotationmagnetic separation for the beneficiation of rare earth ores

2018年4月1日 The agglomeration of fine bastnaesite particles has been observed by (REO) content and recovery from the Maoniuping rare earth concentrate However, REO recovery from Dalucao rare earth ores remained low at about 20% Dalucao rare The sample was initially crushed into 3mm particles using a combination of jaw crushing The invention provides hydrometallurgical processes for the recovery of rare earth values from ore, using simple crushing without beneficiation to produce an enriched and purified mixed rare earth concentrate Ore is crushed to a relatively coarse particle size, and then treated with relatively small amounts of acid, at a relatively modest elevated temperature, to render the rare earth elements fine crushingHXJQ Crusher Machine2022年8月22日 Although rare earth deposits are found on all continents, China produces more than 90% of all globally used rare earth metals Besides its economic dominance, China has also gained a monopolistic (PDF) Economic analysis of rare earth element processing 2023年7月28日 Crushing and Grinding The rare earth ore is first crushed into smaller particles to increase the surface area for further processing It is then ground into a fine powder to liberate the rare earth minerals from the gangue minerals Gravity Separation In some cases, gravity separation techniques can be used to separate rare earth minerals from Rare Earth Ore: From Mining to Application JXSC Mineral

.jpg)

Review on hydrometallurgical recovery of rare earth metals

2016年10月1日 To recover rare earth metals from these ores, The composition of phosphor powder obtained after crushing and sieving of the lamps generally contains halophosphate phosphor (45 wt%), fine glass particles and silica (20 2023年9月29日 As a weathered soil, ionabsorbed rareearth ores exhibits a loose texture, comprising sand, silt, and clay, with a notable presence of fine particles measuring less than 75 μm in the weathered layer (Chen et al 2020)Consequently, variations in both physical and chemical conditions possess the potential to impact the shear strength of the soil (Guo et al Weakening of mechanical parameters of ionabsorbed rareearth ores 2015年12月25日 In Chap 2, the most important occurrences of the rare earths were describedThis chapter will deal with what happens when the rare earths have been mined It answers the question: how are the ores processed? Mineral Processing and Extractive Metallurgy of the 2015年8月31日 The escalating demand of rare earth metals (REMs) in various applications and their continuous depleting ores have laid emphasis to produce metals from their complex resources by developing energy (PDF) Process development to recover rare earth metals from

.jpg)

Unlocking Potential: Rare Earth Elements Processing Solutions

2023年11月9日 The hammer crushercan achieve preliminary crushing of rare earth minerals by impacting and striking them The coarsely crushed minerals are then sent to the impact crusher for secondary crushing The impact crusher is suitable for medium and fine crushing operations and can produce rare earth particles with a finer particle size(≤25 mm)Total content and partitioning of ionexchangeablephase rare earth in the rare earth raw ores (expressed as oxides) REO Type La 2 O 3 CeO 2 Pr 6 O 11 Nd 2 O 3 Sm 2 O 3 Eu 2 O 3 Gd 2 O 3 Tb 4 O 7Effect of Fine Particle Content on Solution Flow and Mass Transfer 2022年3月21日 Rareearth elements (REEs) are required for use in modern hightech applications and demand has increased significantly over the last decade 1 However, processing of REE ores poses potential hazards to human health and the environment due to challenges in the management of thorium (Th) and uranium (U) in waste products 2 If well managed, REE Processing the ores of rareearth elements MRS BulletinDownload scientific diagram Crushing of large size of studied ores to fine sizes from publication: Evaluation of some natural ores from Egyptian eastern desert to be utilized in producing of Crushing of large size of studied ores to fine sizes Download

.jpg)

Application of ferrous pyrometallurgy to the beneficiation of rare

2017年8月15日 Similarly, a study by She et al (2016) into the mechanism of iron reduction and the transformation of rare earth minerals in Bayan Obo iron ore during direct reduction also found that rare earth minerals underwent decomposition with the rare earths concentrating into calcium rare earth silicophosphate and rare earth oxysilicate phases of formulae {Ca 3 Ce 2 [(Si x, P minerals [1]—this includes rareearth deposits State of the art rareearth mineral processing methods include the crushing and grinding of the entire extracted material down to liberation size of contained valuable minerals, followed by a separation of minerals by mainly wet processes such as flotation [2][3] At present, no sensorbased Investigations on the Detectability of RareEarth Minerals Using 2023年2月26日 1 Introduction Rare earth elements (REEs) have unique and irreplaceable electrical, optical, magnetic, and thermal properties due to their large atomic magnetic moments, anisotropy, rich electronic energy level transitions, and unique lanthanide shrinkage [1,2]Known as “vitamins of new materials,” REEs are a key element of strategic resources and Exploring rare earth mineral recovery through characterization of 2023年10月1日 Rare earth elements (REEs) comprise 17 chemical elements, including scandium (Sc), yttrium (Y) and 15 lanthanide elements (Ln), which are essential raw materials for hightechnology industries because of their unique physical and chemical properties (Jordens et al, 2013)China is the major producer of REEs and >70%–80% of heavy REEs are derived Effect of particle size on the leaching of a weathered crust elution

.jpg)

A review of flotation reagents for bastnäsite(Ce) rare earth ore

2023年11月1日 According to the 2023 data summary of the United States Geological Survey (USGS), the global proven reserves of rare earth oxide are estimated to be around 130 million tons, concentrated in countries such as China, Russia, Vietnam, Australia, and Brazil [18, 19]The total world production of rare earths is about 24 million tons, mainly concentrated in the United Journal of Mining and Environment, 2016 This study aims to investigate and optimize the effects of the main parameters including the particle size, gravity and magnetic separation combination, high gradient magnetic separation, magnetic field intensity, shaking table slope, washing water flow, and electrostatic separation upon the rare earth element (REE) recoveries from iron mine A Review of Rare Earth Mineral Processing Technology2024年11月11日 The Kalgoorlie plant is expected to create around 115 direct jobs in the Goldfields region by processing ores from Lynas’ nearby Mt Weld mine to create a mixed rare earth carbonateAustralia’s first rare earths processing plant opens2017年12月28日 PDF To detect the evolutional characteristics of pore structure in ore leaching process of iontype rare earth, rare earth ores e matrix of rare earth ore is strong, weathered granite,(PDF) Experimental Research on the Impact of Ion Exchange and

.jpg)

Upgrading a manufactured fine aggregate for use in concrete

2019年11月1日 Crushing is an important stage in processing manufactured fine aggregates, and several studies have demonstrated the benefit of impact (vertical shaft impact or VSI) over compressive crushing as a method to improve particle shape (Gonçalves et al, 2007, Åkesson and Tjell, 2010, Nanthagopalan and Santhanam, 2011, Cepuritis et al, 2016)2024年8月28日 Fine particle content significantly affects the in situ leaching of ionadsorptiontype rare earth ores This study investigated the effect of fine particle content on solution flow and mass transfer in leaching The results showed that with the increase in fine particle content, the peak concentration and peak time of rare earth increased When the fine particle content Effect of Fine Particle Content on Solution Flow and Mass MDPIcurrently utilized at the major rare earth mines and processing plants in China Bayan Obo REE−Fe−Nb deposit The rareearth resources in Bayan Obo were discovered in 1927 and industrial production of rareearth concentrates started from 1957 Though Bayan Obo is the largest REE deposit, it istechnology of rare earth ores in China Semantic Scholarconomic analysis of rare earth element processing methods for Mountain Pass ore 408 ULY 2022 VOLUME 122 The Journal of the Southern African Institute of Mining and Metallurgy separation of REE minerals with relatively high densities (47 g/cm3) and gangue minerals with low specific gravity such as quartz, calcite and fluorite (Ferron, Bulatovic and Salter, 1991)Economic analysis of rare earth element processing methods for

.jpg)

CHINA’S RARE EARTH ORE DEPOSITS AND BENEFICIATION

ERES2014: 1st European Rare Earth Resources ConferenceMilos04‐07/09/2014 PAGE 26 CHINA’S RARE EARTH ORE DEPOSITS AND BENEFICIATION TECHNIQUES Ling ZHI LI1, Xiaosheng YANG2 1China Western Mining Co, Ltd, Xining, Qinghai, PRChina : lzli8288@sina2016年1月1日 Currently, the rare earth supply in China mainly comes from the Bayan Obo REE–niobium–iron deposit situated in Inner Mongolia, the ion adsorption rare earth deposits in Jiangxi, Guangdong, Fujian, and Guangxi, the Mianning bastnaesite deposit in Sichuan and the Weishan bastnaesite deposit in Shandong, and the placer monazite and xenotime deposits in China’s Rare Earth Resources, Mineralogy, and Beneficiation2023年9月17日 Weathered crust elutiondeposited rare earth ores are key strategic resources and the main source of medium and heavy rare earths This paper summarizes the development of leaching technology of rare earth ores, Development Review on Leaching Technology and 2015年8月1日 According to EPA, United States Environmental Protection Agency, 2012, the abundance of REEs in earth’s crust shows that lanthanides with lower atomic numbers are more abundant than one with higher atomic numbers as presented in Table 1They do not occur as metallic elements but exists in wide range of minerals of carbonates, oxides, phosphates and Process development to recover rare earth metals from monazite

Comparing Mineral Processing Equipment for Different Ore Types

2024年11月13日 The selection of appropriate types of equipment for mineral processing is vital in order to increase the yield, reduce the unit cost and, above all, successfully recover the valuable minerals []2017年8月1日 JOURNAL OF RARE EARTHS, Vol 35, No 8, Aug 2017, P 739 Foundation item: Project supported by the Research Initiation Grant of Queen’s University, Canada (#) and Ontario Centers of Excellence VIP fund (#25394) * Corresponding author: Ahmad Ghahreman (Email: [ protected]; Tel: +16135333294) DOI: 101016/S1002 A review on the cracking, baking and leaching processes of rare earth 2018年4月1日 The agglomeration of fine bastnaesite particles has been observed by (REO) content and recovery from the Maoniuping rare earth concentrate However, REO recovery from Dalucao rare earth ores remained low at about 20% Dalucao rare The sample was initially crushed into 3mm particles using a combination of jaw crushing Flotationmagnetic separation for the beneficiation of rare earth ores The invention provides hydrometallurgical processes for the recovery of rare earth values from ore, using simple crushing without beneficiation to produce an enriched and purified mixed rare earth concentrate Ore is crushed to a relatively coarse particle size, and then treated with relatively small amounts of acid, at a relatively modest elevated temperature, to render the rare earth elements fine crushingHXJQ Crusher Machine

(PDF) Economic analysis of rare earth element processing

2022年8月22日 Although rare earth deposits are found on all continents, China produces more than 90% of all globally used rare earth metals Besides its economic dominance, China has also gained a monopolistic 2023年7月28日 Crushing and Grinding The rare earth ore is first crushed into smaller particles to increase the surface area for further processing It is then ground into a fine powder to liberate the rare earth minerals from the gangue minerals Gravity Separation In some cases, gravity separation techniques can be used to separate rare earth minerals from Rare Earth Ore: From Mining to Application JXSC Mineral