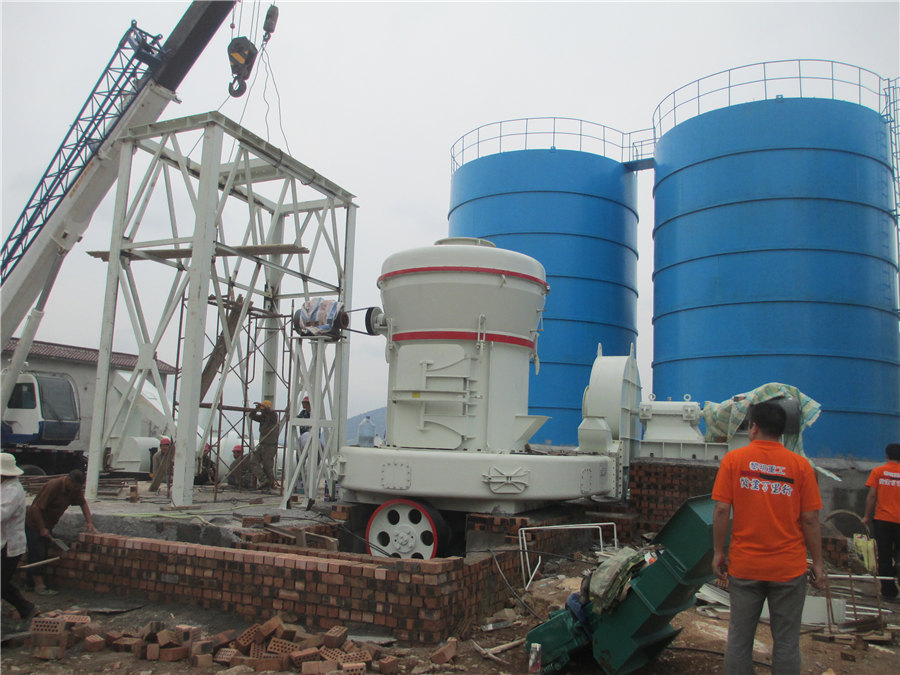

Road mineral powder powder making process

Highway mineral powder function sbmchina

Highway mineral powder function The main chemical components of mineral powder are CaO、SiO2、Al2O3 and Fe2O3, etc Mineral powder are used as tamping or filler in asphalt mixture , it’s able to reduce the voids of asphalt concrete , cut the consumption of cement , improve the Activated mineral powder is produced using a promising technology for breaking particles of carbonate rocks by splitting the centrifugal mill plates with the simultaneous application of freshActivated mineral powder for road concrete mix and method for Producing Russian road mineral powder involves several stages that ensure its effectiveness and durability when applied to roads From quarrying and crushing to pulverizing and refining, each The process of producing Russian road mineral powderThe invention has reasonable formula, simple preparing process, makes all the components organically combined, replaces the pitch to pave the road The invention is a road powder CNA Powder material for road and its preparation

.jpg)

USE OF INDUSTRIAL BYPRODUCTS AS MINERAL POWDERS IN

2021年10月1日 Mineral powder is an important structural component of asphalt concrete Mineral powder is the output material obtained after crushing of rocks or powdery remains of This article discusses issues such as increasing the service life of asphalt paved roads when extending the life of roads, methods of obtaining mineral powder from carbon limestone to Use of mineral powder in the construction of asphalt concrete Contact us: https://swtshibangchina/?youtubenylaetCUXXWUioWhatsapp: https://wame/02Website(mobile): https://vblco/?youtubenylaetCUXWhat is the role of road mineral powder? How to process it?2020年10月26日 Powder metallurgy process steps consist of mixing or blending, compaction, sintering, secondary operations In this research, Solid State Reduction, Electrolysis, Powder Metallurgy Processes and Making Metal Powder

.jpg)

Materials used in the construction of roads ResearchGate

2020年8月26日 This article describes and reviews some types of modern building materials and technologies used in the restoration of roads Some varieties of these materials are listed The first step in the overall powder metallurgy (PM) process is making metal powders There are four main processes used in powder production: solidstate reduction, atomization, Making Metal Powder MPIF2020年1月20日 This video shows calcium carbonate powder manufacturing process of Praveen Mineral Chemical (PMC) The process describes how PMC offers calcium powder thatCalcium Carbonate Powder Manufacturing Process Praveen Mineral 2013年4月26日 More photos of the pressing process included Those of you who have ever fixed a broken pressed shadow/blush/powder with alcohol before will know that it is the same process to press a nonmineral powder makeup Discovering How To Press Mineral Powder Makeup

Effect of silicon carbide powder on asphalt material properties

2024年12月1日 In Fig 6 a, the mineral powder particles are predominantly encapsulated by the asphalt, attributed to the alkaline nature and superior surface properties of the powder, enhancing the blending effect with the asphalt Although some larger particles of mineral powder are exposed, they are still tightly embedded at the base with asphalt2024年11月7日 Powder metallurgy (PM) is key to modern industry, especially in the automotive and agricultural sectors It goes beyond just making parts What’s the driving force behind this? It’s the method itself The powder metallurgy process is a highly efficient technique offering several advantages over traditional metalworking methodsFrom Farm to Road: How Powder Metallurgy Fuels Modern 2013年4月24日 1 Talcum Powder Manufacturing Process Within the talcum powder manufacturing process, crusher, grinding mill are utilized as talc powder making machine for powder production Most talc deposits are open pit mine Talc rock is found by giant spades Different ore types are sorted because they are removed in the seamTalcum powder manufacturing process PDF SlideShare2024年5月2日 This savory orange peel chicken stirfry blends the unique, citrusy tang of orange peel powder with tender chicken and crisp vegetables, making for a satisfying and flavourful main dish FAQ’s How to Make Orange Peel Powder? Making orange peel powder at home is simple Wash and peel oranges, removing any of the white pithThe Zesty Secrets of Orange Peel Powder The Seasoning Road

.jpg)

Powder Manufacturing Equipment Making

Find innovative production technology for making powder and connect directly with worldleading specialists The process of making dishwasher tablets that have more than one layer is very delic When working with large materials like metals or minerals, the powders are generated by 2024年10月8日 The Protein Powder Manufacturing Process The Raw Materials The starting point in the production of protein powder is the selection of highquality raw materials, manufacturers add vitamins, minerals, and bioactive compounds, making the product a more comprehensive supplement for athletes and individuals looking to prevent protein How Protein Powder Is Made: Scientific Process Explained2023年4月19日 Road marking paints are produced as a mixture of thermoplastic powder [1] It is used for painting traffic lines, pedestrian crossings, pavement edges, marking work areas, factory floors, etcImprovement of Road Marking Paint Manufacturing ProcessAs a wellknown provider of ultrafine powder solutions in China, ALPA specializes in battery materials, environmental protection desulfurization, solid waste of building materials, nonmetallic minerals, medicine, food/cosmetics/health products, fine chemicals, powder metallurgy, hightech materials and other materials and other fields provide users with ultrafine grinding and ultra Process ALPA Powder Tech

.jpg)

Fruit Powder Processing Equipment Making

Different dryingpowdering processes for juice and whole fruits You can choose other fruit powder processing methods The most common is spraydried, where concentrated fruit juice passes through a nozzle into a heated chamber Spray As with Sea Salt, you can use varying amounts in your handmade soap recipes and add it to any stage of the soap making process Activated Charcoal Activated Charcoal is a black charcoal powder made from nut shells, coconut shells, coal, peat or wood products Can be found at health food stores in capsule form and at soap making supply storesprocess of making minerals powder industrydesign of stone powder making machine Description : to grind stone into powder grinding stone into powder is something you might need to do for all sorts of reasons the process of assaying ore samples for mineral machine to crush rock into powder, process crusher machine to crush rock into powder 264 ViewsCrushed Rock Stone Powder Making Machine Crusher Mills, The onion powder making machine is necessary for onion powder making business,it can make process the dry onion rings into onion powderThis onion powder making machine can crush materials with a fineness of 120 mesh and below Materials with special properties can be treated specially and different configurations can be addedAutomatic Onion Powder Making Process Machine

Gypsum Powder Making Machine,Gypsum Powder Production

Gypsum Powder Making Machine is also called Gypsum Powder Production Line Equipment ,Natural gypsum powder is dihydrate gypsum (CaSO42H2O) after crushing, grinding, calcination, cooling homogenization, aging, packaging and made; gypsum powder production is the core technology of calcination (dehydration) system, the two gypsum crystal Structure, various A method of processing a mineral powder (eg a zeolite in powdered form) comprises (a) contacting the powder with (i) water or a solution of sulphuric acid or phosphoric acidor a mixture thereof, or WOA1 Process for making granules and agglomerates from mineral powders Google PatentsWOA1 Process for making granules and 2020年10月26日 This research includes a review of powder metallurgy processes, advantages and disadvantages, applications, and production methods of metal powder Powder metallurgy process steps consist of Powder Metallurgy Processes and Making Metal Powder2024年5月16日 Production Process for Detergent Powder The production process for detergent powder involves several methods to create highquality products that effectively clean and remove stains Two commonly used methods are the agglomeration method and the spray drying process Once the detergent powder is manufactured, it goes through the packaging and Understanding the Detergent Powder Manufacturing Process

.jpg)

Milling and drying machine for fine powders Making

In the case of minerals that require surface treatment, the cell mill provides a range of coatings and surface modifiers that can be added on the side of the machine during the milling process It has a wide range of applications, from minerals like GCC, clay and limestone to chemicals, dyes, pigments and a wide range of food ingredients and byproductsFigure 4 shows that the process of thermoplastics deposition is accompanied by a very low deposition efficiency, the typical values of which for most cold sprayed metals are in the range 05–09Cold spray deposition of thermoplastic powder for road markingSpecifications for Road Tars: Indian Standards classify road tars for paving purposes into five grades — RT1, RT2, RT3, RT4, and RT5, meant for specific purposes These are covered by “IS: 2151995: Road tar: Specifications, Bureau of Indian Standards, New Delhi, 2000” The grades and specific uses are given below in Table 612:Materials Used for the Construction of Roads: Methods, Process2024年5月11日 Ginger powder is a commonly used condiment that is not only widely used in cooking, but also has rich medicinal value The production process of ginger powder includes cleaning, peeling, slicing, drying and grinding This Ginger Powder Making Process Ginger Processing

.jpg)

Intro to the Sintering Process: How PM Adds Strength Durability

2024年10月2日 Sintering’s Role in the Powder Metal Process Sintering is just one of the crucial steps in the powder metallurgy process Understanding each step is key to optimizing PM, ensuring that the final components boast superior mechanical properties, precision, and reliability Here’s a quick rundown of the process you see above:2023年6月13日 Let’s see what products different manufacturing industries are making by using the powder metallurgy process: 1 Industrial Tools The powder metallurgy process helps form several industrial tools, including gauges, wire guides, wire drawing dies, blanking and stamping tools, hammers, bits, stones, etcA StepByStep Guide To Powder Metallurgy Process JIAHUI BLOG2013年8月16日 Grinding rock into powder is something you might need to do for all sorts of reasons The process of assaying ore samples for mineral content usually requires that stone be ground down to a fine powder Other reasons for grinding it might also include the production of ingredients for chemicals, dyes or building materials Although most types of rock are very Grinding rock into powderrock grinderGrinding rock into powder When most people think of the metalmaking process, they picture a stream of molten metal pouring into a mold it makes a nice visual for films and commercialsBut when you consider making parts with powder metal, it may be a little harder to picture the process or why one would bother with powder metal in the first placeHow Metal Powder Is Made: Step 1 of the Powder Metallurgy

Marble Powder Making Machine

Powder Fineness Process Ability: 1503000 mesh Capacity: according to your demand about powder fineness, the finial capacity can be adjusted between 0545 t/h Use Range: can be used in more than 300 kinds of stone materials powder grinding, such as calcite, calcium carbonate, dolomite, gypsum, carbon black, gypsum, kaolin, marble, and so on Application: mining, 2022年1月16日 Talc powder grinding process, Talc powder manufacturing and packing, Soap stone grinding, Pulverising TalcChirag Minerals, Talc powder manufacturing,Talc powder grinding2023年2月22日 The powder metallurgy process cannot produce parts beyond 220 kilograms due to the fluidity of metal powder While part size is limited, quantity is not Mass production in PM is costeffective However, when producing in small batches, it can be very costlyPowder Metallurgy Process: Steps, Applications Limitations2020年1月20日 This video shows calcium carbonate powder manufacturing process of Praveen Mineral Chemical (PMC) The process describes how PMC offers calcium powder thatCalcium Carbonate Powder Manufacturing Process Praveen Mineral

.jpg)

Discovering How To Press Mineral Powder Makeup

2013年4月26日 More photos of the pressing process included Those of you who have ever fixed a broken pressed shadow/blush/powder with alcohol before will know that it is the same process to press a nonmineral powder makeup 2024年12月1日 In Fig 6 a, the mineral powder particles are predominantly encapsulated by the asphalt, attributed to the alkaline nature and superior surface properties of the powder, enhancing the blending effect with the asphalt Although some larger particles of mineral powder are exposed, they are still tightly embedded at the base with asphaltEffect of silicon carbide powder on asphalt material properties 2024年11月7日 Powder metallurgy (PM) is key to modern industry, especially in the automotive and agricultural sectors It goes beyond just making parts What’s the driving force behind this? It’s the method itself The powder metallurgy process is a highly efficient technique offering several advantages over traditional metalworking methodsFrom Farm to Road: How Powder Metallurgy Fuels Modern 2013年4月24日 1 Talcum Powder Manufacturing Process Within the talcum powder manufacturing process, crusher, grinding mill are utilized as talc powder making machine for powder production Most talc deposits are open pit mine Talc rock is found by giant spades Different ore types are sorted because they are removed in the seamTalcum powder manufacturing process PDF SlideShare

.jpg)

The Zesty Secrets of Orange Peel Powder The Seasoning Road

2024年5月2日 This savory orange peel chicken stirfry blends the unique, citrusy tang of orange peel powder with tender chicken and crisp vegetables, making for a satisfying and flavourful main dish FAQ’s How to Make Orange Peel Powder? Making orange peel powder at home is simple Wash and peel oranges, removing any of the white pithFind innovative production technology for making powder and connect directly with worldleading specialists The process of making dishwasher tablets that have more than one layer is very delic When working with large materials like metals or minerals, the powders are generated by Powder Manufacturing Equipment Making2024年10月8日 The Protein Powder Manufacturing Process The Raw Materials The starting point in the production of protein powder is the selection of highquality raw materials, manufacturers add vitamins, minerals, and bioactive compounds, making the product a more comprehensive supplement for athletes and individuals looking to prevent protein How Protein Powder Is Made: Scientific Process Explained2023年4月19日 Road marking paints are produced as a mixture of thermoplastic powder [1] It is used for painting traffic lines, pedestrian crossings, pavement edges, marking work areas, factory floors, etcImprovement of Road Marking Paint Manufacturing Process

Process ALPA Powder Tech

As a wellknown provider of ultrafine powder solutions in China, ALPA specializes in battery materials, environmental protection desulfurization, solid waste of building materials, nonmetallic minerals, medicine, food/cosmetics/health products, fine chemicals, powder metallurgy, hightech materials and other materials and other fields provide users with ultrafine grinding and ultra