Waterwashed coal industrial mill

Coal wastes: handling, pollution, impacts, and utilization

2023年1月1日 The coal mining industry creates hundreds of millions of tons of rock, waste coal, and cleaning waste streams comprising coal bed methane (CBM), coal sludge, fine coal, coal 2016年11月1日 Water washing has a significant effect on the pore structure and content of mineral matters in Zhundong coals With the increase of washing water temperature, the Effect of water washing on reactivities and NOx emission of Coal preparation, which may also be called washing, cleaning or processing, is the methodology by which coal feedstocks are upgraded in order to reduce freight costs, improve utilization Coal Preparation SpringerLinkWashing coal generally describes a water based process where the denser material (rocks and high ash coal particles) are separated and removed from the coal The coal generally is Washed Coal from a Utilization Perspective Coal Combustion

.jpg)

CHARACTERISTICS AND IMPACT OF DIFFERENT

2015年4月4日 In a wet washing plant, or coal preparation plant, the raw coal is crushed and mixed with a large amount of water, magnetite, and organic chemicals The huge volume of waste water left2006年4月1日 The MODSIM mineral processing plant simulator is used to find optimal combinations of target separation specific gravities for the separation units in a typical coal washing plant(PDF) Coal preparation plant optimization: A critical 2022年12月29日 Coalwashing wastewater is the residual produced by the coal industry, which may represent a high risk of serious environmental problems worldwide However, prevailing Optimization modeling and mechanism discussion on specific 2020年10月26日 Handling and disposal of high volume of fine coal tailings is a biggest challenge for coal washeries Separation of clean coal by density separation and flotation shows limited Effective Utilization of Coal Processing Waste: Separation of Low

.jpg)

Economic and Environmental Impact of Coal Washing in India

New plants to be installed after 1 January 2017 shall have to meet SWC up to maximum of 25m3/MWh and achieve zero waste water discharge The new notification implies huge 2018年10月13日 221 Pollutants Released from Pulp and Paper Industry Pulp and paper industry heavily consumes raw materials eg wood, chemical, energy and water The waste material resulting from this industry includes 418% as bleached pulp, 42% as solid waste, 525% as dissolved organic matter and 23% as suspended solids (Table 21) (Nemade et al 2003)Treatment and Recycling of Wastewater from Pulp and Paper Mill2016年1月15日 The rank of coals in the USCB ranges from subbituminous to highvolatile bituminous coals Maceral composition is uniform with humic coals rich in vitrinites predominating, and rare sapropelic coals (Kotarba et al, 2002)The general features of the organic matter contained in the coal wastes are similar to those of the bituminous coals in the Upper Silesia The impact of waterwashing, biodegradation and selfheating 2021年9月30日 Afriyanti et al (2016) mentioned that Indonesia could fulfil most of the global and Asian palm oil demand in the future Meanwhile, Malaysia is the world's secondlargest palm oil producer (PDF) Palm Oil Industries in Malaysia and Possible Treatment

Adsorption of LowConcentration Ammonia Nitrogen from Water

Water 2023, 15, 956 4 of 13 Waterwashed CFA and NaOH were coupled in a weight ratio of 1:1; the mixture was calcined in the muffle furnace at 300 C for 3 hThe roasted sample was cooled,2023年1月1日 Washery wastes result from the coal separation process They account for about 80% of the total waste mass on average, which are subdivided into the following groups: (1) tailings or slurries generated from flotation processes, and their sizes are finer than 1 mm in diameter, (2) finegrained waste produced from sedimentation procedures where the sizes Coal wastes: handling, pollution, impacts, and utilizationThis document analyzes the comilling of coal and wood biomass in a ringball mill It describes tests conducted pulverizing hard coal with additions of 8% and 16% pine sawdust at different moisture contents Key findings include: 1) Biomass has weaker grinding properties than coal and increases circulation ratio, layer thickness, and separation area particle concentration in the Analysis of Coal Mill Operation2020年6月15日 For example, in US, a typical coal gasification plant that gasified 424753 million liters of coal per day generated approximately 84951–226534 million liters per day of wastewater that has to be processed [7]This type of wastewater usually has complex components, which contains a variety of organic pollutants, such as fatty acids, phenols, Study on coal water slurries prepared from coal chemical wastewater

The layout of the coal mill with a rotary classifier

Vertical Coal Mill (VCM) is equipment for grinding and pulverizing coal into micron size Rotary kilns then use the powders as fuel burners The VCM has a housing section equipped with a lining The Barbegal water mill complex: (A): ruins of the mill complex; (B): reconstruction of the site; and (C) crosssection through one train of mill wheels From Passchier, CW, Bourgeois M, Viollet PL, Surmelihindi G, Bernard V, Leveau P and Spotl C (2020) Reconstructing the hydraulics of the world's first industrial complect, the second century CE Barbegal watermills, FranceWater Mill an overview ScienceDirect Topics2019年1月1日 2 Locally Derived Activated Carbon From Domestic, Agricultural and Industrial Wastes for the Treatment of Palm Oil Mill Effluent Author links open overlay panel O Abdulrahman Adeleke 1 , Ab Aziz Abdul Latiff 2 , Mohammed Radin Saphira 2 , Zawawi Daud 2 , Norli Ismail 1 , Amimul Ahsan 3 4 , N Adila Ab Aziz 2 , Mohammed Ndah 2 , Vicky Kumar 2 , Nanotechnology in Water and Wastewater TreatmentMinistry of Coal Room No 622A, Shastri Bhawan, New Delhi, Dated: 27th May, 2021 To, water bodies 432 Actions for disposal of rejects under this route shall be taken up only 442 If coal is washed in a 3rdparty Washery, such linkage holders/Ministry of Coal, GOI

Industrial Salts Cargill

This salt is intended for industrial use only including: Industrial brine makeup Water Treatment Drilling fluid makeup Textiles Packaging: Bulk Product Sheet : HiTex ® A100 Granulated Salt This product is intended for a variety of industrial uses where alkaline earth metals (eg calcium and magnesium) must be kept to a minimum2023年4月1日 Coal mine effluent: 65: Double layer PTFE: 02: ∼6 L/m 2h: 999 % of TDS [82] VMD: These factors include; the location of a reclaimed water source (inside the palm oil mill), treatment infrastructure (based on the Largescale studies covering industrial water recovery from POME by the different membrane designs is Water reclamation from palm oil mill effluent (POME): Recent 2022年10月17日 能源生产:洗煤:洗精煤在12012012达64,206000千吨,相较于11012012的64,603000千吨有所下降。能源生产:洗煤:洗精煤数据按月更新,01012008至12012012期间平均值为41,192000千吨,共60份观测结果。该数据的历史最高值出现于11012012,达64,603000千吨,而历史最低值则出现于02012008,为13,129500千吨。中国 Industrial Production: Washed Coal: Refined 经济指标 CEIC2016年8月11日 US Environmental Protection Agency (1980) Ozone for industrial water and wastewater treatment: a literature survey EPA600280060 Ada, April 1980 Google Scholar Lackey LW, Mines RO Jr, McCreanor PT (2006) Ozonation of acid yellow 17 dye in a semibatch bubble column J Hazard Mater 138(2):357–362Treatment and Management of Industrial Dye Wastewater for Water

Water Recycling from Palm Oil Mill Effluent ResearchGate

2021年1月8日 Nowadays, oil palm production in Malaysia has reached 20 000 000 tons The conventional treatment method for palm oil mill effluent (POME) is a ponding system, which is an easy‐to‐operate but Effect of Additives on the Fluidity and Stability of Coal Water Mixture Hiromoto USUI, Toshio TAMURA, in 1991 International Conference on Coal Science Proceedings, 1991 Publisher Summary This chapter describes the effect of additives on the fluidity and stability of coal water mixture (CWM) The establishment of the preparation technique for the highly loaded coal Coal Water Mixture an overview ScienceDirect Topics2019年12月10日 In this paper, we investigated the pozzolanic activity of thermalactivated coalseries kaolin and two types of waterwashed kaolin, which were calcined at temperatures ranging from 600 to 700 °C for 3 h Chapelle test and strength activity index were used to evaluate the pozzolanic activity of thermaltreated paring pozzolanic activity from thermalactivated waterwashed The capacity in pounds per hour of the mill is calculated on the assumption that the coal hardness is 55 on the Hardgrove Grindability Index and has a moisture content of 8% This would produce an output based on 70% of the coal passing through a 200 mesh screen Capacities available range from 3,500 #/hr (#312) to 59,100 #/hr (753)Industrial Bowl Mills Bowl Mill Pulverizer for Sale Wabash

.jpg)

Engineering and technology of industrial water power at

2015年12月16日 The place where the Roman ford was, is a little above the cascade: the stones are in great part left, but the milldam lays it too deep under water The country people have a notion of its being an old city, and of the Roman road crossing the meadows by the ford; and of great feats and palaces having been here formerly Great coalworks here 年2月1日 The world’s chemical industries face formidable environmental regulatory challenges in treating their wastewater effluents The present work aims at highlighting the various industrial (PDF) Waste Water Treatment in Chemical Industrial Palm Oil Mill Ashes and Coal Fly Ash as Potent Constituent and Reinforcer for Soil Bearing water, air, territorial disputes, and social problems [1], [15], [16]Industrial Palm Oil Mill Ashes and Coal Fly Ash as Potent The CLSA Report warns that this might not just be a problem for China’s coal but also for Mongolian coal washed in Inner Mongolia But it is more than coal! It’s power, cement, steel, coaltoliquid, coaltochemical China Water Risk Water for Coal: Thirsty Miners? China Water Risk

.jpg)

Experimental investigation of water washing effect on high

2022年7月1日 Water washing treatment is one of the most effective methods for removing chlorine and alkali metals from coal or biomass prior to combustion [8]Water washing treatment can affect the fuel properties of coal [9], since the mineral matters play an important role in the combustion process of coal [10]The research of Deng et al [11] about effect of water washing Characterization and preparation of biomass, oil shale and coalbased feedstocks O Trass, in Advances in Clean Hydrocarbon Fuel Processing, 2011 Coal–water slurry fuels The abbreviation for coal–water slurry fuels should be CWSF, but either CWF or CWS is used, with the distinction that CWF is, indeed, a fuel for combustionCoalWater Fuel an overview ScienceDirect Topics2021年1月12日 Which manufacturer sells ore mill equipment with an annual output of tons? HCMilling(Guilin Hongcheng) has many types of ore mills We have vertical roller mill, ultrafine mill, Raymond mill, superfine vertical grinding mill, etc HCM always meets the needs of customers, and recommends a new type of water washing kaolin equipment with an annual T / A Water Washed Kaolin Superfine Vertical Grinding MillSwift Waters: The Industrial Revolution in the Age of Waterpower, an Overview Jamie H Eves Also see: SwiftWatersHotSteam, a PowerPoint presentation on the different types of industrial power, including electricity, used by the mills at Willimantic Falls, 18222012 Like the rest of New England, eastern Connecticut is a land of steep hills, plentiful rainfall, and anSwift Waters: – Windham Textile and History Museum – The Mill

Ground Water Contamination in Coal Mining Areas: A Critical

oven plants and coal beneficiation plants result water pollution The coal washeries discharges effluents containing coal fines from the sedimentation tanks pours into river or stream causes environmental pollution (Tiwary and Abhishek, 2004 2005) V HEAVY METAL POLLUTION Coal mining activity in India started decades back,Alibaba offers 50 Industrial Production Of Washed Coal Suppliers, and Industrial Production Of Washed Coal Manufacturers, Distributors, Factories, Companies There are 31 OEM, 27 ODM, 12 Self Patent Find high quality Industrial Production Of Washed Coal Suppliers on AlibabaIndustrial Production Of Washed Coal Suppliers, Manufacturer The coal mill in a cement plant should be reliable and should be operated with great care, or it is easy to cause safety accidents In the process of grinding Feed coal water content (%) ≤15: ≤10: Coal powder fineness (008mm hole sieve residue, %) 8: 8: Grinding INDUSTRIAL SOLUTIONS Active Lime Production; Activated Carbon Coal Mill in Cement Plant2018年10月13日 221 Pollutants Released from Pulp and Paper Industry Pulp and paper industry heavily consumes raw materials eg wood, chemical, energy and water The waste material resulting from this industry includes 418% as bleached pulp, 42% as solid waste, 525% as dissolved organic matter and 23% as suspended solids (Table 21) (Nemade et al 2003)Treatment and Recycling of Wastewater from Pulp and Paper Mill

The impact of waterwashing, biodegradation and selfheating

2016年1月15日 The rank of coals in the USCB ranges from subbituminous to highvolatile bituminous coals Maceral composition is uniform with humic coals rich in vitrinites predominating, and rare sapropelic coals (Kotarba et al, 2002)The general features of the organic matter contained in the coal wastes are similar to those of the bituminous coals in the Upper Silesia 2021年9月30日 Afriyanti et al (2016) mentioned that Indonesia could fulfil most of the global and Asian palm oil demand in the future Meanwhile, Malaysia is the world's secondlargest palm oil producer (PDF) Palm Oil Industries in Malaysia and Possible Treatment Water 2023, 15, 956 4 of 13 Waterwashed CFA and NaOH were coupled in a weight ratio of 1:1; the mixture was calcined in the muffle furnace at 300 C for 3 hThe roasted sample was cooled,Adsorption of LowConcentration Ammonia Nitrogen from Water 2023年1月1日 Washery wastes result from the coal separation process They account for about 80% of the total waste mass on average, which are subdivided into the following groups: (1) tailings or slurries generated from flotation processes, and their sizes are finer than 1 mm in diameter, (2) finegrained waste produced from sedimentation procedures where the sizes Coal wastes: handling, pollution, impacts, and utilization

.jpg)

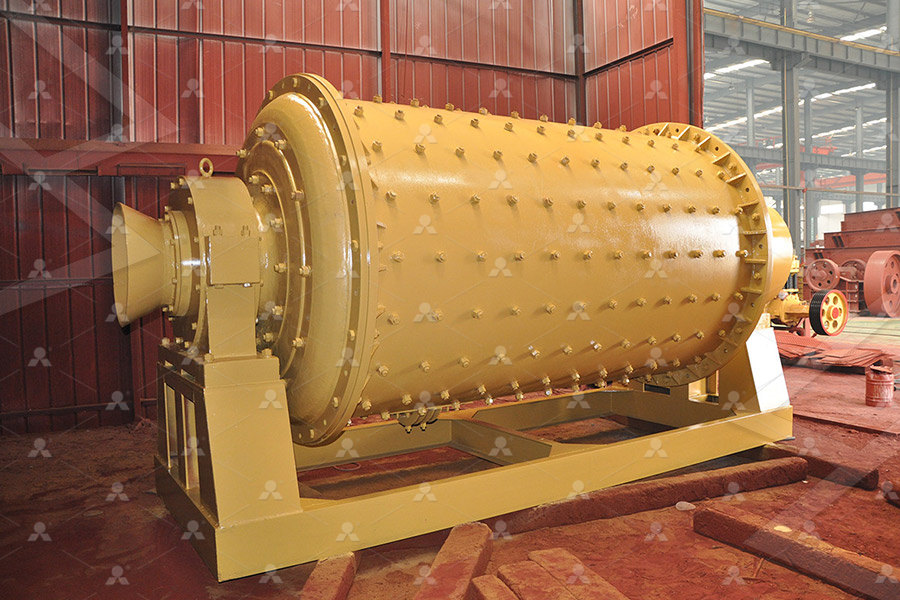

Analysis of Coal Mill Operation

This document analyzes the comilling of coal and wood biomass in a ringball mill It describes tests conducted pulverizing hard coal with additions of 8% and 16% pine sawdust at different moisture contents Key findings include: 1) Biomass has weaker grinding properties than coal and increases circulation ratio, layer thickness, and separation area particle concentration in the 2020年6月15日 For example, in US, a typical coal gasification plant that gasified 424753 million liters of coal per day generated approximately 84951–226534 million liters per day of wastewater that has to be processed [7]This type of wastewater usually has complex components, which contains a variety of organic pollutants, such as fatty acids, phenols, Study on coal water slurries prepared from coal chemical wastewater Vertical Coal Mill (VCM) is equipment for grinding and pulverizing coal into micron size Rotary kilns then use the powders as fuel burners The VCM has a housing section equipped with a lining The layout of the coal mill with a rotary classifierThe Barbegal water mill complex: (A): ruins of the mill complex; (B): reconstruction of the site; and (C) crosssection through one train of mill wheels From Passchier, CW, Bourgeois M, Viollet PL, Surmelihindi G, Bernard V, Leveau P and Spotl C (2020) Reconstructing the hydraulics of the world's first industrial complect, the second century CE Barbegal watermills, FranceWater Mill an overview ScienceDirect Topics

.jpg)

Nanotechnology in Water and Wastewater Treatment

2019年1月1日 2 Locally Derived Activated Carbon From Domestic, Agricultural and Industrial Wastes for the Treatment of Palm Oil Mill Effluent Author links open overlay panel O Abdulrahman Adeleke 1 , Ab Aziz Abdul Latiff 2 , Mohammed Radin Saphira 2 , Zawawi Daud 2 , Norli Ismail 1 , Amimul Ahsan 3 4 , N Adila Ab Aziz 2 , Mohammed Ndah 2 , Vicky Kumar 2 ,