Original standard for producing gypsum powder

1116 Gypsum Manufacturing US EPA

Gypsum is calcium sulfate dihydrate (CaSO4 2H2O), a white or gray naturally occurring mineral Raw gypsum ore is processed into a variety of products such as a portland cement additive, soil conditioner, industrial and building plasters, and gypsum wallboardASTM standards govern the manufacture of gypsum board and set strict criteria for strength, Making Gypsum Board Gypsum AssociationGypsum board is manufactured to consensus standard ASTM C1396, Standard Specification Standards Gypsum AssociationStandard size gypsum boards are 48 or 54 inches wide and 8 (2440 mm), 10 (3050 mm), 12 Maintaining the highest standards Aspiring to the highest ideals

Tikrit Journal of Pure Science

major components of gypsum powder According to comparison standard specification No (28), It begins with definitions, according to ASTM, EN, and ISO standards, of the most common Gypsum Products SpringerThe production method comprises the following steps: (1) mixing phosphogypsum with a dry Production method of alphagypsum powder with high strength2024年11月5日 The manufacturing process of gypsum powder is a meticulous operation that Essential Guide to Gypsum Powder Manufacturing Process

Gypsum Products SpringerLink

2021年3月3日 This chapter reviews the complex market of gypsumbased products It begins Building gypsum can be used to manufacture concrete, high strength gypsum sticky powder, Gypsum Product an overview ScienceDirect Topics21 ASTM Standards: 2 C11Terminology Relating to Gypsum and Related Building Materials and Systems C 471M Test Methods for Chemical Analysis of Gypsum and Gypsum Products [Metric] C 472 Test Methods for Physical Testing of Gypsum, Gypsum Plasters and Gypsum Concrete 3 Terminology 31 Definitions—Definitions shall be in accordance with Standard Specification for Gypsum1Standard Specification for the Production of Recycled Gypsum from Scrap Gypsum Drywall Construction and Demolition Recycling Association Executive Summary Construction and demolition (CD) debris is one of the largest waste streams in the United States with an estimated 534 million tons produced in 2014 Gypsum drywall accounts for 25% of theStandard Specification for the Production of Recycled Gypsum

.jpg)

Process for producing alpha gypsum powder by liquid phase

2007年10月24日 A technology of gypsum powder and liquid phase method, which is applied in the field of α gypsum powder production, which can solve problems such as unstable product performance, uneven heating, temperature adjustment, etc, and achieve stable product performance, small restrictions, and simple processApplication and Finishing of Gypsum Board1 This standard is issued under the fixed designation C 840; the number immediately following the designation indicates the year of original adoption or, in the case of revision, 324 dry type, n—a compound Standard Specification for Application and Finishing of Gypsum This is Kefid designed one set of gypsum powder production technology with large capacity and high efficiency based on nearly 30 years experience in the development of mill machine According to process requirements, the main process of building gypsum production line includes the following aspects, crushing, grinding, calcination, storage conveyor, electric control systemThe processing of gypsum powder production line for buildingPROJECT OBJECTIVES The ultimate goal of the project is to make profit by producing and selling gypsum powder to local and Original value Annual rate 010 010 010 (Birr) 72,760,500 Ayshea, 2021 102,791,00000 10,279,10000 Table: Repair and maintenance costs based on the standard rate Description Machineries Equipment Building Vehicles Feasibility Study For Gypsum Powder Manufacturing

ASTM C471 Standard Test Methods for Chemical Analysis of Gypsum

Designation: C 471M – 01 METRIC Standard Test Methods for Chemical Analysis of Gypsum and Gypsum Products [Metric] 1 This standard is issued under the fixed designation C 471M; the number immediately following the designation indicates the year of original adoption or, in the case of revision, the year of last revisionIraqi standard chemical properties of gypsum types based on IQS 261988 (IBB 311, 2017)Iraqi standard chemical properties of gypsum types basedStandard Test Methods for Chemical Analysis of Gypsum and Gypsum Products (Metric)1 This standard is issued under the fixed designation C 471M; the number immediately following the designation indicates the year of original adoption or, in the case of revision, the year of last revision A number in parentheses indicates the year of last Standard Test Methods for Chemical Analysis of Gypsum and Gypsum Gypsum Powder Technical Free download as Powerpoint Presentation (ppt / pptx), PDF File (pdf), Text File (txt) or view presentation slides online This document describes the production process and technology selection for gypsum powder There are two main production methods a rotary kiln process that produces betahemihydrate and a fluidized bed furnace process that Gypsum Powder Technical PDF Scribd

.jpg)

Durability of Concrete Containing Gypsum Powder Recycled from

2022年11月1日 To address the negative contribution of cement production on global carbon emissions, this study aims to reduce the cement content typically required in concrete using partial replacement by 2023年12月1日 Additionally, 3D powder printing technology (3DP) is gaining a lot of attention in the fields of building and decoration because of its excellent consistency and straightforwardness (Feng et al, 2019; Xu et al, 2023; Park et al, 2021; Ingaglio et al, 2019; Guo et al, 2022)Furthermore, gypsum has been a fundamental component in the 3DP process and Flowability prediction of recycled αhemihydrate gypsum for 3D powder 2013年9月1日 Formulation of gypsum powder and binder for use in 3D print prototype was developed The 3D printing technique consists of the threedimensional deposition of binders on successive layers of (PDF) Development of gypsum powder and binder for 3D print 2023年5月3日 In the reviewed works [27] [28][29][30][31], the influence of the calcination temperature and additives on the properties of anhydrite was investigated, but it was not determined which factor had Light Weight Plasters Containing Vermiculite and FGD Gypsum for

.jpg)

Processing a Locally Sourced Gypsum Material for Medical and

completely degrit the samples; producing high grade gypsum powder The original dehydrate gypsum powder was treated to produce a hemihydrate product that will be used for various medical and industrial applications Quality tests such as setting and durability test were also carried out on products obtained from theThe invention provides a process method for quickly producing gypsum building products with the advantages of water and energy conservation and top quality, particularly a method for producing gypsumbuilding products by pressing process The method comprises the following steps: firstly, preparing building gypsum, packing powder, plasticizing agent, adjustable solidification agent, CNA Method for producing gypsum building The production process of building gypsum powder with ardealite, the side product of wet phosphoric acid production process, as material includes fast dewatering in stoving machine to obtain halfhydrated gypsum product, adding citric acid or sodium citrate, and pulverizing to decrease the medium size D50 value to 07 time the original A Method for producing building gypsum powder China Gypsum Powder Production wholesale Standard: AISI, ASME, BS, ANSI, JIS, GB, GOST, ASTM, DIN Surface Treatment: Customized Manufacturing Process: Customized 1 / 6 Favorites Quartz Limestone Kaolin Calcium Carbonate Gypsum Grinding Raymond Mill Machine Price Stone Powder Grinder Production Plant Line US$ Gypsum Powder Production MadeinChina

Standard Specification for Application and Finishing of Gypsum

Standard Specification for Application and Finishing of Gypsum Board1 This standard is issued under the fixed designation C840; the number immediately following the designation indicates the year of original adoption or, in the case of revision, the year of last revision A number in parentheses indicates the year of last reapproval AThis document proposes establishing a gypsum powder production plant in East Gojam Zone, Ethiopia Gypsum has many uses in construction, agriculture, and other industries There is currently no factory producing gypsum powder in the region, despite abundant local gypsum quarry resources The plant would mine local quarry gypsum, crush, bake, mill, and bag it into Gypsum Powder Production Plant PDF ScribdThis document is a business plan for a proposed gypsum powder manufacturing plant by AMX Manufacturing PLC in Ayshea, Ethiopia The plant aims to produce 150,000 tons of gypsum powder annually, utilizing abundant local gypsum Feasibility Study For Gypsum Powder Manufacturing2023年11月2日 Setting up a gypsum powder production line requires careful planning and a good understanding of the overall process How To Set Up a Gypsum Powder Production Line From Scratch Gypsum powder is widely used in the construction industry for making drywall, plaster, and other building materialsHow To Set Up a Gypsum Powder Production Line From Scratch

Standard Specification for Application and Finishing of Gypsum

Standard Specification for Application and Finishing of Gypsum Board1 This standard is issued under the fixed designation C 840; the number immediately following the designation indicates the year of original adoption or, in the case of revision, the year of last revision A number in parentheses indicates the year of last reapproval APlease feel free to wholesale cheap gypsum powder production line for sale here and get quotation from our factory All customized products are with high quality and low price 58 betty@seyibm ★ Drying Closed Standard Section Utility model patent certificate, Patent No: ZL 2020 2 3 04China Customized Gypsum Powder Production Line The measured values of the porosity were 894%, the water content varied between 25–30% for the two studied typologies, coming from Agadir and Safi, respectively Gypsum powder was used for fabricating samples, which were investigated in terms of thermal and acoustic performance Thermal properties were measu(PDF) Gypsum and Gypsum Products Dr Ralph Michael ParoliIS : 2542 (Part I/Sec 1 to 12) 1978 2 (Continued from page 1)Members Representing SHRI D MOHTA Raj Plasters Ltd, Bikaner SHRI L RAMIAH Gypsum Industries Pvt Ltd, Tiruchirapalli DR A V R RAO National Buildings Organization, New Delhi SHRI G T BHIDE (Alternate) SHRI M V S RAO EngineerinChief’s Branch, Army Headquarters SHRI V K RAZDAN (Alternate) IS to 12 (1978): Methods of Test for Gypsum Plaster,

.jpg)

Recovering LowDensity Polyethylene Waste for Gypsum Board Production

2024年8月6日 be seen when replacing the original gypsum raw material with LDPE waste Thus, for the specific case of this research, substitution percentages of up to 15% by mass were used1973年10月10日 Indian Standard SPECIFICATION FOR MINERAL GYPSUM ( Second Revision ) 0 FOREWORD 01 This Indian Standard (Second Revision) was adopted by the Indian Standards Institution on 10 October 1973, after the draft finalized by the Inorganic Chemicals (Miscellaneous) Sectional Committee had been approved by the Chemical Division CouncilIS 1290 (1973): Mineral gypsum LawNatural gypsum may be obtained from gypsum rock or gypsum sand Synthetic gypsum typically originates from flue gas desulphurization (FGD) or phosphonic acid production Plaster wherein x is 05 is known as "calcium sulphate hemihydrate" (HH) or "calcium sulphate semihydrate" (SH), ie CaSO 4 05H 2 O Calcium sulphate HH can occur in different crystalline forms; known as Plasticizer composition for producing gypsum boards42 Gypsum (Specification C22/C22M)—Gypsum samples will be received in the form of rocks or powder, or both If necessary crush and reduce the entire dried sample in accordance with 413 and 415 43 Gypsum Plaster (Specification C28/C28M): 431 Gypsum Readymixed Plaster or Gypsum Woodfibered Plaster—Screen the dried sample Standard Test Methods for Chemical Analysis of Gypsum and Gypsum

.jpg)

Standard Specification for Gypsum1

21 ASTM Standards: 2 C11Terminology Relating to Gypsum and Related Building Materials and Systems C 471M Test Methods for Chemical Analysis of Gypsum and Gypsum Products [Metric] C 472 Test Methods for Physical Testing of Gypsum, Gypsum Plasters and Gypsum Concrete 3 Terminology 31 Definitions—Definitions shall be in accordance with Standard Specification for the Production of Recycled Gypsum from Scrap Gypsum Drywall Construction and Demolition Recycling Association Executive Summary Construction and demolition (CD) debris is one of the largest waste streams in the United States with an estimated 534 million tons produced in 2014 Gypsum drywall accounts for 25% of theStandard Specification for the Production of Recycled Gypsum 2007年10月24日 A technology of gypsum powder and liquid phase method, which is applied in the field of α gypsum powder production, which can solve problems such as unstable product performance, uneven heating, temperature adjustment, etc, and achieve stable product performance, small restrictions, and simple processProcess for producing alpha gypsum powder by liquid phase Application and Finishing of Gypsum Board1 This standard is issued under the fixed designation C 840; the number immediately following the designation indicates the year of original adoption or, in the case of revision, 324 dry type, n—a compound Standard Specification for Application and Finishing of Gypsum

-2.jpg)

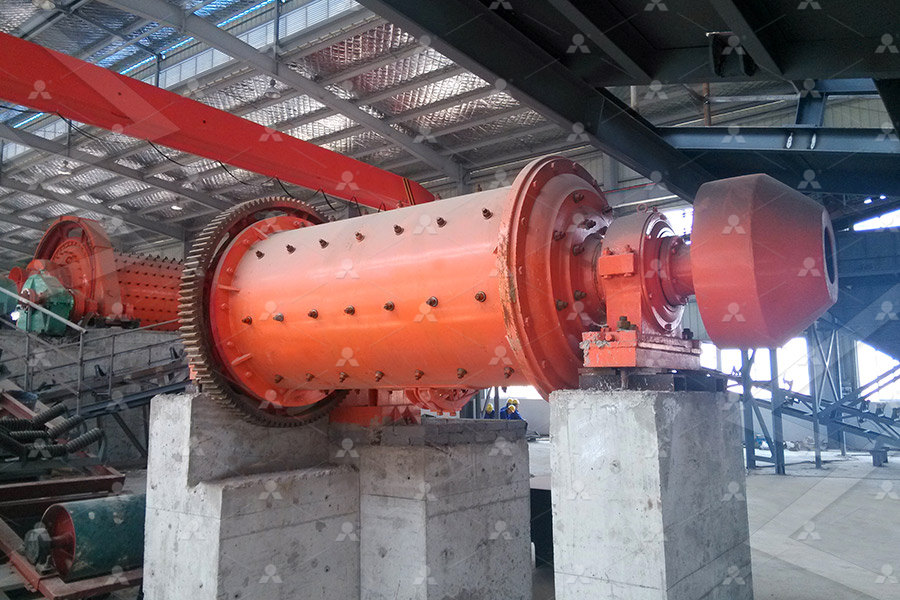

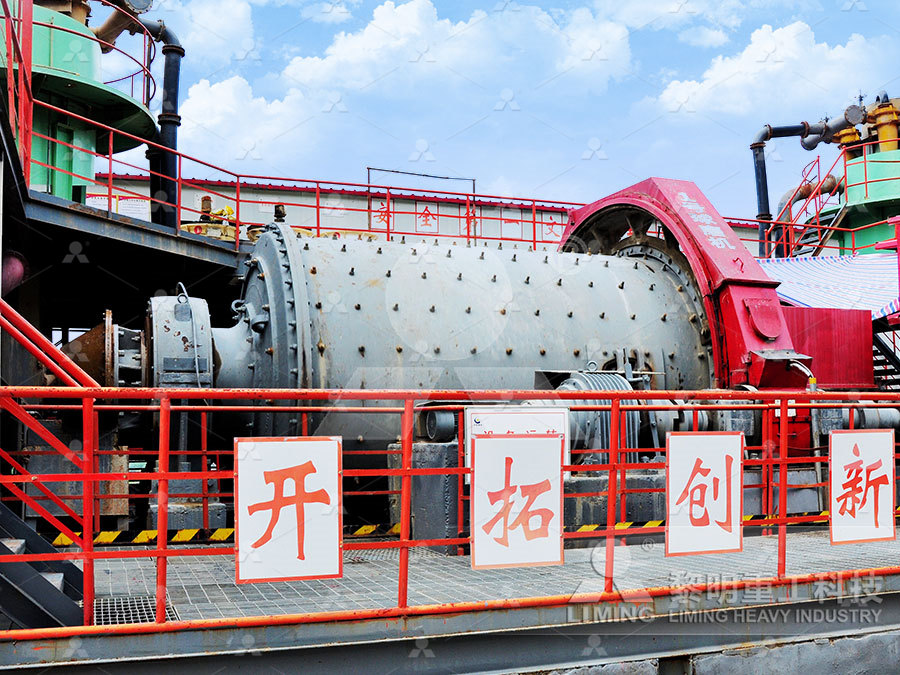

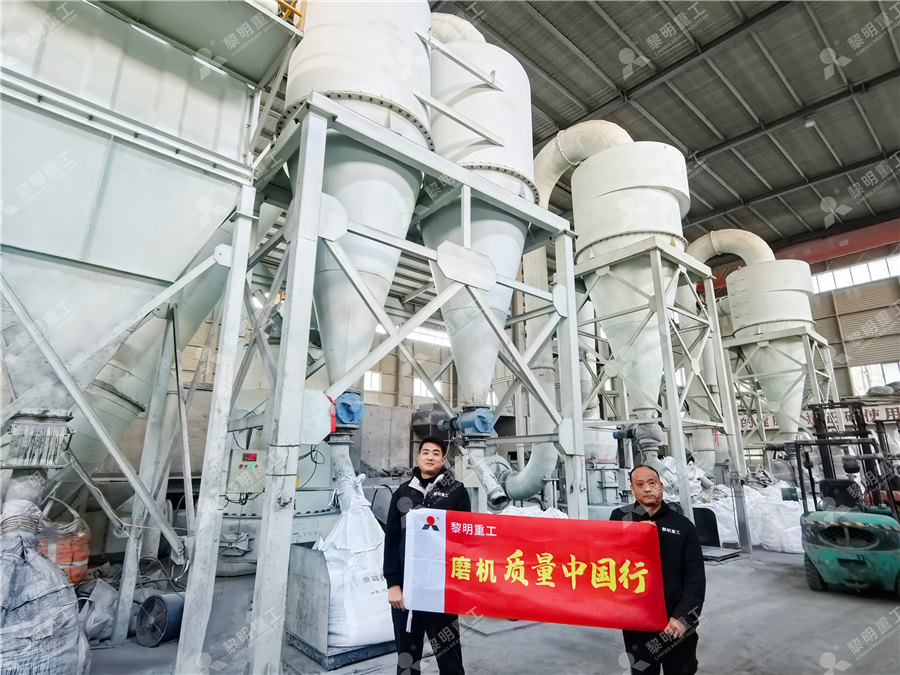

The processing of gypsum powder production line for building

This is Kefid designed one set of gypsum powder production technology with large capacity and high efficiency based on nearly 30 years experience in the development of mill machine According to process requirements, the main process of building gypsum production line includes the following aspects, crushing, grinding, calcination, storage conveyor, electric control systemPROJECT OBJECTIVES The ultimate goal of the project is to make profit by producing and selling gypsum powder to local and Original value Annual rate 010 010 010 (Birr) 72,760,500 Ayshea, 2021 102,791,00000 10,279,10000 Table: Repair and maintenance costs based on the standard rate Description Machineries Equipment Building Vehicles Feasibility Study For Gypsum Powder ManufacturingDesignation: C 471M – 01 METRIC Standard Test Methods for Chemical Analysis of Gypsum and Gypsum Products [Metric] 1 This standard is issued under the fixed designation C 471M; the number immediately following the designation indicates the year of original adoption or, in the case of revision, the year of last revisionASTM C471 Standard Test Methods for Chemical Analysis of Gypsum Iraqi standard chemical properties of gypsum types based on IQS 261988 (IBB 311, 2017)Iraqi standard chemical properties of gypsum types based

Standard Test Methods for Chemical Analysis of Gypsum and Gypsum

Standard Test Methods for Chemical Analysis of Gypsum and Gypsum Products (Metric)1 This standard is issued under the fixed designation C 471M; the number immediately following the designation indicates the year of original adoption or, in the case of revision, the year of last revision A number in parentheses indicates the year of last Gypsum Powder Technical Free download as Powerpoint Presentation (ppt / pptx), PDF File (pdf), Text File (txt) or view presentation slides online This document describes the production process and technology selection for gypsum powder There are two main production methods a rotary kiln process that produces betahemihydrate and a fluidized bed furnace process that Gypsum Powder Technical PDF Scribd