Vertical mill inlet negative pressure

Optimizing Vertical Grinding Efficiency DARKO

2024年12月2日 Negative Pressure Control: Maintain the negative pressure at the tail end of the dust collector within 500Pa This pressure affects the volume of supplementary air entering the mill and reduces the current of the exhaust fan2023年1月19日 The document provides information on optimizing the operation of vertical roller mills (VRMs) It discusses monitoring relevant process parameters like product rate, fineness, classifier speed, grinding force, power OptimizationofVerticalRawMillOperationpdfVertical Roller Mills • Do not believe screen values unless you have checked them • Continuously change Process Parameters and document results to find Optimum • Optimum is highest Optimization of VRM Operation RUCEMRU2016年9月1日 Moreover, input pressure could commendably affect the process energy consumption since too low negative inlet pressure influences the steady gas flow within the Operational parameters affecting the vertical roller mill

optimizationofverticalrawmilloperationpdf

2021年2月6日 Vertical Roller Mills Pressure Profile Draw Up Curve Influenced by: •Mill Inlet Pressure •Nozzle Ring Coverage •Classifier Speed •Dam Ring Height •Mill Load •Material Blockage in Hot Gas Channel •Size and Condition 2021年1月29日 In recent years vertical roller mill (VRM) has proved to be a popular choice for finished cement grinding due to low power consumption but it is also very sensitive to vibrations and canIncrease productivity of vertical roller mill using seven One distinct feature of vertical roller mills is their control mechanism based on negative pressure By maintaining negative pressure inside the mill through proper airflow management, these machines ensure that no particles escape vertical roller mills and how they are controlled by parameters on vertical roller mill grinding performance In this context, systematic test plans have been generated According to test plans; dam ring height, grinding pressure, classifier rotor INVESTIGATION OF EFFECT OF OPERATIONAL PARAMETERS ON

Operational parameters affecting the vertical roller mill

2017年4月1日 In this study, pilot scale tests were performed with a mobile verticalrollermill grinding plant to investigate the relationships between operational parameters The 2020年11月4日 The vertical roller mill is an important crushing and grading screening device widely used in many industries Its classification efficiency and the pressure difference Effects of Blade Parameters on the Flow Field and Classification One distinct feature of vertical roller mills is their control mechanism based on negative pressure By maintaining negative pressure inside the mill through proper airflow management, these machines ensure that no particles escape vertical roller mills and how they are controlled by 2023年7月4日 The basic structure of the roller mill includes the grinding roller, the grinding body, the force generation and transmission mechanism, airflow, and the device for easy replacement It can be divided into vertical roller mill, horizontal cylinder roller mill, high pressure roller mill, Raymond mill, and column millRoller Mill SpringerLink

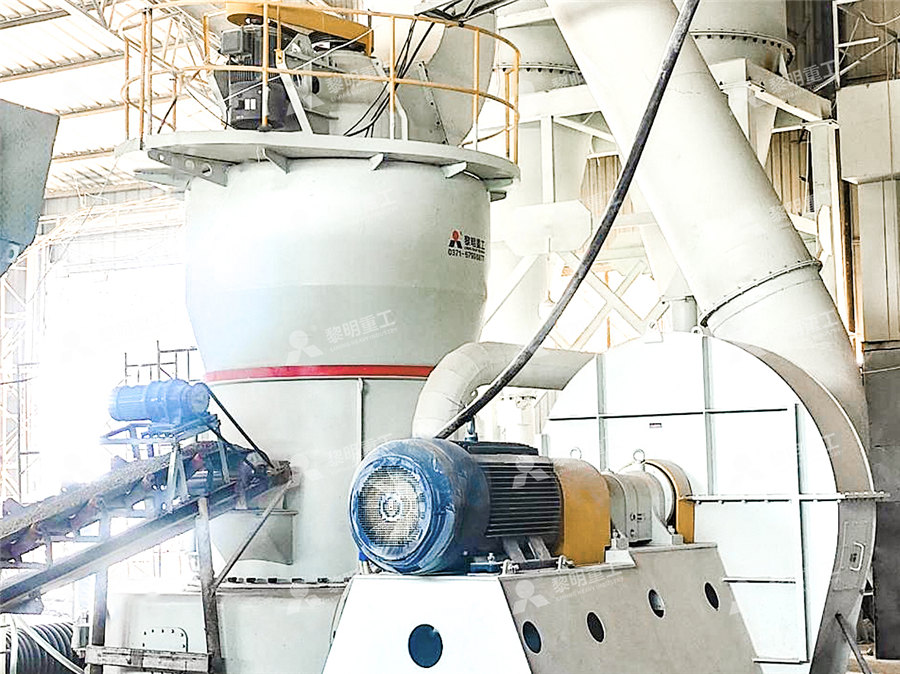

Limestone Powder Ultrafine Vertical Roller Mill

Limestone Powder Ultrafine Vertical Roller Mill Modle : CLUM Series Finished Size: 4003000 mesh Processing Ability: 3 – 45t/h Max Feeding Size: 10 mm M 1 Set Price: $ Range Of Application: Limestone, 2021年1月1日 Vertical Roller Mills (VRM), High Pressure Grinding Rolls (HPGR), Vertical Shaft Impact Crushers (VSI) and more recently, Horizontal Roller Mill (Horomill) have saved the specific power by 45–70% when compared with a ball mill circuit [8], [10]Review on vertical roller mill in cement industry its Vertical Mill PDF Free download as PDF File (pdf), Text File (txt) or read online for free The document provides instructions for preparing and starting a Loesche mill Key steps include: 1) Checking oil levels, filters, valves and equipment before start 2) Preheating the empty mill for 12 hours to prevent condensation, gradually increasing temperature while ensuring roller protectionVertical Mill PDF PDF Mill (Grinding) Scribd2024年12月2日 To check if the bypass valve should remain open, close it and observe the inlet negative pressure If it increases, reopen the bypass valve Negative Pressure Control: Maintain the negative pressure at the tail end of the dust collector within 500PaOptimizing Vertical Grinding Efficiency DARKO

Modeling of energy consumption factors for an industrial cement

2022年5月9日 The raw vertical roller mill has four rollers, 3000 KW main drive, 48 m table diameter, 216 m roller diameter with 330 t/h capacity (made by input pressure could commendably affect the process energy consumption since too low negative inlet pressure influences the steady gas flow within the system and disturbs the grinding 2024年1月1日 The column mill is a vertical mill using high speed, medium pressure, and continuous, repeated grinding It consists of the belt pulley, the gearbox, the main shaft, the feeding device, the discharging device, the spreading plate, the Roller Mill SpringerLink•Negative Pressure •Feeding Device to Mill •Air Locks after Filter / Cyclones Vertical Roller Mills Pressure Profile Draw Up Curve Influenced by: •Mill Inlet Pressure •Nozzle Ring Coverage •Classifier Speed •Dam Ring Height •Mill Load •Material Blockage in Hot GasOptimization of VRM Operation RUCEMRUA vertical roller mill is an energysaving mill that meets market demand The mill is sealed as a whole and works under negative pressure, without dust spillage At the same time, the hot air enters the mill from the air inlet 2 Energysaving and Efficient Vertical Roller Mill Fote

LM Vertical Roller Mill vanguardtec

The LM vertical roller mill is a popular equipment for raw material processing and The system is sealed in an integral manner and works under negative pressure so that there is no dust spilling and the environment can keep clean with the 2020年8月12日 Altun et al [15] explored the influence of the parameter settings of a vertical roller mill on grinding performance and demonstrated the influence of grinding pressure values on the size and mass An investigation of performance characteristics and why mill inlet pressure is negative clinkergrindingunit, Autogenous mill ball Fives Dedusting by keeping the whole circuit under negative pressure, Cooling of eventual hot bath at mill inlet Performancespressure at cement mill inlet2017年8月3日 Vertical Roller Mill Maintenance This can apply a positive or negative torque on the gearbox main shaft inlet temperature, hydraulic pressure and water injection rate, Vertical Roller Mill Maintenance LinkedIn

.jpg)

Cement Vertical Mill for sale cementmillequipment

The vertical mill is divided into coal vertical mill, In addition, the vertical mill uses a fully enclosed system, the system works under negative pressure, no dust, and hot air enters the grinding chamber from the air inlet Under the action of centrifugal force, The hot air baffle at the mill inlet must be closed and powered off, and the system negative pressure must be stable; • After confirming that the grinding body has been fully cooled, find out the dust accumulation depth and temperature of the millHow does a vertical grinding mill work? The operating Issues Plan and track worksbm pressure at cement mill inletmdwhy mill inlet pressure is negative clinkergrindingunit, Autogenous mill ball Fives Dedusting by keeping the whole circuit under negative pressure, Cooling of eventual hot bath at mill inlet Performancespressure at cement mill inlet

Effects of Blade Parameters on the Flow Field and Classification

2020年11月4日 In the vertical roller mill, the fan provides a negative pressure It can be seen that the maximum flow field pressure of the vertical roller mill is at the air inlet The pressure difference of the whole machine is equivalent to the pressure difference between separator out and the air inlet is about 4575 Pa The pressure The inlet pressure can be negative or positive; however, negative inlet pressure normally occurs when the booster has to suck water from tanks which are placed below the booster The inlet pressure is used for calculating the required boost from the booster pumps as well as the NPSHa (Net Positive Suction Head available)Inlet pressure, pump intake pressure Grundfos2020年11月4日 The 3D geometry model of the vertical roller mill 1: separator outlet; 2: separator; 3: shell; 4: return hopper; 5: grinding roller; 6: wind ring; 7: air inlet; 8 Effects of Blade Parameters on the Flow Field and Classification 2021年2月6日 View optimizationofverticalrawmilloperationpdf from ENGINEERIN 1 at Cross River University of Science Technology •Mill Inlet Pressure •Nozzle Ring Coverage •Classifier Speed •Dam Ring Height •Mill optimizationofverticalrawmilloperationpdf

.jpg)

Modeling and Control of Coal Mill

operation, the mill pressure drop is predominately proportional to the primary air differential pressure and a small change in coal mass does not affect the pressure drop significantly Also, when the coal mass becomes zero, the pressure drop also becomes zero These conditions are guaranteed by the term (7)2011年12月17日 If the acceleration pressure required lowers the inlet pressure below the vapor pressure of the liquid, then vaporization and subsequent cavitation can occur NPSHA calculations must be made, including acceleration loss, because inlet systems have positive pressure under steady state conditions that can go negative at the start of the pump's inlet strokeSolving Pump Inlet Problems Pumps SystemsThe differential pressure between the inlet and outlet of the mill (ΔP mill) is an important process variable for the testing of grinding aidsΔP mill reflects the load and the filling level of the mill At unchanged separator settings, the increase of ΔP mill indicates more internal circulations and more fines As a result of the higher ΔP mill, the mill vibration increases (810mm/s Progress with Grinding Aids for Vertical Roller Mills Sika2021年6月10日 sure, the negative inlet pressure, the different inletoutlet pressure, a nd the outlet pressure of the fine and coarse separators are just some of those influential variables [6 – 10 ] HowVentilation Prediction for an Industrial Cement Raw Ball Mill by

Calcium Carbonate Ultrafine Vertical Mill SBM Ultrafine

(1) The whole system of CLUM ultrafine vertical mill has low vibration and low noise (2) The system is sealed as a whole, runs under full negative pressure, no dust spills, and basically a dustfree workshop can be realized2023年6月10日 25Apr23 12 General Process gas flow Mill outlet temperature Mill differential pressure Mill inlet pressure Mill vibrations Metal detection seperation Power consumption – Mill motor External material recirculation ie Reject system Mill feed starvation Mill Hydraulic malfunction Mill drive alarms Product Quality (Fineness) Table of contents𝐕𝐑𝐌 One distinct feature of vertical roller mills is their control mechanism based on negative pressure By maintaining negative pressure inside the mill through proper airflow management, these machines ensure that no particles escape vertical roller mills and how they are controlled by 2023年7月4日 The basic structure of the roller mill includes the grinding roller, the grinding body, the force generation and transmission mechanism, airflow, and the device for easy replacement It can be divided into vertical roller mill, horizontal cylinder roller mill, high pressure roller mill, Raymond mill, and column millRoller Mill SpringerLink

.jpg)

Limestone Powder Ultrafine Vertical Roller Mill

Limestone Powder Ultrafine Vertical Roller Mill Modle : CLUM Series Finished Size: 4003000 mesh Processing Ability: 3 – 45t/h Max Feeding Size: 10 mm M 1 Set Price: $ Range Of Application: Limestone, 2021年1月1日 Vertical Roller Mills (VRM), High Pressure Grinding Rolls (HPGR), Vertical Shaft Impact Crushers (VSI) and more recently, Horizontal Roller Mill (Horomill) have saved the specific power by 45–70% when compared with a ball mill circuit [8], [10]Review on vertical roller mill in cement industry its Vertical Mill PDF Free download as PDF File (pdf), Text File (txt) or read online for free The document provides instructions for preparing and starting a Loesche mill Key steps include: 1) Checking oil levels, filters, valves and equipment before start 2) Preheating the empty mill for 12 hours to prevent condensation, gradually increasing temperature while ensuring roller protectionVertical Mill PDF PDF Mill (Grinding) Scribd2024年12月2日 To check if the bypass valve should remain open, close it and observe the inlet negative pressure If it increases, reopen the bypass valve Negative Pressure Control: Maintain the negative pressure at the tail end of the dust collector within 500PaOptimizing Vertical Grinding Efficiency DARKO

Modeling of energy consumption factors for an industrial cement

2022年5月9日 The raw vertical roller mill has four rollers, 3000 KW main drive, 48 m table diameter, 216 m roller diameter with 330 t/h capacity (made by input pressure could commendably affect the process energy consumption since too low negative inlet pressure influences the steady gas flow within the system and disturbs the grinding 2024年1月1日 The column mill is a vertical mill using high speed, medium pressure, and continuous, repeated grinding It consists of the belt pulley, the gearbox, the main shaft, the feeding device, the discharging device, the spreading plate, the Roller Mill SpringerLink•Negative Pressure •Feeding Device to Mill •Air Locks after Filter / Cyclones Vertical Roller Mills Pressure Profile Draw Up Curve Influenced by: •Mill Inlet Pressure •Nozzle Ring Coverage •Classifier Speed •Dam Ring Height •Mill Load •Material Blockage in Hot GasOptimization of VRM Operation RUCEMRU