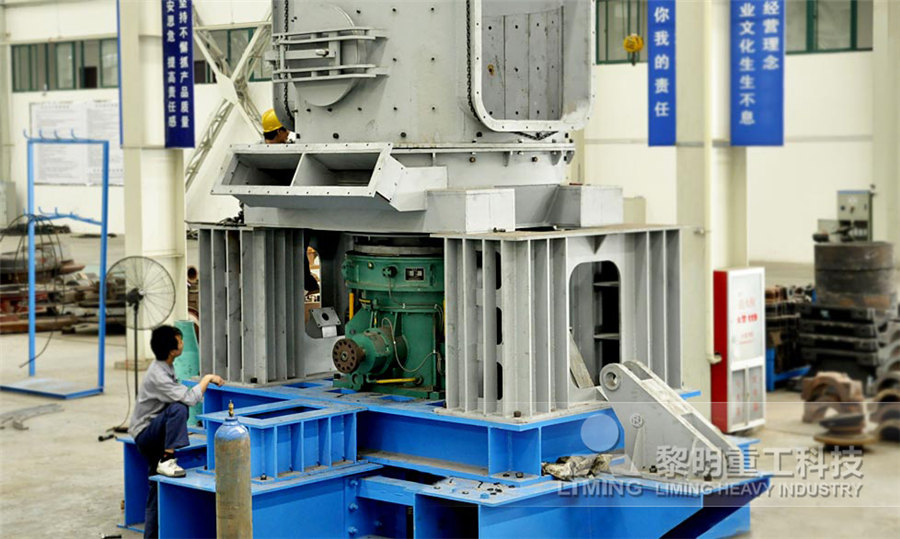

New highway surface material calcium carbonate powder making equipment

.jpg)

Calcium Carbonate Powder Coating Machine DASWELL

Ground calcium carbonate coating machine in Daswell can produce quality coated calcium carbonate powder with high coating rate, high consistency, controlled particle sizes, and great brightness As a result, produced coated The Calcium carbonate powder surface modifying, widely used in the fields of nonmetal stuffing or pigment like plastic, rubber, adhesive, macromolecule materials, high polymer composite, Calcium carbonate Powder Coating MachineWith highquality raw materials, EPIC Powder can provide a qualitytailored system that produces uniform ground calcium carbonate with high brightness, large surface area, high stability, and Calcium Carbonate Powder Production Line – Powder EquipmentBecause different industrial applications have different requirements on the particle size, shape, whiteness and particle size distribution of ground calcium carbonate powder, the processing ALPA Calcium Carbonate powder Processing Technology

.jpg)

Heavy calcium carbonate grinding, surface modification

2024年7月10日 Common surface modification equipment for heavy calcium carbonate includes SLG continuous powder surface modifier, HEM highefficiency hybrid modifier, highspeed 2023年12月15日 Surface treatment of calcium carbonate powder involves modifying the surface properties of the particles to enhance their performance and compatibility with variousEquipment and solutions for calcium carbonate powder surface The common processing equipment of ground calcium carbonate produced by largescale dry process includes Raymond mill, Table Roller Mill, Ring roller mill and Ball mill Due to the CALCIUM CARBONATE POWDER2021年10月12日 The purpose of nanocalcium carbonate modification is to reduce the cohesion between particles and improve its dispersibility; improve surface activity; improve compatibility Surface modification of nano calcium carbonate ALPA Powder

.jpg)

Ground Calcium Carbonate Powder Surface Modification Machine

Ground Calcium Carbonate Powder Surface Modification Machine is a surface coating machine that uses modifiers to modify the surface of calcium carbonate powder Through modification, Ground Calcium Carbonate Powder Surface Modification Machine The surface modification technology of ground calcium carbonate is mainly through the addition of surface modifiers for surface chemical treatment Surface Ground Calcium Carbonate Powder Surface 2024年10月23日 Nanocalcium carbonate is a new type of light calcium carbonate product developed using nanotechnology since the 1980s, with particle sizes typically ranging from 20 to 100 nmAnalysis of the Full Industry Chain Development of New Materials 2021年10月8日 Calcium carbonate concrete (CCC), a new type of concrete inspired by natural calcite concretion (Yoshida et al 1 2015), was proposed by the authors' research group previously (Maruyama et al A New Concept of Calcium Carbonate Concrete

Surface modification of nano calcium carbonate ALPA Powder Equipment

2021年10月12日 Nano calcium carbonate is a new type of ultrafine solid powder material developed in the 1980s, and its particle size is between 001 and 01 μm It is precisely due to the ultrafineness of nano calcium carbonate particles that have produced characteristics that ordinary calcium carbonate does not have, so nano calcium carbonate is widely used in various fields2024年10月24日 Positive Modification Effects of Calcium Carbonate 1 Environmental Benefits of Calcium Carbonate 11 Conservation of Petroleum Resources Calculated Impact of Calcium Carbonate in Plastic Packaging Using 30% calcium carbonate in PE, 3 million tons of plastic bags could save 900,000 tons of petroleumbased resin and 27 million tons of posite Materials: The Transformation of Calcium Carbonate Powder Surface Coating Machine Capacity: 407000 kg/h Max feeding size: Optional Processing ability: 407000 kg/h Range of application: Heavy/light calcium carbonate, kaolin, talcum, wollastonite, mica, white carbon black, zinc oxide, alumina, silicon powder, graphite, magnesiumhydroxide bariumcarb, illite claystone and pyrophyllite, hexagonite, etcPowder Surface Coating Machine2023年9月3日 As the paper industry has stricter requirements on product quality and more diversified product types, surface modification, nanotechnology, specialization and the development of new calcium carbonate products will become a new direction for the development of calcium carbonate product technology 1 Surface modificationFour major development trends of calcium carbonate technology

.jpg)

Heavy calcium carbonate dry production process and equipment EPIC Powder

2024年8月23日 However, the heavy calcium carbonate powder products produced by the ball mill plus classifier process have problems such as excessive volume fraction of 2μm fine powder and excessive specific surface area, easy agglomeration of particles, poor product dispersion performance, and excessively high energy consumption per ton of product2019年7月22日 YGM high pressure Raymond grinding mill: 20325 mesh(06130033 mm) calcium carbonate powder making,with capacity 125 t/h CLUM ultrafine powder vertical grinding mill: 4003000 mesh (D97 less than 3000 mesh, D50 less than 2 micron) calcium carbonate powder making, with capacity 318 t/h The chemical method for calcium carbonate powder How to make the calcium carbonate powder?Type: Powder Surface Coating Machine Motor Type: AC Motor Application: Mine Materials: Calcium Carbonate; Clay;Barite;Talc;Gypsum Condition: New Power of Main Machine: 119kwMicro Powder Surface Coating Machine for Calcium Carbonate2020年2月10日 In this work, The modification of heavy calcium carbonate powder was studied by dry surface modification with stearic acid and anhydrous citric acid we have developed a facile and inexpensive dry Dry surface modification of heavy calcium carbonate powder

Black tea adsorption on calcium carbonate: A new application

2002年3月26日 Black tea was used as a dyeing material for making brown powder materials Chalk and pure calcium carbonate powders were reacted with the black tea aqueous solution from 30 min to 3 weeks at room temperature and the brown 1 Machine can be customized We design our vertical roller mills based on the specific needs of our users as well as the characteristics of materials to be processed, so as to meet the actual requirements of our users, such as calcium carbonate vertical roller mill, talc vertical roller mill, barite vertical roller mill, magnesium oxide vertical roller mill, magnesium hydroxide vertical Talc Powder, Calcium Carbonate Powder and Other Fine Powder Making After surface modification, the dispersion is improved and the interspace between particles is reduced At the same time, the coverage of modified molecules on the surface of calcium carbonate reduces the voids in the particles, which changes the surface properties of calcium carbonate, weakens the surface polarity, reduces the friction between particles, makes the Surface Modification? Expert in highvalue treatment of calcium carbonate6th International Conference on Materials Science and Nanotechnology For Next Generation (MSNG2019) October 1618, 2019, Niğde , TURKEY (ORAL FULL TEXT) 233Surface Modification of Calcium Carbonate by Tumbling Ball

calcium carbonate powder,Fujian Longyi Powder Equipment

2024年8月31日 Longyi is devoting to become the world's leading provider for customized powdermaking solutions Manufacturer for set of ultrafine powder equipment +29 Get A Quote2021年12月20日 The equipment used during the processing of calcium carbonate powder affects grain types and particle size distribution Prater Equipment for Calcium Carbonate Manufacturing Processes Prater Industries makes a number of machines wellsuited for breaking apart aggregates like limestone, chalk, or marble to make calcium carbonateCalcium Carbonate Manufacturing Process and Equipment2024年3月21日 Calcium carbonate is classified from the perspective of production methods, including activated calcium carbonate, light calcium carbonate and heavy calcium carbonate It occupies active calcium carbonate, which is surface calcium carbonate treatment, colloidal calcium carbonate, which is obtained by treating heavy calcium carbonate or light calcium General Introduction of Calcium Carbonate Powder2021年12月28日 Calcium carbonate based filler additive materials have approximately 70% market share in North America, and can be added to a maximum of 20 to 25% based on fiber materialInSitu Precipitated Calcium Carbonate Paper Filler Material: A

.jpg)

Calcium Carbonate Coating Machine Factory

2024年9月4日 Powder coating machines specifically designed for calcium carbonate are used to apply a thin, uniform layer of powder coating to the surface of calcium carbonate particles Surface Preparation: In the case of nonmetallic surfaces like calcium carbonate, surface preparation might involve preheating or chemical treatment to improve the adhesion of the trial to make calcium carbonate precipitate between aggregate particles to bind them for making construction materials 2 Experiment 21 Materials To imitate demolished concrete materials, carbonatedA New Concept of Calcium Carbonate Concrete using2021年12月31日 Grinding aid chemicals which are used in the grinding of calcium carbonate (CaCO3) to prevent agglomeration are chemisorbed on the surfaces of particles, and the compatibility of them with the (PDF) Effects of Grinding Aids Used in Grinding Ground calcium carbonate grains can be as coarse as 1,300 microns in poultry feed or as fine as 2 microns in paper coatings Milling the limestone to the correct particle size distribution is a test for GCC processing But addressing this Grinding calcium carbonate down to size Making

Calcium carbonate ALPA Powder Equipment

In recent years, calcium carbonate has been widely used in the plastic filling industry because of its excellent properties and low price Compared with other inorganic mineral powder materials, the color of calcium carbonate itself is whiter, with better stability and better plasticization 1 Rubber industry2023年4月8日 The paper industry is one of the largest markets for calcium carbonate As an important papermaking filler and coating pigment, calcium carbonate is rich in sources and cheap in price; fine particles and high whiteness can significantly improve the opacity of paper; fast ink absorption speed can increase Ink absorption of paper; it can make the paper softer, tighter 7 types of calcium carbonate commonly used in the paper industryCalcium Carbonate Mining Equipment for Sale US$60,00000120,00000: 1 Set (MOQ) : Product DetailsCalcium Carbonate Mining Equipment for Sale Grinding 1 Machine can be customized We design our vertical roller mills based on the specific needs of our users as well as the characteristics of materials to be processed, so as to meet the actual requirements of our users, such as calcium carbonate vertical roller mill, talc vertical roller mill, barite vertical roller mill, magnesium oxide vertical roller mill, magnesium hydroxide vertical Factory Cheap Price Calcium Carbonate/ Calcite / Talc Powder Making

.jpg)

Calcium Carbonate Powder Production Line – Powder Equipment

Tailored turnkey solution EPIC Powder specializes in designing and engineering calcium carbonate processing lines We also provide a complete set of equipment to meet customers’ needs in calcium carbonate powder fineness, production capacity, ground calcium carbonate applications, etc Controlled calcium carbonate particle sizeRaw Material:Calcium carbonate Capacity:1t/h Feeding Size:100 mesh Product Size:D97:412μm Address:ShandongWeifang a new material company calcium carbonate dispersion Ground Calcium Carbonate Powder Surface Modification Machine The surface modification technology of ground calcium carbonate is mainly through the addition of surface modifiers for surface chemical treatment Surface Ground Calcium Carbonate Powder Surface 2024年10月23日 Nanocalcium carbonate is a new type of light calcium carbonate product developed using nanotechnology since the 1980s, with particle sizes typically ranging from 20 to 100 nmAnalysis of the Full Industry Chain Development of New Materials

.jpg)

A New Concept of Calcium Carbonate Concrete

2021年10月8日 Calcium carbonate concrete (CCC), a new type of concrete inspired by natural calcite concretion (Yoshida et al 1 2015), was proposed by the authors' research group previously (Maruyama et al 2021年10月12日 Nano calcium carbonate is a new type of ultrafine solid powder material developed in the 1980s, and its particle size is between 001 and 01 μm It is precisely due to the ultrafineness of nano calcium carbonate particles that have produced characteristics that ordinary calcium carbonate does not have, so nano calcium carbonate is widely used in various fieldsSurface modification of nano calcium carbonate ALPA Powder Equipment2024年10月24日 Positive Modification Effects of Calcium Carbonate 1 Environmental Benefits of Calcium Carbonate 11 Conservation of Petroleum Resources Calculated Impact of Calcium Carbonate in Plastic Packaging Using 30% calcium carbonate in PE, 3 million tons of plastic bags could save 900,000 tons of petroleumbased resin and 27 million tons of posite Materials: The Transformation of Calcium Carbonate Powder Surface Coating Machine Capacity: 407000 kg/h Max feeding size: Optional Processing ability: 407000 kg/h Range of application: Heavy/light calcium carbonate, kaolin, talcum, wollastonite, mica, white carbon black, zinc oxide, alumina, silicon powder, graphite, magnesiumhydroxide bariumcarb, illite claystone and pyrophyllite, hexagonite, etcPowder Surface Coating Machine

Four major development trends of calcium carbonate technology

2023年9月3日 As the paper industry has stricter requirements on product quality and more diversified product types, surface modification, nanotechnology, specialization and the development of new calcium carbonate products will become a new direction for the development of calcium carbonate product technology 1 Surface modification2024年8月23日 However, the heavy calcium carbonate powder products produced by the ball mill plus classifier process have problems such as excessive volume fraction of 2μm fine powder and excessive specific surface area, easy agglomeration of particles, poor product dispersion performance, and excessively high energy consumption per ton of productHeavy calcium carbonate dry production process and equipment EPIC Powder2019年7月22日 YGM high pressure Raymond grinding mill: 20325 mesh(06130033 mm) calcium carbonate powder making,with capacity 125 t/h CLUM ultrafine powder vertical grinding mill: 4003000 mesh (D97 less than 3000 mesh, D50 less than 2 micron) calcium carbonate powder making, with capacity 318 t/h The chemical method for calcium carbonate powder How to make the calcium carbonate powder?Type: Powder Surface Coating Machine Motor Type: AC Motor Application: Mine Materials: Calcium Carbonate; Clay;Barite;Talc;Gypsum Condition: New Power of Main Machine: 119kwMicro Powder Surface Coating Machine for Calcium Carbonate