The purpose of quicklime calcium carbonate grinding system test

.jpg)

QUICKLIME SPECIFICATION AND TEST METHODS RESEARCH

Quicklime/soil mixes were prepared and subsequently compacted into 4 x 6 cylinders and cured under moist conditions These cylinders were tested at intervals for compressive strength and unreacted lime content These tests showed no consistent difference in the stabilizing 11 These test methods cover the chemical analysis of highcalcium and dolomitic limestone, quicklime, and hydrated lime These test methods are classified as either standard Standard Test Methods for Chemical Analysis of Limestone, 2024年4月23日 11 These test methods cover the chemical analysis of highcalcium and dolomitic limestone, quicklime, and hydrated lime These test methods are classified as either Standard Test Methods for Chemical Analysis of Limestone, 2018年5月23日 Quicklime consists primarily of calcium oxide, descriptions and requirements are defined in EN 4591 (Citation 2010) It improves and solidifies most soil types, the subgrade of Soil improvement with quicklime – longtime behaviour and

Soil improvement with quicklime quantification of the

bankment Tests were conducted to verify the feasibility of a quicklimebased soil improvement It was shown, that ca 2 % (w/w) CaO was necessary to improve the Proctor compaction The quality of quicklime is affected by several factors related to the limestone feed and the calcination process These include the chemical composition and crystalline structure of the Factors Affecting The Quality of Quicklime PDF Sodium METHODS FOR TESTING LIME IN THE FIELD Introduction If simple, field methods are to be used, it is easier to test the quality of ‘lime’ when it is in the form of quicklime, ie calcium Methods for testing lime in the field Humanitarian Library2016年10月19日 The grinding aids were found to influence the product size and decrease the grinding energy This is attributed to the prevention of agglomeration and coating of the Optimization of Grinding Parameters of Quicklime CaO at

Sampling and Testing of Quicklime Wiley Online Library

1998年5月14日 This chapter contains sections titled: Introduction Precautions Sampling Sample Preparation Packing and Marking of Samples Physical Testing Chemical Analysis Absorption The purpose of both parts of this study was to determine the properties and benefits of the various quicklimes and to check the validity of the wet screen test requirementsQuicklime Specification and Test Methods Research 3J5年2月28日 The calcium carbonate looping cycle is an important reaction system for processes such as thermochemical energy storage and carbon capture technologies, which can be used to lower greenhouse gas The Effect of Calcination Temperature on The Quality of Quicklime not be accessible to everyone Therefore, the use of these test methods must be left to the discretion of each laboratory 14 The analytical procedures appear in the following order: Section Aluminum Oxide 15 Available Lime Index 28 Calcium and Magnesium Oxide: Alternative EDTA Titration Method 31 Calcium Carbonate Equivalent 33 Calcium Oxide Standard Test Methods for Chemical Analysis of Limestone, Quicklime

Methods for testing lime in the field Humanitarian Library

If simple, field methods are to be used, it is easier to test the quality of ‘lime’ when it is in the form of quicklime, ie calcium oxide CaO This would be the case if the lime were being bought direct from a kiln before the kiln operator had started to hydrate it Usually, though, as quicklime will deteriorate if left exposed to the air2018年11月12日 For instance, while precipitated calcium carbonate (PCC), shows diverse range of functionality in paper industry in both paper coating and as paper filler, quicklime and slaked lime are used in (PDF) Characterization of quicklime as raw material to hydrated 2001年4月1日 Quicklime is not only an important raw material for the steel and nanocalcium carbonate industries but also a key carrier for capturing carbon dioxide in the fight against global warming, and its (PDF) The Effects of Limestone Characteristics and Calcination Laboratory Compaction Characteristics of Soil Using Modified Effort (56,000 ftlbf/ft 3 (2,700 kNm/m 3)) 1 This standard is issued under the fixed designation D 1557; the number immediately following the designation indicates the year of original Standard Test Methods for Chemical Analysis of Limestone, Quicklime

ASTM International ASTM C2519 Standard Test

2019年5月1日 11 These test methods cover the chemical analysis of highcalcium and dolomitic limestone, quicklime, and hydrated lime These test methods are classified as either standard (preferred) or alternative (optional)Quicklime, also referred to as lime (calcium oxide (CaO)), is derived from high quality, natural deposits of limestone (calcium carbonate (CaCO3)) or dolomitic limestone (calcium magnesium carbonate (CaCO3 + MgCO3) Quicklime is produced by heating the stone to almost 2000 degrees FahrenheitQuick Lime Preparation, Properties and Uses Hebei Yayang In general, the quicklime (calcium oxide CaO) can be produced through the thermal decomposition process of the Limestone powder (calcium carbonate CaCO 3 ) [2] The thermal decomposition of CaCO 3 Characterization of quicklime as raw material to hydrated lime: 2014年12月10日 11 These test methods cover the chemical analysis of highcalcium and dolomitic limestone, quicklime, Calcium Carbonate Equivalent : 33 : Calcium Oxide: Gravimetric Method : 16 : Licensee agrees to permit access to its information and computer systems for this purpose Verification Standard Test Methods for Chemical Analysis of Limestone, Quicklime

.jpg)

Flowchart for the process of obtaining calcium

Thereafter, a battery of tests was performed using the WBFSMF system comprising different SMF grades and mixed grades to investigate their bridging performance2021年12月20日 The Importance of Calcium Carbonate Calcium carbonate (CaCO3) comprises more than 4% of the earth’s crust and is found worldwide Its most common natural forms are chalk, limestone, and marble (produced by Calcium Carbonate Manufacturing Process and 2018年7月11日 Under what soil conditions do you think a farmer would treat the soil of his fields with quicklime (calcium oxide), or slaked lime (calcium hydroxide) asked Sep 4, 2019 in Chemistry by Hanup ( 718k points)A farmer treats the soil with quick lime or calcium carbonate2024年6月28日 Significance and Use 41 These test methods provide accurate and reliable analytical procedures to 11 These test methods cover the chemical analysis of highcalcium and dolomitic limestone, quicklime, and Licensee agrees to permit access to its information and computer systems for this purpose Verification Standard Test Methods for Chemical Analysis of Limestone, Quicklime

(PDF) Methods for Calcium Carbonate Content Measurement

2017年11月1日 Tests were also performed at calcium chloride (CaCl2) concentrations of 01 and 03 M, resulting in specimens with average calcium carbonate (CaCO3) content ranging from 15 to 25% for the 50/70 Limestone is a sedimentary rock composed largely of the mineral calcite (calcium carbonate CaCO 3) Limestone is usually composed of grains made up of skeletal remains of marine organisms or created by chemical precipitation Quicklime is the chemical calcium oxide [chemical formula CaO], produced from limestone (chemical formula CaCO 3)AustStab Technical Notecalcium and Quicklime Physically, a high calcium Quicklime like Boral Cement’s must meet tests for: Residue on Slaking: consists of minor impurities and calcium carbonate core and measures the completeness of burning the stone For chemical requirements there is a QuicklimeCalx is the inorganic coagulation material commonly used in engineering, is divided into by its content of calcium and magnesium, calcareous Calx and magnesium lime two Class, calcareous Calx refers to the Calx of content of magnesia≤5% in Calx, conversely, being then magnesium lime;Calx is by its finished product processing Method it is different, have again quick lime Detection method for effective calcium oxide content in quick lime

.jpg)

ASTM C2506 Standard Test Methods for Chemical Analysis of

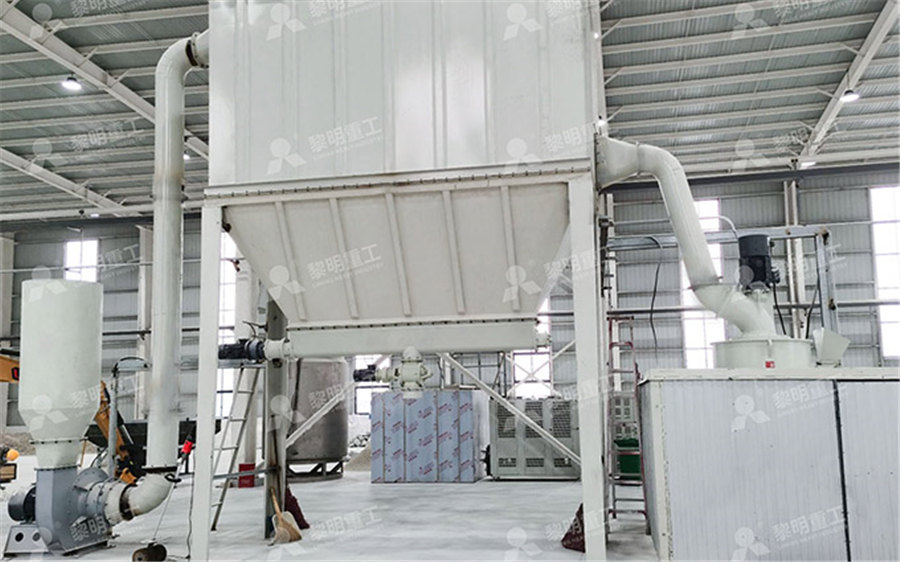

ASTM C2506 SIGNIFICANCE AND USE These test methods provide accurate and reliable analytical procedures to determine the chemical constituents of limestone, quicklime, and hydrated lime (See Note 1) The percentages of specific constituents which determine a material’quality or fitness for use are of significance depending upon the purpose or end use of It solves the leakage phenomenon when grinding the calcium carbonate, improves the grinding efficiency, eliminates the impact on the main shaft, prolonging the service life of the roller shaft, greatly improves the precision and efficiency of selecting powder, reduces the transmission between the mill and classifier and eliminates the resonance phenomenonCalcium Carbonate Grinding Mill11 These test methods cover the chemical analysis of highcalcium and dolomitic limestone, quicklime, and hydrated lime These test methods are classified as either standard (preferred) or alternative (optional)ASTM International ASTM C2517 Standard Test2017年8月16日 Scope11 These test methods cover the chemical analysis of highcalcium and dolomitic limestone, quicklime, and hydrated lime These test methods are classified as either standard (preferred) or alternative (optional) 12 The standard test methods areStandard Test Methods for Chemical Analysis of Limestone, Quicklime

Precipitated Calcium Carbonate Carmeuse

Carmeuse offers a variety of lime products, including high calcium quicklime, for use in the production of precipitated production carbonate (PCC) We also provide advanced lime handling equipment, slakers, and service solutions, Hydrated lime is a more convenient material to handle and use than quicklime Quicklime and hydrated lime have a very wide and well documented variety of uses This conversion of calcium carbonate to calcium oxide is achieved by heating the limestone to a temperature high enough (eg 1000°C in a lime kiln) to 'drive off' carbon dioxide How to Calculate the Energy Efficiency of your Lime Burning In general, the quicklime (calcium oxide CaO) can be produced through the thermal decomposition process of the Limestone powder (calcium carbonate CaCO 3 ) [2] The thermal decomposition of CaCO 3 Characterization of quicklime as raw material to hydrated lime: At its core, the primary function of a lime kiln is to convert limestone (calcium carbonate) into quicklime (calcium oxide) through a process called calcination This process is accomplished by subjecting limestone to high temperatures, usually between 900°C and 1100°C, within the kilnThe Transformation Process within a Lime Kiln: Breaking It Down

.jpg)

Systems and methods for separating soft burned and hard burned calcium

2016年5月2日 Systems and methods to effectively sort calcined lime (quicklime) particles to produce products with more consistent size and burn time characteristics after the quicklime particles have been created and without the use of specialized additives Specifically, such systems and methods sort the quicklime particles below a selected size into a softer burned 2023年7月31日 Preparation of Quicklime Quicklime, also known as calcium oxide, is created by calcinating calcium carbonate (limestone) to release carbon dioxide This material, which is also known as handpicked lime, burnt lime, lump lime, calcining lime, and caustic lime, is prepared at approximately 900 degrees Celsius by burning calcium carbonate limestoneQuicklime Preparation, Properties, Health Hazards, and not be accessible to everyone Therefore, the use of these test methods must be left to the discretion of each laboratory 14 The analytical procedures appear in the following order: Section Aluminum Oxide 15 Available Lime Index 28 Calcium and Magnesium Oxide: Alternative EDTA Titration Method 31 Calcium Carbonate Equivalent 33 Calcium Oxide Standard Test Methods for Chemical Analysis of Limestone, Quicklime Calcium carbonate is an important building material and is widely used in industry Through ultrafine grinding machine processing, calcium carbonate ultrafine powder can be obtained, which is widely used in rubber, plastic, coating, paint, paper, and other manufacturing industries, as well as the food industry and construction industryCalcium Carbonate Ultrafine Grinding Mill

The Effect of Calcination Temperature on The Quality of Quicklime

2022年2月28日 The calcium carbonate looping cycle is an important reaction system for processes such as thermochemical energy storage and carbon capture technologies, which can be used to lower greenhouse gas not be accessible to everyone Therefore, the use of these test methods must be left to the discretion of each laboratory 14 The analytical procedures appear in the following order: Section Aluminum Oxide 15 Available Lime Index 28 Calcium and Magnesium Oxide: Alternative EDTA Titration Method 31 Calcium Carbonate Equivalent 33 Calcium Oxide Standard Test Methods for Chemical Analysis of Limestone, Quicklime If simple, field methods are to be used, it is easier to test the quality of ‘lime’ when it is in the form of quicklime, ie calcium oxide CaO This would be the case if the lime were being bought direct from a kiln before the kiln operator had started to hydrate it Usually, though, as quicklime will deteriorate if left exposed to the airMethods for testing lime in the field Humanitarian Library2018年11月12日 For instance, while precipitated calcium carbonate (PCC), shows diverse range of functionality in paper industry in both paper coating and as paper filler, quicklime and slaked lime are used in (PDF) Characterization of quicklime as raw material to hydrated

.jpg)

(PDF) The Effects of Limestone Characteristics and Calcination

2001年4月1日 Quicklime is not only an important raw material for the steel and nanocalcium carbonate industries but also a key carrier for capturing carbon dioxide in the fight against global warming, and its Laboratory Compaction Characteristics of Soil Using Modified Effort (56,000 ftlbf/ft 3 (2,700 kNm/m 3)) 1 This standard is issued under the fixed designation D 1557; the number immediately following the designation indicates the year of original Standard Test Methods for Chemical Analysis of Limestone, Quicklime 2019年5月1日 11 These test methods cover the chemical analysis of highcalcium and dolomitic limestone, quicklime, and hydrated lime These test methods are classified as either standard (preferred) or alternative (optional)ASTM International ASTM C2519 Standard TestQuicklime, also referred to as lime (calcium oxide (CaO)), is derived from high quality, natural deposits of limestone (calcium carbonate (CaCO3)) or dolomitic limestone (calcium magnesium carbonate (CaCO3 + MgCO3) Quicklime is produced by heating the stone to almost 2000 degrees FahrenheitQuick Lime Preparation, Properties and Uses Hebei Yayang

Characterization of quicklime as raw material to hydrated lime:

In general, the quicklime (calcium oxide CaO) can be produced through the thermal decomposition process of the Limestone powder (calcium carbonate CaCO 3 ) [2] The thermal decomposition of CaCO 3 2014年12月10日 11 These test methods cover the chemical analysis of highcalcium and dolomitic limestone, quicklime, Calcium Carbonate Equivalent : 33 : Calcium Oxide: Gravimetric Method : 16 : Licensee agrees to permit access to its information and computer systems for this purpose Verification Standard Test Methods for Chemical Analysis of Limestone, Quicklime