How to process quicklime aluminum in Sichuan

Lime/quicklime for metallurgy – how producing and briquetting

Lime, also known as quicklime or burnt lime, is mainly composed of calcium oxide, molecular formula CaO, which is a white block or powder cubic 展开2023年7月19日 From raw materials to highquality quicklime, explore the science behind the process and optimize your production for superior results Watch now! Get yours Quicklime Production Plant today!Quicklime Production Process YouTube2020年2月1日 Aluminium is becoming more frequently used across industries due to its beneficial properties, generally within an alloyed form This paper outlines the entire The aluminium industry: A review on stateoftheart technologies Primary production involves mining bauxite deposits from the earth, chemically refining it into pure aluminum oxide and performing electrometallurgical processing to ultimately form aluminum Aluminum Production and Processing

.jpg)

Modern Aluminum Industry in China SpringerLink

2024年1月1日 Develop large efficient energysaving ecofriendly production processes and equipment in Chinese aluminum industry, the highly energyefficient technology for alumina A highend aluminum processing project in Guangyuan, Sichuan province, will enter production in January, 2023 Workers work hard at the Sichuan Shimei Technology Co Highend aluminum processing project to enter operation soonPVTIME – On 6 December 2023, Sichuan Qiya Group has confirmed their investment agreement in Kaili City, Guizhou Province of China, for 20GW monocrystalline silicon rods, 20GW 20GW Silicon Rods and 20GW Wafers! Qiya to Invest in SiliconIn order to understand the rapid developments in aluminum smelting in China, we have to discuss the history of the Chinese aluminum industry, the research activities and engineering History and Recent Developments in Aluminum Smelting in China

Aluminum Processing Production Explained HARBOR

In general, the aluminummaking process involves three steps: mining for bauxite, extracting alumina from the mined bauxite and turning the alumina into aluminum In this guide, we’ll look The process heats the limestone from ambient temperature to 900°C, which is the point where the carbon dioxide is driven off, leaving calcium oxide, also known as quicklime Modern kilns are Vertical Shaft Kilns HWI2024年6月12日 All you need is quicklime and aluminum powder and your heat pack is ready Find out how to make your own heat packs for cooking During this process, CaO is converted into calcium hydroxide with a significant Make Heat Packs For Cooking Yourself With Quicklime 2022年10月15日 Net CO 2 emissions from the production of quicklime can be reduced by introducing renewable solid fuels or sustainably produced electricity for heating of the process This paper reports the results of a study examining the effects of new heat sources on quicklime surface reaction products and on quicklime microstructureSolid biofuel combustion or electrification for limestone

.jpg)

KRA How to Recycle Quicklime Sludge in Converter Process

The present invention relates to a method for recycling the CaO component contained in the sludge generated in the quicklime manufacturing process, in the treatment of limestone sludge generated in the calcining process by adding 5% or more cement pellets of more than 2㎜ size After the production, it is used less than 500kg each time during the blow in the steelmaking Understand quicklime properties, from its caustic nature to its high pH, It is used in the paper manufacturing process, specifically in the causticizing process where it helps in the regeneration of sodium hydroxide Conclusion Quick lime is a vital industrial material with a wide array of applications Its high Understanding Quick Lime: Types, Properties, and Applications2023年2月10日 Quicklime, also known as calcium oxide (CaO), is a white or gray powder that is created by heating limestone to a high temperature, typically above 900°C (1652°F) This process, known as What Is Quicklime And How Does It Work? Medium2024年4月16日 Store your quicklime After you’ve let your quicklime cool, you need to prepare to store it Storing it properly is extremely important as quicklime is a potentially dangerous substance There are a number of things you should consider when storing quicklime Store it in a dry heavyplastic or metal container Seal your container wellHow to Make Quicklime: 10 Steps (with Pictures) wikiHow

.jpg)

Lime in Soil Stabilization Graymont

Lime can be used almost all year round for effective soil drying and soil stabilization using lime can occur almost all year round In a road construction context, the correct application of quicklime or hydrated lime can improve load bearing performance, optimize moisture content, pavement durability and assist to avoid costly delays in project timelinesQuicklime is a chemically unstable and hazardous material and is therefore normally hydrated, becoming not only more stable but also easier and safer to handle Hydrated lime is produced by adding water to quicklime in a process called 'hydration' or 'slaking', where the calcium oxide and water combine chemically to form calcium hydroxideLime An IntroductionThe choice of using hydrated lime or quicklime will depend on the feed rate that the process requires Also the ” reactivity ” of the powder will be a factor of choice For instance, in the sludge liming for sludge stabilization process, the Quicklime is more desired for its exothermic reaction where the increase of temperature will help to kill the pathogen existing in the sludgeHydrated Lime vs Quicklime: What’s the Difference and How to Quicklime from Uma Lime Industry LLC is essential in the steelmaking process Acting as a flux, it effectively removes impurities such as sulphur, silica, and phosphorus from molten steel, resulting in higher quality steel and improved furnace efficiencyQuicklime Applications – Uma Lime Industry LLC

LIME SLAKING 101 Carmeuse

rate, as well as issues around the slaking temperature and wasted quicklime High levels of phosphates can similarly impact the slaking process, although are generally less detrimental to the process The third factor to watch in slaking water chemistry is hardness, which can result in scaling and may necessitate the use of a water softenerQuicklime is widely used for the processing of nonferrous ores In the steelmaking process, quicklime is added to molten iron to remove impurities present in the iron to form slag Therefore, it can help to improve the purity of the steel Quicklime is used to make aluminum, magnesium, calcium salts, and glassCalcium Oxide Quicklime Chemical Formula, Uses2020年9月10日 When quicklime reacts with water, it releases a large amount of hydroxyl ions, leading to an alkaline environment and activating FA Amorphous silicon and aluminum liberated by activated FA particles consume portlandite to anticipate in hydration reaction, producing ettringite and C–S–H/C–A–S–HQuicklime and Calcium Sulfoaluminate Cement Used as Mineral 2017年1月31日 Before we get into the recipe, let me talk about a common mistake people make when it comes to grinding Sichuan peppercorns One of my friends once complained: “My ground Sichuan pepper tastes like sand So gritty!” Later I found out that she put Sichuan peppercorns straight into her regular pepper mill to grind over her foodSichuan pepper, how to grind it correctly? Red House Spice

.jpg)

What is Quicklime and How is it Made? Science Struck

The production of quicklime is one of the oldest chemical processes developed by mankind But there is often a lot of confusion between terms like lime and quicklime Are you wondering what quicklime is, and what it is made of? Then you've come to the right page! ScienceStruck gives you a lot of information about quicklime, and explains how it is industrially madehow is quicklime produced zwemschooldewaterman How to Calculate the Energy Efficiency of your Lime It is relatively easy to obtain a figure if limestone is burned using a batch process However, if a continuous or semicontinuous process is used, then care must be taken that the mass of fuel used and the mass of quicklime produced correspond directly In our example, we how is quicklime produced Welcome to Tables ThymeCoagulation and flocculation provide the water treatment process by which finely divided suspended and colloidal matter in the water is made to agglomerate and form flocs This North Sudan and Sichuan (China) still in use in the 20th century Preparation and application of Moringa seed coagulants14 Coagulation and flocculation SamSamWaterdioxide – a process known as calcination This leaves quicklime, or calcium oxide (CaO), a material that has been used by humans throughout history Adding water to the quicklime will result in an exothermic reaction and the production of hydrated lime, or calcium hydroxide (Ca(OH) 2), a fine dry white powder not dissimilar to baby powderHOW TO CHOOSE THE RIGHT LIME PRODUCT

How to Make Quicklime: 10 Steps The Tech Edvocate

Spread the loveQuicklime, also known as calcium oxide (CaO), is an essential component in many industrial and construction applications Though it is a common product, making quicklime requires careful handling due to its caustic nature In this article, we will outline the 10 steps necessary for making quicklime 1 Gather materials: To make quicklime, you will need Porous ceramics with hierarchical pore and high strength were prepared by secondary aluminum dross and quicklime as main raw materials The influence of quicklime content and thermal treatment on the porosity, pore morphology, compressive strength and bulk density of porous ceramics has been investigated Scanning electron microscopy, computed tomography, xray High strength porous ceramics and its potential in adsorption and It is relatively easy to obtain a figure if limestone is burned using a batch process However, if a continuous or semicontinuous process is used, then care must be taken that the mass of fuel used and the mass of quicklime produced correspond directly In our example, we will take a figure for the coal used as 200 kg/tonne of quicklime producedHow to Calculate the Energy Efficiency of your Lime Burning Process摘要: In the process of hydraulic fracturing of shale gas horizontal wells in the Weiyuan area of Sichuan, China, casing deformation (CD) is a frequent problem that has seriously affected the benefits of shale gas development and remains to be solved for many yearsHow can casing deformation be prevented during hydraulic

.jpg)

High strength porous ceramics and its potential in adsorption and

Article "High strength porous ceramics and its potential in adsorption and building materials: A short process to codisposal secondary aluminum dross and quicklime" Detailed information of the JGLOBAL is an information service managed by the Japan Science and Technology Agency (hereinafter referred to as "JST") It provides free access to secondary information on 2022年1月1日 The effect of quicklime in decomposition process es of human remains in a tropical climate has not yet been investigated, but a similar investigation was carried out in Belgium(PDF) The Effects of Quicklime on the Decomposition Process in a Mahinroosta, A promising green process for synthesis of high purity activatedalumina nanopowder from secondary aluminum dross, J Clean Prod, № 179, с 93High strength porous ceramics and its potential in adsorption and 2022年6月22日 No Mala Without Huajiao Many recipes on this blog include ground 花椒 (huājiāo), Sichuan pepper, but the steps are so simple we’ve always included how to grind Sichuan pepper as a recipe noteYet it’s worth taking extra care to get the most of our premium, singleorigin Sichuan pepper offerings—from the gorgeous sixpetaled, flowershape “Da How to Grind Sichuan Pepper (Huajiao, 花椒) The Mala Market

.jpg)

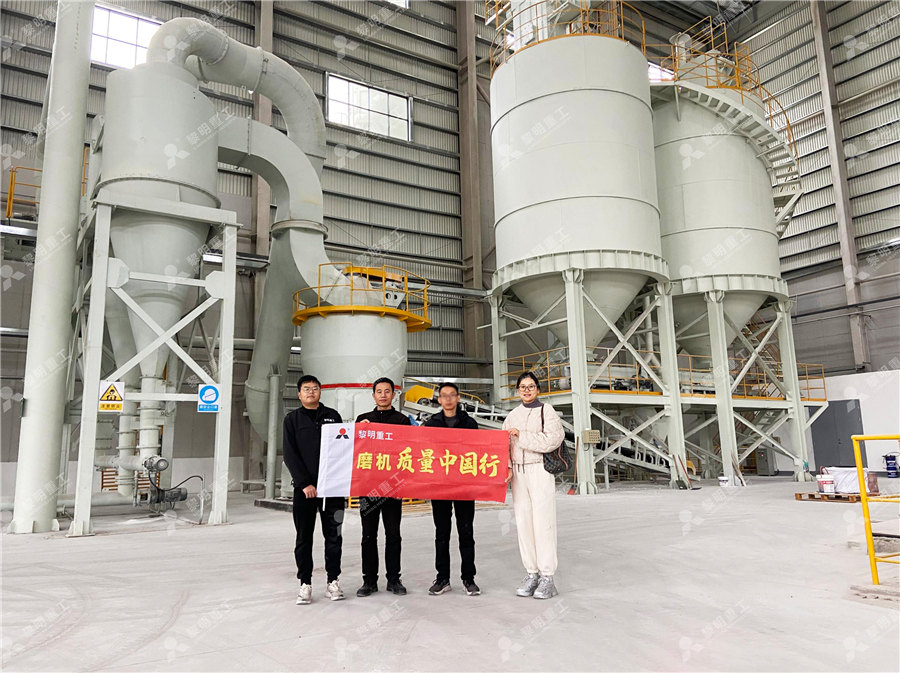

How to do a good job of grinding in the lime industry?

2022年2月28日 Introduction of grinding technology in lime industry Quicklime, whose main component is calcium oxide, is usually prepared by calcining natural rock whose main component is calcium carbonate at high temperature to decompose into carbon dioxide and calcium oxide (chemical formula: CaO, namely quicklime, also known as marble)development in China’s urbanization process Keywords: China; aluminum electrolysis; high amperage aluminum reduction cell 1 Introduction At the present time the electrolysis of cryolitealumina molten salts, also known as HallHéroult process, is the only industrial process for the primary aluminum production The temperature ofHistory and Recent Developments in Aluminum Smelting in China 2024年9月17日 We are a company dedicated to providing highquality industrial materials, focusing on the supply of fly ash, granulated Granulated blast furnace slag, ground granulated Granulated blast furnace slag, cement clinker and quicklimeThe role of quicklime in the steelmaking process2023年7月31日 In the basic oxygen steelmaking (BOS) process, quicklime plays a crucial role Quicklime and hydrated lime can significantly increase the loadcarrying capacity of claycontaining soils by participating in chemical reactions with finely divided alumina and silica to create calcium silicates and aluminates, which have cementing propertiesQuicklime Preparation, Properties, Health Hazards, and

Make Heat Packs For Cooking Yourself With Quicklime

2024年6月12日 All you need is quicklime and aluminum powder and your heat pack is ready Find out how to make your own heat packs for cooking During this process, CaO is converted into calcium hydroxide with a significant 2022年10月15日 Net CO 2 emissions from the production of quicklime can be reduced by introducing renewable solid fuels or sustainably produced electricity for heating of the process This paper reports the results of a study examining the effects of new heat sources on quicklime surface reaction products and on quicklime microstructureSolid biofuel combustion or electrification for limestone The present invention relates to a method for recycling the CaO component contained in the sludge generated in the quicklime manufacturing process, in the treatment of limestone sludge generated in the calcining process by adding 5% or more cement pellets of more than 2㎜ size After the production, it is used less than 500kg each time during the blow in the steelmaking KRA How to Recycle Quicklime Sludge in Converter Process Understand quicklime properties, from its caustic nature to its high pH, It is used in the paper manufacturing process, specifically in the causticizing process where it helps in the regeneration of sodium hydroxide Conclusion Quick lime is a vital industrial material with a wide array of applications Its high Understanding Quick Lime: Types, Properties, and Applications

What Is Quicklime And How Does It Work? Medium

2023年2月10日 Quicklime, also known as calcium oxide (CaO), is a white or gray powder that is created by heating limestone to a high temperature, typically above 900°C (1652°F) This process, known as 2024年4月16日 Store your quicklime After you’ve let your quicklime cool, you need to prepare to store it Storing it properly is extremely important as quicklime is a potentially dangerous substance There are a number of things you should consider when storing quicklime Store it in a dry heavyplastic or metal container Seal your container wellHow to Make Quicklime: 10 Steps (with Pictures) wikiHowLime can be used almost all year round for effective soil drying and soil stabilization using lime can occur almost all year round In a road construction context, the correct application of quicklime or hydrated lime can improve load bearing performance, optimize moisture content, pavement durability and assist to avoid costly delays in project timelinesLime in Soil Stabilization GraymontQuicklime is a chemically unstable and hazardous material and is therefore normally hydrated, becoming not only more stable but also easier and safer to handle Hydrated lime is produced by adding water to quicklime in a process called 'hydration' or 'slaking', where the calcium oxide and water combine chemically to form calcium hydroxideLime An Introduction

43.jpg)

Hydrated Lime vs Quicklime: What’s the Difference and How to

The choice of using hydrated lime or quicklime will depend on the feed rate that the process requires Also the ” reactivity ” of the powder will be a factor of choice For instance, in the sludge liming for sludge stabilization process, the Quicklime is more desired for its exothermic reaction where the increase of temperature will help to kill the pathogen existing in the sludgeQuicklime from Uma Lime Industry LLC is essential in the steelmaking process Acting as a flux, it effectively removes impurities such as sulphur, silica, and phosphorus from molten steel, resulting in higher quality steel and improved furnace efficiencyQuicklime Applications – Uma Lime Industry LLC