Factors to note when selecting a concrete mixing station site

How to choose the proper concrete mixing station site

2018年7月12日 To sum up, in the process of selecting the concrete mixing station site, need to consider various factors, according to its own characteristics of concrete mixing station, choose reasonable scientific terminal, only in this way, to build an efficient economic concrete mixing 2 天之前 What is concrete mix design? Concrete mix design involves the deliberate selection and proportioning of materials to create a concrete mixture that possesses specific properties What are the Factors Affecting the Choice of Concrete Mix Design?The job site conditions, especially the methods of concrete production, transport, placement, compaction and finishing; The characteristics of the available raw materials; The various factors affecting the choice of concrete mix design are: What are the Factors Affecting the Choice of Concrete 2022年5月27日 The process of selecting concrete mixture proportions is a process of optimization of several desirable characteristics based on the project requirements The 4 FUNDAMENTAL FACTORS TO CONSIDER DURING CONCRETE

.jpg)

Factors to Consider When Selecting Concrete Mix for

2020年5月20日 Concrete Mix formula is referred to as the appropriate mixture and selection of materials and constituents used to prepare a concrete with predetermined characteristics in perfect hardened concrete states The ready mix Selecting Proportions for Concrete ” The procedure is as follows: Step 1 Choice of slump Step 2 Choice of maximum size of aggregate Step 3 Estimation of mixing water and air content Step Chapter 8: Proportioning Concrete Mixes ObjectiveHow to select a suitable concrete mixing station? Select the concrete mixing plant is a more complex process It works with the user's size, nature, requirements, terrain, funding, Choosing factors for concrete batching station2015年5月5日 Suggested criteria for the selection of mixer are as under: Size of aggregate; Easy to clean; Difficulty of replacing the blades or parts; Sensitivity of the blades to wear and tear; Mixer Capacity (Size of drum) Mixing energy 16 PARAMETERS TO CONSIDER WHILE PROCURING

Factors To Consider During Selection of Site PDF

There are many factors to consider when selecting a site for building construction Key factors include the purpose of the building, availability of facilities and amenities, terrain conditions, type of ground soil, and compliance with 2024年8月12日 When selecting a concrete mix, you must consider both compressive strength and tensile strength Compressive strength measures the concrete’s ability to withstand loads What Factors Should You Consider When Choosing the Right 2020年5月20日 The amount and areas of spacing which is to be reinforced, concrete delivery, dispatching operation and compaction techniques are also other factors affecting the workability of concrete If you have to install Factors to Consider When Selecting Concrete Mix The following points highlight the ten main factors to be considered in selection of suitable site Some of the factors are: 1 Availability of Rawmaterials 2 Nearness to the Market 3 Nearness to Sources of Operating Power 4 Labour Supplies 5 Transportation 6 Finance 7 Climate 8 Industrial Inertia and Others Selection of Suitable Site Factor # 1 Availability of Raw Selection of a Suitable Site: 10 Factors to Consider Economics

16 PARAMETERS TO CONSIDER WHILE PROCURING

2015年5月5日 Mixing energy required; Efficiency of a mixer; Mixing time; Mixing method; Location of the construction site (distance from the batching plant) Amount of concrete needed; 6 Accurate Weigh Batching of Concrete 2016年10月27日 The following factors have to be considered in selecting a site for a stream gauging station (1) The section should be straight and uniform for a length of about 10 to 20 times the width of the What factors should be considered in selecting a site for a 2001年3月1日 As for all materials, the performance of concrete is determined by its microstruc ture Its microstructure is determined by its composition, its curing conditions, and also by the mixing method Concrete Mixing Methods and Concrete Mixers: State of the ArtThe various factors affecting the choice of concrete mix design are: 1 Lastly, An important feature of a satisfactory aggregate is the uniformity of the grading that achieved by mixing different size fractions Fig7: aggregate grading types 6 Quality Control at siteWhat are the Factors Affecting the Choice of Concrete Mix Design?

.jpg)

Five Essential Factors to Consider in Site Selection

2023年6月29日 However, with numerous factors to consider, navigating the site selection process can be a complex endeavor In this blog post, we will explore the primary factors to consider when evaluating potential locations, helping you make informed decisions and maximize your chances of finding the perfect site for your business 1I am just wondering how we can cover the water consumption for BW/CEB in constant flow ultrafiltration (deadend) We can imagine two UF lines for example 2 x 25 m3/h net production, working 2+0What factors should be considered in selecting a site for 2022年1月10日 Analysis of the various factors to consider in site selection should be the first step to be undertaken before deciding finally to go into actual farming This also applies where the crop to be grown has already been decided and what remains is the finding of a suitable land where it is to be grownWhat Are the Factors to Consider in Location and Farm Site There are many factors to consider when selecting a site for building construction Key factors include the purpose of the building, availability of facilities and amenities, terrain conditions, type of ground soil, and compliance with government laws and regulations Additional important factors are the shape and size of the plot, natural light and air access, and environmental conditions A Factors To Consider During Selection of Site PDF Scribd

.jpg)

5 Factors to Consider when Selecting a Site for

2023年3月2日 When selecting a site, look for areas with potential for expansion or repurposing of the building down the line Consider whether the property will remain feasible in 10 years or more, and if not, what modifications would need 2021年1月25日 Remember, concrete is a musthave in building and renovation projects, whether you are constructing a basement or a driveway Essentially, a concrete mixer mixes water, cement, and aggregate that form concrete for construction work For large construction, mixers provide an efficient alternative to manual mixing and offer consistent concreteHow To Choose The Right Concrete Mixer PDQuipment2024年11月30日 1:2:4 concrete mix strength: Concrete is the foundation (literally!) of countless construction projects, from towering skyscrapers to your backyard patio It’s a versatile material, but its success hinges on using the Unlocking the Mysteries of Concrete Mix Ratios: A 2018年9月21日 Site must have adequate stream flow record and Flood Frequency Analysis Site is easily accessible; approach road is present or can be developed easily Site Selection for Dams should be such that construction material are available nearby easily Site near load center (demand area) for water utilization as well as consumption of generated powerSite Selection for Dams Factors affecting Dam Site Selection

.jpg)

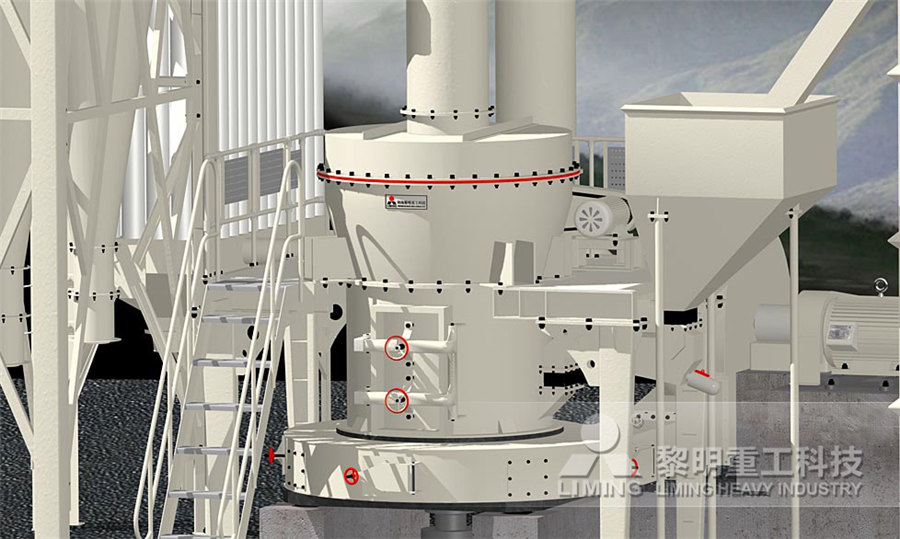

Concrete Mixing Stations MadeinChina

China Concrete Mixing Stations wholesale Guaranteed Quality Cement Concrete Mixing Station Fixed Stabilized Soil Mixing Station US$ 10000 / Set consider factors such as product quality, production capacity, reputation, and aftersales serviceFollowing factors should be considered while site selection for railway station: 1 Drainage The proposed railway station site should be on a fairly leveled ground and it should be well drained 2 Water Supply There should be plentiful supply for water at the site of station 3Site Selection for Railway Station Engineering Articles2015年1月13日 Some factors might be: Proximity to the equator The closer the launch site to the equator, the easier it is to launch to equatorial orbit, and the more help you get from Earth's rotation for a prograde orbitBriefly, what are the factors to consider when choosing a launch site?2024年4月5日 Whether you’re a seasoned construction professional or a DIY enthusiast embarking on your first project, finding the right concrete mixer can make all the difference in the efficiency and quality of your work Let’s explore the key factors and discover why the MudMixer stands out as the top choice for DIY and small concrete jobsA Comprehensive Guide To Buying a Concrete Mixer MudMixer

Dam and types of dam with site selection PPT SlideShare

2017年4月3日 15 It is an arch – shaped solid structure made up of concrete which is designed in such a way that a major part of the thrust forces acting on the dam are transmitted to arch There are mainly two types of ach dams : • Constant radius arch dams : radius of curvature throughout the structure is constant and upstream face is verticalThe portable Mixing Station is the ultimate solution for mixing selflevelling cements, MAKINEX 100L Concrete Mixing Station MS100 ; MAKINEX 100L Concrete Mixing Station MS100 SKU MPN MS100 Please note that these delivery timeframes are estimates and are not guaranteedMAKINEX 100L Concrete Mixing Station MS100 Total Tools2015年12月2日 Question: What are some important steps to remember in setting up a mixing station? Answer: A properly set up mixing station is an important part of a successful topping installationNot only should the mixing station be outfitted with all the equipment and supplies you’ll need to mix materials properly, it should also provide efficient access to the point of Setting up a Mixing Station Concrete ConstructionSustainable agriculture aims to satisfy human needs for food and fiber over the long term in an environmentally friendly way It enhances natural resources and makes efficient use of nonrenewable inputs while maintaining economic Factors To Consider in Site Selection and Choice of

How to Select a Site and Layout for a Hydropower Plant LinkedIn

Learn about the key factors to consider when designing a hydropower plant, such as water availability, topography, energy demand, environmental impact, and more Skip to main content LinkedIn Articles2020年5月20日 Factors to Consider When Selecting Concrete Mix for Your Project May 20, 2020 By Huddle Digital In Ready Mix Concrete dispatching systems and lack of knowledge of mixing, placing, testing and curing 5 Maximum Nominal Size and Structure of ConcreteFactors to Consider When Selecting Concrete Mix for Your Project2024年3月18日 When it comes to building, the efficiency and quality of concrete mixing may have a major impact on how a project turns out Choosing the right concrete mixer is important whether you’re running Concrete Mixer: A Comprehensive Guide to Choosing the Right Concrete 2021年9月1日 society; (ii) the relevant factors to support site choice modeling, as well as the classification and 84 detailed explanation of each one of them; and (iii) the methods used in the selection of (PDF) Wind power plant site selection: A systematic review

Factors to Take into Account When Selecting Concrete Pumps

2023年10月9日 It expedites the seamless transfer of concrete from its source to the intended pour site, alleviating the laborious and timeconsuming task of manual transport Agree Join LinkedIn2017年10月4日 Other factors to consider when selecting a mixer Note also that each mixer has a minimum concrete requirement to guarantee proper mixing results In addition, a concrete mixing plant must always have a sufficient stock of raw material for maximized efficiencyChoosing concrete plant mixer batch size for costeffective2024年8月6日 Choosing the right mixer for concrete in your project is crucial for ensuring efficiency, costeffectiveness, and a highquality end result But with so many options available, how do you know which mixer is the best fit for your needs? In this blog post, we will guide you through the process of selecting the ideal mixer for concrete, exploring various types, sizes, Mixer for Concrete: The Ultimate Guide to Choosing Certified 2023年7月13日 TENDON SYSTEMS Now a part of CMC 7340 McGinnis Ferry Rd Suwanee, GA 30024 Phone: (678) 83511009 Key Factors to Consider When Choosing a Concrete

Factors to Consider When Selecting Concrete Mix

2020年5月20日 The amount and areas of spacing which is to be reinforced, concrete delivery, dispatching operation and compaction techniques are also other factors affecting the workability of concrete If you have to install The following points highlight the ten main factors to be considered in selection of suitable site Some of the factors are: 1 Availability of Rawmaterials 2 Nearness to the Market 3 Nearness to Sources of Operating Power 4 Labour Supplies 5 Transportation 6 Finance 7 Climate 8 Industrial Inertia and Others Selection of Suitable Site Factor # 1 Availability of Raw Selection of a Suitable Site: 10 Factors to Consider Economics 2015年5月5日 Mixing energy required; Efficiency of a mixer; Mixing time; Mixing method; Location of the construction site (distance from the batching plant) Amount of concrete needed; 6 Accurate Weigh Batching of Concrete 16 PARAMETERS TO CONSIDER WHILE PROCURING 2016年10月27日 The following factors have to be considered in selecting a site for a stream gauging station (1) The section should be straight and uniform for a length of about 10 to 20 times the width of the What factors should be considered in selecting a site for a

.jpg)

Concrete Mixing Methods and Concrete Mixers: State of the Art

2001年3月1日 As for all materials, the performance of concrete is determined by its microstruc ture Its microstructure is determined by its composition, its curing conditions, and also by the mixing method The various factors affecting the choice of concrete mix design are: 1 Lastly, An important feature of a satisfactory aggregate is the uniformity of the grading that achieved by mixing different size fractions Fig7: aggregate grading types 6 Quality Control at siteWhat are the Factors Affecting the Choice of Concrete Mix Design?2023年6月29日 However, with numerous factors to consider, navigating the site selection process can be a complex endeavor In this blog post, we will explore the primary factors to consider when evaluating potential locations, helping you make informed decisions and maximize your chances of finding the perfect site for your business 1Five Essential Factors to Consider in Site SelectionI am just wondering how we can cover the water consumption for BW/CEB in constant flow ultrafiltration (deadend) We can imagine two UF lines for example 2 x 25 m3/h net production, working 2+0What factors should be considered in selecting a site for

.jpg)

What Are the Factors to Consider in Location and Farm Site

2022年1月10日 Analysis of the various factors to consider in site selection should be the first step to be undertaken before deciding finally to go into actual farming This also applies where the crop to be grown has already been decided and what remains is the finding of a suitable land where it is to be grownThere are many factors to consider when selecting a site for building construction Key factors include the purpose of the building, availability of facilities and amenities, terrain conditions, type of ground soil, and compliance with government laws and regulations Additional important factors are the shape and size of the plot, natural light and air access, and environmental conditions A Factors To Consider During Selection of Site PDF Scribd