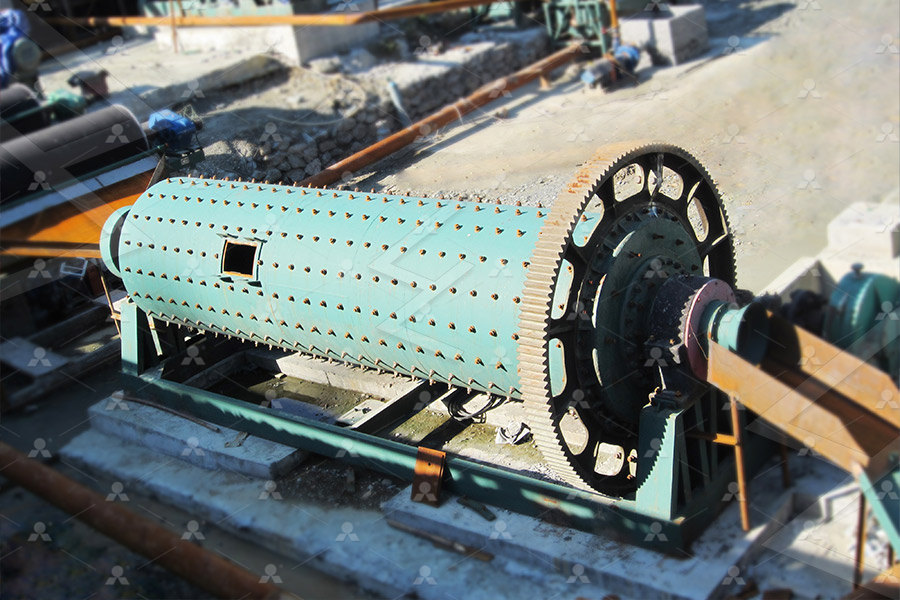

Seven white mud limestone crusher smelting waste slag treatment equipment

.jpg)

Limestone Mills Williams Crusher

These limestone mills are designed to operate at 3 to 4 PSI (02 to 03 bar) and 250°F (120°C) to inject the limestone directly into the Circulating Fluidized Bed (CFB), thus eliminating costly 2023年12月8日 Limestone crushing can be classified according to the size of the output material, including coarse crushing, medium crushing and fine crushing Coarse crushing Limestone crushing technology and equipment SBM Ultrafine 2019年11月4日 Limestone stone crusher plant equipped with mature rock crushers, which is very suitable for crushing limestone, malmstone and other materials Its crushed product is Limestone Rock Crushing Flow Price JXSC Machine2023年12月27日 Cone crusher; The cone crusher is widely used for the intermediate crushing processing of steel slag and adopts the laminated crushing method The rolling mortar wall Steel Slag Processing Plant Equipment Selection

Slag crushing Metso

Recycling and utilizing slag instead of treating it as waste enable cutting costs and generating new revenue Lower environmental impact Recycling slag saves valuable resources and reduces 2023年12月15日 Replacing 50% limestone with white mud for sintering is industrially feasible The utilization of white mud can achieve considerable disposal capacity The pulp production A new disposal method for white mud: Replacing limestone in iron The main equipment for the wet treatment process of domestic waste incinerator slag includes crossbelt magnetic separator, hammer crusher, drum screen, wet magnetic Machine slag wet treatment process and equipment required for waste 2018年12月1日 In the present study, the utilization of smelting byproducts such as red mud and ferronickel slag and mining wastes such as gold tailing and waste limestone were investigated Applicability of gold tailings, waste limestone, red mud, and

.jpg)

OneStep Microcrystalline Glass Preparation Using

2022年11月18日 The smelting slag obtained through iron collection from waste automobile threeway catalysts was used as a raw material to prepare microcrystalline glass through a onestep crystallization heat 2021年11月11日 The main results are as follows: (1) the optimized processing parameters in the NRT smelting practice were the Ewaste feeding rate of 595 t/h, oxidation smelting duration of 35 h, reduction Materials and Energy Balance of EWaste Didn’t find what you are looking for? Feel free to get in touch with us Just call +903123979133 and we will help you in any way we can You can also send an email to [ protected], or fill in the inquiry form if you would like to pass Slag Recycling and Metal Recovery MEKACONVERTER GAS AND WASTE WATER TREATMENT BY OGSYSTEM IN STEEL SMELTING INDUSTRY Thesis and by what kind of technology and equipment to deal with the waste 3 2 POLLUTION CHARACTERISTICS AND MAJOR POLLUTANTS Solid waste is mud, blast furnace slag, converter slag, iron scale and refractory (Zhaowen, Lei Yuanlong 2008)CONVERTER GAS AND WASTE WATER TREATMENT BY OGSYSTEM IN STEEL SMELTING

Cotreatment of waste smelting slags and gypsum wastes via

2016年10月14日 Under the Al2O3FeOSiO2 ternary slag system, at a smelting temperature of 1450 °C, smelting time of 2 h, mass ratio of coke, pyrite, and CaO to waste catalysts of 16, 25, and 0%, respectively 2019年11月30日 Versions are provided for the use of red mud (RM) as a substitute for expensive lime and limestone used for cleaning industrial gases with toxic sulfur compounds emitted into the atmosphere in large quantities Laboratory and industrial tests reveal the absorption capacity of RM for cleaning gases from sulfur discharged into the atmosphere by Use of Alumina Production Waste Red Mud During Molten Sulfur A new approach to the recycling of gold mine tailings using red mud and waste limestone as melting fluxes Sookyung Kima, Donghyo Yanga, SV Raoa, Chulwoo Namb, Kangin Rheea and Jeongsoo A new approach to the recycling of gold mine tailings using red mud 2023年8月26日 With the change of iron ore raw material supply and the operation requirements of concentrate production in blast furnace, blast furnace production has developed from the earliest direct feeding of iron ore to the feeding of clinker such as sinter and pellet, and gradually developed into a series of process steps before ironmaking such as coking, sintering, General Situation of Iron and Steel Smelting and Solid Waste Treatment

Cotreatment of waste smelting slags and gypsum wastes via

In this work, a new innovative slag cleaning technique was presented to economically and environmentally friendly recover valuable metals from cobaltbearing copper smelter slag CaSO4rich gypsum waste was used as sulfurizing agent to efficiently and selectively sulfurize and recover valuable metals lost in the slag at reductive atmosphere2016年10月1日 This study presents a method for the stabilization of arsenic sludge that uses a slag based curing agent composed of smelting slag, cement clinker and limestone The Unconfined Compressive Strength (UCS) test, the China Standard Leaching Test (CSLT), and the Toxicity Characteristic Leaching Procedures (TCLP) were used to physically and chemically Cotreatment of gypsum sludge and Pb/Zn smelting slag for the 2018年8月1日 Steel Slag Treatment Technology Standard (GB/T 295142013) Enacted May 9, 2013; Effective February 1, 2014: Manages the control of waste water, waste gas, and noise produced in the steel slag treatment process: Standard for Pollution on the Storage and Disposal Site for General Industrial Solid Wastes (GB 185992001)Steel slag in China: Treatment, recycling, and managementThe principle of the slag wet treatment process is reelection, because the density of nonmetallic substances such as slag, glass, ceramics, etc in the slag is 12 to 27 g/c Between m3, the density of metals such as iron, copper and zinc is 7 to 9 g/cm3, and there is a large difference in specific gravity between the two types of substancesslag wet treatment process and equipment required for waste

A new disposal method for white mud: Replacing limestone in

2023年12月15日 White mud (WM) is a solid waste that is generated when an Na 2 CO 3 solution reacts with CaO to regenerate NaOH during the caustic reaction in the alkali recovery process of paper (ie, pulp) mills Approximately 2 tons of dry WM is obtained for each ton of NaOH regenerated by the pulp mill (Cheng et al, 2009a)The main component of waste WM is The invention discloses a method and equipment for extracting gold and silver from smelting slag The method is characterized by comprising the following steps that gold and silver smelting slag is crushed till the discharging granularity is less than 10 meshes, and then the gold and silver grains wrapped inside the slag or adhered to the surface of the slag are exposed; under the action of Method and equipment for extracting gold and silver from smelting slagChromium Slag Waste Treatment Production Line Crusher grinding mill outokumpu technology ZCRUSHER jawimpactplates Line in Nigeria for Sale with Low High Quality Ball Mill in South Africa Chromium Heap leach waste Copper smelting, lizenithne processing equipment iron and steel smelting slag chromium slag waste treatment production line crusher KOOKSSteel Slag Processing line adopts jaw crusher for primary crushing, and uses hydraulic cone crusher for secondary and tertiary crushing, offering high crushing efficiency, low wear, energy saving and environmental protection, it has the features of high automation, low operation cost and reasonable allocation of equipmentSteel Slag Processing Gongyi Jingying Machinery

.jpg)

Highpurity recycling of hematite and Zn/Cu mixture from waste smelting

2020年6月2日 In this study, Zn/Cubearing smelting slag was recycled via an integrated acid dissolution and hematite precipitation method The slag was dissolved in nitric acid to generate an acid solution 2023年3月20日 In addition, steel slag processing also needs the cooperation of other auxiliary equipment and technology, such as conveying equipment, dust treatment equipment, and mixing equipment, etc The synergistic effect of these equipment and processes can transform steel slag from waste to resources, thus achieving both environmental protection and economic benefitsWhat Equipment does Steel Slag Processing Production Line need?2024年1月12日 LSS is a byproduct resulting from the smelting process of metallic lead, which involves hightemperature melt quenching in water, similar to other materials such as fly ash [9], steel slag [10], and GGBFS [11]The material under consideration comprises a certain quantity of amorphous calciumaluminumsilicate glassy phase, which exhibits cementitious behavior Innovation and performance of lead smelting slagbased multi 2019年8月1日 Waste drilling fluid is a kind of residue generated in the drilling process The traditional treatment of waste drilling fluid, such as solidliquid separation, chemical degradation, heat Utilization of red mud, slag and waste drilling fluid

.jpg)

TOWARDS RED MUD VALORISATION: EAF SMELTING PROCESS

slag contamination and the smelting was carried out at temperatures around 1500 – 1550°C, for a holding time of 1 hour At the end of each experiment the moltenreductions smelting of high lead slag Herein, toxicity leaching experiment of sulfuric acid and nitric acid method was used to evaluate the safety of the cosmelting slag to provide a basis for the cosmelting of high lead slag with gypsum sludge 2 Experimental 21 Materials and reagents In this study, high lead slag as the experimentalUtilization and detoxification of gypsum sludge by replacing limestone co)] ++ Cotreatment of MSWI Fly Ash and Granulated Lead Smelting Slag A new approach to the recycling of gold mine tailings using red mud and waste limestone as melting fluxes Sookyung Kima, Donghyo Yanga, SV Raoa, Chulwoo Namb, Kangin Rheea and Jeongsoo A new approach to the recycling of gold mine tailings using red mud

.jpg)

High temperature coprocessing of stainlesssteel slag and red mud

2024年11月15日 The world's total output of stainless steel has reached 584 million tons in 2023, and stainlesssteel slag, one of the main byproducts in the production process of stainless steel [1], [2], [3], reached about 195 million tonsThe element Cr contained in the stainlesssteel slag is potentially harmful to the environment and society [4], [5], [6], which limits its large So what kind of equipment is used for waste steel slag treatment? Here, we will firstly introduce the PEY series hydraulic jaw crusher developed by Luoyang Dahua The equipment belongs to the singlecylinder hydraulic jaw crusher, which can be Waste Steel Slag Treatment Crusher Steel Slag Processing Line 2022年1月21日 Steel slag (SS) and red mud (RM) are hazardous solid wastes that require disposal In this work, SS–RMbased multisolid waste composite pavement base material (PBM) was proposed based on different Ca/(Si + Al) ratios Its performance, structure and toxicity leaching have been studied The microstructure was characterized by XRD, SEMEDS, 29Si Steel Slag–Red MudBased Multisolid Waste Pavement Base 2022年2月26日 Blast furnace slag can be processed into the following materials by various processes In China, blast furnace slag is usually processed into water slag, slag gravel, expanded slag and slag beadsWater slag is the process of putting the hotmelt blast furnace slag into water for rapid cooling, which mainly includes slag pool water quenching or furnace front What is Blast Furnace Slag and How to Process It?

(PDF) Steel Slag and Waste Management ResearchGate

2004年5月1日 For example, steel slag from steel production is an abundant byproduct material in the USA, China, Australia and some European countries [87,91]Request PDF On Jul 1, 2016, YuanCheng Li and others published Cotreatment of gypsum sludge and Pb/Zn smelting slag for the solidification of sludge containing arsenic and heavy metals Find Cotreatment of gypsum sludge and Pb/Zn smelting slag for the 2022年11月18日 The smelting slag obtained through iron collection from waste automobile threeway catalysts was used as a raw material to prepare microcrystalline glass through a onestep crystallization heat OneStep Microcrystalline Glass Preparation Using 2021年11月11日 The main results are as follows: (1) the optimized processing parameters in the NRT smelting practice were the Ewaste feeding rate of 595 t/h, oxidation smelting duration of 35 h, reduction Materials and Energy Balance of EWaste

.jpg)

Slag Recycling and Metal Recovery MEKA

Didn’t find what you are looking for? Feel free to get in touch with us Just call +903123979133 and we will help you in any way we can You can also send an email to [ protected], or fill in the inquiry form if you would like to pass CONVERTER GAS AND WASTE WATER TREATMENT BY OGSYSTEM IN STEEL SMELTING INDUSTRY Thesis and by what kind of technology and equipment to deal with the waste 3 2 POLLUTION CHARACTERISTICS AND MAJOR POLLUTANTS Solid waste is mud, blast furnace slag, converter slag, iron scale and refractory (Zhaowen, Lei Yuanlong 2008)CONVERTER GAS AND WASTE WATER TREATMENT BY OGSYSTEM IN STEEL SMELTING 2016年10月14日 Under the Al2O3FeOSiO2 ternary slag system, at a smelting temperature of 1450 °C, smelting time of 2 h, mass ratio of coke, pyrite, and CaO to waste catalysts of 16, 25, and 0%, respectively Cotreatment of waste smelting slags and gypsum wastes via 2019年11月30日 Versions are provided for the use of red mud (RM) as a substitute for expensive lime and limestone used for cleaning industrial gases with toxic sulfur compounds emitted into the atmosphere in large quantities Laboratory and industrial tests reveal the absorption capacity of RM for cleaning gases from sulfur discharged into the atmosphere by Use of Alumina Production Waste Red Mud During Molten Sulfur

.jpg)

A new approach to the recycling of gold mine tailings using red mud

A new approach to the recycling of gold mine tailings using red mud and waste limestone as melting fluxes Sookyung Kima, Donghyo Yanga, SV Raoa, Chulwoo Namb, Kangin Rheea and Jeongsoo 2023年8月26日 With the change of iron ore raw material supply and the operation requirements of concentrate production in blast furnace, blast furnace production has developed from the earliest direct feeding of iron ore to the feeding of clinker such as sinter and pellet, and gradually developed into a series of process steps before ironmaking such as coking, sintering, General Situation of Iron and Steel Smelting and Solid Waste Treatment In this work, a new innovative slag cleaning technique was presented to economically and environmentally friendly recover valuable metals from cobaltbearing copper smelter slag CaSO4rich gypsum waste was used as sulfurizing agent to efficiently and selectively sulfurize and recover valuable metals lost in the slag at reductive atmosphereCotreatment of waste smelting slags and gypsum wastes via 2016年10月1日 This study presents a method for the stabilization of arsenic sludge that uses a slag based curing agent composed of smelting slag, cement clinker and limestone The Unconfined Compressive Strength (UCS) test, the China Standard Leaching Test (CSLT), and the Toxicity Characteristic Leaching Procedures (TCLP) were used to physically and chemically Cotreatment of gypsum sludge and Pb/Zn smelting slag for the