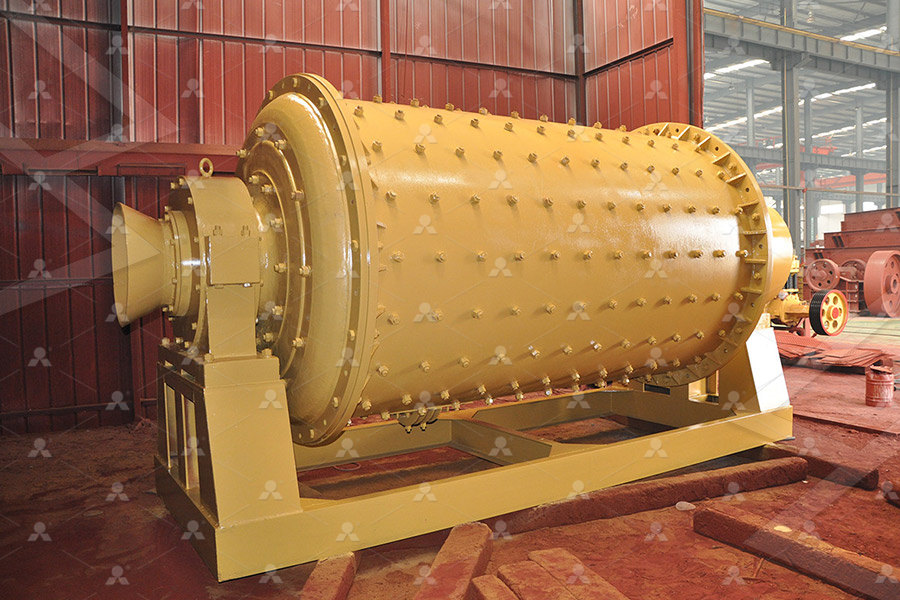

Cement column grinding equipment

Roller Press KHD Humboldt Wedag

Grind cement raw materials, clinker, and slag, as well as minerals, with a roller press from the technical leader The machine frame – open or closed? We offer both open and closed frame layouts But what’s the difference? Open frames We master the construction and design schemes of various cement grinding plant systems such as vertical mill system, combined system, and ball mill system No matter what type and strength of cement you want to produce, and what Cement Grinding Plant Expert Cement Grinding XKJ Group production line Mineral Grinding Production Line equipment column provides you with the advantages, parameters, quotes, picture information of each Cement Grinding production Cement Grinding production line mining processing machineGrinding with propylene glycol generates approximately 800 Cm 2 /gram cement more surface than grinding without an aid, given the same energy consumption the most popular grinding CEMENT GRINDING SYSTEMS INFINITY FOR CEMENT EQUIPMENT

Cement Grinding Plant Manufacturers NT Engitech

The cement grinding unit manufactured by our company combines drying, grinding, powder classification, dust collection and cement packing It can grind cement clinker and process cement mixtures such as gypsum, fly ash, furnace From grinding machinery to kilns and crushers, our portfolio ensures optimized cement manufacturing processes Each piece of equipment is engineered for durability, efficiency, and compliance with the latest safety standards, meeting Cement Equipment Manufacturer SINOMALYAGICO offers 4 types of crushers for cement plants: hammer crusher, jaw crusher, impact crusher, and cone crusher Jaw crushers are popular size reduction machines for the crushing of very hard and abrasive materials A Cement Manufacturing Equipment for Sale AGICO AGICO offers superiorquality cement kiln, cement vertical mill, cement ball mill, cone crusher, hammer crusher, Raymond mill, etc All of the cement plant equipment has a low cost and long service lifeCement Making Machines AGICO Cement Cement

.jpg)

Cement Grinding Equipment Cement Mills

SINOMA Zibo provides not only technical solutions but also cement grinding equipment to help customers build their cement grinding units such as cement mills, cement mill separators, bucket elevators, cement silos, conveyors, The final manufacturing stage at a cement plant is the grinding of cement clinker from the kiln, mixed with 45% gypsum and possible additives, into the final product, cement In a modern cement plant the total consumption of electrical energy is about 100 kWh/t The cement grinding process accounts for approx 40% if this energy consumptionCEMENT GRINDING SYSTEMS INFINITY FOR CEMENT EQUIPMENTRoller press machines for pregrinding, semifinish finish grinding For extreme efficiency and high equipment availability, look no further than roller press technology and products from FLSmidth The roller press is a uniquely Roller presses FLSmidth Cement[ultimateheading mainheading=”Cement Mill, Clinker Mill” alignment=”left” spacer=”lineonly” spacerposition=”bottom” lineheight=”4″ linecolor Cement Mill, Clinker Mill – SBCCOCEMENT

Vertical Shaft Lime Kiln for Cement Plant

Active lime vertical kiln equipment supporting Calcination of limestone Qualified limestone goes to the top of the preheater through the belt conveyor, and the material is introduced into the body of the preheater from the silo at the top of the preheater through the discharge chute, and at the same time, the hightemperature flue gas from the rotary kiln preheats the material to 600°C Grinding: the material is ground between rollers and grinding table while passing from the center of the table to the nozzle ring The commnation method belongs to the most efficient grinding processes applied in the cement manufacturing Separation: the ground and dried material is lifted up with the drying gasesCement Manufacturing Process INFINITY FOR CEMENT EQUIPMENTGrinding Process: From Rough to Polished – Transforming Concrete Surfaces Transforming a concrete surface from rough and uneven to smooth and polished is an art that involves a meticulous grinding process This transformation not only enhances the aesthetic appeal of the concrete but also extends its durability and functionalityGrinding Process: From Rough to Polished Transforming What Is Raymond Mill Raymond mill is also called Raymond roller mill It is a new type of highfineness grinding mill with high efficiency and closed circulation, which can completely replace the cement ball millThis kind of machine is commonly used in cement plants for raw materials fine grinding, such as limestone, coal, gypsum, etc Under normal conditions, these materials’ Raymond Mills Raymond Roller Mill Grinding Mill AGICO Cement

Rotary Kiln SBCCOCEMENT

Cement plant building equipment Home; About Us; Turnkey Projects Cement Projects Overview; Slag Crushing and Grinding Plant; Cement Crushing and Grinding Plant; Clinker Plant; Lime Production Line; Equipment Crusher Jaw Crusher; Hammer Crusher; 30px !important;}”][vccolumn offset=”vccollg12 vccolmd12 vccolxs12″]Vertical roller mills and ball mills represent two clearly distinct technologies However, with proper adjustments to the operational parameters of the vertical roller mill almost identical cement properties can be achieved by the two mills Cement grinding Vertical roller mills VS ball millsWork sessions are scheduled to allow for an interactive study of the design, function, and evaluation of grinding systems in a cement plant Cement Production Seminar: Grinding CourseNr: US24006 SEE OPEN COURSES Any questions? meganschaffer@ Ball vertical mill systems and equipment components; Process design basic parameters Cement Production Seminar: GrindingCement plant building equipment Home; About Us; Turnkey Projects Cement Projects Overview; Slag Crushing and Grinding Plant; Cement Crushing and Grinding Plant; Clinker Plant; Lime Production Line; Equipment Crusher Jaw Wobbler Feeder SBCCOCEMENT

.jpg)

Cement Grinding Plant Solution And Equipment Provider

Factory SINOMA Zibo Heavy Machinery Co, Ltd has more than 60 largescale advanced production equipment and testing equipment The main equipment includes 2×15t traveling crane, 130×3000 horizontal down type three roller plate rolling machine, tka6920 CNC boring and milling machine, Germany’s spike direct reading spectrometer, 8m vertical lathe, 8m gear hobbing Free download as PDF File (pdf), Text File (txt) or read online for free The document discusses various equipment used in the cement production process including cement crushers, cement mills, cement kilns, clinker coolers, dryers, and other machines It describes the functions of key equipment like crushers for breaking raw materials, mills for grinding, kilns for Continue PDF Cement Mill (Grinding)Wholesale Alumina Grinding Column or Cylinders at and other excellent properties Alumina Grinding column are also used for grinding bodies of fine grinding equipment such as ball mills, pot mills, and in these industries: metallic minerals, nonmetallic minerals , silicon carbide, talcum, white pigments, cosmetics, cement, Alumina Ceramic Grinding ColumnAGICO is specialized in design and supply equipments for complete cement production lines of different scales, capacity from 300 to above 2500TPD,main equipments:Rotary Kiln, grinding equipment, Jaw Crusher, cooler Welcome to AGICO Cement, we are leading cement production equipment supplier! 86 Leading Supplier of Cement Plant Equipments Rotary

Everything you need to know about clinker/cement Grinding

Everything you need to know about clinker/cement Grinding if You read and understand this article , you will be ready to be a cement grinding area manager FEED AND FEED SYSTEM Feed Temperature Plants with satellite coolers have high clinker temperatures: eg Cumarebo, Oujda Exit satellite cooler 200250°C Exit grate cooler 100150°C2018年5月23日 Cement manufacturing brief description of a cement mill Vertical roller mill working principle The fixed cement packing machine working principle Cement Production LineCement EquipmentGrinding 25 years in the cement industry supplying engineering and equipment for assembly and commissioning of clinker and slag Grinding Station, cement plants, metallic and concrete silos, vertical mills, horizontal mills, PLUGGRIND modular and portable grinding stations CEMENGAL Engineering, equipment and assembly for the cement The main grinding equipment cement mills grind the clinker to finished cement powders Material – batching – Cement Mill – cement packing – bulk loading In the process, the clinker, gypsum, and additives are ground into particles with a Cement Grinding Units Cement Plant Equipment

.jpg)

Cement Grinding Plant Expert Cement Grinding

As a leading cement plant builder, AGICO offers an expert cement grinding plant EPC service Cement Grinding Unit EPC Solution With a strong RD team, experienced engineers, and firstclass technical services, we aim to provide An Asian cement manufacturer integrated highpressure grinding rolls (HPGRs) into its existing grinding circuit, resulting in a 30% increase in grinding capacity The addition of HPGRs allowed the plant to process harder materials while improving energy efficiency and HighCapacity Cement Grinding Solutions: Enhancing Efficiency Comparison of Grinding Equipment The priority study cement grinding shop compares the full shop power consumption using the 3 main types of technology, see the table below: * Integral grinding is not used for cement grinding due mainly to quality issues with the narrow particle size distribution of the parison of Grinding Equipment INFINITY FOR CEMENT EQUIPMENTHighEfficiency Cement Separators and Classifiers has been supplied by AGICO for 15 years, this equipment is mainly used to improves cement grinding sCement Seperator Improves Cement Grinding System

Wet grinding in closed circuit INFINITY FOR CEMENT EQUIPMENT

The reduction of oversize material to the kiln reduces the number of unburnt cores in the clinker Some plants report an increased kiln output of almost 30 % with the same grinding equipment At the present time 160 DSM Screens have been sold to the cement industry in the United States [163] Cement slurryAGICO supplies various capacity of ball mills and verticle mills for cement production line for cement grinding Welcome to AGICO Cement, we are leading cement production equipment supplier in vibration ball mill Introduction 2ZM series of two roll vibrating ball mill is a new type of efficient grinding equipment in grinding fine and super Ball Miller and Verticle Miller for Cement GrindingXKJ Group production line Mineral Grinding Production Line equipment column provides you with the advantages, parameters, quotes, picture information of each Cement Grinding production line series Home About Us Cement Grinding production line mining processing machine AGICO executes the cement grinding plant, the onestop turnkey project of cement manufacturing, related cement equipment including cement mill, cement silo, packing machine, etc Skip to content +86 Cement Equipment For Finished Cement Plant Cement Grinding

.jpg)

Leading Supplier of Cement Plant Equipments Rotary

AGICO is specialized in design and supply equipments for complete cement production lines of different scales, capacity from 300 to above 2500TPD,main equipments:Rotary Kiln, grinding equipment, Jaw Crusher, cooler Welcome to AGICO Cement, we are leading cement production equipment supplier in the world!SINOMA Zibo provides not only technical solutions but also cement grinding equipment to help customers build their cement grinding units such as cement mills, cement mill separators, bucket elevators, cement silos, conveyors, Cement Grinding Equipment Cement MillsThe final manufacturing stage at a cement plant is the grinding of cement clinker from the kiln, mixed with 45% gypsum and possible additives, into the final product, cement In a modern cement plant the total consumption of electrical energy is about 100 kWh/t The cement grinding process accounts for approx 40% if this energy consumptionCEMENT GRINDING SYSTEMS INFINITY FOR CEMENT EQUIPMENTRoller press machines for pregrinding, semifinish finish grinding For extreme efficiency and high equipment availability, look no further than roller press technology and products from FLSmidth The roller press is a uniquely Roller presses FLSmidth Cement

.jpg)

Cement Mill, Clinker Mill – SBCCOCEMENT

[ultimateheading mainheading=”Cement Mill, Clinker Mill” alignment=”left” spacer=”lineonly” spacerposition=”bottom” lineheight=”4″ linecolor Active lime vertical kiln equipment supporting Calcination of limestone Qualified limestone goes to the top of the preheater through the belt conveyor, and the material is introduced into the body of the preheater from the silo at the top of the preheater through the discharge chute, and at the same time, the hightemperature flue gas from the rotary kiln preheats the material to 600°C Vertical Shaft Lime Kiln for Cement PlantGrinding: the material is ground between rollers and grinding table while passing from the center of the table to the nozzle ring The commnation method belongs to the most efficient grinding processes applied in the cement manufacturing Separation: the ground and dried material is lifted up with the drying gasesCement Manufacturing Process INFINITY FOR CEMENT EQUIPMENTGrinding Process: From Rough to Polished – Transforming Concrete Surfaces Transforming a concrete surface from rough and uneven to smooth and polished is an art that involves a meticulous grinding process This transformation not only enhances the aesthetic appeal of the concrete but also extends its durability and functionalityGrinding Process: From Rough to Polished Transforming

Raymond Mills Raymond Roller Mill Grinding Mill AGICO Cement

What Is Raymond Mill Raymond mill is also called Raymond roller mill It is a new type of highfineness grinding mill with high efficiency and closed circulation, which can completely replace the cement ball millThis kind of machine is commonly used in cement plants for raw materials fine grinding, such as limestone, coal, gypsum, etc Under normal conditions, these materials’ Cement plant building equipment Home; About Us; Turnkey Projects Cement Projects Overview; Slag Crushing and Grinding Plant; Cement Crushing and Grinding Plant; Clinker Plant; Lime Production Line; Equipment Crusher Jaw Crusher; Hammer Crusher; 30px !important;}”][vccolumn offset=”vccollg12 vccolmd12 vccolxs12″]Rotary Kiln SBCCOCEMENT