Fly ash equipment deep processing equipment

Fly Ash Processing Equipment FEECO International Inc

FEECO provides custom, highquality agglomeration and bulk material handling equipment for dedusting fly ash and turning it into a more 展开The fly ash processing plant produced by AGICO includes a ball mill grinding system, conveying system, dust collecting system, ash classifying system and ash storing system It helps our customers realize reasonable solid waste Fly Ash Processing Plant Cement Equipment Coal Fly Ash Recycling and encapsulating fly ash into concrete, grout, gypsum and other building and construction products provides many welldocumented benefits From improved workability and durability of concrete to a more cost Coal Fly Ash Carrier Process Equipment GroupFly Ash Processing Plant Equipment Equipment for a fly ash processing plant mainly includes raw material silos, a scale machine, a belt conveyor, a feeder, a grinding machine, a bag filter, a bucket elevator, and a dust collector Among Fly Ash Processing Plant Superfine Final Product

.jpg)

Ash Handling Systems Sumitomo Heavy Industries, Ltd

SPE offers optimized fly ash transport systems with a range of vacuum and pressuredriven transport options Fly ash is transported by air from electrostatic precipitator, air preheaters, and coal economizers to fly ash silos, where the As the energy industry moves from freshly generated ash to harvested ash, you need the best separation equipment to recover, harvest, and beneficiate fly ash to make it suitable for use in Fly Ash STETIn this article, we will discuss the fly ash processing flow, equipment used, and application values in detail Fly Ash Collection and Conditioning: The fly ash is first collected from the flue gas Fly ash processing process flow, fly ash equipment and application 2024年11月26日 UCC has nearly a century of experience and expertise in the design, engineering and installation of pneumatic fly ash handling systems The NUVEYOR® Dry Vacuum transfer System is the industry standard for efficient Fly Ash Handling Systems Vacuum Material Ash

Powerful, HeavyDuty Fly Ash Drag Conveyor, Handling

Our fly ash handling drag conveyor designs allow horizontal, vertical, and combination styles for highcapacity ash conveying arrangements—and we can achieve 70 degrees of incline with highly efficient and dependable conveyingFly Ash Processing Equipment feeco Equipment FEECO has been processing fly ash for over 65 years, providing custom, highquality agglomeration and material handling equipment for dedusting fly ash, and turning it into a more marketable productfly ash handling equipmentFly ash grinding mill, also called fly ash Raymond mill, is a device for grinding, processing and reusing fly ash This equipment has good grinding products, stable work, and reliable operation It is mainly responsible for the preparation Fly Ash Production ProcessFly Ash Processing Fly ash or flue ash, also known as pulverised fuel ash in the United Kingdom, is a coal combustion product that is composed of the particulates (fine particles of burned fuel) that are driven out of coalfired boilers together with the flue gasesAsh that falls to the bottom of the boiler's combustion chamber (commonly called a firebox) is called bottom ashfly ash handling equipment

.jpg)

Fly Ash Processing Plant Ball Mill, Raymond Mill, EPC Project

AGICO CEMENT provides the ingrate solution for fly ash processing, including fly ash equipment and fly ash processing technology Fly ash processing plants turn fly ash into useful products and make a profit for you Are you interested in it? Skip to content +86 s about blog contact EN ES RU MenuFly ash processing equipment plays a critical role in making this possible Fly ash is a fine, powdery material that is carried out of coalfired power plants with flue gases It is a complex mixture of inorganic and organic materials that can be used in a variety of applications, The Benefits of Utilizing Fly Ash Processing EquipmentThe finished mesh of Raymond mill is adjusted between 80325 mesh, output 125t/h, can grind fly ash with Mohs hardness not greater than 93 and humidity below 6%, if the raw material humidity is too high , Small output can be dried naturally, and large output needs to What equipment is needed to build a fly ash processing plant?Перевод контекст "fly ash processing" c английский на китайский от Reverso Context: Discussion on desulfurization, acid, fly ash processing and dioxins control processing technology of urban garbage power plantfly ash processing Перевод на китайский

.jpg)

Fly Ash Processing System Manufacturer from Ahmedabad

Manufacturer of Fly Ash Processing System offered by Aesha Conveyors And Crushing Equipment, Ahmedabad, Gujarat Aesha Conveyors And Crushing Equipment Odhav, Ahmedabad, Gujarat GST No 24AKQPP5648D1ZV TrustSEAL Verified Call 58% Response Rate SEND vertical milling machine grinding ash process, which improves the grinding efficiency, to meet the requirements of the project fly ash handling equipment Ash grinding in the country started relatively late [3], which is still relatively superficialCurrently,coal ash tube mill grinding equipment is used by the transition from the cementGrinding Fly Ash Process and Equipment with Vertical Milling Now, due to the needs of market development, we need to add a highquality fly ash deep processing production line again After multiple understanding, and purchased the complete set of fly ash deep processing production line equipment of our company +86 16638017614 100,000 Tons Fly Ash Deep Processing Project2023年8月16日 Fly Ash Processing Equipment and Solutions The Atritor Dryer Pulveriser offers simultaneous drying, deagglomeration, and classification in a single stage It can produce a product feed rate of up to 20 tonnes per hour Fly ash processing: Tailored solutions for reclaimed fly

.jpg)

What To Consider When Conveying Fly Ash •

What To Consider When Conveying Fly Ash Ash handling in pneumatic conveying can create problems such as wear, dust industry updates, and realworld success stories in powder and bulk solids processing equipment Dive Sly offers a complete line of dust collection equipment to keep biomass processing operations clean from potentially combustible, hazardous dust and remove or recycle it into production Call Sly to design, fabricate, and install a dust collection What Equipment is Used for Biomass Processing? SLY, LLC使用Reverso Context: Discussion on desulfurization, acid, fly ash processing and dioxins control processing technology of urban garbage power plant,在英语中文情境中翻译"fly ash processing"fly ash processing翻译为中文例句英语 Reverso ContextWet unloading equipment for the fly ash Pneuplan has comprehensive solutions for the material processing of the fly ash from power plants Wet unloading devices for ash silos are part of Pneuplan’s competencies Wet unloading procedures Unloading fly ash from silos many carried out using either wet or dry unloading proceduresWet unloading equipment for the fly ash Pneuplan Oy

.jpg)

How to Process Fly Ash and What Is It Used for? Fote Machinery

2023年5月27日 Fly ash processing technology has transformed fly ash from waste into a popular construction material It can be used in cement, concrete, lightweight aggregate, grouting, siding, and soil stabilization To achieve the abovementioned uses, fly ash needs to go through processing processes such as drying, separation, grinding, granulation, etcFly ash is the main solid waste discharged from coalfired power plants Fly ash can be used as cement mixture after being processed by grinding equipment to improve the performance of concrete With the development of industry, fly ash is used in more fields, and the fly ash vertical mill has gradually attracted people's attentionVertical Mill For Fly Ash ProcessingGrinding Mill,Grinding Equipment Now, due to the needs of market development, we need to add a highquality fly ash deep processing production line again After multiple understanding, and purchased the complete set of fly ash deep processing production line equipment of our company +86 16638017614 100,000 Tons Fly Ash Deep Processing ProjectPneuplan has comprehensive solutions for the material processing of the fly ash from power plants Dry unloading devices for ash silos are part of Pneuplan’s competencies Silos maybe unloaded dry using loading bellows for loading into a tank vehicle or using an ash vaporiser for loading on an open vehicle platformDry unloading equipment for the fly ash Pneuplan O

Minerals processing equipment Metso Corporation PDF

Consult Metso Corporation's entire Minerals processing equipment catalogue on DirectIndustry Page: 1/24 Exhibit with us {{>currencyLabel}} Back (Deep Vane) Mechanism impeller consists of a unique arrangement of vertical vanes with shaped lower edges Metso Centrifugal Air Classifier for Fly Ash Processing 2 Pages Air Classifier This pneumatic conveying system is designed specifically for conveying hot abrasive ash, such as bottom ash (or fly ash) from boiler beds, baghouses, or electrostatic precipitators These systems can handle temperatures up to Pneumatic Conveying System for Transfer of Ash fly ash processing equipment from china fly ash machinery and equipment production fly ash processing equipment production There are forty years of manufacturing history, with three major production bases,over 160 senior RD engineers and 600 large and mediumsized digital processing equipment, The firstline technicians and professional aftersales service personnel fly ash processing equipment from China2020年7月3日 The ST Equipment Technology electrostatic separation process can treat raw fly ash by removing the unwanted residual coal char The resulting product is a mineralrich concrete grade, trademarked ProAsh® The Benefits of Fly Ash in ReadyMix Concrete STET

.jpg)

Fly Ash Pollutants, Treatment and Recycling SpringerLink

2013年1月1日 Fly ash can be classified into several categories: coal fly ash obtained from power plant burning coal; flue gas desulphurisation fly ash, that is the byproduct generated by the air pollution control equipment in coalfired power plants to prevent (reduce) the release of SO 2; biomass fly ash produced in the thermal conversion of biomass; and municipal solid waste 2020年5月1日 ASTM International ASTM E126620 Standard Practice for Processing Mixtures of Lime, Fly Ash, and Heavy Metal Wastes in Structural Fills and Other Construction ApplicationsASTM International ASTM E126620 Standard Practice for Processing 2024年6月18日 Elevate your recycling operations with cuttingedge industrial systems, equipment, components, and accessories Explore our categories for the latest innovations in recyclable material processing Upgrade sustainability todayThe FAW (Acid Fly Ash Washing) Process RecyclingInsideFly Ash Processing Process There are different equipment configurations and processes for grinding fly ash On the market, ultra fine ball mill grinding, Raymond mill grinding, and vertical roller mill grinding all exist SINOMA prioritizes production efficiency and the quality of finished fineness and has developed the TRM series VRM for fly ash grinding and the TRMF series for Fly Ash Processing Plant Superfine Final Product CNBMSINOMA

.jpg)

Operations: Operated Own Processing and Packing JAYCEE

Our investments demonstrate our deep focus and commitment to gainful utilisation of coal combustion products Fly Ash Processing and Packing Plant at Sembcorp Energy India Limited (Owned and Operated by JAYCEE) 0 km from thermal power plant Ensure all testing equipment is regularly serviced and calibrated and that detailed tests are One important, but often overlooked factor of an efficient ash handling system, is its compatibility with your facility With options varying from fly ash to bottom ash conveyors, and pneumatic versus mechanical ash handling systems, our experts are ready to help evaluate which application is best for your plantCustomdesigned, Efficient Ash Handling Equipment2023年12月13日 Fly ash can be turned into more than just an industrial byproduct With economically effective and environmentally sound strategies for processing, like those provided by Economy Ball Mill and our stateoftheart ball mills, fly ash can become a valuable commodity in the industrial and construction marketplaceUsing Ball Mills for Fly Ash Processing Economy Ball MillFly Ash Processing Equipment feeco Equipment FEECO has been processing fly ash for over 65 years, providing custom, highquality agglomeration and material handling equipment for dedusting fly ash, and turning it into a more marketable productfly ash handling equipment

.jpg)

Fly Ash Production ProcessFly Ash Processing

Fly ash grinding mill, also called fly ash Raymond mill, is a device for grinding, processing and reusing fly ash This equipment has good grinding products, stable work, and reliable operation It is mainly responsible for the preparation Fly ash or flue ash, also known as pulverised fuel ash in the United Kingdom, is a coal combustion product that is composed of the particulates (fine particles of burned fuel) that are driven out of coalfired boilers together with the flue gasesAsh that falls to the bottom of the boiler's combustion chamber (commonly called a firebox) is called bottom ashfly ash handling equipmentAGICO CEMENT provides the ingrate solution for fly ash processing, including fly ash equipment and fly ash processing technology Fly ash processing plants turn fly ash into useful products and make a profit for you Are you interested in it? Skip to content +86 s about blog contact EN ES RU MenuFly Ash Processing Plant Ball Mill, Raymond Mill, EPC ProjectFly ash processing equipment plays a critical role in making this possible Fly ash is a fine, powdery material that is carried out of coalfired power plants with flue gases It is a complex mixture of inorganic and organic materials that can be used in a variety of applications, The Benefits of Utilizing Fly Ash Processing Equipment

What equipment is needed to build a fly ash processing plant?

The finished mesh of Raymond mill is adjusted between 80325 mesh, output 125t/h, can grind fly ash with Mohs hardness not greater than 93 and humidity below 6%, if the raw material humidity is too high , Small output can be dried naturally, and large output needs to Перевод контекст "fly ash processing" c английский на китайский от Reverso Context: Discussion on desulfurization, acid, fly ash processing and dioxins control processing technology of urban garbage power plantfly ash processing Перевод на китайский Manufacturer of Fly Ash Processing System offered by Aesha Conveyors And Crushing Equipment, Ahmedabad, Gujarat Aesha Conveyors And Crushing Equipment Odhav, Ahmedabad, Gujarat GST No 24AKQPP5648D1ZV TrustSEAL Verified Call 58% Response Rate SEND Fly Ash Processing System Manufacturer from Ahmedabadvertical milling machine grinding ash process, which improves the grinding efficiency, to meet the requirements of the project fly ash handling equipment Ash grinding in the country started relatively late [3], which is still relatively superficialCurrently,coal ash tube mill grinding equipment is used by the transition from the cementGrinding Fly Ash Process and Equipment with Vertical Milling

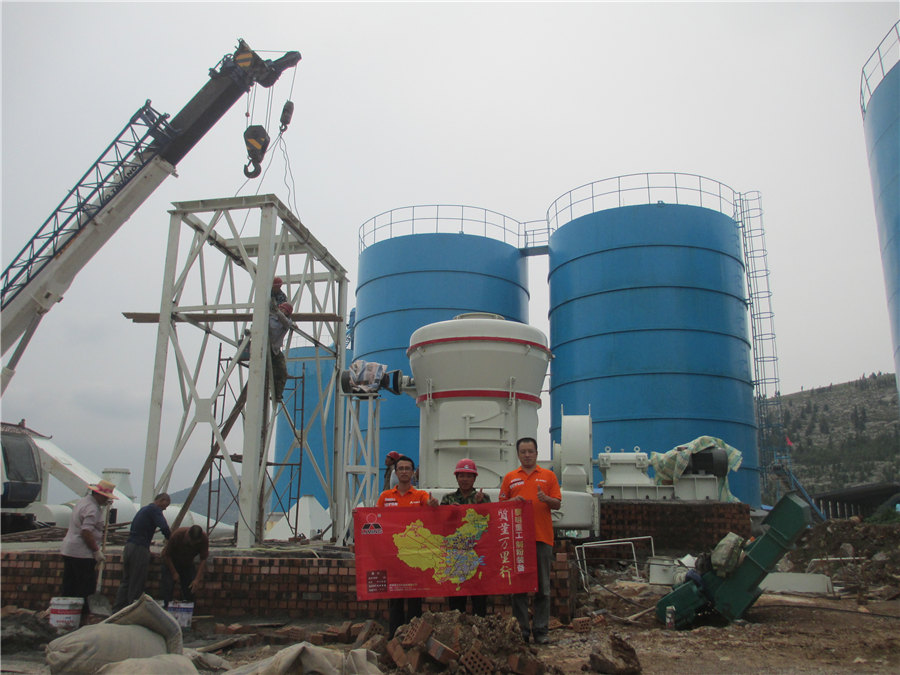

100,000 Tons Fly Ash Deep Processing Project

Now, due to the needs of market development, we need to add a highquality fly ash deep processing production line again After multiple understanding, and purchased the complete set of fly ash deep processing production line equipment of our company +86 16638017614