Working principle of mine bentonite environmental protection conveyor belt

Conveyor Belt Solutions for every mining task Continental Industry

We provide a wide range of conveyor belts and related products, longtime experience, comprehensive technical and project management expertise and technical solutions for all conveying issuesConveyor belts in mining are primarily used to transport bulk materials like ore, coal, and minerals They move the materials from the point of extraction (often underground or in remote surface The Role of Conveyor Belts in the Mining IndustryConveyor belts used in underground mines necessitate good wear resistance, corrosion resistance, and dust resistance to ensure stable longterm operation within the humid, dusty, Everything You Need Know about Mining Conveyor BeltsPrimarily, by reducing the exposure of mine personnel to unsafe and hazardous conveyor belt systems and thereby reducing the number of belt related fatalities and injuries Secondarily, it Best Practice: Conveyor Belt Systems MHSC

Mining guide: Conveyor belt monitoring and control in mines

2018年12月19日 Mining guide: Conveyor belt monitoring and control in mines One of the most important aspects of a successful mining operation is the effectiveness of a project’s conveyor 2016年6月1日 This paper presents the initial findings of a research program to reduce the annual equivalent costs of belt conveying systems The work utilizes models to predict the (PDF) Development of Conveyor Belts Design for Reducing Energy As underground mining is often characterised by limited space and potentially combustible material due to the flammable atmosphere, Sempertrans provides conveyor belt solutions with Mining Conveyor Belts Semperit2017年6月1日 The proposed AMIGA system for extinguishing fires on underground coal mine conveyor belts, incorporating spraying and water mist installations, is supported by a (PDF) The need for sustainable technology diffusion in mining

An Effective Belt Conveyor for Underground Ore IOPscience

2017年12月1日 As the key elements of a belt conveyor, the energyefficient conveyor belt and optimised carrying idlers have been developed for the new generation of underground conveyorsConveyor belts are a triedandtrue energy saver designed to increase efficiency Let’s take a look at how conveyor belts work and why they’ve stood the test of time How a Conveyor Belt Works A conveyor belt works by using two motorized pulleys that loop over a How Do Conveyor Belts Work? Belt Functions, UsesConveyor belting is one of the most expensive components on a conveyor system and a fully functional conveyor system is crucial to the operation of a mine or plant With the ever increasing cost of mining operations it has become of Conveyor Belt Monitoring: New Technologies for the 2022年5月1日 The Belt conveyor is economical in terms of cost per unit tonne that it can handle Disadvantage: The Belt conveyor is expensive Selection of Belt Conveyor The capacity of a belt conveyor depends on the crosssection Belt Conveyor Principle, Construction And How it

Belt conveyor PPT SlideShare

2017年4月7日 10 Idler type 1 Flat belt idler Used for granular materials of angle of repose not less than 35º Preferred for low capacity where inexpensive conveying is required 2 Toughing idlers with 20º trough Used for conveying all kinds of bulk material 3 Toughing idlers with 35º and 45º trough Mainly used for transportation of small particle light weight materials like grains, 2018年7月30日 Conveyor belts, as well as roller conveyors, have a key role to play in the efficient movement of all types of goods within a production plant, an industrial warehouse or any logistics company What are conveyor belts and how do they work? Conveyor belts are used to move goods and products that require further stability See moreThe conveyor belt and its operating principles RoltiaMagnetic Belt Conveyors Magnetic belt conveyors are the most prevalent type of magnetic conveyor due to their ease of construction and operation They are equipped with a magnetized sheet metal belt featuring either permanent magnets or a series of electromagnets that attract ferrous materials to the conveyor beltBelt Conveyors: Components, Types, Design, and Applications2021年5月10日 Belt conveyor is economical in terms of cost per unit tonne that it can handle Disadvantage: Belt conveyor is expensive Selection of Belt Conveyor: The capacity of a belt conveyor depends on the crosssection of the load and the speed of the belt The crosssection of the load depends on the width and slope of the belt and the size of the Construction And Working of Belt Conveyor Solution Parmacy

Conveyor Belts: What Is It? How Does It Work? Types, Parts

2023年3月13日 Conveyor belts resemble a band or loop of rollers connected to rotors powered by a motor The belts can be as narrow as one inch (25 mm) or as wide as five feet (15 m), with plastic modular belts as wide as ten feet (3 m) Conveyor belts are made of highly durable and sturdy materials, much like heavyduty machinery2021年11月15日 Working principle of belt conveyor The belt conveyor uses the tape connected by winding the head pulley and tail pulley to form a closed annular belt It receives electricity through the motor, converts the electric energy into kinetic energy to drive the head pulley to run, and uses the friction between the head pulley and the belt to drive the belt to run continuouslyStructure, function and working principle of belt conveyor2024年5月20日 Belt: The belt itself is the conveyor’s workhorse, carrying the load from one point to another It needs to be durable, flexible, and capable of withstanding the rigors of industrial environmentsWhat is the working principle of a belt conveyor?2024年3月19日 Smart Conveyor Belts: The integration of sensors and IoT (Internet of Things) technology in conveyor belts is revolutionizing Conveyor Belt System Design Smart conveyor belts can monitor their own performance, Conveyor Belt System Design: Best Practices, Types,

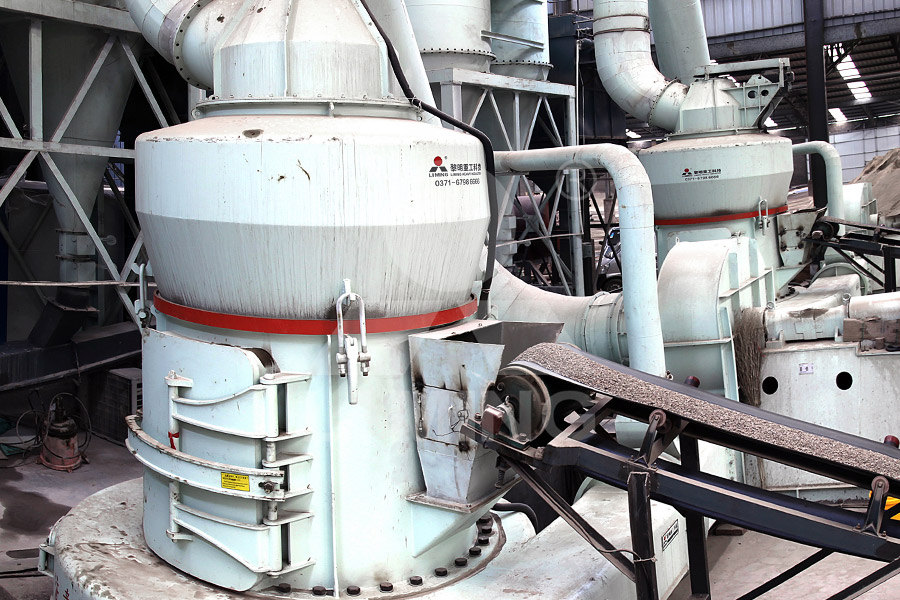

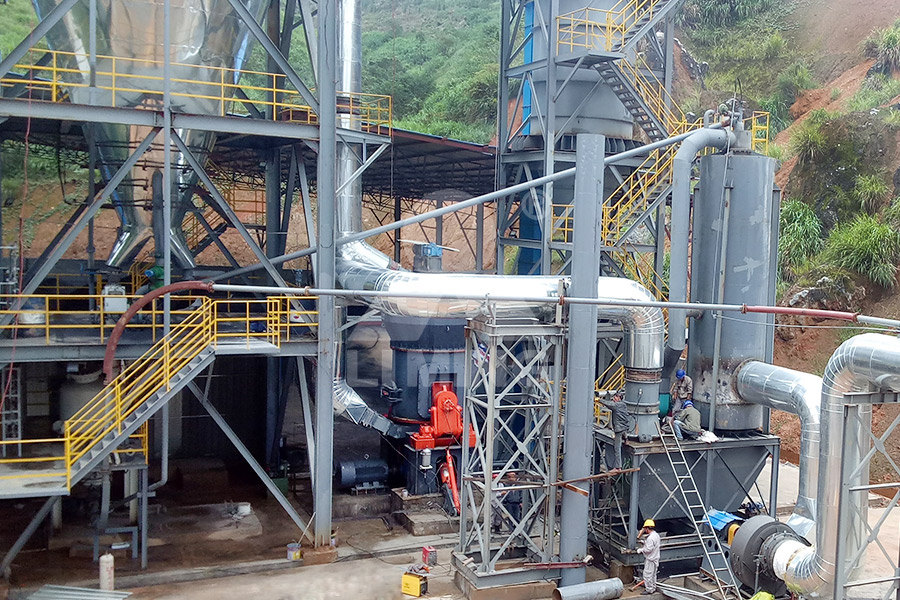

Bentonite Processing Plant And Grinding Machine

bentonite grinding machine Equipment composition of bentonite grinding machine: The complete set of bentonite grinding machines includes a hammer crusher, bucket elevator, storage bin, vibrating feeder, grinding machine host, This chapter briefly introduces the working principle, main features, application scope, domestic and foreign levels and development trends, and structural forms of the air supported belt conveyor; analyzes and summarizes the general design and determination of the main parameters of the air supported belt conveyor, the selection of the main components such as Air Supported Belt Conveyor SpringerLink2024年3月20日 The primary parts of a belt conveyor system include the conveyor belt, which is the medium of transport; the idler rollers, which support the belt and the materials being conveyed; the pulleys (head and tail pulleys), which drive the belt and provide tension to it; the drive system, consisting of a motor and a gearbox, which powers the conveyor; and the Parts of Belt Conveyor System: Types, Functions, Materials2024年3月15日 Curved Belt Conveyors: Description: These belts can navigate corners and turns, optimizing space Applications: Suitable for complex layouts in various industries Features: Smooth transitions, reduced product handling Wire Mesh Belt Conveyors: Description: Constructed from metal wires, these belts are heat resistant and durableTypes of Mining Conveyor Belt: Selection and Implementation

Working Principle of Mobile Belt Conveyor YouTube

2024年5月17日 Mobile belt conveyor uses a motor to drive the conveyor belt to realize continuous transportation and movement of materials https://dahanmachine/pro2024年3月20日 On the basis of introducing the characteristics, status and development trends, classification, and numbering of general belt conveyors, this chapter analyzes in detail the technical characteristics and working principles of the typical layout, towing and carrying unit, driving unit, tension unit, discharge device, support device, loading device, cleaning device, General Belt Conveyors SpringerLink2024年6月2日 Fabric Conveyor Belts: Made from multiple layers of fabric, these belts are flexible and suitable for transporting a variety of materials, including ore and overburden Chevron Conveyor Belts: Equipped with a chevron pattern, these belts prevent material rollback on steep inclines, making them ideal for transporting materials up and out of the pitEssential Types of Conveyor Belts Used in Mining2020年8月17日 Belt Conveyor IntroductionComponents of Belt Conveyor SystemConveyor Belt ConstructionIdentification of Conveyor BeltsCalculations for Designing Belt ConveyoBelt Conveyor Design, Working Principle, Designation of

.jpg)

Research and Application on Energy Saving of Port Belt Conveyor

2011年1月1日 Keywords:belt conveyor; energysaving; less motor operation technique 1 Introduction As a kind of continuous transportation equipment, belt conveyor is widely used in today’s modern port, especially in the transport of coal and mineral powder because of its high efficiency and environmental protectionTo learn more about how conveyor belts made with Kevlar® can help address your extreme mining conditions, download the latest brochure here Replacing conventional polyester/nylon (EP) and steel cord in carcasses with straight Conveyor Belt Material Mining Conveyor Belts with 2020年7月1日 At present, the damage detection methods of conveyor belt can be divided into manual detection and automatic detection methods The manual detection method mainly refers to the observation method Infrared Spectrum Analysis Method for Detection and Early 2021年8月10日 A conveyor system is a type of mechanical handling equipment that is used to transfer material from one place to anotherConveyors provide ease of use in applications such as the transportation of heavy or bulky materials Conveyor systems permit fast and efficient transportation of a broad variety of materials These are extremely popular where there is a What is Conveyor System? Types, Parts, Working, Uses [PDF]

Pipe conveyor belts (tube conveyor belt) Metso

Pipe conveyor belts, or tube conveyor belts, Note that the working life of the belt is also determined by the application This method of conveying contributes to safe, clean and spillagefree material transport, which helps protect the 2021年4月1日 As one of the most important transportation equipment in the field of continuous conveyance of bulk materials, belt conveyor is developing towards the direction of longdistance, high belt speed, large volume, and intelligence [1]Intelligence refers to the belt conveyor can realize its running state of selfawareness, independent decisionmaking, and selflearning, by Deep learningbased damage detection of mining conveyor belt2021年4月1日 The mining conveyor belt is an important component of the coal mine belt conveyor, which plays the role of carrying materials and transmitting powerAiming at the problem that mining conveyor belts are easily damaged under severe working conditions, based on the reclassification and definition of conveyor belt damage types, a special data set for conveyor Deep learningbased damage detection of mining conveyor beltbut can detect the fine cracks during working It also can advanced protect the conveyor Through research of the belt conveyor, belt tear phenomenon more likely to occur in the nose and tail So set two signal acquisition devices in the nose and tail In order to ensure the accuracy of detection, it put other two devices uniform in the workingAISC 181 The Research of Coal Mine Conveyor Belt Tearing

Pipe Belt Conveyors SpringerLink

2024年3月20日 On the basis of introducing the composition and working principle, structure and parameters of main components, and design and selection of pipe belt conveyors, this chapter analyzes in detail the technical characteristics and working principles of the conveyor belt, idler, pulley, and driver of pipe belt conveyors; recommends the methods of the main technical transportation equipment, belt conveyor is widely used in today‟s modern port, especially in the transport of coal and mineral powder because of its high efficiency and environmental protection [1] Beltconveyors are more acceptable than other means of transporting bulk materials; theyAnalysis Prospects of Modification in Belt Conveyors A Conveyor belts are a triedandtrue energy saver designed to increase efficiency Let’s take a look at how conveyor belts work and why they’ve stood the test of time How a Conveyor Belt Works A conveyor belt works by using two motorized pulleys that loop over a How Do Conveyor Belts Work? Belt Functions, UsesConveyor belting is one of the most expensive components on a conveyor system and a fully functional conveyor system is crucial to the operation of a mine or plant With the ever increasing cost of mining operations it has become of Conveyor Belt Monitoring: New Technologies for the

Belt Conveyor Principle, Construction And How it

2022年5月1日 The Belt conveyor is economical in terms of cost per unit tonne that it can handle Disadvantage: The Belt conveyor is expensive Selection of Belt Conveyor The capacity of a belt conveyor depends on the crosssection 2017年4月7日 10 Idler type 1 Flat belt idler Used for granular materials of angle of repose not less than 35º Preferred for low capacity where inexpensive conveying is required 2 Toughing idlers with 20º trough Used for conveying all kinds of bulk material 3 Toughing idlers with 35º and 45º trough Mainly used for transportation of small particle light weight materials like grains, Belt conveyor PPT SlideShare2018年7月30日 Conveyor belts, as well as roller conveyors, have a key role to play in the efficient movement of all types of goods within a production plant, an industrial warehouse or any logistics company What are conveyor belts and how do they work? Conveyor belts are used to move goods and products that require further stability See moreThe conveyor belt and its operating principles RoltiaMagnetic Belt Conveyors Magnetic belt conveyors are the most prevalent type of magnetic conveyor due to their ease of construction and operation They are equipped with a magnetized sheet metal belt featuring either permanent magnets or a series of electromagnets that attract ferrous materials to the conveyor beltBelt Conveyors: Components, Types, Design, and Applications

.jpg)

Construction And Working of Belt Conveyor Solution Parmacy

2021年5月10日 Belt conveyor is economical in terms of cost per unit tonne that it can handle Disadvantage: Belt conveyor is expensive Selection of Belt Conveyor: The capacity of a belt conveyor depends on the crosssection of the load and the speed of the belt The crosssection of the load depends on the width and slope of the belt and the size of the 2023年3月13日 Conveyor belts resemble a band or loop of rollers connected to rotors powered by a motor The belts can be as narrow as one inch (25 mm) or as wide as five feet (15 m), with plastic modular belts as wide as ten feet (3 m) Conveyor belts are made of highly durable and sturdy materials, much like heavyduty machineryConveyor Belts: What Is It? How Does It Work? Types, Parts2021年11月15日 Working principle of belt conveyor The belt conveyor uses the tape connected by winding the head pulley and tail pulley to form a closed annular belt It receives electricity through the motor, converts the electric energy into kinetic energy to drive the head pulley to run, and uses the friction between the head pulley and the belt to drive the belt to run continuouslyStructure, function and working principle of belt conveyor