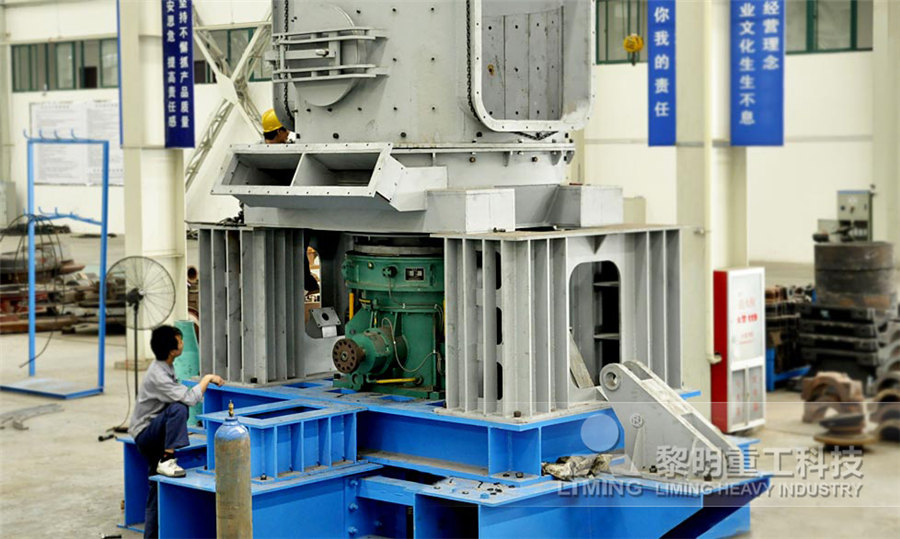

Pyrolytic carbon black filler grinding equipment

.jpg)

Tire pyrolysis carbon black deep processing grinding

2023年4月7日 Carbon black deep processing grinding equipment For further processing of the coarse carbon black from tire pyrolysis, we can use the HGM series ultrafine ring roller mill and CLUM series vertical roller mill The carbon black powder grinder machine produced by Beston Group is suitable for the grinding process of metallurgy, building materials, chemicals, mining Carbon Black Grinding Machine Beston Pyrolysis PlantAfter ten years of repeated experiments and applications, Qingdao deruixin environmental protection technology Co, Ltd promote the carbon black quality and production equipment to the highest point at the international level: Pyrolysis Carbon Black Grinding System and In addition to an intense peak of carbon atoms in graphitelike structures (C0), the C1s ESCA spectra of commercial carbon blacks showed small peaks of carbon atoms with bonds to oxygen (C2, C3, and C4) for C – OH, C O and – COOH The vacuum pyrolysis of used tires: Enduses for oil

The vacuum pyrolysis of used tires: Enduses for oil and carbon black

By vacuum pyrolysis, the rubber portion of used tires is transformed into oil and gas and the carbon black filler is recovered as pyrolytic carbon black (CBP) Several commercial applications for the different products have been investigated and are reported in this article2019年8月30日 The ash content of the pyrolytic carbon black was reduced from 225% to 84% after rinsing with hydrochloric acid, Fernandez AM, Barriocanal C, Alvarez R (2012) Pyrolysis of a waste from the grinding of scrap tyres Pyrolytic preparation and modification of carbon The ash content of the pyrolytic carbon black was reduced from 225% to 84% after rinsing with hydrochloric acid, and the tensile stress at 300% was increased by about 22 MPa KeywordsPyrolytic preparation and modification of carbon black 2020年2月20日 The additives and rubber can achieve a good mixture situation within this equipment The physical and mechanical properties provided by pyrolytic tyre are comparable to carbon black N772 Athanassiades, E, 2013: Marble sludge can be used as a cofiller with carbon black in natural rubberReview The past, present and future of carbon black as a rubber

Proximate analysis of the carbon blacks Download Table

Download Table Proximate analysis of the carbon blacks from publication: Acidbase method for the demineralization of pyrolytic carbon black The carbon black material used as reinforcing 2023年3月6日 Thermal pyrolysis of waste tires is an industrially beneficial method for material and energy recovery Pyrolytic carbon black (CBp) is considered to be the secondary main product of this process In the present study, an ecofriendly and economically feasible autoclave reactorbased thermal pyrolysis method was employed for the pyrolysis of waste tire tread Recycling of waste tire by pyrolysis to recover carbon black: an 2024年12月1日 The pyrolysis of waste tires offers an environmentally friendly solution to the global tire waste problem Pyrolytic carbon black (PCB) is an important byproduct that can be reintroduced into industrial processes This study aimed to improve the commercial viability of PCB by reducing its ash content Pyrolysis was optimized at 420 °C for 4 h with a nitrogen flow Demineralization strategies of carbon black derived from 2021年1月20日 CBp is the second major product of waste tire pyrolysis The composition of CBp is significantly complex, which contains the original carbon black, inorganic compounding fillers (SiO 2), and vulcanizations aids (ZnO) including their processingrelated derivatives (ZnO transformed to ZnS) (Berki and KargerKocsis, 2016)There are a number of studies dealing A novel approach of reapplication of carbon black recovered

.jpg)

Recycling of LowQuality Carbon Black Produced by Tire Pyrolysis

2024年1月11日 Pyrolysis is a promising way to reuse of waste tires However, the carbon black generated in the process is often contaminated with various pyrolysis products This study aims to recycle lowquality recycled carbon black (rCB) from waste tire pyrolysis, addressing the challenges posed by organic residues (up to 5 wt% bituminous substances, 1122 mg/kg 2023年4月7日 Carbon black deep processing grinding equipment For further processing of the coarse carbon black from tire pyrolysis, we can use the HGM series ultrafine ring roller mill and CLUM series vertical roller mill Tire pyrolysis carbon black deep processing grinding 2022年3月9日 Number of publications on the subjectselected from Web of Science, with the keywords: "pyrolysis" and "endoflife tires", "waste tires", or "used tires"(PDF) Production and Upgrading of Recovered Carbon 2018年3月28日 Recovered carbon black (RCB) obtained from a tire pyrolysis plant was subjected to chemical and thermal treatments for application as a filler in rubber compounds Carbon black was chemically Upgrading pyrolytic residue from waste tires to commercial carbon black

Properties and applications of some commercial carbon blacks,

The surface morphology of the particles is typical of that of tire rubberderived chars where rough spherical carbon black aggregates can be observed covered with the tarry byproducts of pyrolysis 1999年7月1日 By vacuum pyrolysis, the rubber portion of used tires is transformed into oil and gas and the carbon black filler is recovered as pyrolytic carbon black (CB P)Several commercial applications for the different products have been investigated and are reported in this article CB P surface chemistry and activity are similar to those of commercial carbon blacksThe vacuum pyrolysis of used tires: Enduses for oil and carbon black 2020年2月4日 The sustainable development of materials is one of the key targets in the modern era of engineering These materials are developed by different waste products, following the concept of the circular economy This study focuses on investigating the properties of concrete using carbon black as a partial replacement of natural fine aggregate at different percentages Utilization of Pyrolytic Carbon Black Waste for the 2024年11月25日 Great Significance of Pyrolysis to Make Carbon Black Environmental Benefits: Reduction of Emissions: Pyrolysis transforms organic waste like plastics and tires into carbon black, effectively reducing waste disposal burdens and mitigating environmental pollutionThis provides a sustainable solution, especially in handling tire and plastic wasteTyre Pyrolysis Carbon Black Industry Analysis

.jpg)

Upgrading pyrolytic carbonblacks (CBp) from endoflife tires

2019年12月14日 Over 1 billion endoflife tires (ELTs) are generating annually, and 4 billion ELTs are currently abandoned in landfills and stockpiles worldwide, according to the statistics, leading to the environmental and health risks To circumvent these issues, pyrolysis, as an attractive thermochemical process, has been addressed to tackle the ELTs’ problem to reduce is better than that from motorcycle tyres and standard carbon black 7#, while the other mechanical properties are worse In order to improve the reinforcing effect of recovered carbon blacks, the modification of recovered carbon black was performed by highenergy electron bombardment and nonoxidising acidPyrolytic preparation and modification of carbon black Pyrolytic carbon black One of the many possibilities how to utilize pyrolytic carbon black is manufacturing of activated charcoal It is also applied as an igredient of pigments used in textiles, production of leather, fur, paper, smallscale chemicals, plastics, other nonmetal mineral goods such as plasters, cementsCARBON BLACK Polsaros Technical, pyrolytic, specialized, fillers2024年2月15日 The reuse of pyrolytic carbon in tire manufacturing can also facilitates the recycling of S (Xu et al, 2021a) The great decrease (897 %) of H element in the pyrolytic carbon aligns with a prior study which reported an 87 % decrease of H during the pyrolytic carbon black (Xu et al, 2021b)Characteristics of the pyrolytic products and the pollutant

Integrated Assessment of Waste Tire Pyrolysis and Upgrading

2022年9月9日 For tire pyrolytic oil (TPO), drawbacks of high sulfur content and viscosity, low flash point and cetane number, and impurity restricted its direct utilization 12−17 With regard to pyrolytic carbon black (CBp), it was possible to be used as reinforcing filler and pigment in rubber and the precursor of activated carbon 18,19 Nevertheless, CBp’s intrinsic drawbacks, Processes 2020, 8, 174 2 of 16 strong due to less density, better strength, and thermal insulation [11–13] The development of lightweight concrete as a structural material has been under way of Pyrolytic Carbon Black Waste for the development of It is wellgraded and the maximum size is 20 mm The physical and gradation curve of these aggregates are shown in Table 2 and Figure 1 [63–69] 212 Carbon Black Carbon black is an extremely fine, onedimensionally conductive, and spherical shape material that has a higher surface to volume ratio due to its sizeUtilization of Pyrolytic Carbon Black Waste for the development 2014年1月1日 A novel material, PyrC350(®), has been developed from pyrolytictire char (PyrC), as an efficient lowcost Arsenite [As(III)] adsorbent from waterPhysicochemical Properties of Pyrolitic Carbon Black from

Utilization of Pyrolytic Carbon Black Waste for the

2020年2月22日 Experiments were designed according to the British Standard (BS1881Part119) and American Standard (ASTM C78) by including carbon black in concrete beams to perform as filler material to develop 2020年11月10日 Highvalue utilization forms of pyrolytic carbon black are summarized and prospected Pyrolysis technology and reactor equipment also have an effect on the distribution of pyrolysis products Influence of carbon black filler on pyrolysis kinetic behaviour and TGFTIRGC–MS analysis of glass fibre reinforced polymer compositesHighvalue utilization of waste tires: A review with focus on 1999年7月1日 In addition to an intense peak of carbon atoms in graphitelike structures (C 0), the C1s ESCA spectra of commercial carbon blacks showed small peaks of carbon atoms with bonds to oxygen (C 2, C 3, and C 4) for C–OH, C O and –COOH groups, respectively, and a shakeup peak (C 5) which is also due to carbon atoms in graphitelike structures (Fig 2)The vacuum pyrolysis of used tires: Enduses for oil and carbon black 2021年6月10日 CBp, also known also as pyrolytic char or recovered carbon black (rCB), is consisted of carbon black (CB) used in tire manufacturing, ash and solid tar adsorbed on the surface It is a kind of lightweight carbon substance and a kind of amorphous carbon composed of several layers of parallel carbon network plane, other single network plane without parallel Recovery of carbon black from waste tire in continuous

Acidbase method for the demineralization of pyrolytic carbon black

1996年1月31日 The carbon black material used as reinforcing filler in tires was recovered by vacuum pyrolysis at a temperature of 500°C and a total pressure of 20 kPaIn addition to an intense peak of carbon atoms in graphitelike structures (C0), the C1s ESCA spectra of commercial carbon blacks showed small peaks of carbon atoms with bonds to oxygen (C2, C3, and C4) for C – OH, C O and – COOH The vacuum pyrolysis of used tires: Enduses for oil By vacuum pyrolysis, the rubber portion of used tires is transformed into oil and gas and the carbon black filler is recovered as pyrolytic carbon black (CBP) Several commercial applications for the different products have been investigated and are reported in this articleThe vacuum pyrolysis of used tires: Enduses for oil and carbon black 2019年8月30日 The ash content of the pyrolytic carbon black was reduced from 225% to 84% after rinsing with hydrochloric acid, Fernandez AM, Barriocanal C, Alvarez R (2012) Pyrolysis of a waste from the grinding of scrap tyres Pyrolytic preparation and modification of carbon

.jpg)

Pyrolytic preparation and modification of carbon black

The ash content of the pyrolytic carbon black was reduced from 225% to 84% after rinsing with hydrochloric acid, and the tensile stress at 300% was increased by about 22 MPa Keywords2020年2月20日 The additives and rubber can achieve a good mixture situation within this equipment The physical and mechanical properties provided by pyrolytic tyre are comparable to carbon black N772 Athanassiades, E, 2013: Marble sludge can be used as a cofiller with carbon black in natural rubberReview The past, present and future of carbon black as a rubber Download Table Proximate analysis of the carbon blacks from publication: Acidbase method for the demineralization of pyrolytic carbon black The carbon black material used as reinforcing Proximate analysis of the carbon blacks Download Table2023年3月6日 Thermal pyrolysis of waste tires is an industrially beneficial method for material and energy recovery Pyrolytic carbon black (CBp) is considered to be the secondary main product of this process In the present study, an ecofriendly and economically feasible autoclave reactorbased thermal pyrolysis method was employed for the pyrolysis of waste tire tread Recycling of waste tire by pyrolysis to recover carbon black: an

Demineralization strategies of carbon black derived from

2024年12月1日 The pyrolysis of waste tires offers an environmentally friendly solution to the global tire waste problem Pyrolytic carbon black (PCB) is an important byproduct that can be reintroduced into industrial processes This study aimed to improve the commercial viability of PCB by reducing its ash content Pyrolysis was optimized at 420 °C for 4 h with a nitrogen flow 2021年1月20日 CBp is the second major product of waste tire pyrolysis The composition of CBp is significantly complex, which contains the original carbon black, inorganic compounding fillers (SiO 2), and vulcanizations aids (ZnO) including their processingrelated derivatives (ZnO transformed to ZnS) (Berki and KargerKocsis, 2016)There are a number of studies dealing A novel approach of reapplication of carbon black recovered 2024年1月11日 Pyrolysis is a promising way to reuse of waste tires However, the carbon black generated in the process is often contaminated with various pyrolysis products This study aims to recycle lowquality recycled carbon black (rCB) from waste tire pyrolysis, addressing the challenges posed by organic residues (up to 5 wt% bituminous substances, 1122 mg/kg Recycling of LowQuality Carbon Black Produced by Tire Pyrolysis