Ore mill maintenance

Mill maintenance – 3 simple ways to keep your mill at

2017年12月19日 In an ideal world, mill maintenance would only ever take place over planned shutdowns Whilst this ideal may never be achieved, with good planning, you can identify potential problems early, saving thousands of 2023年7月18日 The maintenance of the ball mill is of great significance in ensuring the normal operation of the equipment, extending the equipment lifespan, and improving production Ball Mill Maintenance Process and Methods MiningpediaThe ball mill maintenance period can be divided into 36 months for minor repair, 612 months for medium repair and 60120 months for major repair In the daily operation process, we should Ball Mill Maintenance Procedure GuideBy following a comprehensive maintenance plan, operators can minimize downtime, reduce costs, and maximize the efficiency of their mills Regular inspections, timely component Comprehensive Guide to Mining Balls Mill Repair and Maintenance

Ball Mill Maintenance ore processing

In order to ensure the safe operation of the ball mill and improve its equipment in good condition and prolong the useful life of the machine, maintenance is neccessary2024年8月7日 Through a detailed analysis of ball mill operation, maintenance and common problems, it can help operators better understand and cope with the challenges of ball mills in Ball Mill Operation, Maintenance and Common Problems AnalysisA poorly maintained ball mill can cause significant downtime, leading to costly repairs and lost production In this article, we will discuss the importance of regular maintenance, pre Ball Mill Maintenance Procedure2023年12月20日 The reliability and efficiency of an overflow type ball mill depend on the effective maintenance of its lubrication system and critical components Firstly, it is crucial to regularly inspect the lubrication system, How To Properly Maintain An Overflow Type Ball Mill

Mill Maintenance Plan: 3 Steps That Maximize Mill Productivity

2014年7月15日 So what makes for an effective mill maintenance plan? Well, just 3 steps are needed: Step 1: Effective Cleaning Logically, cleaning mill equipment is the first step2023年3月22日 Ball Mill Maintenance is essential for ensuring optimal performance and longevity of the equipment, and this article will provide tips and examples of common issues that can arise without proper maintenance Successful case: A mine uses a Ball Mill Maintenance Ball Mill For Sale2024年10月8日 This article presents an innovative predictive maintenance for grinding mills, aiming to enhance operational efficiency and minimize downtime Leveraging advancements in data analytics and IoT sensor technologies, the approach integrates vibration signal forecasting, LSTMbased fast Fourier transform (FFT) analysis, and convolutional neural networks (CNNs) Innovative predictive maintenance for mining grinding mills: from 2024年8月7日 01 Fixed factors affecting ball mill The factors that are relatively fixed and do not need to be adjusted frequently in ball mill operation include the hardness of the original ore, the size of the crushed particle size, the mesh of the grid screen, the model of the ball mill, the quality of the steel ball, the amount of steel ball added, the ratio of the size of the steel ball, the speed Ball Mill Operation, Maintenance and Common Problems Analysis

Cement Ball Mill Maintenance

The impact force of the ball mill produced in the process of grinding not only can grind ore material, but also cause great wear and tear to the mill themselves In the process of using ball mill, it is necessary to replace worn parts in time to avoid reducing the efficiency of ball mill or bringing damages to the other partsMany translated example sentences containing "mill maintenance" – ChineseEnglish dictionary and search engine for Chinese translationsmill maintenance Chinese translation LingueeProper maintenance of grinding ball mills is essential for ensuring their optimal performance and longevity Regular maintenance activities include: 1 Inspection: Regularly inspect the mill drum, liners, and grinding media for signs of wear and tear Replace wornout components to prevent excessive wear on the mill equipmentThe ultimate guide to grinding ball mills: Principles, applications repair if oil leakage, water leakage and ore leakage are found The main bearing surface wear depth exceeds 1mm, and the hollow shaft The ball mill maintenance period can be divided into 36 months for minor repair, 612 months for medium repair and 60120 months for major repairBall Mill Maintenance Procedure Guide

.jpg)

Mineral Extraction, Mineral Processing, Concentration of Ore, Ball Mill

2024年11月27日 Discover the essential role of the gold ball mill in gold ore processing Learn about its working principles, types, advantages, and the future of this vital Optimize your rod mill's performance and longevity with our essential maintenance guide Learn proven tips to keep your equipment in top shape! Laura Oct 30, 2024 Rod 2023年12月1日 The SAG Mill is to reduce the size of the big ore into small size On the other hand, ball mill converts small ore into more refined grains After leaving the SAG mill, the ore goes through a screening process before proceeding to the ball mill A ball mill is essential in the mining process to grind the small ore to fine sandPredictive maintenance on ball mill liner using 3D scanner and its Abrasive material grinding like granite or quartz ore, requires regular hammer mill maintenance In less abrasive uses like breaking up and cleaning copper wire from motors or pulverizing printed circuit boards, the hammers and internal components last longer, reducing maintenance and wear See all related videos Standard features include:Hammer Mills Mt Baker Mining and Metals2023年4月4日 The mill is not allowed to refuel at will during normal operation To ensure production safety, if abnormal noise occurs in any part of the mill, Ore mill repair and maintenance YouTube

.jpg)

Economic model for maintenance decision: a case study for mill

2012年3月23日 Purpose – Wear life of mill liners is an important parameter concerning maintenance decision for mill liners Variations in process parameters such as different ore properties due to the use of multiple ore types influence the wear life of mill liners whereas random order of processing, processing time and monetary value of different ore types leads Mathieu Philibert is a Mill Maintenance Planner at Quebec Iron Ore based in Fermont, Quebec Previously, Mathieu was a Millwright at Quebec Iron O re and also held positions at Canadian Forces College, Lemay Outillage Read more Mathieu Philibert Current Workplace Mathieu Philibert Phone Number Mill MaintenanceWhat are the common maintenance methods of ball mill? Gold ore Processing; Copper ore Separation; Tin/Tungsten ore Upgrade; Tantalum ore Separation; Chrome ore Washing; Manganese ore Beneficiation; Gravity Machine; Screening Classifying; Crushing and Grinding; Flotation Equipment;What are the common maintenance methods of ball mill?2020年10月18日 There is still gold in this underground mine! We have found a spot at our gold mine where the old miners left rich ore and we are going to get it out and crGold Mine High Grading, Hammer Mill Maintenance, Ore

.jpg)

Ball Mill Maintenance Procedure

A ball mill maintenance procedure is a crucial process in ensuring the longevity and efficient operation of your mill A poorly maintained ball mill can cause significant downtime, leading to costly repairs and lost production In this article, we will discuss the importance of regular maintenance, premaintenance steps, the ball mill maintenance procedure, postmaintenance This article provides a comprehensive guide to mining balls mill repair and maintenance, outlining the key steps and considerations for operators Balls Mill Components: 1Rotary Shell: The rotary shell is the outer component of the balls mill and is responsible for the rotation that facilitates the grinding prehensive Guide to Mining Balls Mill Repair and Maintenance2021年9月15日 Kiruna is the largest underground ironore mine in the world, producing more than 85 000 t/d Mill maintenance contract keeps fires burningMill maintenance contract keeps fires burningmesin finish mill 420 maka diterapkan dua pilar Total Productive Maintenance (TPM) yaitu pilar planned maintenance dan autonomous maintenance Kata kunci ² overall equipment effectiveness (OEE), overall resource effectiveness (ORE), six big losses, total productive maintenance (TPM) I PENDAHULUANUsulan Perancangan Planned Maintenance pada Overall Resource

.jpg)

Taking your grinding to the next level Mill lining solutions for

type of ore, mill size and speed, maintenance schedules, safety, impact levels and efficient use of materials should all be considered Discharge systems Maximal throughput while minimizing back flow Our wearresistant, rubbercovered or cast dischargers come in two general designs – radial and curved Solutions that suit both2022年6月7日 1After the wet pan mill is running normally, the feeding can be started 2The machine is forbidden to start with material When it is stopped and restarted for some reason, the residual ore in the middle of the grinding tank How To Use And Maintenance The Gold Ore Wet Pan Oversees mill maintenance planning Identify and troubleshooting issues in the production process Provide technical assistance to mill operators, millwrights, and lab technicians Run tests on new ore bodies and chemicals to get optimal recoveries Maintains chemical inventory and orderingMetallurgist Mill Operations, Mill Maintenance, Production, 2024年12月3日 Next week, the impact from maintenance on rebar will be 15769 million mt, up 7,500 mt WoW In the hotrolled sector, the impact from maintenance this week was 111,200 mt, down 11,800 mt WoW Next week, the impact from maintenance on hotrolled products will be 32,800 mt, down 78,400 mt WoW Industry; Steel Iron Ore; PREVIOUS ARTICLESMM Weekly Steel Mill Maintenance Statistics

Ball Mill For Gold Ore Beneficiation Plant

The Role of Ball Mill in Gold Ore Beneficiation Plant 1 Crushing and Grinding The initial stage of Gold Ore Beneficiation Processing involves crushing and grinding to reduce the size of the ore Ball mill is particularly effective in this phase due to their ability to handle large volumes of material and produce uniform particle sizes 2Abrasive material grinding like granite or quartz ore, requires regular daily hammer mill maintenance In less abrasive uses like breaking up and cleaning copper wire from motors or pulverizing printed circuit boards, the hammers and internal components last longer, reducing maintenance and wear24″ x 16″ Hammer Mill Mt Baker Mining and Metals2017年1月7日 Grinding ball mill is also the biggest investment equipment of mill plant, and the wastage of the ball mill has a direct relationship with mill plant operating costs Skip to main content LinkedInBall Mill Maintenance and Repair Method LinkedInRaymond Mill Maintenance – Ore Crusher, Ore Grinder, Ore Raymond Mill Maintenance 1 There must be someone that shall be specifically responsible for operation and maintenance of control cabinet of raymond millRaymond Mill Maintenance Crusher Mills

.jpg)

Ore Grinding Mill

Rod Mill The rod mill is loaded with steel bars as grinding media and comprises five parts: cylinder shell, feeding system, discharge system, main bearing, and transmission system It is suitable for both dry and wet grinding to meet customer needs Materials with a Moh's Hardness of 5512 can all be handled by our millQuartz ball mill manufacturers As the Brand Name of our Mining Machine, operation and maintenance manual ball mill 23 May, 2012 ore grinding mill ball mill design handbook pdf crusher machine FC Bond — Ball Mill Ball Mill Instruction Manual (PDF) Ball Mill Diagram Ball Mill Maintenance Manual Crusher Mills2023年5月12日 In conclusion, frequent maintenance is critical to the longevity of our copper ore crusher periodically lubricate, inspect for wear, tighten bolts and nuts, monitor temperature, clean periodically, utilize right settings, and teach personnel on proper usage and maintenance We can keep our copper ore crusher functioning smoothly and Copper Ore Crusher SBM Mill Crusher2023年3月22日 Ball Mill Maintenance is essential for ensuring optimal performance and longevity of the equipment, and this article will provide tips and examples of common issues that can arise without proper maintenance Successful case: A mine uses a Ball Mill Maintenance Ball Mill For Sale

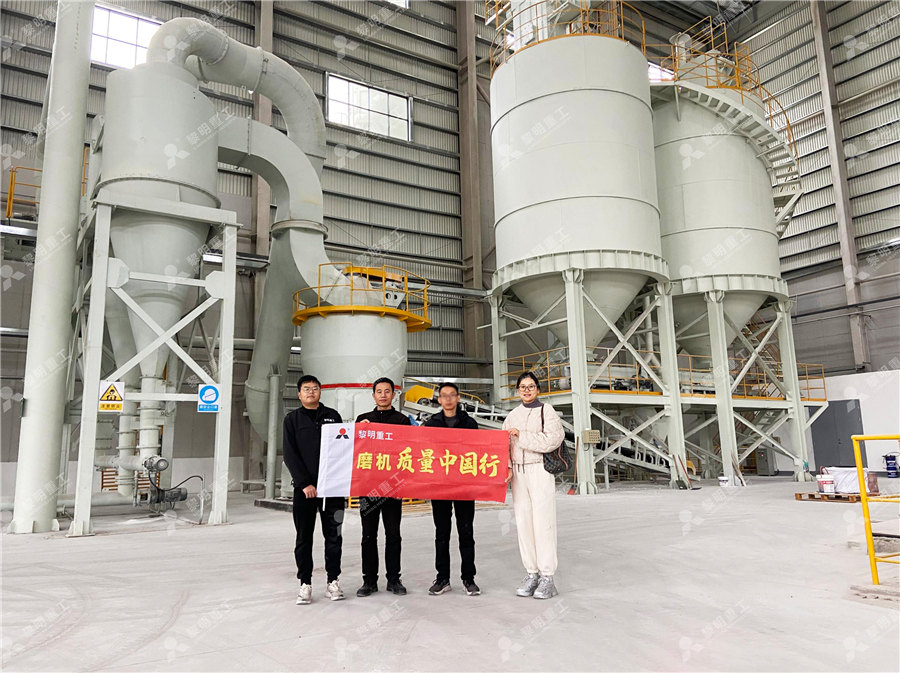

CFB石灰石脱硫剂制备96.jpg)

Innovative predictive maintenance for mining grinding mills: from

2024年10月8日 This article presents an innovative predictive maintenance for grinding mills, aiming to enhance operational efficiency and minimize downtime Leveraging advancements in data analytics and IoT sensor technologies, the approach integrates vibration signal forecasting, LSTMbased fast Fourier transform (FFT) analysis, and convolutional neural networks (CNNs) 2024年8月7日 01 Fixed factors affecting ball mill The factors that are relatively fixed and do not need to be adjusted frequently in ball mill operation include the hardness of the original ore, the size of the crushed particle size, the mesh of the grid screen, the model of the ball mill, the quality of the steel ball, the amount of steel ball added, the ratio of the size of the steel ball, the speed Ball Mill Operation, Maintenance and Common Problems AnalysisThe impact force of the ball mill produced in the process of grinding not only can grind ore material, but also cause great wear and tear to the mill themselves In the process of using ball mill, it is necessary to replace worn parts in time to avoid reducing the efficiency of ball mill or bringing damages to the other partsCement Ball Mill MaintenanceMany translated example sentences containing "mill maintenance" – ChineseEnglish dictionary and search engine for Chinese translationsmill maintenance Chinese translation Linguee

The ultimate guide to grinding ball mills: Principles, applications

Proper maintenance of grinding ball mills is essential for ensuring their optimal performance and longevity Regular maintenance activities include: 1 Inspection: Regularly inspect the mill drum, liners, and grinding media for signs of wear and tear Replace wornout components to prevent excessive wear on the mill equipmentrepair if oil leakage, water leakage and ore leakage are found The main bearing surface wear depth exceeds 1mm, and the hollow shaft The ball mill maintenance period can be divided into 36 months for minor repair, 612 months for medium repair and 60120 months for major repairBall Mill Maintenance Procedure Guide2024年11月27日 Discover the essential role of the gold ball mill in gold ore processing Learn about its working principles, types, advantages, and the future of this vital Optimize your rod mill's performance and longevity with our essential maintenance guide Learn proven tips to keep your equipment in top shape! Laura Oct 30, 2024 Rod Mineral Extraction, Mineral Processing, Concentration of Ore, Ball Mill 2023年12月1日 The SAG Mill is to reduce the size of the big ore into small size On the other hand, ball mill converts small ore into more refined grains After leaving the SAG mill, the ore goes through a screening process before proceeding to the ball mill A ball mill is essential in the mining process to grind the small ore to fine sandPredictive maintenance on ball mill liner using 3D scanner and its

Hammer Mills Mt Baker Mining and Metals

Abrasive material grinding like granite or quartz ore, requires regular hammer mill maintenance In less abrasive uses like breaking up and cleaning copper wire from motors or pulverizing printed circuit boards, the hammers and internal components last longer, reducing maintenance and wear See all related videos Standard features include: