HOME→What parts does the grinding production line consist of What parts does the grinding production line consist of

What parts does the grinding production line consist of What parts does the grinding production line consist of

Grinding powder production line: Process configuration and flow

The grinding powder production line is a critical component in various industries, including mining, construction, and chemicals It involves the transformation of raw materials into fine powders through a series of processing stages 1 Raw Material Handling The first stage in the grinding Grinding Wheel: The primary component used for grinding, made of abrasive grains held together by a binder Wheel Head: It houses the grinding wheel and contains mechanisms for Grinding in Engineering:Definition,Process,and ApplicationsGrinding machine parts consist of the following parts: The base or bed is made of cast iron, which rests on the floor and carries all the machine parts Tables are usually two in some types of What is Grinding Machine? its Diagram and How it Works2022年11月28日 Grinding removes material through an abrasive process using a rotating abrasive wheel – Part size: Turning is better suited for removing larger amounts of material What is Grinding Process How It Works Different Types of

.jpg)

What is Grinding: Definition, Process, Types Specifications

2024年1月23日 Grinding involves a rotating grinding wheel made of abrasive particles which act as miniature cutting tools As the grinding wheel passes over the workpiece’s surface, it 2024年7月23日 Key components of grinding operations typically include the grinder, workpiece, and the use of coolant to minimize heat generation and mitigate thermal damage during What is Grinding: Definition, Types, Uses, and Working Process2020年11月18日 Grinding, also called surface grinding, is a machining operation in which material is removed using a powered abrasive wheel, stone, belt, paste, sheet, compound, etc Manufacturing Process: Grinding HuyettSurface Grinding Cylindrical Grinding Centerless Grinding Tool Cutter Grinding Jig Grinding Gear Grinding Centre Grinding Die Grinding Angle Grinding 1 Surface Grinding– A surface grinder consists of an abrasives Parts and Functions of Grinding Machine Mechanical

What is Grinding:Definition, Process, Types Specifications

Form grinding, a process that uses formed grinding wheels to create complex shapes, is perfect for parts that require a specific contour or profile Technical Specifications Running Speeds: Operating speeds for form grinding range from 3,500 to 4,500 fpm (18 to 23 m/s)2021年8月27日 The supply line consists of an electrolyte tank The pump is used to draw the electrolyte from the tank which is followed by the filter, pressure gauge, and flow meter The end of the supply line is connected with a nozzle Electrochemical Grinding: Definition, Parts or What parts does the plastic mill consist of? The plastic grinding machine consists of several important parts, each of which plays an important role in the performance and operation of plastic grinding One of these main parts is the plastic tank that collects plastic materials and is What is a plastic grinding machine and what are its uses?A grinding machine has a production cycle that consists of 36 minutes of setup time, followed by 29 minutes of production While producing, the grinding machine produces 174 parts per minute Round your answer to one decimal placeSolved A grinding machine has a production cycle that

What Does Mill Liner Do? ball mills supplier

Mill liners are an essential component in grinding mills, providing a protective surface to minimize wear and extend the lifespan of the mill In this article, we will explore what mill liners do, their importance, and the different types available Mill liners are protective components that shield the interior of a grinding mill from the abrasive forces generated by grinding media and oreGrinding Rollers The grinding rollers are a crucial part of the vertical roller mill They are responsible for crushing and grinding the material, and they are usually made from highquality steel The grinding rollers are also coated with a wearresistant material to increase their lifespan Grinding Table LinersWhat are the Parts of Vertical Roller MillThe barite grinding production line is a production line specially used to process barite raw ore into fine barite powder; it has the advantages of simple configuration, stable operation, high output, low energy consumption, and the fineness of the finished product meets the requirements Barite is a pure natural stone with high practical value in mining, machinery, metallurgy, Barite Grinding Production Line TAYMACHINERY2024年1月27日 Highvolume production grinding of cylindrical parts Achieving tight tolerances in roundness and diameter Grinding long, slender parts that could deform if held between centers Most Useful For: Centerless grinding is essential in mass production settings, particularly in the manufacturing of automotive components and precision partsWhat is a Grinding Machine: Definition, Types, Components

.jpg)

What is Grinding? Understanding the Basics and Applications

2024年7月17日 Grinding is a complex abrasive machining process that uses a grinding wheel as a cutting tool It’s known for producing very fine finishes and extremely accurate dimensions on metal parts Grinding uses a rotating grinding wheel made up of abrasive particles, which act like tiny cutting tools Now, let’s get into the details of what is 2013年1月1日 Principles of Modern Grinding Technology explains the principles that led to rapid improvements in modern grinding technology over recent decadesPrinciples of Modern Grinding TechnologyCenterless grinding is a precise and efficient machining process used to remove material from a workpiece without the use of a grinding machine This process is ideal for cylindrical and bar grinding, resulting in an excellent surface finish The Ultimate Guide to Centerless Grinding in Precision 2024年4月21日 Introduction to Grinder Part Identification Grinders are essential tools used in various industries for grinding and cutting materials They consist of numerous parts that work together to ensure efficient and safe operation Understanding the different parts of a grinder and their functions is crucial for proper usage and maintenanceUnderstanding The Different Parts Of A Grinder: A ShunTool

What does the welding production line consist of?Hongtai

A welding production line is a complex assembly setup designed to automate and streamline the welding process, ensuring efficiency, consistency, and quality in the production of welded components It typically consists of several key components and subsystems, each playing a vital role in the overall operation Welding production line 2024年7月23日 Manufacturing precision molds and fixtures, creating intricate geometries in hardened parts Form Grinding: Uses shaped grinding wheels to create complex shapes, ideal for custom or specialized parts in small batches Production of uniquely shaped parts like turbine blades and gear hobs Camshaft and Crankshaft GrindingWhat is Grinding: Definition, Types, Uses, and Working Process2022年5月28日 Centerless grinding is used to work on parts without places to hold the parts or centers It works on the outer diameter of bars and tubes As the name implies, it works without having the workpiece held in a positionPrecision Grinding: Understanding the Principle, Types, and This production line is for the assembly of a bicycle (seen above) As the bicycle frame travels down the production line each person at a workstation workstation has a specific task to carry out ( see below) ADVANTAGES: A production line is a very efficient way of manufacturing and assembling a productWHAT IS A PRODUCTION LINE?

.jpg)

Surface Grinding: A Guide to the Process and Precision okdor

2024年1月11日 The finishing process on a surface grinding machine depends heavily on the type of grinding wheel used – straight wheels for flat surfaces, recessed surfaces, and wheel face grinding for more intricate profiles In doubledisc grinders, continuous or indexed rotation facilitates the production of uniform finishesDownload scientific diagram Elements of the grinding process from publication: A Wavelet Approach to Estimate The Quality of Ground Parts The manufacturing process of metal parts is subjected Elements of the grinding process Download Scientific DiagramGrinding Machine A grinding is metal cutting operation which is performed by means of a rotating abrasive wheel that acts as a tool; These are mostly used to finish workpieces which must show a high surface quality, accuracy of shape and dimension Mostly, it is finishing operation because it removes material in very small size of chips 025 – 05 mmGrinding Machine Definition,Working,Parts,OperationTypes2019年6月18日 Production Machining’s November 2024 technology showcase includes some of the latest Kyzen Solvents Provide Ease of Cleaning for Medical Parts The Metalnox line of solvent products are designed to improve Using Grinding Instead of Turning in Series Production

.jpg)

Grinding Machine: Definition, Types, Parts, Working

Bench Grinding Machine: Parts, Working What is Bench Grinding Machine? It is the most common type of grinding machine found in tool rooms and workshops It is used to sharpen the tools, grind the workpiece surface and remove 2002©John Wiley Sons, Inc M P Groover, “Fundamentals of Modern Manufacturing 2/e” Material removal by action of hard, abrasive particles usually in the form of a bonded wheel • Generally used as finishing operations after part geometry has been established by conventional machining • Grinding is most important abrasive processLesson 6 GRINDING AND OTHER ABRASIVE PROCESSES KSU2017年1月1日 This can be traduced in different thermal situations that need different analyses   Fig 1 Angular grinding production example (left) straight face said the straight face grinding technique consists of a straight wheel that strategy ï‚ Dressing is also an important part of the whole grinding State of the art of different industrial approaches for face grinding 2024年3月12日 Grinding is commonly one of the last machining operations performed to complete a part Cylindrical and centerless grinders are used for cylindrical parts Grinding machines for flat surfaces are called surface grinders Form grinders move the work and/or the wheel in various axes to grind surfaces that are precisely contouredGrinding for Precision Machining Production Machining

Solved A grinding machine has a production cycle that

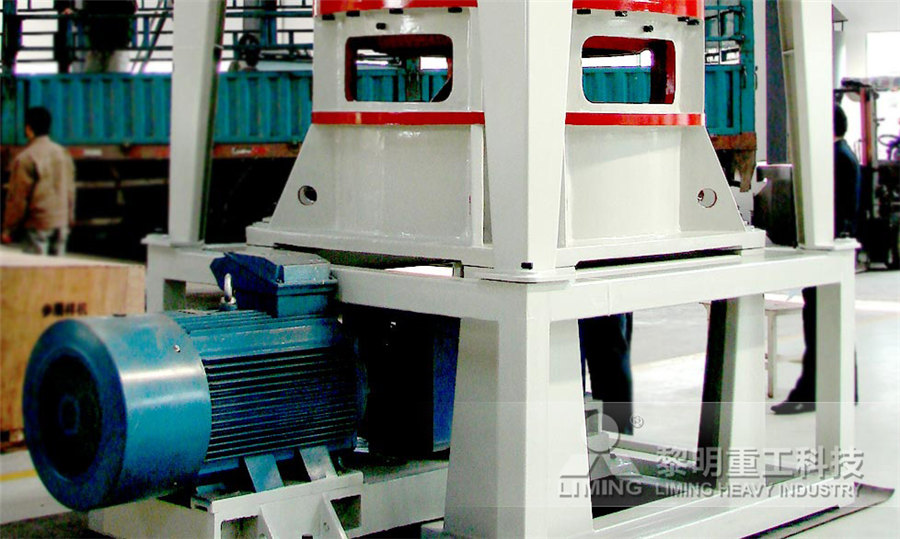

Question: A grinding machine has a production cycle that consists of 30 minutes of setup time, followed by 20 minutes of production While producing, the grinding machine produces 60 parts per minuteWhat is the capacity of the grinding machine in parts per minute?Note: Round your answer to 1 decimal placeCapacity (per minute)What is Grinding Production Line ? Grinding plant consists of mainframe, speed reducer, powder separator, blower, bag filter, pipes, cyclone, motor, etc The airflow is sucked into centrifugal blower through wind recycling pipe at the upper part of cyclone powder collectorQuarry equipment: Grinding Production LineThe Concept of Rail Grinding was originated in 1930s for removal of rail surface defects First production grinder was built in 1954 by Frank Speno Railroad Ballast Cleaning Co It was a 9 car train with 96 grinding motors (75 hp each) working at 3 kmph Later Speno International and Loram Maintenance of Way built many different types ofINTRODUCTION OF RAIL GRINDING ON INDIAN RAILWAYSCylindrical grinding: how does it work? To grind a cylindrical part, the hydrostatic slide machine is the most suitable piece of equipment It can work with a variety of materials and modify delicate parts while preventing them from vibrating and breaking The part to be ground is placed between two points that will make it rotate on itselfWhat Are the Basic Principles of Cylindrical Grinding?

The Details of Accurate Grinding: A Practical Guide ProleanTech

2023年8月2日 Consistency: Precision grinding is excellent for mass production of parts as it ensures consistent quality across large batches Selecting the Right Precision Grinder Precision grinding is a critical manufacturing process that plays an essential role in producing parts with high precision and surface finishSurface Grinding Cylindrical Grinding Centerless Grinding Tool Cutter Grinding Jig Grinding Gear Grinding Centre Grinding Die Grinding Angle Grinding 1 Surface Grinding– A surface grinder consists of an abrasives Parts and Functions of Grinding Machine Mechanical Form grinding, a process that uses formed grinding wheels to create complex shapes, is perfect for parts that require a specific contour or profile Technical Specifications Running Speeds: Operating speeds for form grinding range from 3,500 to 4,500 fpm (18 to 23 m/s)What is Grinding:Definition, Process, Types Specifications2021年8月27日 The supply line consists of an electrolyte tank The pump is used to draw the electrolyte from the tank which is followed by the filter, pressure gauge, and flow meter The end of the supply line is connected with a nozzle Electrochemical Grinding: Definition, Parts or

.jpg)

What is a plastic grinding machine and what are its uses?

What parts does the plastic mill consist of? The plastic grinding machine consists of several important parts, each of which plays an important role in the performance and operation of plastic grinding One of these main parts is the plastic tank that collects plastic materials and is A grinding machine has a production cycle that consists of 36 minutes of setup time, followed by 29 minutes of production While producing, the grinding machine produces 174 parts per minute Round your answer to one decimal placeSolved A grinding machine has a production cycle thatMill liners are an essential component in grinding mills, providing a protective surface to minimize wear and extend the lifespan of the mill In this article, we will explore what mill liners do, their importance, and the different types available Mill liners are protective components that shield the interior of a grinding mill from the abrasive forces generated by grinding media and oreWhat Does Mill Liner Do? ball mills supplierGrinding Rollers The grinding rollers are a crucial part of the vertical roller mill They are responsible for crushing and grinding the material, and they are usually made from highquality steel The grinding rollers are also coated with a wearresistant material to increase their lifespan Grinding Table LinersWhat are the Parts of Vertical Roller Mill

Barite Grinding Production Line TAYMACHINERY

The barite grinding production line is a production line specially used to process barite raw ore into fine barite powder; it has the advantages of simple configuration, stable operation, high output, low energy consumption, and the fineness of the finished product meets the requirements Barite is a pure natural stone with high practical value in mining, machinery, metallurgy, 2024年1月27日 Highvolume production grinding of cylindrical parts Achieving tight tolerances in roundness and diameter Grinding long, slender parts that could deform if held between centers Most Useful For: Centerless grinding is essential in mass production settings, particularly in the manufacturing of automotive components and precision partsWhat is a Grinding Machine: Definition, Types, Components2024年7月17日 Grinding is a complex abrasive machining process that uses a grinding wheel as a cutting tool It’s known for producing very fine finishes and extremely accurate dimensions on metal parts Grinding uses a rotating grinding wheel made up of abrasive particles, which act like tiny cutting tools Now, let’s get into the details of what is What is Grinding? Understanding the Basics and Applications