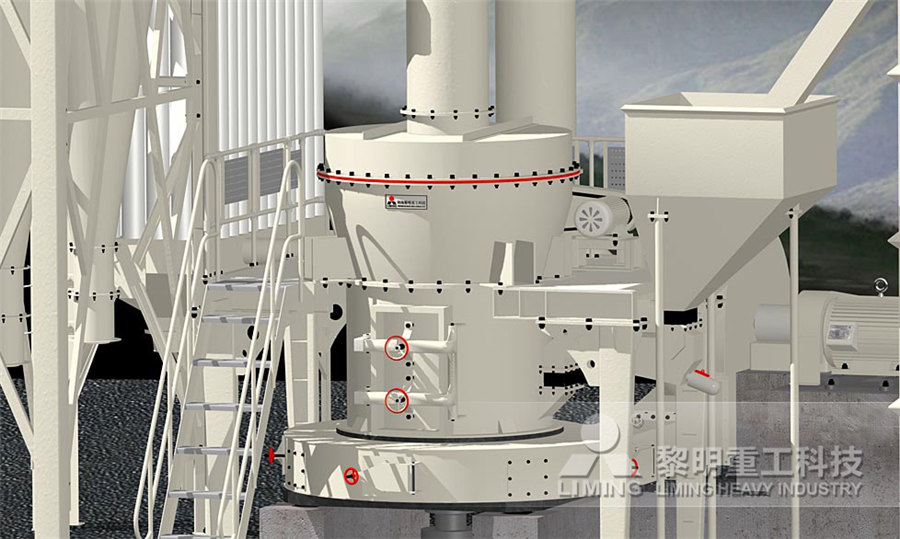

Grinding station operating procedures

.jpg)

VRM Operation SOPs PDF Mill (Grinding) Pressure

The document provides standard operating procedures for grinding mills It discusses four mill operation conditions based on relationships between mill power, pressure loss, and process parameters For each condition, it identifies OPERATIONAL SAFETY CHECKS 1 Stand to the side of the wheels when starting up 2 Let the wheels gain maximum speed before starting to grind 3 Do not grind on the side of the wheel Safe Operating Procedures SOP 02 Bench Grinder University of (16)During grinding and before the grinding wheel stops rotating after work is finished,do not attempt to clean the shavings of the work piece or to move the workpiece (17)When tak ing INSTRUCTION MANUAL FOR PRECISION SURFACE GRINDER Grinding is the process of removing metal by the application of abrasives which are bonded to form a rotating wheel When the moving abrasive particles contact the workpiece, they act as GRINDING MACHINES Carnegie Mellon University

.jpg)

G32P(A)CNCmanual(Eng)A Sharp Industries

Never clean, remove chips the workpiece before finishing the grinding operation Before first time operation it is required to check the wheel condition and be sure the rotation should be To provide guidance to workers on the safe use, operation, and maintenance of all grinders All grinders and abrasive wheels must comply with manufacturer's recommendations and SAFE WORK PRACTICE SWP26 July 30, 2019 GRINDER Ensure the wheel is not damaged Look for chips, cracks or embedded metals 2 Operation: Use smooth, slow fluid motions Never make abrupt fast movements Turn machine off to make Safe Work Procedure Grinder Pedestal and Bench GrinderThe grinding operation transforms power from the air tool into material removed plus heat The optimum is in fact quite naturally the point when the feed force applied gives the most material Pocket Guide to Grinding Technique Atlas Copco

.jpg)

Standard Operating Procedure: Electrochemistry Experiments

Standard Operating Procedure: Electrochemistry Experiments Last Updated 05/15/17 by Selene Li Reagents: Check the availability of solvent in the small glovebox If solvents need to be pumped in the box, make sure they are dry and airfree If not, please dry and degas it Common supporting electrolytes used in the McCusker lab are NBu 4 PF 6,Standard operating procedures manuals ensure that the employees are made aware of the operating procedures and that they have detailed instructions on how to follow them While this does not guarantee that every employee will follow the standard operating procedures to the letter, it does ensure that most employees will adhere to the guidelines and rules you have Coffee Shop Standard Operating Procedures Overview (Checklist Searching for Grinding Station for Fifth Dawn? Look no further We have all the necessary details needed to quench your knowledge thirst, from mana value to rarity to artist And everything in betweenGrinding Station (Fifth Dawn) Gatherer Magic: The GatheringPortable Grinder Operating Procedures Free download as Powerpoint Presentation (ppt / pptx), PDF File (pdf), Text File (txt) or view presentation slides online This document provides safety guidelines for using portable grinders It outlines the necessary personal protective equipment (PPE) including safety helmets, eye protection, gloves, high visibility clothing, and safety shoesPortable Grinder Operating Procedures PDF Personal Scribd

procedure of grinding KOOKS

Standard Operating Procedure Standard Polisher/Grinder Standard Operating Procedure – Standard Polisher/Grinder About this SOP This document describes the standard operating pr ocedure for using the polisher/grinders in room 157 Engineering II It covers hazards, emergency procedures, basic specifications and operating procedures Who to Portable Grinder Operating Procedures Free download as PDF File (pdf), Text File (txt) or read online for free The document outlines safety procedures for operating portable grinders It details 10 steps for proper use including preparing the work area, inspecting the grinder and wheel, performing a ring test on new wheels, properly mounting wheels, wearing personal protective Portable Grinder Operating Procedures13 Grinding, smoothing, lapping, polishing surfaces This procedure is for surface refinement, which is based on the classic procedure These processes are normally performed in machines or systems designed especially for this However, with the right tool equipment (springmounted spindles), this work can also be performed using CNC machinesDeburring – Procedure and methods Gravostar• Keep the tool rest as close to the grinding wheel as possible without touching it The tool rest must be minimally within 1/8th of an inch of the grinding wheel • Prior to starting the grinder, ensure the tang at the top of the wheel opening is located within ¼ inch of the wheelSTANDARD OPERATING PROCEDURES for COMMON TOOL

Safe Operating Procedures SOP 14 Fuelling Vehicles University

Safe Operating Procedures This SOP should be used in conjunction with relevant machinery manuals and manufacturer recommendations Procedure Reference Version Effective Date Review Date Page Number Date Printed WHS SOP 14 10 28/03/2018 28/03/2021 2 24/04/2018 allow for expansion of the tank 3standard operating procedures sop: 2006 page: 1 of 22 rev: 00 date: 08/11/94 sampling equipment decontamination contents 10 scope and application 20 method summary 30 sample preservation, containers, handling, and storage 40 interferences and potential problems 50 STANDARD OPERATING PROCEDURES2020年8月19日 STANDARD OPERATING PROCEDURES METHOD FOR GENERAL PLANT SAMPLE PROCESSING Contact Details: Telephone: +254 (20) /4279/4301/4163 : Plant sample processing entails preparation of samples by grinding or milling to the required size before they are introduced to different spectral instruments for analysis in the lab STANDARD OPERATING PROCEDURES Center for International 50 Standard Operating Procedure for 33 KV Substation Maintenance SEC – 05 60 Standard Operating Procedure for Loading delivery of Product SEC – 06 Material Grinding 20 SCOPE:Cement Mill (Clinker, gypsum, flyAsh), Cement Mill HoppersHoppers all associated machineries 30 DEFINITIONS:Cement Corporation of India Limited DOC NO : CCIL Unit:

.jpg)

Ball Mill: Standard Operating Procedure PDF Mill

The document provides standard operating procedures for a ball mill It lists 18 steps for operating the ball mill, including connecting power, loading materials and grinding media, starting and stopping the mill, and unloading processed 1998年4月28日 Unlike other forms of writing, standard operating procedures are written from a technical perspective This means they must be: Clear and concise—getting directly to the point and avoiding wordy sentences Standard operating procedures should be communicated in the fewest possible words, phrases, and paragraphsWriting Standard Operating Procedures Modern Machine Shop2016年2月2日 The grinding circuit operator must ensure that the ball mill runs properly loaded and gives the correct ore grind A major practical indication of mill loading is the sound made by the mill A properly loaded mill will have a deep rhythmic roar, while an under loaded mill will have a metallic rattling type noise and an overloaded mill will be quite silentGrinding Circuit Startup and Shutdown ProcedureThis procedure will be broken out by specific tasks being done on site They will be broken out by: Transfer of fuel from 205L drums to an envirotank in the Designated Fuel Station Transfer of fuel from a sleighmounted envirotank to equipment, drills and other machines that require fuel Health Safety Environment – Safe Working ProceduresBULKFUEL MANAGEMENT FACILITY MONITORING: STANDARD OPERATING PROCEDURES

.jpg)

STANDARD OPERATING PROCEDURES Grinder Angle

Use only in designated grinding area – erect screens if necessary Examine the power cord, extension lead, plugs, sockets and power outlet for damage Ensure that the grinding disc, guard and attachments (including handle) are secure and correctly fitted Inspect the grinding disc for damage Do not use damaged grinding discOverflow ball mills, on the other hand, are suitable for both coarse and fine grinding but require a higher level of maintenance Safety Procedures and Precautions Importance of Safety When Operating a Ball Mill Ball mills can be dangerous if not used properly It is essential to follow safety procedures to avoid accidents and injuriesA Comprehensive Guide to Ball Mill ManualOperating procedures for grinding OPERATING PROCEDURES FOR GRINDING Peripheral velocity of the wheel during grinding; 2 Feed velocity depending on grit size and type of grinding Leave a request for an order Add your file Download catalog Operating procedures for grinding POLTAVA DIAMOND TOOLSHome / Reference information / Operating procedures for grinding Calculation of spindle turns for grinding wheels of different diameters International size Standarts and their applications by operation Application of diamond and CBN tools and their advantages over abrasive toolsOperating procedures for grinding POLTAVA DIAMOND TOOLS

safe operating procedure conveyor belt Grinding Mill China

2013年4月22日 GUIDELINE – About CMA 34 Personnel Training in Safe Working and Operating Procedures "conveyor belt installation" means a mechanical system used for the transportation of » More detailed safety operating procedure of belt conveyor – Crusher South GUIDELINE Safety Around Belt Conveyors CMA Guideline Rev 01 Mar2010 CONVEYOR The purpose of an operating manual, is not only to help the operation engineers and staff at the customer side to operate the plant safely, but also to present all detailed procedures for the plant startup and shut down in the various operation cases 2 Extent of description a Operating manuals should contain all operating procedures, guidance,PLANT OPERATING MANUALS (PROJECT STANDARDS AND 2020年7月10日 What’s a Standard Operating Procedure (SOP)? A standard operating procedure, or SOP, is a set of detailed stepbystep instructions that describe how to carry out any given process Most companies that are serious Standard Operating Procedure (SOP) GuideSafe Operating Procedures This SOP should be used in conjunction with relevant machinery manuals and manufacturer recommendations Procedure Reference Version Effective Date Review Date Page Number Date Printed WHS SOP 2 10 28/03/2018 28/03/2021 2 24/04/2018 POTENTIAL HAZARDS 1 Hot metal – use appropriate tools to manage heat 2Safe Operating Procedures SOP 02 Bench Grinder University of

manual operational procedure coal fired power plant

Describe startup and shut down procedures of power • Detailed Course Reference Manual for Power station was a coal fired Power Station operating » Free online chat! Power Plant Operations Audit Program – AuditNet: Knowledge is Operations Department – Coal Fired Power Plant FY 2003 I AUDIT OBJECTIVES E Procedure review3 Ensure that grinding disc, guard and attachments (including handle) are secure and correctly fitted 4 Inspect the grinding disc for damage Do not use damaged grinding disc 5 Always inspect the work piece to ensure that there aren’t any items which might damage the grinding wheel or cause injury to the operator 6SAFE OPERATING PROCEDURE (SOP) Angle GrinderStandard Operating Procedures (SOP) Variable speed in the range 700 – 1200 rpm; Variable grinding duration; Accessing the operating instructions; Direct spare parts inquiry; Sample/machine data exportable in csv format; Updatefriendly app and firmware; Closed, soundinsulated housing Optional pneumatic closing device Space under the mill Laboratory disc mills by SIEBTECHNIK TEMAThe Surface Grinder Safe Operating Procedure (SOP) outlines the necessary steps for safe and efficient use of the equipment, helping workers manage associated risks effectively Contents Hazards: Identifies potential hazards such as noise, electricity, and sharp edges so workers are aware of what can cause harmGrinder (Surface) SOP SafetyDocs PDF Word Templates

.jpg)

Standard Operating Procedures (SOP) For Fire Prevention

2024年11月26日 Fire prevention is critical to workplace safety, especially when flammable materials are handled, stored, or processed Having a detailed and wellimplemented Standard Operating Procedure (SOP) for Fire Prevention is crucial in reducing the risks associated with fires and ensuring the safety of employees, assets, and the surrounding environment1) The document provides standard operating procedures for internal grinding of components on a CNC grinding machine It details checks to perform on the machine, tools, and components before and during production 2) Key steps include checking coolant, oil, and clamping jaw movement before starting and inspecting components during production Abnormal sounds or sizes SOP Template PDF Grinding (Abrasive Cutting) ScribdStandard Operating Procedure: Electrochemistry Experiments Last Updated 05/15/17 by Selene Li Reagents: Check the availability of solvent in the small glovebox If solvents need to be pumped in the box, make sure they are dry and airfree If not, please dry and degas it Common supporting electrolytes used in the McCusker lab are NBu 4 PF 6,Standard Operating Procedure: Electrochemistry ExperimentsStandard operating procedures manuals ensure that the employees are made aware of the operating procedures and that they have detailed instructions on how to follow them While this does not guarantee that every employee will follow the standard operating procedures to the letter, it does ensure that most employees will adhere to the guidelines and rules you have Coffee Shop Standard Operating Procedures Overview (Checklist

Grinding Station (Fifth Dawn) Gatherer Magic: The Gathering

Searching for Grinding Station for Fifth Dawn? Look no further We have all the necessary details needed to quench your knowledge thirst, from mana value to rarity to artist And everything in betweenPortable Grinder Operating Procedures Free download as Powerpoint Presentation (ppt / pptx), PDF File (pdf), Text File (txt) or view presentation slides online This document provides safety guidelines for using portable grinders It outlines the necessary personal protective equipment (PPE) including safety helmets, eye protection, gloves, high visibility clothing, and safety shoesPortable Grinder Operating Procedures PDF Personal ScribdStandard Operating Procedure Standard Polisher/Grinder Standard Operating Procedure – Standard Polisher/Grinder About this SOP This document describes the standard operating pr ocedure for using the polisher/grinders in room 157 Engineering II It covers hazards, emergency procedures, basic specifications and operating procedures Who to procedure of grinding KOOKSPortable Grinder Operating Procedures Free download as PDF File (pdf), Text File (txt) or read online for free The document outlines safety procedures for operating portable grinders It details 10 steps for proper use including preparing the work area, inspecting the grinder and wheel, performing a ring test on new wheels, properly mounting wheels, wearing personal protective Portable Grinder Operating Procedures

.jpg)

Deburring – Procedure and methods Gravostar

13 Grinding, smoothing, lapping, polishing surfaces This procedure is for surface refinement, which is based on the classic procedure These processes are normally performed in machines or systems designed especially for this However, with the right tool equipment (springmounted spindles), this work can also be performed using CNC machines• Keep the tool rest as close to the grinding wheel as possible without touching it The tool rest must be minimally within 1/8th of an inch of the grinding wheel • Prior to starting the grinder, ensure the tang at the top of the wheel opening is located within ¼ inch of the wheelSTANDARD OPERATING PROCEDURES for COMMON TOOL Safe Operating Procedures This SOP should be used in conjunction with relevant machinery manuals and manufacturer recommendations Procedure Reference Version Effective Date Review Date Page Number Date Printed WHS SOP 14 10 28/03/2018 28/03/2021 2 24/04/2018 allow for expansion of the tank 3Safe Operating Procedures SOP 14 Fuelling Vehicles University standard operating procedures sop: 2006 page: 1 of 22 rev: 00 date: 08/11/94 sampling equipment decontamination contents 10 scope and application 20 method summary 30 sample preservation, containers, handling, and storage 40 interferences and potential problems 50 STANDARD OPERATING PROCEDURES