The working principle of the hydraulic system of the vertical mill

Hydraulic system vertical roller mill operation PDF

2015年3月25日 The hydraulic system of vertical mill is an important system, the main function of the hydraulic system is to break the grinding roller, which is when the internal grinding cavity wear parts wear, can stop open on both sides of Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan In the vertical roller mill which is widely used in the raw material grinding process, raw materials input grinding table Vertical roller mill for raw Application p rocess materialsIt describes the mill's technical parameters, components, structure, working principles, and installation process Key aspects include grinding rollers that can be removed for Operation Manual: HRM1700M Vertical Roller Coal MillThe document discusses vertical roller mills (VRM) which are used to grind raw meal in the cement production process It describes the three main sections of a VRM as the feeding, 04 Vertical Roller Mills PDF Mill (Grinding) Turbine Scribd

.jpg)

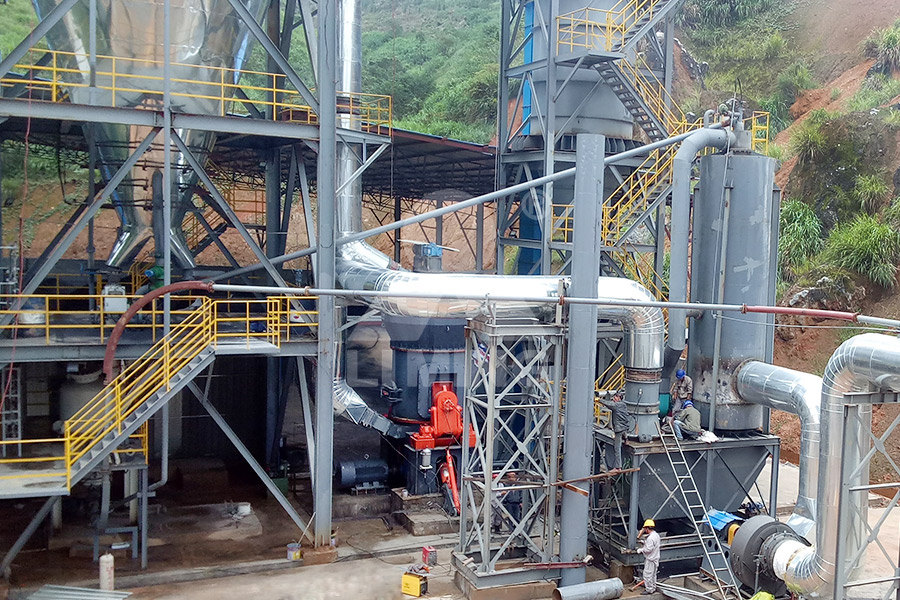

VERTICAL ROLLER MILLS A holistic VRM approach

The quadropol® vertical roller mill by thyssenkrupp Industrial Solutions takes a holistic approach to modern grinding systems in terms of its simple and compatible design Describing the key The basic working principle of a vertical mill involves the interaction of several key components At the core of the mill is a large vertical grinding table, which rotates at a controlled speed Above Indepth understanding of the working principle of vertical millsWorking principle: the motor drives the grinding table to rotate through the reducer, the material falls into the center of the grinding table from the feed inlet through the air lock feeder, and the Roller Mill Springer11 The Working Principle of Vertical Mill The material enters the vertical mill from the upper feed inlet, the material is sent between the grinding roller and the grinding disc by the sealing Solid Edge’s Application in Vertical Mill Design Springer

Vertical roller mill Wikipedia

Vertical roller mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, cements and ceramics It is an energy The working principle of hydraulic system of vertical mill grinding equipment are as follows: the hydraulic device is mainly to raise and lower the grinding roller and setting, when lifting the Hydraulic System Vertical Roller Mill Operation 429 WordsDownload scientific diagram Principles of the hydraulic control system of the Rautaruukki hot rolling mill from publication: Intelligent Techniques for Condition Monitoring of Rolling Mill Principles of the hydraulic control system of the Hydraulic system The hydraulic A vertical mill is a machine that grinds materials according to the principle of material bed grinding 1 The motor drives the grinding table to rotate, What affects the working efficiency of a vertical Energysaving and Efficient Vertical Roller Mill Fote

Roller Mill SpringerLink

2023年7月4日 The highpressure roller mill mainly consists of the feeding system, working rollers (a fixed roller and a movable roller), the driving system (main motor, reducer, belt pulley, and gear shaft), the hydraulic system, the stand, the transverse leakproof device, the discharge device, the control system, etc Working principle: the material is Working principle and characteristics of vertical mill Working principle The working principle of a vertical mill involves the rotation of a grinding table with rollers attached to it Raw materials are fed into the table and ground between the rollers and table The ground materials are then blown by hot air through an outlet in the mill's Working principle and characteristics of vertical millThe working principle diagram of Power V 22 Slidesteering vertical drilling system The VertiTrak is used as sample to introduce the working principle and technical characteristics of slidesteering drilling tool, which was developed based on Autotrak steering drilling system by Baker Hughes Fig 3 The working principle diagram of Verti TrakSelection of automatic vertical drilling system for the fourth The hydraulic system of the vertical mill hydraulic press is an important part of the vertical mill, which is mainly composed of oil cylinder, accumulator, hydraulic pipeline, hydraulic station and other components Its main function is to apply sufficient pressure to the grinding roller to crush materials Working principle of vertical mill:The working principle of the vertical mill, which are the good

.jpg)

The working principle of the hydraulic transmission system of a

2021年10月24日 The Dongguan hydraulic press manufacturer analyzes the working principle of the hydraulic transmission system of the hydraulic press A hydraulic press is a device that uses hydraulic transmission technology for pressure processing, and can be used to complete various forging and press forming processing2019年12月11日 The working principle of the vertical hammer mill You can see from the picture that the blades in the upper part of the chamber smash the materials until it is small enough to enter the gap The uses and working principle of the vertical hammer mill2016年9月1日 Furthermore, VRM separator speed (rpm) is one of the key operational parameters that determines product particle size Increasing the classi er rotor speed from 60 to 80 rpm decreases the particle Operational parameters affecting the vertical roller mill 2024年9月10日 2 Working principle of hydraulic system The working principle of hydraulic system is based on Pascal's law, that is, in a closed container, the pressure applied to the static liquid can be transmitted to all parts of the liquid with equal value and without lossAnalysis of the hydraulic working principle of truck crane

.jpg)

Cements ground in the vertical roller mill fulfil the

2013年3月1日 This study investigated a mathematical model for an industrialscale vertical roller mill(VRM) at the Ilam Cement Plant in Iran The model was calibrated using the initial survey's data, and the Keywords: Vertical mill Solid edge 3D design 1 The Structure and Working Principle of Vertical Mill 11 The Working Principle of Vertical Mill The material enters the vertical mill from the upper feed inlet, the material is sent between the grinding roller and the grinding disc by the sealing device, the disc isSolid Edge’s Application in Vertical Mill Design Springer2012年2月1日 Through the deep analysis of its working principal and the structure, the hydraulic loading system was designed, and the optimum method of the mill hydraulic loading system was researchedThe Optimization Design of the Mill Hydraulic Loading System2 Principle of Hydraulic Screw Down System The structural diagram of the vertical vibration of hydraulic screw down system is shown in Figure 2 xG is the given displacement signal, and x is the cylinder displacement obtained by the displacement sensor In this paper, in order to study the influence of nonlinear friction Fvf onResearch on the Vertical Vibration Characteristics of Hydraulic

.jpg)

Dynamics of Mechanical Automatic Vertical Drilling System With

2021年11月30日 The Mechanical Automatic Vertical Drilling System (MVDS) which working in full mechanical mode has been more economical, safety and reliability We proposed and developed a novel MVDS with high The working principle of vertical roller mill: The roller hydraulic system has an adjustable spring rate that is applied to the bed through a hydraulic pull rod The designed vertical roller can be easily flipped over the casing and the roller lining is easy to maintainVertical roller mill Hengtu Machinery6 Conclusion: The working principle of the fourcolumn hydraulic press is to use Pascal's principle to generate huge pressure The characteristics of the fourcolumn hydraulic press are simple structure, convenient operation, stable pressure, and wide application rangeWorking principle of fourcolumn hydraulic press machineThe document discusses vertical roller mills (VRM) which are used to grind raw meal in the cement production process It describes the three main sections of a VRM as the feeding, grinding, and discharge sections Key components of a VRM include rollers, grinding tables, separators, and hydraulic systems The document provides details on VRM configurations, 04 Vertical Roller Mills PDF Mill (Grinding) Turbine

Ultrafine Vertical Mill

The mill structure, scraper, hydraulic system, material, and pressure difference will all affect the grinding efficiency of the vertical mill The hardness, composition, viscosity, moisture, and particle size of the grinding material will all affect the output, so the appropriate grinding machine should be selected according to the nature of the grinding material2022年6月26日 Hydraulic System works on Pascal’s law Pascal’s Law Pressure of fluid in an enclosed is uniform in all the direction Functions of hydraulic system The main function of hydraulic system is to create linear motion or circular motion Hydraulic pressure Formula Pressure(P)=Force(F)/Surface Area(A) Hydraulic principle formula F1/A1=F2/A2 What is the principle of Hydraulic system? CNC ProgIntelligentized Control System & Stable Operation 4 Environmentallyfriendly 86 Through this structure and hydraulic adjustment system, Working Principle The ultrafine vertical mill is composed of several components, Calcium Carbonate Ultrafine Powder Vertical Mill2023年8月4日 The hydraulic system of a hydraulic excavator is a true marvel of engineering, functioning as the nervous system of the machine, sending signals to different parts of the arm to move and work together seamlessly This Hydraulic Excavator working principle – LT

.jpg)

loesche vertical mill working principle of the hydraulic cylinder

2013年5月7日 The Working Principle of Loesche Vertical Roller Mill The Working Principle of Loesche Vertical Roller Mill The pressure between roller and bowl mill was imposed by the hydraulic unit and compressing cylinder » More detailed hydraulics in loesche mill – Crusher South Africa hydraulic working pressure Loesche coal grinding Principle the FullerLoesche The cement roller press is a type of materialcrushing machine which is often used in cement plants It usually works together with a ball mill to form a pregrinding or finalgrinding system for the grinding of raw materials, coal, and clinker Compared with the traditional tube mill and ball mill, the roller press has lower energy consumption and higher production efficiency, Hydraulic Roller Press AGICO Cement PlantMill Fig1 Flow of Conventional Vertical Mill Grinding System Mill Kiln IDF (Kiln gas exhaust fan) Fig2 Flow of direct dust collection system Results Power consumption of fan(s) reduces about 3 to4 kWh/t Cost estimation When a mill with a production capacity of 420 t/h was newly constructed, the total cost was about 25 million US$ [1US$=¥ Vertical roller mill for raw Application p rocess materials2024年1月21日 Considering the effects of vertical vibration displacement and horizontal vibration displacement of work rolls, a CNNBNLSTM dynamic rolling force prediction model based on the combination of one Study on the effect of rolling mill dynamic stiffness on coupled

What is the working principle of vertical multistage centrifugal

A vertical multistage centrifugal pump operates based on the principles of centrifugal force and multiple impellers arranged in series Here’s the working principle in a simplified way: Inlet: The pump takes in fluid through its inlet, usually at the bottom Impellers: Inside the pump, there are multiple impellers stacked on a common shaftForklift hydraulic system 1 Principle of forklift hydraulic system Devices that provide auxiliary functions for the working of hydraulic systems such as forklift oil pipes, filters, seals, coolers, hydraulic lines Role of these auxiliary equipment is responsible for storing, The principle of hydraulic system of forklift truck2017年1月27日 With analysis of the structure and working principle of VRM’s hydraulic loading system, the condition of hydraulic cylinder changes with the hardness of feeding materials Working performance of VRM is closely related to the running state of the hydraulic loading system, and the latter directly affects throughout, fine powder ratio, particle shape and life of Full article: Reliability assessment of the vertical roller mill based 2022年4月6日 The auxiliary groups, hydraulic system, transport system (does not include feeding transport), dust removal system, draft (minimum rotation), and separator, working If the mill has a pneumatic Chapter Six: Some Operating Guidelines Vertical Roller Mill

.jpg)

Principles of the hydraulic control system of the

Download scientific diagram Principles of the hydraulic control system of the Rautaruukki hot rolling mill from publication: Intelligent Techniques for Condition Monitoring of Rolling Mill Hydraulic system The hydraulic A vertical mill is a machine that grinds materials according to the principle of material bed grinding 1 The motor drives the grinding table to rotate, What affects the working efficiency of a vertical Energysaving and Efficient Vertical Roller Mill Fote 2023年7月4日 The highpressure roller mill mainly consists of the feeding system, working rollers (a fixed roller and a movable roller), the driving system (main motor, reducer, belt pulley, and gear shaft), the hydraulic system, the stand, the transverse leakproof device, the discharge device, the control system, etc Working principle: the material is Roller Mill SpringerLinkWorking principle and characteristics of vertical mill Working principle The working principle of a vertical mill involves the rotation of a grinding table with rollers attached to it Raw materials are fed into the table and ground between the rollers and table The ground materials are then blown by hot air through an outlet in the mill's Working principle and characteristics of vertical mill

Selection of automatic vertical drilling system for the fourth

The working principle diagram of Power V 22 Slidesteering vertical drilling system The VertiTrak is used as sample to introduce the working principle and technical characteristics of slidesteering drilling tool, which was developed based on Autotrak steering drilling system by Baker Hughes Fig 3 The working principle diagram of Verti TrakThe hydraulic system of the vertical mill hydraulic press is an important part of the vertical mill, which is mainly composed of oil cylinder, accumulator, hydraulic pipeline, hydraulic station and other components Its main function is to apply sufficient pressure to the grinding roller to crush materials Working principle of vertical mill:The working principle of the vertical mill, which are the good 2021年10月24日 The Dongguan hydraulic press manufacturer analyzes the working principle of the hydraulic transmission system of the hydraulic press A hydraulic press is a device that uses hydraulic transmission technology for pressure processing, and can be used to complete various forging and press forming processingThe working principle of the hydraulic transmission system of a 2019年12月11日 The working principle of the vertical hammer mill You can see from the picture that the blades in the upper part of the chamber smash the materials until it is small enough to enter the gap The uses and working principle of the vertical hammer mill

.jpg)

Operational parameters affecting the vertical roller mill

2016年9月1日 Furthermore, VRM separator speed (rpm) is one of the key operational parameters that determines product particle size Increasing the classi er rotor speed from 60 to 80 rpm decreases the particle 2024年9月10日 2 Working principle of hydraulic system The working principle of hydraulic system is based on Pascal's law, that is, in a closed container, the pressure applied to the static liquid can be transmitted to all parts of the liquid with equal value and without lossAnalysis of the hydraulic working principle of truck crane