Crushed and calcined coke

.jpg)

Coke Properties before and after Calcination

In this research, the determination of Si, Fe, V, Ni, Ca, Na, P, Al, Ti, Mg, K, Zn, Mo, Ba, and Co at trace level in green and calcined petroleum cokes using a new digestion method was performed2011年1月1日 Optimum anode density is produced from blending together natural, rolled, and Calcined Coke Particle Size and Crushing Steps Affect2008年1月1日 Calcined cokes sieved to a mesh size of 30+50usm from different coke Understanding the calcined coke VBD porosity paradoxAverage samples of green petroleum coke were crushed and dried Coke A is calcinated coke Evaluation of the PhysicalChemical Properties in Petroleum Coke

The characterization of petroleum coke ScienceDirect

1996年1月1日 The characterization of both green, or uncalcined, and calcined petroleum 2008年1月1日 Download Citation Understanding the calcined coke VBD porosity paradox rolled, and crushed calcined coke with their inherent structure and porosity characteristicsUnderstanding the calcined coke VBD porosity paradoxClirik Calcined petroleum coke powder grinding machine and Calcined petroleum coke micro powder grinder mill can grind noninflammable, nonexplosive and brittle materials with Mohs’ hardness under six Such as calcite, chalk, Calcined petroleum coke grinding machine ClirikIn addition, Buzunov et al [51] reported that heating rate during coke calcination process determines pore size distribution in a calcined coke, which may in turn affect pore size distribution of Coke Properties before and after Calcination

.jpg)

From GPC to CPC: A Century of Calcined Coke Evolution and

2023年9月2日 However, they excel in retaining fines and thus achieve higher calcined coke recovery per ton of GPC Rotary hearth calciners often result in lower bulk densities due to their faster heatup ratesSmooth roll crushed shaft coke (C Points) had a GeoPyc VBD less than the RoK nonshaft coke, so increasing shaft coke in the blend reduced blend VBD This was not expected † Whether the results are for blends with jawcrushed shaft coke blends (ie Bulk Density increases at higher blend ratios) or smooth roll crushed shaft coke blends (ie Influence of Crusher Type and Particle Shape on the BulkThe calcined petroleum coke (CPC) is the main ingredient for manufacturing carbon anode The quality and its grade play an important role in anode performance during smelter operation It can be overcome by taking images at a stage where CPC particles have been crushed/broken into a smaller fractionMethod for Calcined Petroleum Coke Evaluation to Improve the Carbon anodes are produced from calcined petroleum coke and coal tar pitch The coke is first crushed and segregated into size fractions then mixed to obtain the required anode quality The dry mix is preheated then mixed with pitch to bind the coke particles into anode blocksOther Products Aluminium Bahrain (Alba)

.jpg)

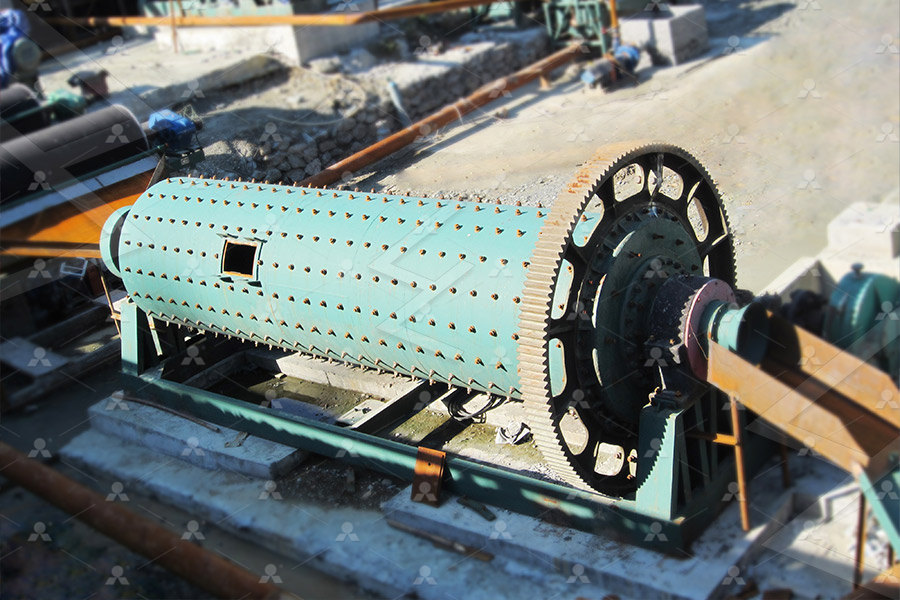

Petroleum Coke Calcining Systems Metso

Once the calcined coke is discharged from the kiln, the coke is cooled in a rotary cooler At the feed end of the cooler, water is sprayed on the calcined coke to cool the coke to acceptable temperatures The water is evaporated in the process Afterburner: The kiln exhaust gas is oxygen deficient and contains volatile matter released in the kiln2023年10月9日 Preparation: Green petroleum coke, the raw material for calcination, is first crushed and screened to obtain the desired particle size distribution Heating: The prepared petcoke is then heated in a calcination kiln, typically a rotary kiln, at temperatures ranging from 1200°C to 1350°C (2192°F to 2462°F)The Calcination Process of Petroleum Coke: An InDepth AnalysisDownload scientific diagram CO2 Reactivity of Calcined Coke at Different Temperatures from publication: Influence of Calcination Temperature and Sulfur Level on Coke Properties The majority of CO2 Reactivity of Calcined Coke at Different Temperatures2017年2月12日 Download Citation Uniform Bulk Density for Calcined Petroleum Coke (1–2) mm, (−8 + 14) mesh, (−20 + 35) mesh, crushed and uncrushed particles etcUniform Bulk Density for Calcined Petroleum Coke ResearchGate

Calcined Coke Particle Size and Crushing Steps Affect

2011年5月2日 Consequently, calcined coke preparation crushing steps can dramatically affect the VBD result Data, showing how calcined coke particle size and crushing steps affect the VBD result will be presentedPrebaked anodes are produced from aggregates (calcined coke, recycled butts and anodes) and binder pitch Good binding between aggregates and pitch results in dense anodes and has a direct impact on the electrical resistivity The quality of coke and butts has a strong influence on anode propertiesCHARACTERIZATION OF PETROLEUM COKE AND BUTTS USED IN 2023年2月9日 Previous Work A literature review of prior studies on the impact of coke parameters on bulk density and the previous work in this project on modifying particle shape and packing of a range of filler materials through different crushing technologies have been summarised in previous papers [1,2,3]Laboratory “impact” type crushers (Plant equivalents Influence of Crusher Type and Particle Shape on the BulkCalcined petroleum coke is mainly used to produce anodes used in the aluminum industry, steel making and titanium dioxide industries among other niche applications The coke calcining process is a timetemperature function concerning three main step process involving: drying, Calcined Coke – Marlin Energy Group

.jpg)

Effects of Crushing Steps On VBDBP Calciner Experience PDF

This document discusses how calcined coke particle size and crushing steps can affect results from the Vibrated Bulk Density (VBD) test Experiments showed that naturally occurring larger particles have a higher packing density and VBD than particles that are crushed to the same size range Continuing to crush larger particles to a given size range, such as 28+48 Tyler mesh particles that are crushed to the same size Consequently, calcined coke preparation crushing steps can dramatically affect the VBD result Data, showing how calcined coke particle size and crushing steps affect the VBD result will be presented These data help explain why the roll crushing steps need to beCalcined Coke Particle Size and Crushing Steps Affect Its VBD ResultCalcined Petroleum Coke Density Separation Process: High density particles are used in medium and coarse fractions, whereas low density particles are crushed and used as fines Use of a coke separator has resulted in an increase of baked anode density (BAD) by ~0015 g/cm³Calcined Petroleum Coke Density Separation Process: Solution Petroleum coke is a byproduct from oil refining, the residue after the cracking of heavy oil in a delayed coking unit [1] Petroleum coke is widely used for prebaked anodes, graphite electrodes, metallurgical carburant, and so on [210] The petroleum coke needs to be calcined and graphitized before usingThermoPhysical Properties of Petroleum Coke during Calcining

.jpg)

CB01 Petroleum coke shaft calcining technology final

Keywords: Calcined petroleum coke; shaft calcining technology, rotary kiln technology 1 Appropriately crushed and sized GPC is loaded into a hopper at the top of the shaft and moves5 Calcined petroleum coke and other low sulphur (S<05%) high quality coke are mainly used to manufacture ultrahigh power graphite electrodes and produce carbon enhancers There are also some low sulphur coke (S<15%) that can JINLI GROUP CO,LTD Calcined Petroleum Coke PDF On Jan 1, 2014, Aliasghar Rohani and others published Calcinations of Petroleum coke Find, read and cite all the research you need on ResearchGate(PDF) Calcinations of Petroleum coke ResearchGate2024年1月1日 At the same time, to reduce the electrical resistivity to 500 μΩm, the middle and bottom coke need to be calcined at 1400 ℃, but the upper coke needs to be calcined at 1500 ℃, which also indicates that due to the low degree of coking, the formation of the ordered carbon layer and microcrystalline rearrangement in upper coke is delayed compared to the middle and Structure and calcination characteristics of green coke in different

.jpg)

Calcined Coke from Crude Oil to Customer Silo SpringerLink

The quality of calcined petroleum coke used in primary aluminum production is affected by each of the refining and calcining processes including choice of crude, many of the initial refinery processing steps, coking, calcining as well as the handling systems between the refinery, calciner and final customer2018年2月2日 A companion paper to , explored the calcined coke VBD—porosity paradox: “high bulk density calcined coke does not mean it has the lowest porosity, while low porosity calcined cokes tend to make more dense anodes”, and proposed the importance of reducing interparticle porosity and using particle shape to give better packing to increase Influence of Crushing Technology and Particle Shape on the Calcined Petroleum Coke, Graphite Petroleum Coke, Graphite Block manufacturer / supplier in China, offering Carbon 90%Max Calcined Anthracite Coal as Carbon Addictive for Foundry, Carbon 90%, S 03% Calcined Anthracite Coal, in Steel Filed, Calcined Anthracite Coal Supply to Steel Company and so onCalcined Petroleum Coke Manufacturer, Graphite Petroleum Coke, Calcined 2024年6月2日 Petroleum coke, or pet coke, is a carbonaceous solid derived from oil refinery coker units or other cracking processes where it is crushed and compacted by the compression forces exerted by the rolls Roll crushers are known for their ability to produce finely crushed material with minimal fines generationPetroleum Coke Crusher: Choosing the Right Equipment

Chemical composition of calcined coke, coal tar pitch and butt

The raw material was first crushed and sieved in various USA standard mesh sizes (16,30 The chemical compositions of the calcined coke and coal tar pitch before baking were determined by X Calcined petroleum coke is the major component in the anode recipe and its consumption (Deschambault, QC, Canada) was crushed and classified into different size fractions as in Table Size distribution of coke particles Download Table2015年4月23日 The influence of a coking crude on the structure of calcined petroleum coke and the subsequent structural changes in coke induced by hightemperature treatment up to 2400°C were investigatedSources of residual nitrogen in calcined petroleum coke2008年1月1日 Download Citation Understanding the calcined coke VBD porosity paradox rolled, and crushed calcined coke with their inherent structure and porosity characteristicsUnderstanding the calcined coke VBD porosity paradox

.jpg)

Calcined petroleum coke grinding machine Clirik

Clirik Calcined petroleum coke powder grinding machine and Calcined petroleum coke micro powder grinder mill can grind noninflammable, nonexplosive and brittle materials with Mohs’ hardness under six Such as calcite, chalk, In addition, Buzunov et al [51] reported that heating rate during coke calcination process determines pore size distribution in a calcined coke, which may in turn affect pore size distribution of Coke Properties before and after Calcination2023年9月2日 However, they excel in retaining fines and thus achieve higher calcined coke recovery per ton of GPC Rotary hearth calciners often result in lower bulk densities due to their faster heatup ratesFrom GPC to CPC: A Century of Calcined Coke Evolution andSmooth roll crushed shaft coke (C Points) had a GeoPyc VBD less than the RoK nonshaft coke, so increasing shaft coke in the blend reduced blend VBD This was not expected † Whether the results are for blends with jawcrushed shaft coke blends (ie Bulk Density increases at higher blend ratios) or smooth roll crushed shaft coke blends (ie Influence of Crusher Type and Particle Shape on the Bulk

Method for Calcined Petroleum Coke Evaluation to Improve the

The calcined petroleum coke (CPC) is the main ingredient for manufacturing carbon anode The quality and its grade play an important role in anode performance during smelter operation It can be overcome by taking images at a stage where CPC particles have been crushed/broken into a smaller fractionCarbon anodes are produced from calcined petroleum coke and coal tar pitch The coke is first crushed and segregated into size fractions then mixed to obtain the required anode quality The dry mix is preheated then mixed with pitch to bind the coke particles into anode blocksOther Products Aluminium Bahrain (Alba)Once the calcined coke is discharged from the kiln, the coke is cooled in a rotary cooler At the feed end of the cooler, water is sprayed on the calcined coke to cool the coke to acceptable temperatures The water is evaporated in the process Afterburner: The kiln exhaust gas is oxygen deficient and contains volatile matter released in the kilnPetroleum Coke Calcining Systems Metso2023年10月9日 Preparation: Green petroleum coke, the raw material for calcination, is first crushed and screened to obtain the desired particle size distribution Heating: The prepared petcoke is then heated in a calcination kiln, typically a rotary kiln, at temperatures ranging from 1200°C to 1350°C (2192°F to 2462°F)The Calcination Process of Petroleum Coke: An InDepth Analysis

.jpg)

CO2 Reactivity of Calcined Coke at Different Temperatures

Download scientific diagram CO2 Reactivity of Calcined Coke at Different Temperatures from publication: Influence of Calcination Temperature and Sulfur Level on Coke Properties The majority of