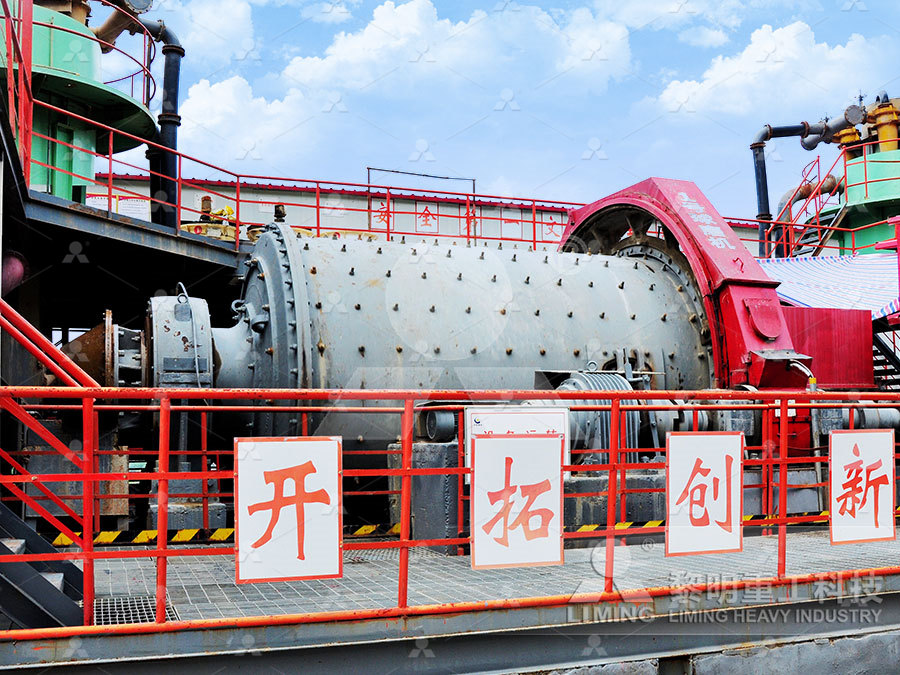

Pyrolytic carbon black grinder

.jpg)

China Pyrolysis Carbon Black Grinder Manufacturer, Supplier

Our Pyrolysis Carbon Black Grinder, developed by Weifang Jinghua Powder Engineering Equipment Co, Ltd, is an advanced machine designed for the efficient grinding and 2019年8月30日 The medium temperature pyrolysis process using a fixedbed reactor at atmospheric pressure was utilised to recover carbon black from motorcycle and automobile tyres Experimental results have shownPyrolytic preparation and modification of carbon black By the principle of combining airflow collision and mechanical collision, this equipment can put the pyrolytic carbon black shattered into 1500 meshPyrolysis Carbon Black Grinding System and 2019年8月30日 In this work, the Argon (Ar) plasma technology is adopted for pyrolytic carbon black (CBp) modification and the N330/Modified‐CBp (MCBp) hybrid is then incorporated into the Natural RubberPyrolytic preparation and modification of carbon black

.jpg)

RECOVERED CARBON BLACK Hosokawa Alpine

After pyrolysis, an intermediate process step is required The carbon black granules are precrushed and prepared for the fine grinding stage using a magnet/metal separator For fine 2022年3月9日 The solid product from ELT pyrolysis, commonly known as recovered carbon black (rCB), is a complex mixture arising from the compounds used during tire manufacture, namely, (i) carbon black (CB), (ii) inorganic Production and Upgrading of Recovered Carbon Black 2021年6月10日 CBp, also known also as pyrolytic char or recovered carbon black (rCB), is consisted of carbon black (CB) used in tire manufacturing, ash and solid tar adsorbed on the Recovery of carbon black from waste tire in continuous 2024年11月1日 Application of plasma modified pyrolytic carbon black in improving mechanical properties of natural rubber composite Strain energy density of carbonblackloaded rubber vulcanizates; Controlled IngredientDistribution Mixing: Effect on Some Properties of Elastomer Blend Compounds;Application of plasma modified pyrolytic carbon black in

Characterization of Chemically Activated Pyrolytic Carbon Black

23 Pyrolytic Carbon Black Characterization and Preliminary Analysis of Carbon Dots The chemical composition, surface morphology, structural information, particle size, and dispersion stability of each pyrolytic carbon black sample were analyzed in detail in order to understand the effect of the activating agent on the carbon’s characteristics2024年7月1日 The samples in Table 4 are defined accordingly as; CBp—raw untreated pyrolytic carbon black, CBp 3H —pyrolytic carbon black treated with HCl in a ratio 1:3, CBp 3HN—pyrolytic carbon black treated with HCl/NaOH in a ratio 1:3, CBp 3N—pyrolytic carbon black treated with NaOH in a ratio 1:3, CBp 5N—pyrolytic carbon black treated with NaOH in a ratio 1:5, CBp Electrochemical performance of chemically treated pyrolytic carbon 2024年1月1日 Pyrolysis is a clean and lowcarbon thermochemical technology for waste tire management, which converts waste tires to highvalue alternative fuels (gas and liquid oil), carbon black, limonene, and monocyclic aromatic hydrocarbons [3, 4]Carbon black is an essential fine chemical product and primarily utilized as a reinforcing ingredient for tire manufacture [5]Carbon black production characteristics and mechanisms from Study on Classification of Pyrolytic Carbon Black and Its Coupled Product Modified Asphalt PG Wei Song1, Youwei Gan2 1Institute of Transportation Engineering, Changsha University of Science Technology, Changsha Hunan 2Communications Design Research Institute Co, Ltd of Jiangxi Province, Nanchang JiangxiStudy on Classification of Pyrolytic Carbon Black and Its Coupled

Production and Upgrading of Recovered Carbon Black from the

2022年3月9日 Increasing awareness regarding fossil fuel dependence, waste valorization, and greenhouse gas emissions have prompted the emergence of new solutions for numerous markets over the last decades The tire industry is no exception to this, with a global production of more than 15 billion tires per year raising environmental concerns about their endoflife recycling or Effect of pyrolytic carbon black content on the storage stability of bitumen Sustainability 2019, 11, 1631 12 of 13 4 Conclusions From the various laboratory tests conducted on the pyrolytic carbon black modified bitumen binders, it can be concluded that pyrolytic carbon black is a promising modifier for bitumen modification(PDF) Bitumen Modification with Pyrolytic Carbon Black from Tires2014年1月1日 A novel material, PyrC350(®), has been developed from pyrolytictire char (PyrC), as an efficient lowcost Arsenite [As(III)] adsorbent from waterPhysicochemical Properties of Pyrolitic Carbon Black from Disclosed is a method for granulating waste tire pyrolytic carbon black, the method comprising the following steps: S1 pretreating waste tires to obtain tire sheets and steel wires; S2 subjecting the tire sheets to pyrolysis to obtain pyrolytic carbon and pyrolytic oil and gas; S3 preparing a granulation solution from a carbon black dispersant, a silane coupling agent, a binder and Method for granulating waste tire pyrolytic carbon black and

Recycling of waste tire by pyrolysis to recover carbon black: an

also known as pyrolytic carbon black (CBp), is the most abundant material, and the process economy greatly depends on the commercial value of this fraction Since the origin of the rubber industry, carbon black has acted as reinforcing ller and is added during the compounding stage [25] The reinforcing mechanism greatly involves various2016年5月13日 Black silicon surface with and without pyrolytic carbon ( a , b ) Black silicon substrate consists of sharp silicon needles randomly distributed uniformly over the Si substrate ( c , d ) After coating the sample with 25 nm thick PyC layer the topography of bSi is well preserved and even smallest details are evenly coated with PyCPyrolytic carbon coated black silicon PMC National Center for Chinese J Chem Eng, 14(5) 654—659 (2006) Surface Modification of Pyrolytic Carbon Black from Waste Tires and Its Use as Pigment for Offset Printing Ink* ZHOU Jie(周洁)a,b, WANG Jingdai(王靖岱)a, REN Xiaohong(任晓红)a, YANG Yongrong(阳永 荣)a and JIANG Binbo(蒋斌波)a,**, a UNILAB Research Center for Chemical Reaction Engineering, Department of Chemical Surface Modification of Pyrolytic Carbon Black from Waste Tires The ash content of the pyrolytic carbon black was reduced from 225% to 84% after rinsing with hydrochloric acid, and the tensile stress at 300% was increased by about 22 MPaPyrolytic preparation and modification of carbon black

Recycling of waste tire by pyrolysis to recover carbon black: an

2023年3月6日 Thermal pyrolysis of waste tires is an industrially beneficial method for material and energy recovery Pyrolytic carbon black (CBp) is considered to be the secondary main product of this process In the present study, an ecofriendly and economically feasible autoclave reactorbased thermal pyrolysis method was employed for the pyrolysis of waste tire tread 2021年6月10日 CBp, also known also as pyrolytic char or recovered carbon black (rCB), is consisted of carbon black (CB) used in tire manufacturing, ash and solid tar adsorbed on the surface It is a kind of lightweight carbon substance and a kind of amorphous carbon composed of several layers of parallel carbon network plane, other single network plane without parallel Recovery of carbon black from waste tire in continuous 2021年1月10日 Carbon blacks (CBs) are almost pure elemental carbon, produced by either incomplete combustion or thermal decomposition of gaseous or liquid hydrocarbonbased feedstocks under controlled conditions (Ciobanu et al, 2016)Nearly 93% of globally produced CB is utilized as an elastomerreinforcing agent in rubber applications (Sebok and Taylor, 2001)Manufacturing of carbon black from spent tyre pyrolysis oil – A 2020年11月6日 23 Pyrolytic Carbon Black Characterization and Preliminary Analysis of Carbon Dots The chemical composition, surface morphology, structural information, particle size, and dispersion stability of each pyrolytic carbon black sample were analyzed in detail in order to understand the effect of the activating agent on the carbon’s characteristicsCharacterization of Chemically Activated Pyrolytic Carbon Black

.jpg)

Synthesis, Purification, and Characterization of Carbon Dots from

2022年1月18日 In this work, carbon dots were created from activated and nonactivated pyrolytic carbon black obtained from waste tires, which were then chemically oxidized with HNO32024年3月1日 Pyrolytic carbon black is one of the leading products of the waste rubber hightemperature pyrolysis industry, and its yield is about 35% It has a very high application value In summary, the appropriate temperature can not only increase the yield of pyrolytic carbon black, but also improve the quality of pyrolytic carbon blackCharacteristics and chemical treatment of carbon black from The carbon black obtained from pyrolysis of scrap tyres at a temperature of 500°C contains 1112 % ash Due to the presence of high ash content limits its application in different products The pyrolytic carbon black obtained (CB) was contaminated by various additives of the original tire(PDF) Carbon black recovery from waste tire pyrolysis by 2 A Chaala et al /Fuel Processing Technology 46 (1996) 115 recovered by pyrolysis of used tires are: an aromaticrich hydrocarbon oil, a carbonAcidbase method for the demineralization of pyrolytic carbon black

.jpg)

The vacuum pyrolysis of used tires: Enduses for oil

In addition to an intense peak of carbon atoms in graphitelike structures (C0), the C1s ESCA spectra of commercial carbon blacks showed small peaks of carbon atoms with bonds to oxygen (C2, C3, and C4) for C – OH, C O and – COOH 2019年8月30日 The ash content of the pyrolytic carbon black was reduced from 225% to 84% after rinsing with hydrochloric acid, and the tensile stress at 300% was increased by about 22 MPaPyrolytic preparation and modification of carbon 2024年10月16日 This minireview examines the adsorption of REEs onto pyrolytic carbonbased materials as a sustainable recovery method from secondary raw materials The review covers different types of carbonbased adsorbents used in several research works, such as activated carbon, chars, and biochar, and discusses their adsorption mechanisms and influencing factorsOpportunities and Constraints of the Adsorption of Rare Earth 2018年10月25日 When waste tyres are transformed by pyrolysis, the obtained solid fraction known as pyrolytic carbon black (CBp) contains the original CB (8090 wt%) added in tyre manufacturing process along Possibilities of carbon black recovery from waste tyre pyrolysis

Characterization of Bitumen Modified with Pyrolytic Carbon Black

Characterization of Bitumen Modified with Pyrolytic Carbon Black from Scrap Tires Haopeng Wang 1,* , Guoyang Lu 2,*, Shuyin Feng 3, Xiaobo Wen 4 and Jun Yang 5Download Table Proximate analysis of the carbon blacks from publication: Acidbase method for the demineralization of pyrolytic carbon black The carbon black material used as reinforcing Proximate analysis of the carbon blacks Download Tablesustainability Article Characterization of Bitumen Modified with Pyrolytic Carbon Black from Scrap Tires Haopeng Wang 1,* , Guoyang Lu 2,*, Shuyin Feng 3, Xiaobo Wen 4 and Jun Yang 5 1 Section of Pavement Engineering, Faculty of Civil Engineering and Geosciences, Delft University of Technology, Stevinweg 1, 2628 CN Delft, The NetherlandsCharacterization of Bitumen Modified with Pyrolytic Carbon Black AbstractPyrolysis of used tires yields oil and pyrolytic carbon black (CB,) The tire pyrolysis process can be performed either in vacua or at atmospheric pressure The CB, recovered CHARACTERIZATION OF PYROLYTIC CARBON BLACKS FROM

.jpg)

of Pyrolytic Carbon Black Waste for the development of

Processes 2020, 8, 174 2 of 16 strong due to less density, better strength, and thermal insulation [11–13] The development of lightweight concrete as a structural material has been under way 2024年11月1日 Application of plasma modified pyrolytic carbon black in improving mechanical properties of natural rubber composite Strain energy density of carbonblackloaded rubber vulcanizates; Controlled IngredientDistribution Mixing: Effect on Some Properties of Elastomer Blend Compounds;Application of plasma modified pyrolytic carbon black in 23 Pyrolytic Carbon Black Characterization and Preliminary Analysis of Carbon Dots The chemical composition, surface morphology, structural information, particle size, and dispersion stability of each pyrolytic carbon black sample were analyzed in detail in order to understand the effect of the activating agent on the carbon’s characteristicsCharacterization of Chemically Activated Pyrolytic Carbon Black 2024年7月1日 The samples in Table 4 are defined accordingly as; CBp—raw untreated pyrolytic carbon black, CBp 3H —pyrolytic carbon black treated with HCl in a ratio 1:3, CBp 3HN—pyrolytic carbon black treated with HCl/NaOH in a ratio 1:3, CBp 3N—pyrolytic carbon black treated with NaOH in a ratio 1:3, CBp 5N—pyrolytic carbon black treated with NaOH in a ratio 1:5, CBp Electrochemical performance of chemically treated pyrolytic carbon

Carbon black production characteristics and mechanisms from

2024年1月1日 Pyrolysis is a clean and lowcarbon thermochemical technology for waste tire management, which converts waste tires to highvalue alternative fuels (gas and liquid oil), carbon black, limonene, and monocyclic aromatic hydrocarbons [3, 4]Carbon black is an essential fine chemical product and primarily utilized as a reinforcing ingredient for tire manufacture [5]Study on Classification of Pyrolytic Carbon Black and Its Coupled Product Modified Asphalt PG Wei Song1, Youwei Gan2 1Institute of Transportation Engineering, Changsha University of Science Technology, Changsha Hunan 2Communications Design Research Institute Co, Ltd of Jiangxi Province, Nanchang JiangxiStudy on Classification of Pyrolytic Carbon Black and Its Coupled 2022年3月9日 Increasing awareness regarding fossil fuel dependence, waste valorization, and greenhouse gas emissions have prompted the emergence of new solutions for numerous markets over the last decades The tire industry is no exception to this, with a global production of more than 15 billion tires per year raising environmental concerns about their endoflife recycling or Production and Upgrading of Recovered Carbon Black from theEffect of pyrolytic carbon black content on the storage stability of bitumen Sustainability 2019, 11, 1631 12 of 13 4 Conclusions From the various laboratory tests conducted on the pyrolytic carbon black modified bitumen binders, it can be concluded that pyrolytic carbon black is a promising modifier for bitumen modification(PDF) Bitumen Modification with Pyrolytic Carbon Black from Tires

Physicochemical Properties of Pyrolitic Carbon Black from

2014年1月1日 A novel material, PyrC350(®), has been developed from pyrolytictire char (PyrC), as an efficient lowcost Arsenite [As(III)] adsorbent from waterDisclosed is a method for granulating waste tire pyrolytic carbon black, the method comprising the following steps: S1 pretreating waste tires to obtain tire sheets and steel wires; S2 subjecting the tire sheets to pyrolysis to obtain pyrolytic carbon and pyrolytic oil and gas; S3 preparing a granulation solution from a carbon black dispersant, a silane coupling agent, a binder and Method for granulating waste tire pyrolytic carbon black and also known as pyrolytic carbon black (CBp), is the most abundant material, and the process economy greatly depends on the commercial value of this fraction Since the origin of the rubber industry, carbon black has acted as reinforcing ller and is added during the compounding stage [25] The reinforcing mechanism greatly involves variousRecycling of waste tire by pyrolysis to recover carbon black: an