What is suitable for grinding silica

.jpg)

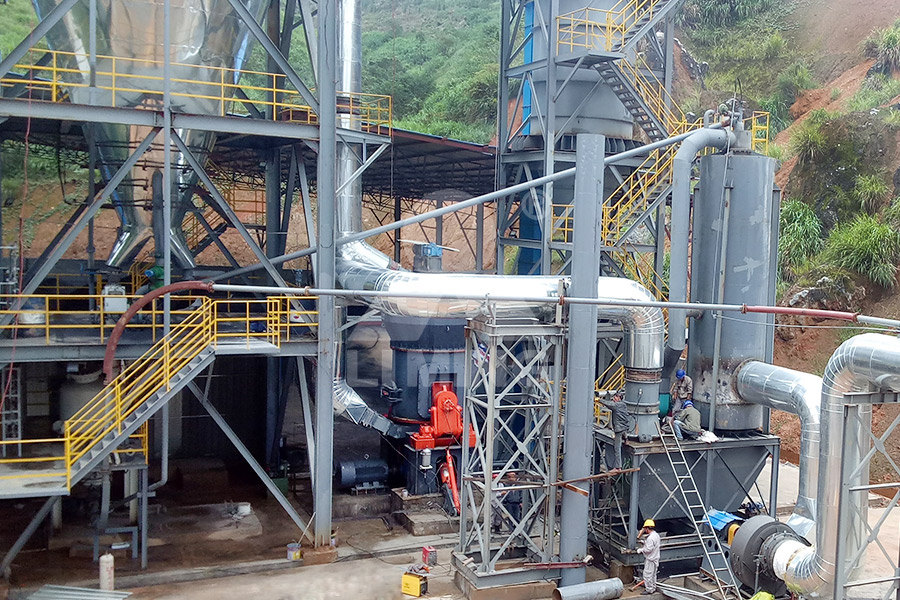

What is the best for grinding silica sand ball mill or vertical mill

silica sand ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and can be used for the Cutting and grinding silica without protection can lead to disastrous outcomes • You can develop silicosis after only a few weeks or months of exposure • The disease can become worse even Silica—Cutting and grinding concrete IHSAIn silica sand production plant, silica sand grinding machine is the key equipment ZENITH offers the following grinding machines for this process stage: Capacity: 345t/h Max Input Size: 50mm Output Size: 80425meshSilica Sand Grinding Machine Zenith CrusherFor Quartz and Silica Sands In many cases, and due to its extraction process or its handling, silica sands contain moisture that makes subsequent processes difficult For this situation, ANIVI offers rotary dryers, either fixed or modular Grinding and Drying of Quartz and Silica Sands ANIVI

.jpg)

Working with silica and silica containing products Safe Work

who has workers (including yourself) that work with silica or silica containing products, except if you are working with engineered stone This guide explains what you must do to keep your Dry grinding is used in the dry type silica sand ball mill, and no liquid is involved in the process of silica sand treatment Dryprocess silica sand production saves energy, has good sealing performance and no dust pollution Wet process Wet Dry Silica Sand Ball Mill for Silica Sand GrindingScabbling and grinding concrete or other construction materials can produce very high levels of silica containing dust Effective control is necessary because this work is high risk This pageConstruction dust: Scabbling or grinding HSESilica dust can be found on nearly all construction sites It is most dangerous when found in the dust that is generated when you’re cutting, grinding, or drillingSilica in Construction SafeWork NSW

Silica dust IOSH

breaking, crushing, grinding or milling silicacontaining material such as concrete, aggregate or mortar; drilling, cutting, chiselling or sanding silicacontaining material; a risk assessment and description of suitable controls, concentrating where possible on eliminating the risk or extraction systems rather than personal 2013年9月28日 In the grinding of high quality fused silica parts with complex surface or structure using ballheaded metal bonded diamond wheel with small diameter, the existing dressing methods are not suitable to dress the ballheaded diamond wheel precisely due to that they are either online in process dressing which may causes collision problem or without consideration Onmachine precision preparation and dressing of ballheaded Silica dust – Silica is a natural mineral present in large amounts in things like sand, sandstone and granite It is also commonly found in many construction materials such as concrete and mortar The silica is broken into very fine dust (also known as Respirable Crystalline Silica or RCS) during many common tasks such as cutting, drilling and grindingDust HSE2020年10月9日 Silica dust (crystalline silica) is now a known hazardous dust in the construction industry found in concrete, brick, tiles, sandstone, quartz, manufactured stone or nonmanufactured benchtopsSilica dust can be a health threat when inhaled, similarly to asbestos except diseases (such as acute silicosis) can develop within weeks rather than years of What You Need To Know About Silica Dust Capital Equipment

.jpg)

Aluminum Oxide vs Silicon Carbide: Choosing the Right Abrasive

2023年12月22日 Metal Grinding and Sanding: Due to its high hardness and durability, Aluminum Oxide is ideal for grinding and sanding metal surfaces, particularly for removing rust, paint, or other coatings Wood Finishing : Coarser grits of Aluminum Oxide are effectively used to shape and finish wood surfaces, while finer grits are favored for polishing and creating smoother 2023年6月13日 Silica dust is a hazardous material that can cause serious health problems if not properly controlled in the workplace Inhalation of this fine particulate matter can lead to serious respiratory conditions, including silicosis and lung cancer To ensure workplace safety, it is crucial to implement effective silica dust control measuresSilica Dust Control Measures: Best Practices for Workplace Safety2023年11月6日 Fused silica, a remarkable ceramic material known for its exceptional properties, plays a pivotal role in a wide range of industries, from semiconductor manufacturing to aerospace technology Achieving precise dimensions and smooth surfaces in fused silica components is a critical challenge In this article, we delve into the world of grinding fused silica, focusing on the Precision Grinding Fused Silica and Quartz with Diamond Wheels2021年10月13日 Silica dust is released from these materials during highenergy operations like sawing, cutting, drilling, chipping, sanding, and grinding These fine particles of crystalline silica release into the air and become a hazardous respirable dust Exposure to Silica Dust Silica dust exposure can occur during common construction tasks such as Good, Better, Best Respiratory Protection for Silica Dust

.jpg)

Silica Processing Plant 4 Major Stages to Make Silica Sand

2023年8月10日 Melting point: Up to about 1,710 degrees Celsius, suitable for a variety of hightemperature applications Color: Light in color, from white to gray It changes according to impurities, The production process of silica sand includes 4 stages of crushing, grinding, purifying, and drying 1 Silica crushing process2017年3月2日 Silica gel contains a nanoporous silica microstructure, suspended inside a liquid Powerful blowing and strong selfcooling capability, suitable for grinding heatsensitive materials 4Silica Gel Powder Grinding Mill MediumThis makes it suitable for applications that involve exposure to extreme temperatures, such as in the manufacturing of refractory materials, ceramics, grinding, and polishing applications Silica is also utilized in the construction Silica vs Silicone What's the Difference? This vs That2022年7月27日 Respirable crystalline silica, or silica dust, is an assortment of airborne particles caused by working with materials containing crystalline silica Manufacturing and construction industry workers are often exposed to these What Masks Work Against Silica Dust? Sunline Supply

Silica Sand Refinement: Leveraging Grinding Balls for Consistent

2024年4月9日 The selection of grinding balls for silica sand refinement is a critical decision that directly impacts process efficiency and product quality By analyzing the specific needs of their refinement process, manufacturers can determine the most suitable type of grinding balls for achieving optimal resultsThis document is both a Warning and a Training guide on Dry Cutting : Grinding Sanding: 1 Silica—Identifying and managing crystalline silica dust exposure This information guide provides brief guidance on the legislative requirements for identifying and managing respirable crystalline silica (RCS) dust exposure in workplaces1 Silica—Identifying and managing crystalline silica dust exposure2024年1月9日 0; Silicon Wafer Material is an essential component in semiconductor and integrated circuit production Silicon wafer material starts as raw quartz sand, which is then purified, grown into crystalline ingots, sliced into discs, polished and cleaned to create a pristine surface for building transistors and integrated circuitsSilicon Wafer Material: From Sand to SemiconductorsRCS is generated in workplace processes such as crushing, cutting, drilling, grinding, sanding, sawing or polishing of natural stone or manufactured crystalline silica containing products A label, product information or safety data sheet (SDS) may not always be available at a workplace or with a product that contains crystalline silicaWorking with crystalline silica and crystalline silica containing

.jpg)

Ball Mill For Silica Quartz Sand Frac sand grinding in silica sand

2023年9月3日 1 Cylinder and Liner Material: The cylinder or drum of the ball mill is typically made of steel, stainless steel, or other suitable materials to withstand the abrasive nature of silica quartz workplace and task If suitable control measures are not in place, anyone working around silica dust has an increased risk of developing lung cancer Figure 1: Common silicacontaining materials and job tasks where you may be exposed to silica dust Figure 2: Hierarchy of risk control Level of health and safety protection Reliability of control Occupational Cancer Risk Series SILICA DUSTSilica during metal production and fabrication What is Crystalline Silica? Crystalline silica (silicon dioxide, SiO2) is one of the most common naturally occurring minerals on the earth In the form of quartz, it is a basic component of many soils, sands, and rocks Crystalline silica is used to make products such asHelping to reduce your exposure to Crystalline Silica during metal Silica is more than dust at a construction site Crystalline silica is a mineral found in concrete, stone, sand, brick, and mortar When a worker grinds, drills or cuts construction materials, such as cutting control joints in a concrete floor, tiny dust particles are created This dust contains silicaThe N95 Respirator Protection Against Silica

Zirconia Ceramic Grinding Media: Sintered Balls and

Industrial tests have proven this grinding media offers up to 15 times higher wear resistance than various highalumina qualities Select larger sizes up to ∅70 mm for ball mills or use them to substitute high alumina grinding media ZTA is The process of wet grinding and dry grinding involves countless products that we use The suitable lining material is selected to solve the problem caused by hard materials and detergents, plastics, glass fiber, leather, white carbon black, silica, titanium bai powder, carbon black, graphene, carbon nanotubes, fullerenes, gels, sols What is the difference between wet grinding and dry grinding?2023年12月11日 Sources of Silica Dust Silica dust can originate from various sources across different industries and work environments Silicacontaining products can emit dust particles during cutting, crushing, drilling, polishing, An Introduction to Silica Dust: Definition, Sources, and 2024年6月18日 Crystalline silica is a mineral that is plentiful, yet dangerous The health risks posed to workers is abundant Read more 8004796801; Regulation Respirable crystalline silica is generated by highenergy operations like cutting, sawing, grinding, drilling and crushing stone, rock, concrete, brick, blockKnow Your Dust: Crystalline Silica Camfil APC

Improving The Efficiency Of Fine Grinding Glencore Technology

11 Grinding Media Types To date, all IsaMill installations have taken advantage of the technology’s ability to use a low cost, but relatively low quality grinding media such as silica sand, river pebble, smelter slag or fine primary mill scats (autogenous milling) Whilst the IsaMill produces high energy efficiencieslevels of silica dust (for example through dust or mist clouds) Workers can also be exposed to silica dust from poor housekeeping methods that disturb accumulated dust, including dry sweeping, using compressed air or highpressure water cleaners and generalpurpose vacuum cleaners not designed for use with hazardous dusts 14Working with silica and silica containing products Safe Work 7 KNOW Workplace Cancer Workers Toolbox Talk Silica What makes silica dust? • Breaking, crushing, grinding or milling materials like concrete and aggregate • Drilling, cutting or sanding things like bricks and concrete • Dealing with cement • Laying, maintaining or replacing ballast • Excavating, mining, quarrying or tunneling • Abrasive blastingTOOLBOX TALK SILICA DUST Cancer CouncilWhen producing prestressed highstrength concrete pipe piles (PHC pipe piles for short), The production process of "secondary curing", which combines atmospheric steam curing and autoclave curing, is usually adopted Silica sand powder (or ground fine sand) is used in the production of PHC pipe piles by taking advantage of the characteristics of hydrothermal What Kind Of Silica Sand Grinding mill Equipment Is Used To

.jpg)

Crystalline Silica Poses Clear Present Danger to Workers

2021年6月16日 Silica dust has also been tied to autoimmune disorders and cardiovascular impairment Because silicosis and other conditions can take years to manifest, they may go underreported as a cause of death Thousands of silica dustrelated conditions go undiagnosed each year What is OSHAs Respirable Crystalline Silica Standard Advised Protections?2024年11月4日 In short, the ball mill is a kind of multipurpose grinding equipment, which is suitable for the production of silicon powder under various conditionsHowever, for specific production needs, such as very high requirements for product perusal, ball mills are not suitableAt this time, other types of grinding equipment, such as air flow grinding or stirring Can a ball mill grind silica?breaking, crushing, grinding or milling silicacontaining material such as concrete, aggregate or mortar; drilling, cutting, chiselling or sanding silicacontaining material; a risk assessment and description of suitable controls, concentrating where possible on eliminating the risk or extraction systems rather than personal Silica dust IOSH2013年9月28日 In the grinding of high quality fused silica parts with complex surface or structure using ballheaded metal bonded diamond wheel with small diameter, the existing dressing methods are not suitable to dress the ballheaded diamond wheel precisely due to that they are either online in process dressing which may causes collision problem or without consideration Onmachine precision preparation and dressing of ballheaded

Dust HSE

Silica dust – Silica is a natural mineral present in large amounts in things like sand, sandstone and granite It is also commonly found in many construction materials such as concrete and mortar The silica is broken into very fine dust (also known as Respirable Crystalline Silica or RCS) during many common tasks such as cutting, drilling and grinding2020年10月9日 Silica dust (crystalline silica) is now a known hazardous dust in the construction industry found in concrete, brick, tiles, sandstone, quartz, manufactured stone or nonmanufactured benchtopsSilica dust can be a health threat when inhaled, similarly to asbestos except diseases (such as acute silicosis) can develop within weeks rather than years of What You Need To Know About Silica Dust Capital Equipment 2023年12月22日 Metal Grinding and Sanding: Due to its high hardness and durability, Aluminum Oxide is ideal for grinding and sanding metal surfaces, particularly for removing rust, paint, or other coatings Wood Finishing : Coarser grits of Aluminum Oxide are effectively used to shape and finish wood surfaces, while finer grits are favored for polishing and creating smoother Aluminum Oxide vs Silicon Carbide: Choosing the Right Abrasive2023年6月13日 Silica dust is a hazardous material that can cause serious health problems if not properly controlled in the workplace Inhalation of this fine particulate matter can lead to serious respiratory conditions, including silicosis and lung cancer To ensure workplace safety, it is crucial to implement effective silica dust control measuresSilica Dust Control Measures: Best Practices for Workplace Safety

Precision Grinding Fused Silica and Quartz with Diamond Wheels

2023年11月6日 Fused silica, a remarkable ceramic material known for its exceptional properties, plays a pivotal role in a wide range of industries, from semiconductor manufacturing to aerospace technology Achieving precise dimensions and smooth surfaces in fused silica components is a critical challenge In this article, we delve into the world of grinding fused silica, focusing on the 2021年10月13日 Silica dust is released from these materials during highenergy operations like sawing, cutting, drilling, chipping, sanding, and grinding These fine particles of crystalline silica release into the air and become a hazardous respirable dust Exposure to Silica Dust Silica dust exposure can occur during common construction tasks such as Good, Better, Best Respiratory Protection for Silica Dust2023年8月10日 Melting point: Up to about 1,710 degrees Celsius, suitable for a variety of hightemperature applications Color: Light in color, from white to gray It changes according to impurities, The production process of silica sand includes 4 stages of crushing, grinding, purifying, and drying 1 Silica crushing processSilica Processing Plant 4 Major Stages to Make Silica Sand2017年3月2日 Silica gel contains a nanoporous silica microstructure, suspended inside a liquid Powerful blowing and strong selfcooling capability, suitable for grinding heatsensitive materials 4Silica Gel Powder Grinding Mill Medium