Ore ore powder production line ore ore powder production

Micronsized ore powder production by propulsion and rapid

2021年9月6日 We describe a micronsized ore powder production by propulsion and rapid unloading of highpressure gas The research consists of three parts Firstly, we obtain the tensile strength parameters and permeability coefficient based on the experimentOre powder production involves the conversion of mined ore into fine particles through a series of crushing, grinding, and classifying processes The equipment used in this process must be Advancements in ore powder production process equipment: 2018年3月1日 Iron ore powder production after CO 2 substitution is an effective method, which not only optimizes the grain size distribution but also saves 95% of the liquid CO 2 The initial Experiment on micronsized particle production of iron ore by 2018年3月1日 Experiments have been carried out to develop a novel approach of producing iron ore powder First, the iron ore is placed in a highpressure chamber, and then liquid CO2 is Experiment on micronsized particle production of iron ore by

.jpg)

Micronsized ore powder production by propulsion and rapid

2021年9月6日 We describe a micronsized ore powder production by propulsion and rapid unloading of highpressure gas The research consists of three parts Firstly, we obtain the 2023年9月1日 The pulverization of ore by GRU results in deformations that not only occur at the crystalline scale but also extend to the macroscopic level, ultimately leading to the crossscale Influence of ore size on the production of microsized ore particles We describe a micronsized ore powder production by propulsion and rapid unloading of highpressure gas The research consists of three parts Firstly, we obtain the tensile strength Micronsized ore powder production by propulsion and rapid 2020年5月19日 For the rare earth ore powder production line, the realtime data detected on the extraction and stirring device, through this method, the equipment operation status of the Research on Fault Detection Method of Mineral Powder

Micronsized ore powder production by propulsion and rapid

2021年9月6日 We describe a micronsized ore powder production by propulsion and rapid unloading of highpressure gas The research consists of three parts Firstly, we obtain the 2020年12月19日 Introduction The production line is for processing fluorite ore dressing, whose function is to improve the grade of fluorite ore So as to meet the needs of industrial productionINTRODUCTION OF PRODUCTION LINE FOR Production of Titanium Powder by the Calciothermic Reduction of Titanium Concentrates or Ore Using the Preform Reduction Process Haiyan Zheng1 ;*1, Hiromasa Ito2 *2 and Toru H Okabe3;*3 1Department of Materials Engineering, Graduate School of Engineering, The University of Tokyo, Tokyo 1138656, Japan 2Graduate School of Engineering, Chiba Institute Production of Titanium Powder by the Calciothermic Reduction 2018年3月1日 Iron ore powder production after CO 2 substitution is an effective method, which not only optimizes the grain size distribution but also saves 95% of the liquid CO 2 The initial water pressure provides high energy to the liquid CO 2 stored inside the iron oreExperiment on micronsized particle production of iron ore by

(PDF) Iron Ore Granulation for Sinter Production: Developments

2022年12月29日 Iron ore granulation for sinter production: Developments, Although the presence of iron ore ultrafine powder can help with the parameters of its HPS line shown in Table 2 122) Fig8 Fig92023年12月1日 250300t/h gold ore crushing production line Major equipment: High level silo1, raw material silo1, iron remover1, vibrating screen2, cone crusher2, vibrating feeder1, jaw crusher1, feeder3 Gold ore crushing equipment Jaw How to crush gold ore?Gold ore crushing production lineHere are the primary uses of lithium ore production lines: 1 Battery Manufacturing Lithiumion Batteries: The most significant use of lithium is in the production of lithiumion batteries, which power electric vehicles (EVs), portable electronics (smartphones, laptops, tablets), and renewable energy storage systemsLithium Ore Production Line TAYMACHINERY2024年1月1日 Therefore, the following scholars have studied the relationship between the chemical composition and basic properties of iron ore powder Regarding the relationship between the chemical composition and foundation characteristics of different iron ore powders, Changdong Shan et al [3] analyzed the relationship between assimilation temperature and the Research on prediction model of iron ore powder sintering

.jpg)

Iron Ore Beneficiation Production Line Hongji Mining Machinery

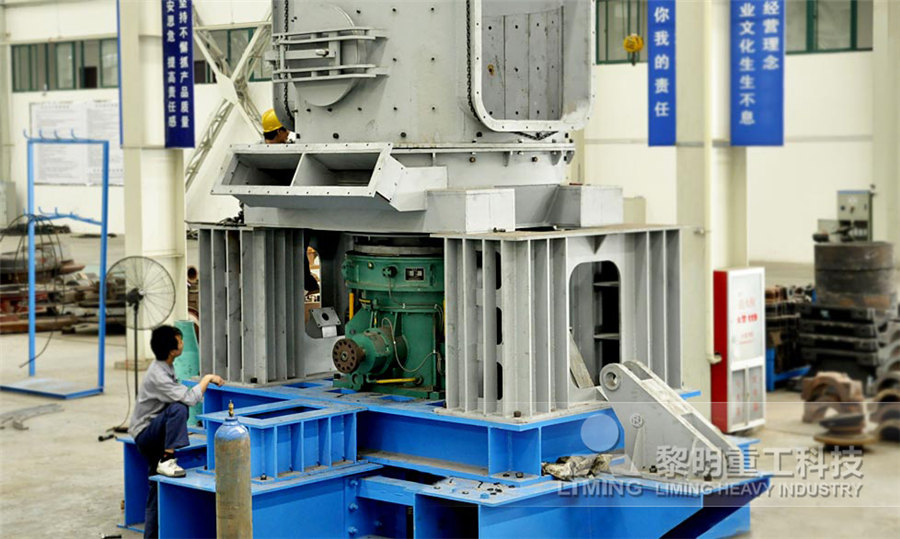

Iron ore production line equipment includes a series of mineral processing equipment such as crushing equipment, screening equipment, grinding equipment, magnetic separation equipment, flotation equipment, concentration equipment, etc Iron ore beneficiation production equipment 1Crushing The original ore is crushedAs a primary constituent of renewable biomass fuel, lignin can be effectively utilized as a reducing agent in the ironmaking process, thereby significantly mitigating CO 2 emissions throughout the procedure This study meticulously evaluates the impact of lignin on the reduction of iron ore powder across diverse levels of mechanical activation through thermogravimetric analysisReduction characteristics and mechanism of mechanically 2010年1月5日 Iron powder may be produced from natural iron ore The production of ironore superconcentrates containing less than 03% silica for ironpowder manufacture is considered The adjustment of magnetite concentrates from Olenegorsk and Lebedinsk enrichment plants and the enrichment of magnetite ore from the Kursk Magnetic Anomaly is investigated The Ironore concentrates in ironpowder productionGypsum Powder Production Line Capacity : 20100t/h Applicable Materials : Gypsum ore Applications: Industrial and building materials, medicine, food processing, literature and art and other fields Case Description: Introduce the establishment of gypsum grinding production line and related productsGypsum Powder Production Line Hongji Mining Machinery

.jpg)

Production of Titanium Powder by the Calciothermic Reduction

Production of Titanium Powder by the Calciothermic Reduction of Titanium Concentrates or Ore Using the Preform Reduction Process Haiyan Zheng1 ;*1, Hiromasa Ito2 *2 and Toru H Okabe3;*3 1Department of Materials Engineering, Graduate School of Engineering, The University of Tokyo, Tokyo 1138656, Japan 2Graduate School of Engineering, Chiba Institute 4 Copper Nickel Ore Flotation Process When process coppersulfide nickel ore, collector and frothier will be used in order to better results A basic principle of coppersulfide nickel ore process is that it is better to let copper assimilate into nickel ore rather than the opposite For it is easier to recovery cooper from nickel concentrateNickel Ore Production Line TAYMACHINERYGuilin Hong Cheng tailor for us a scientific and reasonable copper powder production line, the equipment is very powerful at the scene, stable performance, reliable quality, small footprint, easy operation, costeffective, is a high capacity and efficient, energy saving environmental protection copper and iron processing equipmentCopper Ore powder processingPDF On Jul 11, 2018, Guangrong Li published The Chinese Iron Ore Deposits and Ore Production Find, read and cite all the research you need on ResearchGate(PDF) The Chinese Iron Ore Deposits and Ore Production

.jpg)

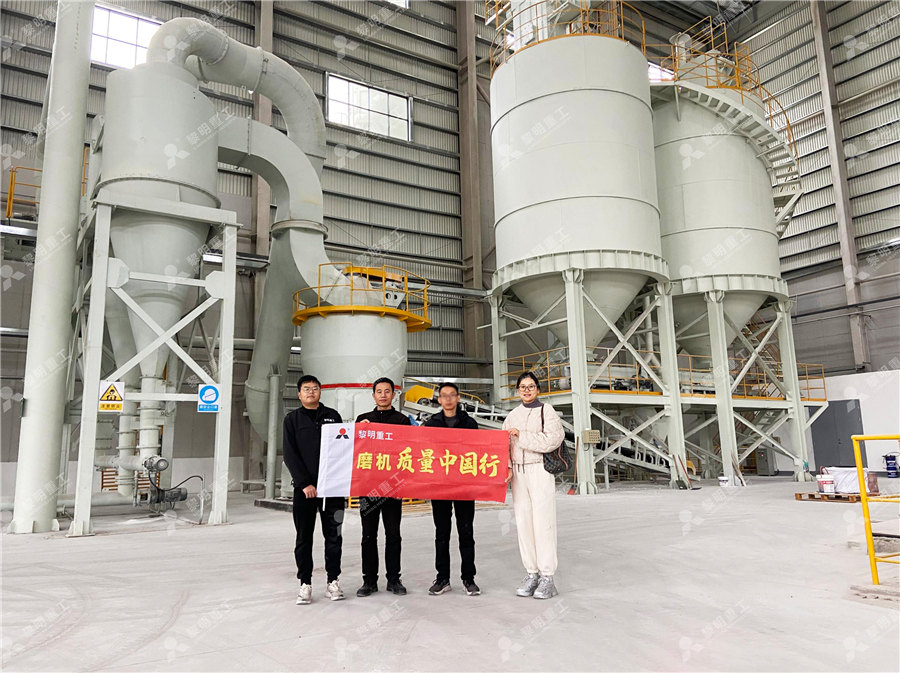

Manganese ore powder drying production line in Kazakhstan

2023年6月4日 The manganese ore powder drying production line purchased by Kazakhstan customers from our company has been installed and debugged and officially put into production Since the signing of theUse the ore gypsum powder production line from Alibaba to discover a whole new level of agricultural and constructional needs The ore gypsum powder production line offer you distinct services All categories Featured selections Trade Assurance Buyer Central Help Center Get Ore gypsum powder production line2018年7月11日 China’s imports of iron ore are mainly iron ore powder, massive iron ore (raw ore) and pellets, respectively, from more than 30 countries and regions, in which Australia, Brazil, India and South Africa are China’s most important source of iron ore imports The imports from the four countries accounted for about 85% The Chinese Iron Ore Deposits and Ore Production IntechOpenOre Powder Dryer The ore dryer is versatile, suitable for drying a range of materials including slag, limestone, clay, We have been professional on grinding mill, stone crushers, sand making machines, production line for ore beneficiation, sand and aggregate industries since 2004Ore Powder Dryer Zoneding Machine

.jpg)

Iron Ore Production Line Shandong Huate Magnet Technology

Tel:+86 ; No 6999 of Huate Road, Linqu, Weifang, Shandong Province, China; jasonliu@chinahuateFinally, the entire chrome ore powder briquette production line feeds smoothly and evenly The workload of the briquetting machine is stable and the production efficiency is high, which solves the problem of the low utilization rate of Iron Powder Briquetting Machine Fote Machinery2009年9月1日 Iron powder may be produced from natural iron ore The production of ironore superconcentrates containing less than 03% silica for ironpowder manufacture is consideredIronore concentrates in ironpowder production ResearchGate2022年8月25日 The unqualified manganese powder is sent to the ball mill for grinding Stage 3: mineral processing The manganese powder meeting the ore dressing requirements is sent to the magnetic separator for strong magnetic separation to remove impurities, and the obtained manganese powder is sent to the dryer for drying to obtain manganese refined powderManganese ore processing production line

PHOSPHATE ORE PELLETIZATION PRODUCTION PROCESS

Our granulating process can granulate the pulverized ore produced in the process of phosphate mining and yellow phosphorus production as well as the phosphate concentrate After granulate, the pellets can meet the requirement of strength and size for the production of yellow phosphorus electrical furnace This process will reduce the comprehensive cost of yellow phosphorus' 2020年5月14日 The concentration of lowgrade iron ores is vital to the continued availability of iron and steel in our everyday lives (Eisele and Kawatra, 2003;Kawatra and Claremboux, 2021a;Zhang et al, 2021)THE GROWING IMPORTANCE OF PELLETIZING FOR IRON ORE 4 Copper Nickel Ore Flotation Process When process coppersulfide nickel ore, collector and frothier will be used in order to better results A basic principle of coppersulfide nickel ore process is that it is better to let copper assimilate into nickel ore rather than the opposite For it is easier to recovery cooper from nickel concentrateNickel Ore Production Line TAYMACHINERYXKJ Group production line Mineral separation and Beneficiation Production equipment column provides you with the advantages, parameters, quotes, picture information of each Gold ore beneficiationGold Flotation Production Line seriesGold ore beneficiationGold Flotation Production Line

.jpg)

Study on the Basic Characteristics of Iron Ore Powder with

2022年7月30日 Study on the Basic Characteristics of Iron Ore Powder with Different Particle Sizes Zezheng Li 1,2,3,4,5, Yifan Li 1,2,3,4,5, In the production of iron ore entering the sintering process, it is not the ultrafinegrained iron ore powder, but there are various grades Therefore, process stages, the ore is exposed to a number of heat cycles, which lead to material oxidation35 Therefore, the pellets and the iron ore fines mainly consist of hematite (Fe 2O 3) by the end of their manufacturing process In this study, iron ore powder fines, collected from the iron ore pelletization process, with a size range between 10 Laserassisted reduction of iron ore using aluminum powder DiVA2020年12月19日 Introduction The production line is for processing fluorite ore dressing, whose function is to improve the grade of fluorite ore So as to meet the needs of industrial productionINTRODUCTION OF PRODUCTION LINE FOR Production of Titanium Powder by the Calciothermic Reduction of Titanium Concentrates or Ore Using the Preform Reduction Process Haiyan Zheng1 ;*1, Hiromasa Ito2 *2 and Toru H Okabe3;*3 1Department of Materials Engineering, Graduate School of Engineering, The University of Tokyo, Tokyo 1138656, Japan 2Graduate School of Engineering, Chiba Institute Production of Titanium Powder by the Calciothermic Reduction

Experiment on micronsized particle production of iron ore by

2018年3月1日 Iron ore powder production after CO 2 substitution is an effective method, which not only optimizes the grain size distribution but also saves 95% of the liquid CO 2 The initial water pressure provides high energy to the liquid CO 2 stored inside the iron ore2022年12月29日 Iron ore granulation for sinter production: Developments, Although the presence of iron ore ultrafine powder can help with the parameters of its HPS line shown in Table 2 122) Fig8 Fig9(PDF) Iron Ore Granulation for Sinter Production: Developments 2023年12月1日 250300t/h gold ore crushing production line Major equipment: High level silo1, raw material silo1, iron remover1, vibrating screen2, cone crusher2, vibrating feeder1, jaw crusher1, feeder3 Gold ore crushing equipment Jaw How to crush gold ore?Gold ore crushing production lineHere are the primary uses of lithium ore production lines: 1 Battery Manufacturing Lithiumion Batteries: The most significant use of lithium is in the production of lithiumion batteries, which power electric vehicles (EVs), portable electronics (smartphones, laptops, tablets), and renewable energy storage systemsLithium Ore Production Line TAYMACHINERY

.jpg)

Research on prediction model of iron ore powder sintering

2024年1月1日 Therefore, the following scholars have studied the relationship between the chemical composition and basic properties of iron ore powder Regarding the relationship between the chemical composition and foundation characteristics of different iron ore powders, Changdong Shan et al [3] analyzed the relationship between assimilation temperature and the Iron ore production line equipment includes a series of mineral processing equipment such as crushing equipment, screening equipment, grinding equipment, magnetic separation equipment, flotation equipment, concentration equipment, etc Iron ore beneficiation production equipment 1Crushing The original ore is crushedIron Ore Beneficiation Production Line Hongji Mining MachineryAs a primary constituent of renewable biomass fuel, lignin can be effectively utilized as a reducing agent in the ironmaking process, thereby significantly mitigating CO 2 emissions throughout the procedure This study meticulously evaluates the impact of lignin on the reduction of iron ore powder across diverse levels of mechanical activation through thermogravimetric analysisReduction characteristics and mechanism of mechanically