HOME→Chromium powder processing technology Chromium powder processing technology Chromium powder processing technology

Chromium powder processing technology Chromium powder processing technology Chromium powder processing technology

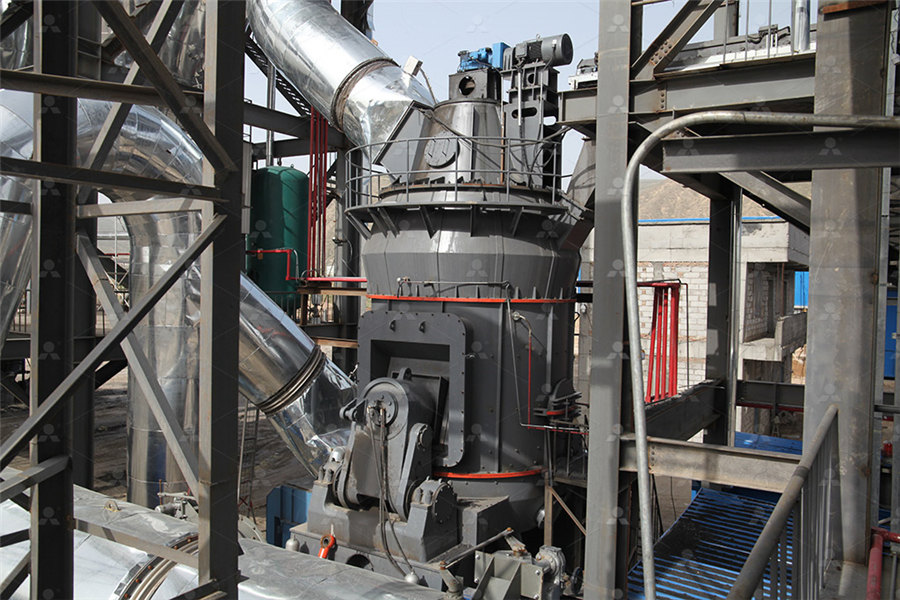

Chromium Metal Powder Processing Equipments JM

2024年2月26日 Chromium metal powder production involves a series of welldefined steps, each crucial for obtaining a highquality, finely powdered form of this versatile metal Here, we’ll explore the key processing stages involved in Exotech produces highpurity Chromium (Cr) powder to meet your specific needs Our Chromium powder production has a capacity of 20,000 kg per month We offer metal purities ranging Chromium Powder Processing Exotech, Pompano Beach, FLExotech is a primary manufacturer of Chromium powder This is accomplished using Chromium in ‘flake’ form, pure Chromium ‘eggs’ or used Chromium sputter targets The ultimate application Manufacturing High Purity Chromium Powder at ExotechCNPC POWDER Chromium powder used pulverizing process with high purity chromium ingots It has gray color and irregular shape, In moist air it has easy oxidation The purity of chromium Chromium Powder Electrolytic Chromium Powder Metal Powder

Blog Manufacturing Chromium Powder for Sputter

Exotech’s Chromium Powder ranges in purity from 997% to as high as 9998% if required We can control critical elements such as Al, Si, Fe, O2 and many others to meet specifications Our Chromium nugget products come in sizes such as 2019年8月23日 Chromium processing description from its geology mineral property to how to extract mineral from rock and placer deposit, related processing plant flow chart and layout designChromium Processing Process Flow, Cases JXSC chromium processing, preparation of the ore for use in various products Chromium (Cr) is a brilliant, hard, refractory metal that melts at 1,857 °C (3,375 °F) and boils at 2,672 °C (4,842 °F) In the pure state it is resistant to ordinary Chromium processing Extraction, Uses Applications We provide regular chromium metal powder with purity 99% and electrolytic chromium powder with purity 999% Chromium powder is with gray color and irregular shape, it will be easily oxidized in moist airChromium Powder – Powders Division – Edgetech

Technology on spheroidization chromium powders with

2017年6月15日 In order to improve the powders' liquidity and explore the preparation processing of spherical powder, irregular shaped chromium powders were prepared for spherical powders 2018年8月20日 Nontraditional metallurgical technology of comprehensive processing of Sevan chromite (with a 43–46% Cr 2 O 3 content) is developed allowing chromium extraction from Preparation of Superconcentrate and Chromium Powder from 2023年7月7日 Keywords: chrome tanning, greener technology, leather processing 1 Introduction Tanning is the process of con verting the raw skin and hides from different animals into a(PDF) Benefits and problems of chrome tanning in Chromium CarbideNickel Chromium Powder is a composite powder composed of chromium carbide and nickelchromium alloy, mainly used for thermal spray process to prepare coatings with wear and corrosion resistanceChromium CarbideNickel Chromium Spherical

.jpg)

Read "HighPurity Chromium Metal: Supply Issues for

The committee considers it possible that a process based on induction plasma technology could use a chromium powder to produce satisfactory electrodes for remelt processing Induction plasma methods, as opposed to arc plasma 2021年10月4日 Benefits and problems of chrome tanning in leather processing: Approach a greener technology in leather industrypdf Available via license: CC BYNC 40 Content may be subject to copyright(PDF) Benefits and problems of chrome tanning in leather processing 2013年1月15日 Compression and oil scraper rings 10D100 of the diesel engine before (A) and after (B) coating with PCCC; PCCC of the compression (C) and oil scraper (D) rings for diesel engines 10D100 piston ringsInnovative Processing Technology of Chromium Carbide Coating The chromium atom has a radius of 128 pm and a Van der Waals radius of 189 pm In its elemental form, chromium has a lustrous steelgray appearance Chromium is the hardest metallic element in the periodic table and the only element that exhibits antiferromagnetic ordering at room temperature, above which it transforms into a paramagnetic solidChromium Powder American Elements

USA Method for producing chromiumchromium carbide powder

USA USA USA USA US A US A US A US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords chromium powder carbon carbide coatings Prior art date Legal status Chromium (atomic symbol: Cr, atomic number: 24) is a Block D, Group 6, Period 4 element with an atomic weight of 519961 The number of electrons in each of Chromium's shells is 2, 8, 13, 1 and its electron configuration is [Ar] 3d 5 4s 1 Louis Nicolas Vauquelin first discovered chromium in 1797 and first isolated it the following yearCobalt Chromium Powder American ElementsLearn about Powder Processing and Technology, a leader in ceramic and inorganic powder processing Contact us at (219) 4624141 (219) 4624141 Partnering with PPT Home; News; Careers; Contact; About Equipment List; Case Studies; Submit an Inquiry Home; Custom Processing Services Rotary Calcining; Spray Drying;About Powder Processing and Technology2010年1月1日 This article reviews the available literature published to date on the development of FeNi soft magnetic materials The nickel content varies from 2% to 90% and the properties change with (PDF) Effect of Chromium on the Mechanical Properties of Powder

Treatment of chromiumcontaining sludge using sintering and

2024年5月1日 A coprocessing strategy for chromiumcontaining sludge (CCS) was proposed • Chromium speciation in real CCS under sintering atmosphere was clarified • Impacts on the environment and sintered products were evaluated • Mass balance analysis revealed that 89% of Cr in the CCS entered the molten iron •Radiofrequency plasma spheroidized chromium powder has the characteristics of high sphericity, powder metallurgy, surface engineering and other fields The company adheres to the RF plasma spheroidization metal powder technology as the guidance, Guangdong Province Institute of Materials and Processing, china Chromium manufacturer,Spherical Pure Cr Powder supplier2019年10月10日 This article studied the impacts of using different powders on the productivity of electro discharge machining (EDM) of Nimonic 8OA alloy The powders used for experiments are chromium (Cr) and Effect of aluminium and chromium powder mixed dielectric fluid 2024年1月15日 When processing powder metallurgy (PM) Consolidation of wateratomized chromium–nickelalloyed powder metallurgy steel through novel processing routes Anok Babu Nagaram [ protected], Chalmers University of Consolidation of wateratomized chromium–nickelalloyed powder

6K Additive Expands Product Portfolio with Angular Chromium

2024年9月10日 Highest purity chromium powder available in the industry opens new applications and markets North Andover, MA, September 10, 2024 – Accelerating its market leadership in sustainable production of advanced materials for additive manufacturing (AM), 6K Additive – a division of 6K, announced the company has expanded its metal powder portfolio Chromium alloy classification There are mainly dispersion strengthened alloys and precipitation strengthened alloys (1) Dispersion strengthened alloy In the early 1960s, American DM Scruggs added magnesium oxide to chromium by powder metallurgy to form a dispersion strengthened alloy Chrome 30 (Cr05Ti6MgO)Processing Technology and Characteristics of Chromium AlloyDuring a powder metallurgy process such as sintering, the primary role played by the atmosphere in furnace is to prevent an excessive oxidation of powder compacts in case of the formation of oxides as residuals on powder surfaces In particular, the adjustment of furnace atmosphere is the key to eliminate the phenomenon “decarburization” likely to occur in carboncontaining Effect of furnace atmosphere on sintering process of chromium For over 40 years, Powder Processing Technology Custom powder processing, ceramic sintering, and materials technology solutions (219) 4624141 Partnering with PPTPowder Processing Ceramic Inorganic Powder Services

Chromium processing Alloying, Refining, Hardening Britannica

Chromium processing Alloying, Refining, Hardening: By far the greatest use of chromium is as a ferrochromium alloying agent in steel manufacture Pure chromium is added to nonferrous alloys and is also applied as a corrosionresistant surfacing for other metals Chromium surfaces are produced on other metals by electroplating and chromizing There are two types of 2024年1月15日 Download Citation Consolidation of wateratomized chromium–nickelalloyed powder metallurgy steel through novel processing routes When processing powder metallurgy (PM) steels, the Consolidation of wateratomized chromium–nickelalloyed powder 2021年10月27日 by conventional cast/wrought processing, but can also be manufactured using powder metallurgy (PM) processing Carpenter Technology conducted the study by manufacturing its version of Alloy 1, Biodur CCM, by conventional cast/wrought processing and comparing it to the same alloy created by powder metallurgy (PM) processingCAST/WROUGHT VS POWDER METALLURGY PROCESSING2019年8月23日 Chromium processing description from its geology mineral property to how to extract mineral from rock and placer deposit, the technology of purifying chromium ore with highintensity magnetic separation has been Chromium Processing Process Flow, Cases JXSC

(PDF) Comparative Study on the Compression Sintering

2023年7月1日 Using powder metallurgy process, the AlCu oil bearings were prepared and the effects of sintering temperature on crushing strength, oil content and microstructure were investigatedConclusion is that adding chromium powder improves to the highest material removal rate, but poor urface finishs while adding aluminium powder has the reverse effects Journal of Materials Processing Technology, Vol 68, No 1, 2732, doi: 101016/S09240136(96)02523XEffect of aluminium and chromium powder mixed dielectric fluid 2011年7月27日 There are several methods involve in processing route such as conventional powder processing (Borsa et al, 1999; much effort has been invested in advanced processing technology to reduce the size and density of processing flaws To prepare nanoscaled chromium carbide powder from the nanometersized Cr 2 O 3, Processing and Characterization of Alumina/ ChromiumIn summary, spherical chromium powder offers a range of advantages that make it a valuable material in various industries Its improved flowability, packing density, sintering characteristics, and uniform particle size distribution contribute to enhanced performance and reliability in applications such as coatings, composites, and additive manufacturingSpherical Chromium Powder: Unlocking the Benefits and Features

Laser Powder Bed Fusion of Chromium Bronze Using Recycled Powder

2021年6月30日 Laser powder bed fusion (LPBF) of Cu05Cr was carried out using recycled powder taken out from the LPBF machine after previous printing Various volumetric defects characterized the powder 2024年4月12日 Postprocessing: 3D printed CoCr parts may require additional postprocessing steps like heat treatment or surface finishing to achieve desired properties Safety: Handling CoCr powder requires proper safety precautions due to the Cobalt chromium 3D printed metal powder MET3DP2024年11月1日 Additionally, the powder flowability is represented by the statistical analysis of the measured avalanche angle and surface fractal (Fig 2 (c)), compared to the Ti–6Al–4V powder, the avalanche angle and surface fractal of pure Cr increased from 392° to 528° and 173 to 195, indicating a noticeable decrease in flowability but acceptable powder bed surface Effects of heat accumulation strategies on defects and Industries / Processing industry Our solutions within Processing industry 3D printed tooling Areas Powder technologies / Surface coating / Deposition techniques / Plasma transferred arc (PTA) Products / By technology / Hot isostatic pressing (HIP)Chromium Carbide (Cr3C2) Höganäs

.jpg)

(PDF) Benefits and problems of chrome tanning in

2023年7月7日 Keywords: chrome tanning, greener technology, leather processing 1 Introduction Tanning is the process of con verting the raw skin and hides from different animals into aChromium CarbideNickel Chromium Powder is a composite powder composed of chromium carbide and nickelchromium alloy, mainly used for thermal spray process to prepare coatings with wear and corrosion resistanceChromium CarbideNickel Chromium Spherical The committee considers it possible that a process based on induction plasma technology could use a chromium powder to produce satisfactory electrodes for remelt processing Induction plasma methods, as opposed to arc plasma Read "HighPurity Chromium Metal: Supply Issues for 2021年10月4日 Benefits and problems of chrome tanning in leather processing: Approach a greener technology in leather industrypdf Available via license: CC BYNC 40 Content may be subject to copyright(PDF) Benefits and problems of chrome tanning in leather processing

Innovative Processing Technology of Chromium Carbide Coating

2013年1月15日 Compression and oil scraper rings 10D100 of the diesel engine before (A) and after (B) coating with PCCC; PCCC of the compression (C) and oil scraper (D) rings for diesel engines 10D100 piston ringsThe chromium atom has a radius of 128 pm and a Van der Waals radius of 189 pm In its elemental form, chromium has a lustrous steelgray appearance Chromium is the hardest metallic element in the periodic table and the only element that exhibits antiferromagnetic ordering at room temperature, above which it transforms into a paramagnetic solidChromium Powder American ElementsUSA USA USA USA US A US A US A US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords chromium powder carbon carbide coatings Prior art date Legal status USA Method for producing chromiumchromium carbide powder Chromium (atomic symbol: Cr, atomic number: 24) is a Block D, Group 6, Period 4 element with an atomic weight of 519961 The number of electrons in each of Chromium's shells is 2, 8, 13, 1 and its electron configuration is [Ar] 3d 5 4s 1 Louis Nicolas Vauquelin first discovered chromium in 1797 and first isolated it the following yearCobalt Chromium Powder American Elements

.jpg)

About Powder Processing and Technology

Learn about Powder Processing and Technology, a leader in ceramic and inorganic powder processing Contact us at (219) 4624141 (219) 4624141 Partnering with PPT Home; News; Careers; Contact; About Equipment List; Case Studies; Submit an Inquiry Home; Custom Processing Services Rotary Calcining; Spray Drying;2010年1月1日 This article reviews the available literature published to date on the development of FeNi soft magnetic materials The nickel content varies from 2% to 90% and the properties change with (PDF) Effect of Chromium on the Mechanical Properties of Powder