Working principle of 3ya1848 high fine vertical mill

.jpg)

Working principle and characteristics of vertical mill

The working principle of a vertical mill involves the rotation of a grinding table with rollers 2015年3月25日 The hydraulic system of vertical mill is an important system, the main function of the hydraulic system is to break the grinding roller, which is when the internal grinding cavity wear parts wear, can stop open on both sides of Hydraulic system vertical roller mill operation PDF11 The Working Principle of Vertical Mill The material enters the vertical mill from the upper Solid Edge’s Application in Vertical Mill Design SpringerSetup: Before starting, secure the workpiece on the table and choose the appropriate cutting tool for the desired operation Tool Selection: Depending on the operation, select the suitable cutting tool and mount it on the spindle Milling Machine Working Principle And Operations

The working principle of ultrafine Raymond mill

2022年6月15日 The working principle of ultrafine Raymond mill adopts closedcircuit air circulation system, which has low noise, low energy consumption and easy maintenance The representative model is HCQ ultrafine Raymond mill, 2024年10月31日 Ultrafine impact mill site picture The working principle of the ultrafine impact mill is as follows: After the material enters the machine body from the feed port at the bottom of the machine body, it is quickly broken up by the hammer head on the rotor, scattered around the stator, and enters the crushing area composed of the rotor and statorWorking principle of ultrafine impact mill JINGHUAAir ring) The highspeed upward hot air is brought to the highefficiency separator integrated with the industrial vertical grinding mill The coarse powder is sorted by the separator and returned to the grinding plate for regrinding; the fine powder is discharged out of the mill with the air flow and is collected in the systemIndustrial Vertical Grinding Mill2015年3月9日 Working principle of vertical roller mill is driven by motor reducer rotating disc, and the hot air from the air inlet into the vertical mill, the material from the feed opening falls on the disc center, due to the centrifugal force, the material is moved from the center to the edge of the grinding disc disc, the disc by an annular groove, the grinding roller compacted by The working principle of vertical roller mill CSDN博客

.jpg)

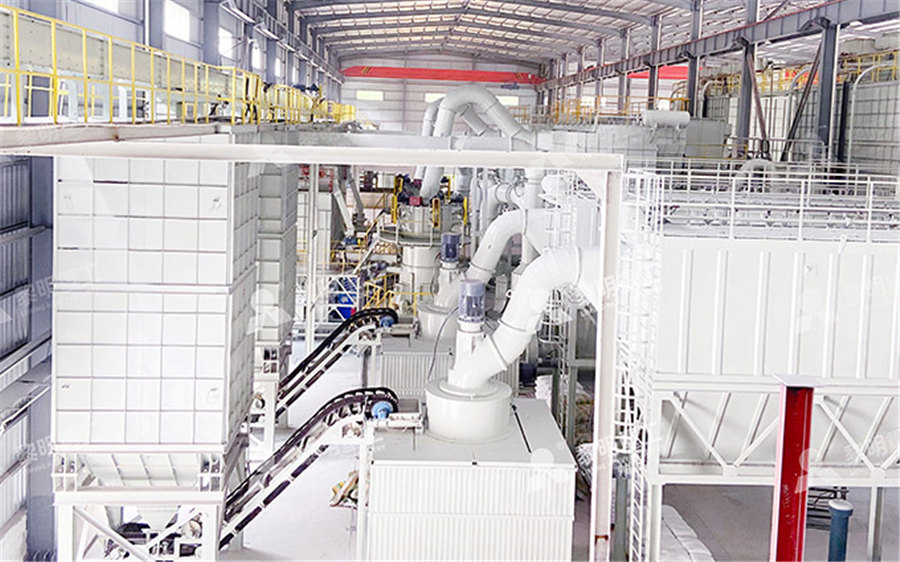

Limestone Ultrafine Vertical Mill

Limestone ultrafine vertical mill is a high quality ores material powder grinding mill +17 [ protected] Working Principle Of Limestone Ultrafine Vertical Mill HGM series Ultra Fine Powder Mill CLRM Series Enhanced Roller Grinding Mill YGM series Raymond Mill Hammer crusher2015年3月25日 1 The working principle of the hydraulic system vertical roller mill The hydraulic system ofvertical mill is an important system, the main function ofthe hydraulic system is to break the grinding roller, which is when the internal grinding cavity wear parts wear, can stop open on both sidesofthe grinding roller mill, to replace the inside parts or repairThis type vertical roller Hydraulic system vertical roller mill operation PDF SlideShareWorking Principle The ultrafine vertical mill is composed of several components, each of which plays a critical role in the operation of the machine And they must work together in harmony to produce highquality, ultrafine powder These components include: Grinding chamber, Agitator, Feed inlet, Discharge outlet, Motor, Calcium Carbonate Ultrafine Powder Vertical Mill2017年9月11日 PDF In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg Samples were collected from Find, read and cite all the research (PDF) Performance Evaluation of Vertical Roller Mill in Cement

An investigation of performance characteristics and energetic

2020年8月12日 efficiency of vertical roller coal mill currently working in the coalfired power plant with all aspects Therefore, this study contributes literature by performing performance analysis2022年3月30日 Overview of Ball Mill Ball mill, also known as tumbling or pebble mill is milling equipment that encompasses cylindercontaining balls and is mounted on a metallic frame that can be rotated along with a longitudinal axis Introduction to HighEnergy Ball Mill: Working Ball Mill, Working Principle, Types, Parts, Applications and Advantages Ball Mill Grinding Machines: Exploring the Working Principle, Types, Parts, Applications, Advantages, and Recent Developments Ball mill grinding machines are Ball Mill Grinding Machines: Working Principle, It is characterized by its unique working principle, which involves a highspeed rotating shaft with agitator elements Its high grinding efficiency, fine particle size distribution, we can provide customers with types of ball mill, vertical mill, rod mill and AG/SAG mill for grinding in a variety of industries and materials ContactWhat is The Working Principle of Attritor Mill? ball mills supplier

.jpg)

Understanding the working principle of lum ultrafine vertical mill

The Working Principle of LUM Ultrafine Vertical Mill: 1 The air current, carrying the fine particles, exits the mill through an exhaust system A separator is used to separate the air from the powdered materials Advantages of LUM Ultrafine Vertical Mill: High Efficiency: 2023年8月5日 High pressure roller mill is a new type of grinding equipment developed on the basis of roller press for cement in recent years Mines increase the specific surface area for fine grinding The high pressure roller mill has the characteristics of high production efficiency, large crushing ratio, low power consumption, significant energy saving and convenient maintenanceWorking principle of high pressure roller millZYminingLimestone Powder Ultrafine Vertical Roller Mill Modle : CLUM Series Finished Size: 4003000 mesh Processing Ability: 3 – 45t/h Max Feeding Size: 10 mm M 1 Set Price: $ Range Of Application: Limestone, Calcium Carbonate, Talc, Limestone Powder Ultrafine Vertical Roller MillBarite ultrafine vertical roller mill is an industrial vertical grinding mill that can grind nonmetallic ore into fine powder The mill has a high production capacity, high fine powder content, high degree of automation, convenient maintenance, long service life, environmental protection, and energysaving, and is an ideal equipment for largescale production of ultrafine powderBarite Ultrafine Vertical Roller Mill

Ultra fine vertical roller millUltra Fine Millultramillindustrial

CLUM series ultrafine vertical roller millwas produced by Shanghai Clirik Machinery Co, Ltd Relying on 12 years of experience in the production of ultrafine powder and based on German and Taiwan ultrafine vertical mill technologies The top technical team members were joined this project Besides, highquality wearresistant parts are used to develop milling equipment which 2019年5月22日 The ball mill consists of a metal cylinder and a ball The working principle is that when the cylinder is rotated, the grinding body (ball) and the object to be polished (material) installed in the cylinder are rotated by the cylinder under the action of friction and centrifugal forceThe working principle of ball mill Meetyou CarbideThe working principle of ultrafine Raymond mill adopts closedcircuit air circulation system, which has low noise, low energy consumption and easy maintenance The representative model is HCQ ultrafine Raymond mill, which can process hundreds of ores with a fineness of 600 meshThe working principle of ultrafine Raymond mill2013年4月12日 Muyang, as one of the best grinding machine manufacturers, provides large of great feed machinesNow, I am here to introduce SWFL82B vertical ultrafine pulverizer SWFL82B vertical ultrafine pulverizer is a new Working Principle on Muyang Vertical Pulverizer

CLUM Ultra Fine Vertical Roller Mill Clirik

Introduction of Ultra fine Vertical Mill CLUM Ultra fine Vertical Mill is a new grinding equipment produced by shanghai Clirik, it can be used in stone powder process with many types Working principle of Ultra fine Vertical Mill The The fine particles of the material ground by the ultrafine vertical mill are sorted, and the fineness range of the sorting is 2um45um A vertical mill can produce products of different specifications, and can also produce products of the Activated Carbon Ultrafine Vertical MillQuartz ultrafine vertical mill has the characteristics of stable operation, energysaving, good ball shape, and high fine powder content, which meets the needs of many highend powder industries and is popular in the highend powder processing field Quartz Ultrafine Vertical Mill Working Principle of Quartz Ultrafine Vertical MillQuartz Ultrafine Vertical Mill2022年1月14日 Working principle of vertical sand mill The horizontal sand mill is especially suitable for dispersing and grinding products with high viscosity and fine particle size parison of the vertical sand mill and horizontal sand mill

Bead Mill Working Principle: How Do Bead Mills Work?

2024年3月9日 Vertical Bead Mill Working Principle Loading procedure Analogous to its horizontal counterpart, the mixture and grinding media are ushered into a vertical chamber Operational differences from horizontal design The defining trait of the vertical bead mill working principle is the vertical shaft’s rotation, equipped with agitating arms or Product advantage of talc powder ultrafine vertical roller mill 1 High quality powder size The fineness of the finished product is D97 545 microns Narrow particle size distribution, can produce 2 micron content of 20%70% products, greatly improving the added value of finished products and application areas 2Talc Powder Ultrafine Vertical Roller MillCompared with the vertical sand mill, the horizontal sand mill has a relatively high price, but its advantages are also obvious • Grinding fineness From the perspective of grinding fineness, the grinding effect of horizontal sand mills is often better, which can meet the fineness requirements of Comparison of the vertical sand mill and horizontal sand millSetup: Before starting, secure the workpiece on the table and choose the appropriate cutting tool for the desired operation Tool Selection: Depending on the operation, select the suitable cutting tool and mount it on the spindle Milling Machine Working Principle And Operations

.jpg)

The working principle of ultrafine Raymond mill

2022年6月15日 The working principle of ultrafine Raymond mill adopts closedcircuit air circulation system, which has low noise, low energy consumption and easy maintenance The representative model is HCQ ultrafine Raymond mill, 2024年10月31日 Ultrafine impact mill site picture The working principle of the ultrafine impact mill is as follows: After the material enters the machine body from the feed port at the bottom of the machine body, it is quickly broken up by the hammer head on the rotor, scattered around the stator, and enters the crushing area composed of the rotor and statorWorking principle of ultrafine impact mill JINGHUAAir ring) The highspeed upward hot air is brought to the highefficiency separator integrated with the industrial vertical grinding mill The coarse powder is sorted by the separator and returned to the grinding plate for regrinding; the fine powder is discharged out of the mill with the air flow and is collected in the systemIndustrial Vertical Grinding Mill2015年3月9日 Working principle of vertical roller mill is driven by motor reducer rotating disc, and the hot air from the air inlet into the vertical mill, the material from the feed opening falls on the disc center, due to the centrifugal force, the material is moved from the center to the edge of the grinding disc disc, the disc by an annular groove, the grinding roller compacted by The working principle of vertical roller mill CSDN博客

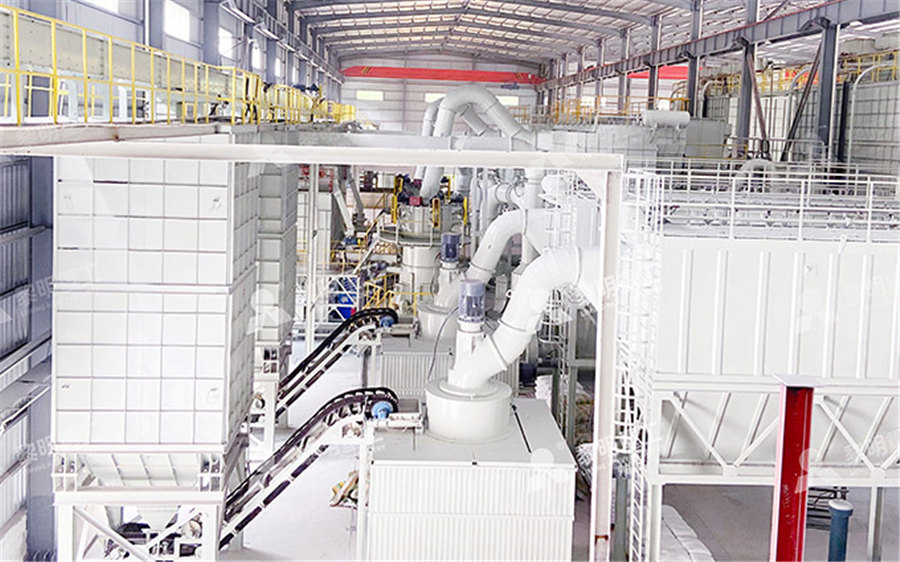

Limestone Ultrafine Vertical Mill

Limestone ultrafine vertical mill is a high quality ores material powder grinding mill +17 [ protected] Working Principle Of Limestone Ultrafine Vertical Mill HGM series Ultra Fine Powder Mill CLRM Series Enhanced Roller Grinding Mill YGM series Raymond Mill Hammer crusher2015年3月25日 1 The working principle of the hydraulic system vertical roller mill The hydraulic system ofvertical mill is an important system, the main function ofthe hydraulic system is to break the grinding roller, which is when the internal grinding cavity wear parts wear, can stop open on both sidesofthe grinding roller mill, to replace the inside parts or repairThis type vertical roller Hydraulic system vertical roller mill operation PDF SlideShareWorking Principle The ultrafine vertical mill is composed of several components, each of which plays a critical role in the operation of the machine And they must work together in harmony to produce highquality, ultrafine powder These components include: Grinding chamber, Agitator, Feed inlet, Discharge outlet, Motor, Calcium Carbonate Ultrafine Powder Vertical Mill2017年9月11日 PDF In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg Samples were collected from Find, read and cite all the research (PDF) Performance Evaluation of Vertical Roller Mill in Cement

An investigation of performance characteristics and energetic

2020年8月12日 efficiency of vertical roller coal mill currently working in the coalfired power plant with all aspects Therefore, this study contributes literature by performing performance analysis