The highefficiency bentonite mill that everyone uses now

.jpg)

Types of Grinding Mills for Bentonite Processing Plant

Raymond Mill is a commonly used grinding mill for bentonite powder production It has a small footprint, low investment cost, and high efficiency The finished product size can be adjusted between 80400 mesh Ultrafine Vertical Mill is a highperformance grinding mill that can The method improves the quality and decolorization power of the highefficiency activated clay by increasing the activation temperature and pressure of the material and washing the slurry with Bentonite Grinding Mill CM Mining Machinery2024年4月22日 The bentonite grinding machine is a mechanical equipment specifically designed for processing bentonite Due to its wide range of uses, high production efficiency, low energy Bentonite Processing Plant And Grinding Machine2015年6月5日 The document summarizes a bentonite processing machine manufactured by Clirik It describes 5 models that can process 0512 tons per hour of bentonite into powders between 1502500 mesh Key features include Bentonite processing machine PDF SlideShare

.jpg)

High Performance Activated Lime Bentonite Raymond Mill

Raymond mill can be used for highfine powder processing of more than 500 kinds of materials in nonflammable and explosive mineral, chemical, construction and other industries with a Mohs Recently, a 200mesh bentonite Raymond mill production line with an annual output of 65,000 tons built by Clirik has entered the production stage According to customer feedback, the Engineering case: Case appreciation of Raymond mill with an Common mills include ball mills or roller mills, especially vertical mills, which are widely used in bentonite grinding due to their high efficiency and automation In the mill, the bentonite Bentonite Grinding Production Line Baichy Heavy IndustryThe 20ton per hour bentonite grinding production line stands as a model of efficiency and innovation in the mineral processing sector Its ability to process bentonite ore into highquality The 20ton per hour bentonite grinding production line

.jpg)

NEWS Raymond Mill

2020年8月10日 For nonmetallic minerals such as bentonite, kaolin, dolomite, marble, limestone, barite, etc, what equipment can achieve highefficiency grinding and processing, and help to grind 80400 mesh powder?Roller mills offer enhanced grinding performance for bentonite due to their ability to apply high pressure uniformly across the material bed This results in efficient particletoparticle Optimizing Bentonite Grinding Efficiency with Roller Mills: A Bentonite grinding mill bentonite crusher is a professional mechanical equipment for grinding ultrafine bentonite powder High Efficiency Albite Grinding Mill Manufactur Milestone Event Now, through continuous development, the bentonite industry has developed vigorously, with many types of products and wide application fieldsWhat Is The Working Principle Of Bentonite Crusher? Professional 2015年6月5日 2 hammer crusher, bucket elevator, storage hopper, vibrating feeder, main unit, inverter classifier, cyclone collector, pulse deduster system, high pressure positive blower, air compressors and electrical control systems Bentonite raymond roller mill PDF SlideShare

Types of Grinding Mills for Bentonite Processing Plant

Raymond Mill is a commonly used grinding mill for bentonite powder production It has a small footprint, low investment cost, and high efficiency The finished product size can be adjusted between 80400 mesh Ultrafine Vertical Mill Chat Now Sale Phone (24/7): +8621 2021年12月30日 In this study, a pintype vertical stirred media mill was used to perform the dry grinding of bentonite Grinding time and stirring speed were investigated for effect on the particle size Dry Grinding of Bentonite by Stirred Media Mill ResearchGate2015年6月5日 The document summarizes a bentonite processing machine manufactured by Clirik It describes 5 models that can process 0512 tons per hour of bentonite into powders between 1502500 mesh Key features include high efficiency, long lifecycles for spare parts, safety and flexibility in adjusting the fineness of powders producedBentonite processing machine PDF SlideShareBall mill grinding body Steel ball Steel ball is a kind of grinding body commonly used in ball mills Ball mill manufacturers often choose steel balls of various specifications with a diameter of 20120mm according to the grinding process requirements of the material; for the coarse grinding chamber of the ball mill, various steel balls with a diameter of 50100mm are generally High Efficiency Mining Ball Mill Production Line Baichy

(PDF) Modification Method of HighEfficiency Organic Bentonite

2023年11月30日 Modification Method of HighEfficiency Organic Bentonite for Drilling Fluids: A ReviewBentonite grinding equipment usually uses ultrafine powder mill or MTW European version trapezoidal mill Investment prospects It is predicted that the amount of bentonite ore resources in my country has exceeded 8 billion tons, which has laid a resource foundation for the development and research of new products, market development, and competitiveness improvementBentonite Grinding Mill CM Mining Machinery2023年11月2日 A highefficiency (HE) washer must use less (than a traditional washer) water, energy, and detergent to be called a HE washer If it falls short of the set guidelines, it cannot sport the HE symbol While not all highefficiency washers are front loaders, they do have some visible signs: The HE symbol proudly displayed and a missing agitatorHighEfficiency vs Regular Washers: What to Know The SpruceAs a mill for bentonite, HC1700 innovative raymond mill with the fully automated system and the workers only need to operate in the central control room Toggle navigation Home; ⑤ At the same time, it can be used as sodium soil for drilling mud due to its excellent dispersibility and expansion, high pulping rate, uses of bentonitebentonite grinding millbentonite raymond mill

.jpg)

Bentonite Properties, Formation, Uses » Geology

2023年5月2日 Bentonite is a type of clay that is composed primarily of the mineral montmorillonite It is a highly absorbent clay that has many uses in various industries, including cosmetics, pharmaceuticals, and construction 2020年3月12日 Bentonite is a mineral ore which has many properties, it is mainly used as a binder, catalyst, thixotropic agent, decolorizer, adsorbent, thickener, and widely applied in metallurgical pellets Superfine Vertical Mill for Bentonite ProductionBentonite Grinding Machine Free download as Word Doc (doc / docx), PDF File (pdf), Text File (txt) or read online for free This document discusses bentonite grinding machines It provides information on bentonite properties and its uses in agriculture, light industry, cosmetics and pharmaceuticals It then discusses that SBM supplies complete bentonite grinding plants and Bentonite Grinding Machine Descargar gratis PDF Mill ScribdFind the right mine mill from Alibaba Explore our mining equipment to find the ideal wholesale bentonite grinding mill model and mills for any mining challengeBentonite grinding mill

Efficiency of bentonite in removing cesium, strontium, cobalt and

2020年5月13日 The results revealed that bentonite and bentonitealginate demonstrated high adsorption capacity at the same pH 55 The breakthrough curve had Sshaped profileHefei Hengcheng Industrial Equipment Technology Co, Ltd hcverticalrollermill@outlook 86 HomeVertical Roller Mills Bentonite Grinding Mill With High Energy Efficiency2019年11月8日 Calcium Bentonite is nonswelling mineral, which is not as commonly used in beauty and wellness applications What is Bentonite Clay Used for? There are many uses for bentonite clay in the beauty and wellness arena, as this product is highly versatile and can be used on the skin, in baths and even internally Some common uses are:What is Bentonite Clay, and How to Use it to Cleanse and Purify 2016年9月1日 R ole of Bentonite in Improving the Efficiency of Cement Grouting in Coarse San d T G Santhoshkumar 1 , B M Abraham 2 , A Sridharan 3 , and B T Jose 4 1 Principal, JBCMET, JB Campus, Kochi Role of bentonite in improving the efficiency of cement grouting

Bentonite Formula, Properties Application

It was named after Fort Benton in Wyoming, where the largest source of the clay was first identified Bentonite possesses some unique properties that make it incredibly useful in many industries and applications, from construction to cosmetics Types of Bentonite There are two primary types of bentonite clay: Sodium bentonite and Calcium 2013年3月1日 This is referred to as the classifier cut size Generally, the plant operator can control the classifier cut size, and thus the comminuted product fineness by adjusting the classifier rotor speed Cements ground in the vertical roller mill fulfil the quality 2023年3月15日 The highest removal efficiency of As(V) ions expressed in % was 7511 at the initial concentration of 15 mg/L and was recorded using HCl acidactivated Cabentonite The efficiency of Hg(II) ion Efficiency of Multistep Process of Fenton Oxidation 2021年3月23日 New ball mill drive system with the prototype energysaving SMH motor [37] Energy Efficiency Analysis of Copper Ore Ball Mill Drive Systems

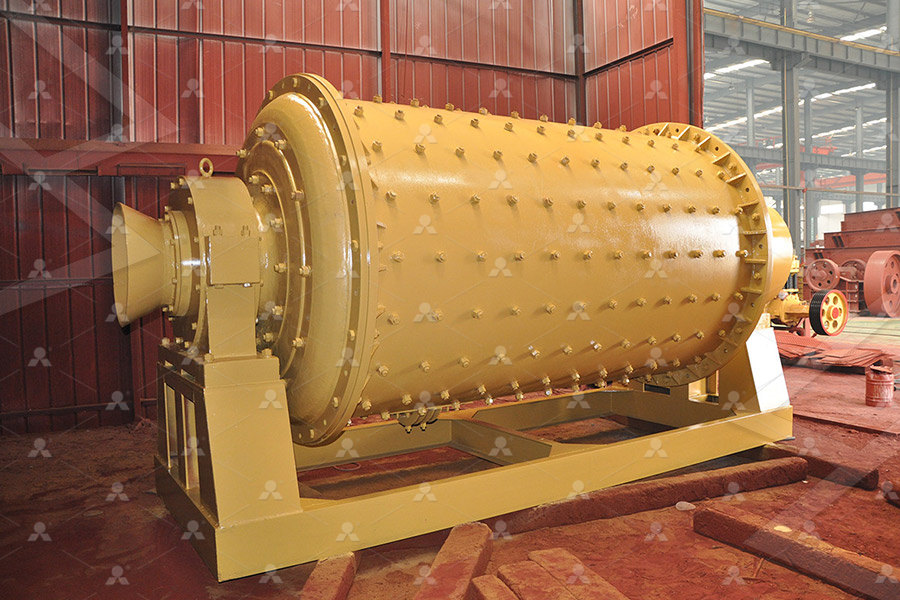

High Efficient Bentonite Grinding Ball Mill Dry Grinding Ball Mill

High Efficient Bentonite Grinding Ball Mill Dry Grinding Ball Mill, You can get more details about High Efficient Bentonite Grinding Ball Mill Dry Grinding Ball Mill from mobile site on Alibaba All categories Featured selections Trade Assurance Buyer Central Help Center One crucial element that significantly enhances piling efficiency is Bentonite This versatile material offers numerous benefits throughout the piling process In this article, we will explore five ways Bentonite enhances piling efficiency and how you can leverage it for successful construction projects Bentonite Piling Efficiency 1Five Ways Bentonite Enhances Piling Efficiency Sepico2015年1月1日 Bentonite are usually found in deep geographical areas They are produced from rock, fossils, weathering of volcanic ash and disposal of highlevel of radioactive waste in many countriesBentonite: Characteristics, uses and implications for2024年1月30日 To ensure the safety and stability of the beach surface of the decommissioned uranium mill tailings pond, this paper uses red claybentonite and red clay (1:1) to carry out covering layer radon reduction simulation experiments to study the temperature, humidity, and radon reduction effect of the covering layer under natural conditionsTemperaturehumidity evolution and radon exhalation mechanism

.jpg)

Competitive Advantages Of Raymond Mill For Grinding 300 Mesh Bentonite

The newly upgraded 300 mesh environmentfriendly Raymond mill has outstanding competitive advantages, high powder yield, stable performance and high cost performance You are welcome to negotiate with HCM factory at any time, and come to the factory to investigate the bentonite grinding mill production line cases and equipment details2006年1月1日 Calcium bentonite is used because of its high absorbent quality The calcium bentonite is dried, crushed, and sized into a granular product for use as a litter box filler In recent years, a new litter called clumping cat litter has become the preferred type of litter This litter is made by blending high swelling sodium bentonite with the Chapter 6 Bentonite Applications ScienceDirectHefei Hengcheng Industrial Equipment Technology Co, Ltd hcverticalrollermill@outlook 86 HomeVertical Roller Mills Bentonite Grinding Mill With High Energy Efficiency2021年11月3日 1) Powdered bentonite organoclay Powdered bentonite organoclay has been assessed in several studies to determine its efficiency in oil removal These studies were based on the Freundlich’s model, which is premised on dispersing powdered bentonite organoclay on the surface of oilbased wastewater to observe its oil adsorption tendenciesThe Efficiency of (Bentonite) Organoclays in Removing Oils from

What Is The Working Principle Of Bentonite Crusher? Professional

Bentonite grinding mill bentonite crusher is a professional mechanical equipment for grinding ultrafine bentonite powder High Efficiency Albite Grinding Mill Manufactur Milestone Event Now, through continuous development, the bentonite industry has developed vigorously, with many types of products and wide application fields2015年6月5日 2 hammer crusher, bucket elevator, storage hopper, vibrating feeder, main unit, inverter classifier, cyclone collector, pulse deduster system, high pressure positive blower, air compressors and electrical control systems Bentonite raymond roller mill PDF SlideShareRaymond Mill is a commonly used grinding mill for bentonite powder production It has a small footprint, low investment cost, and high efficiency The finished product size can be adjusted between 80400 mesh Ultrafine Vertical Mill Chat Now Sale Phone (24/7): +8621 Types of Grinding Mills for Bentonite Processing Plant2021年12月30日 In this study, a pintype vertical stirred media mill was used to perform the dry grinding of bentonite Grinding time and stirring speed were investigated for effect on the particle size Dry Grinding of Bentonite by Stirred Media Mill ResearchGate

.jpg)

Bentonite processing machine PDF SlideShare

2015年6月5日 The document summarizes a bentonite processing machine manufactured by Clirik It describes 5 models that can process 0512 tons per hour of bentonite into powders between 1502500 mesh Key features include high efficiency, long lifecycles for spare parts, safety and flexibility in adjusting the fineness of powders producedBall mill grinding body Steel ball Steel ball is a kind of grinding body commonly used in ball mills Ball mill manufacturers often choose steel balls of various specifications with a diameter of 20120mm according to the grinding process requirements of the material; for the coarse grinding chamber of the ball mill, various steel balls with a diameter of 50100mm are generally High Efficiency Mining Ball Mill Production Line Baichy 2023年11月30日 Modification Method of HighEfficiency Organic Bentonite for Drilling Fluids: A Review(PDF) Modification Method of HighEfficiency Organic Bentonite Bentonite grinding equipment usually uses ultrafine powder mill or MTW European version trapezoidal mill Investment prospects It is predicted that the amount of bentonite ore resources in my country has exceeded 8 billion tons, which has laid a resource foundation for the development and research of new products, market development, and competitiveness improvementBentonite Grinding Mill CM Mining Machinery

HighEfficiency vs Regular Washers: What to Know The Spruce

2023年11月2日 A highefficiency (HE) washer must use less (than a traditional washer) water, energy, and detergent to be called a HE washer If it falls short of the set guidelines, it cannot sport the HE symbol While not all highefficiency washers are front loaders, they do have some visible signs: The HE symbol proudly displayed and a missing agitatorAs a mill for bentonite, HC1700 innovative raymond mill with the fully automated system and the workers only need to operate in the central control room Toggle navigation Home; ⑤ At the same time, it can be used as sodium soil for drilling mud due to its excellent dispersibility and expansion, high pulping rate, uses of bentonitebentonite grinding millbentonite raymond mill